Fixed volume valve system

a fixed volume valve and valve system technology, applied in the field of fluid valves, can solve the problems of reducing repeatability, house pressure/vacuum used to open the valves is often not well controlled, etc., and achieves the effect of reducing the effect of vacuum pressure on the displacement volume, and reducing the variability of the hold up volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

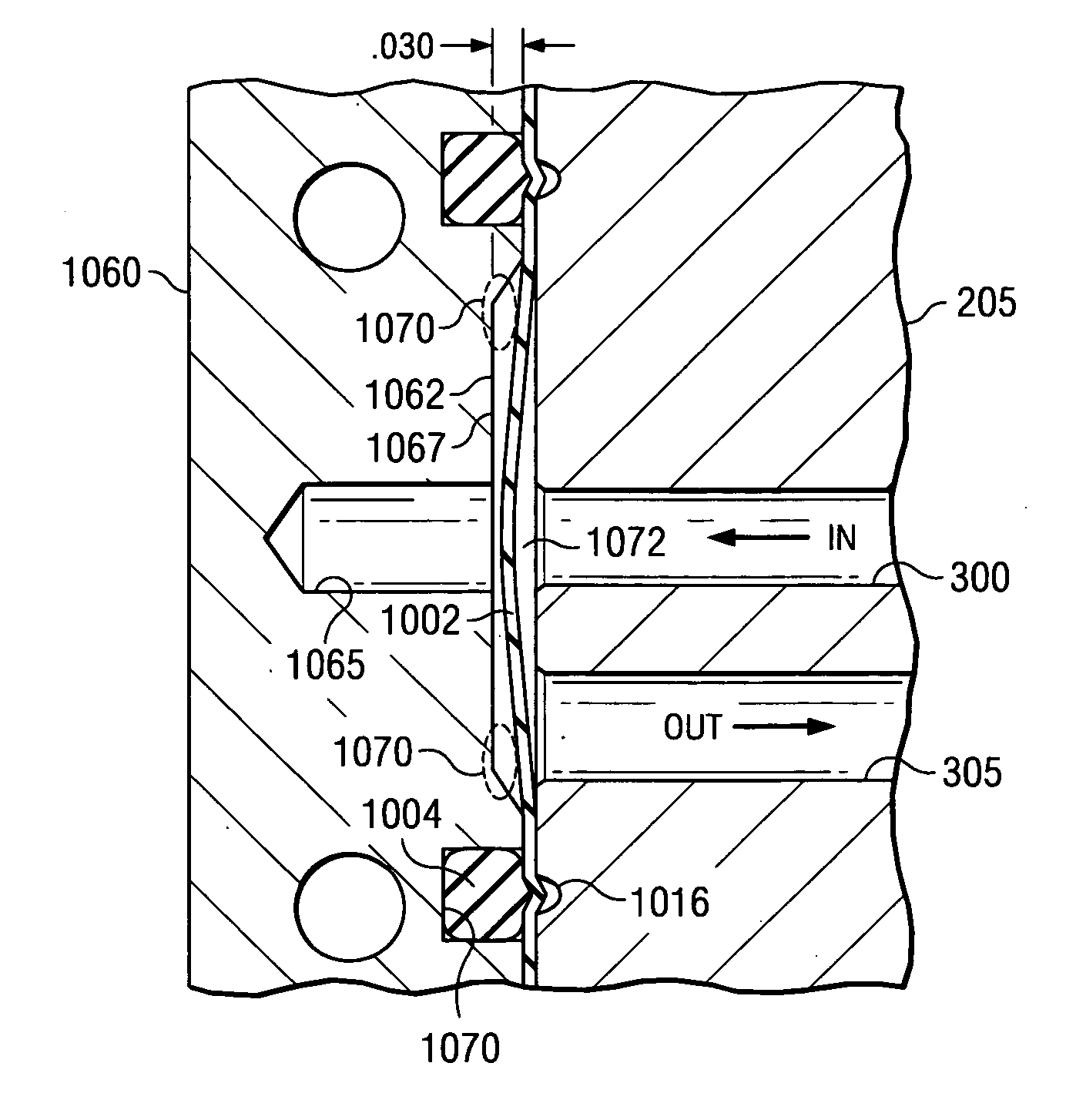

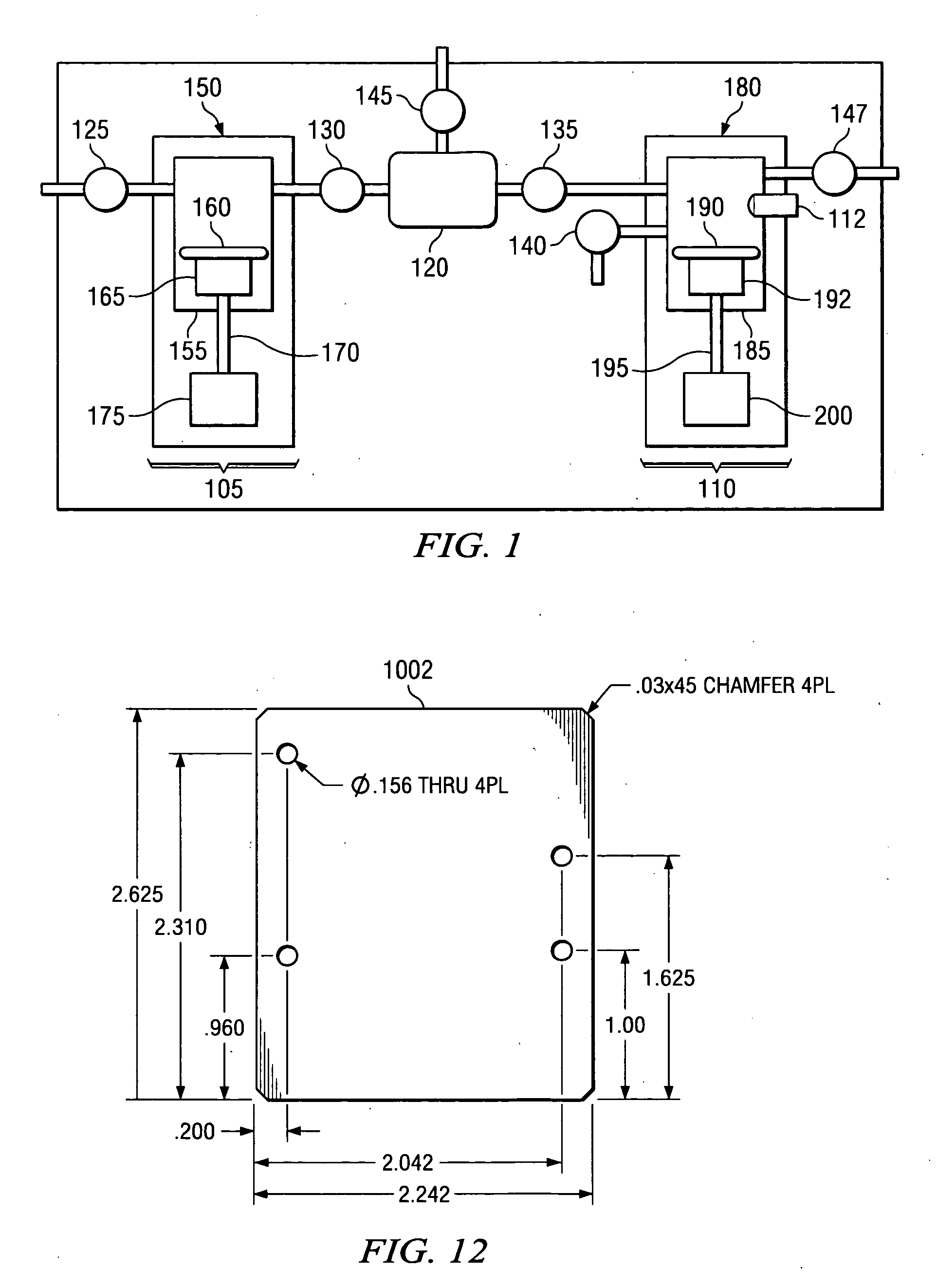

