Magnetic head structure with enlarged insulating layer

a head structure and insulating layer technology, applied in the direction of head carriers, heads with metal sheet cores, instruments, etc., can solve the problems of floating surface deformation and thermal deformation that cannot be fundamentally solved, and achieve the effect of reducing protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

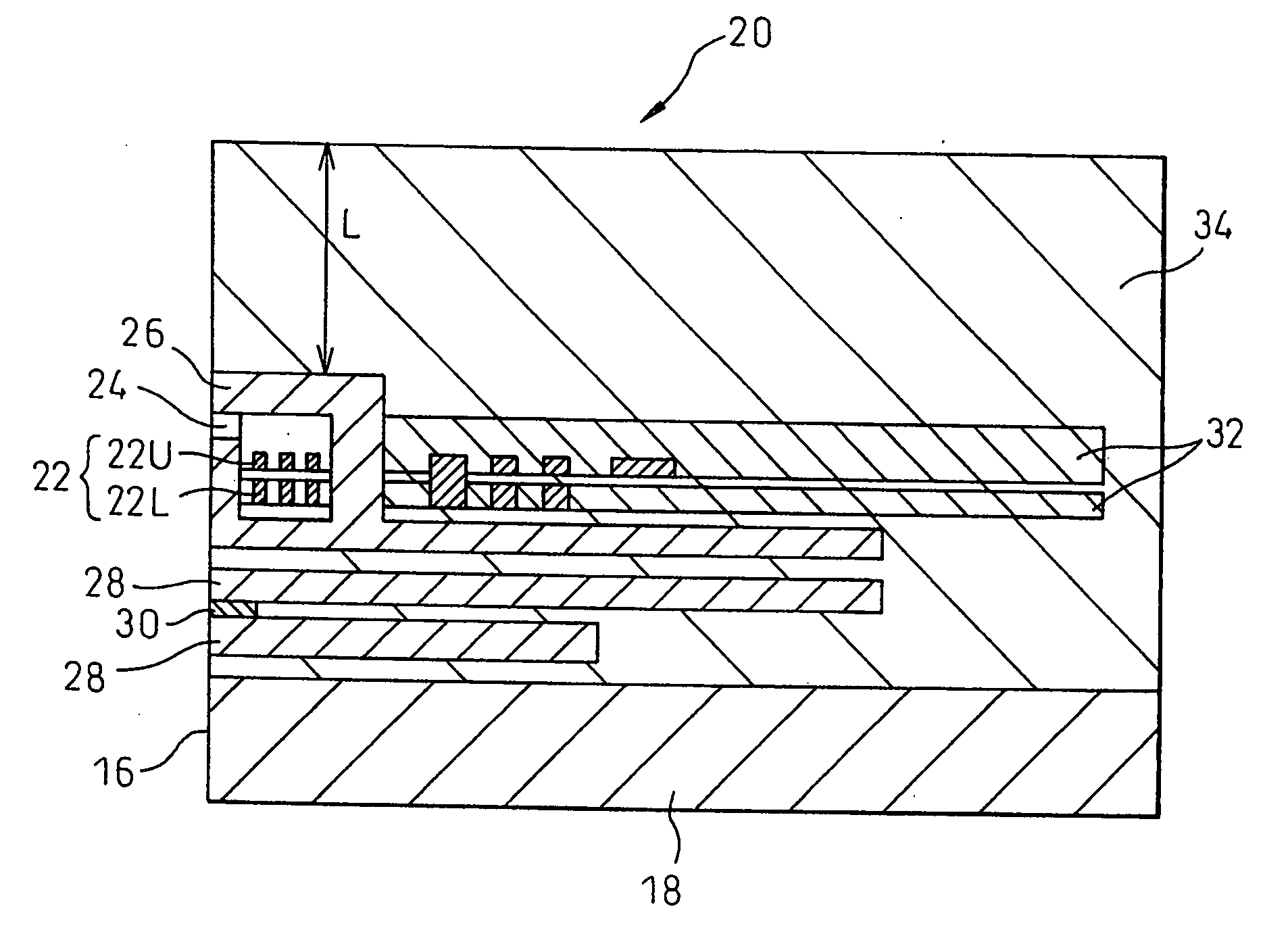