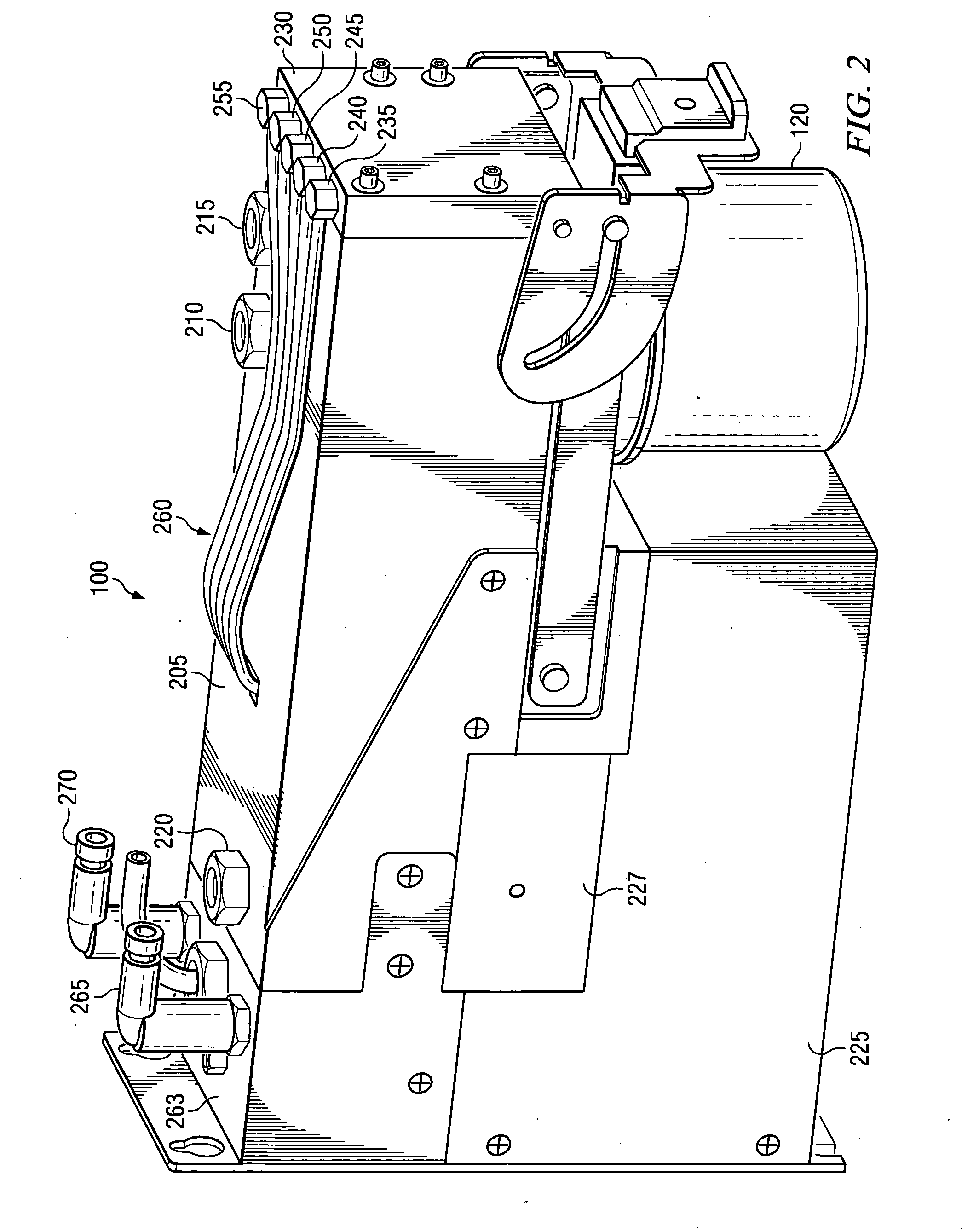

[0027] Preferred embodiments of the present invention are illustrated in the FIGUREs, like numerals being used to refer to like and corresponding parts of the various drawings. To the extent dimensions are provided, they are provided by way of example for particular implementations and are not provided by way of limitation. Embodiments can be implemented in a variety of configurations.

[0028] Broadly speaking, embodiments of the present invention provide valves that are configured to have a fixed hold up volume once a threshold condition is met. For example, the valves can be configured to have a fixed holdup volume once a threshold pressure / vacuum is applied to open the valve.

[0029] According to one embodiment a valve can comprise a valve body defining a valve chamber having a valve seat, an inlet flow passage, an outlet flow passage and a diaphragm control flow passage. The valve body, according to one embodiment, can be made of multiple pieces such as a pump body and a valve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com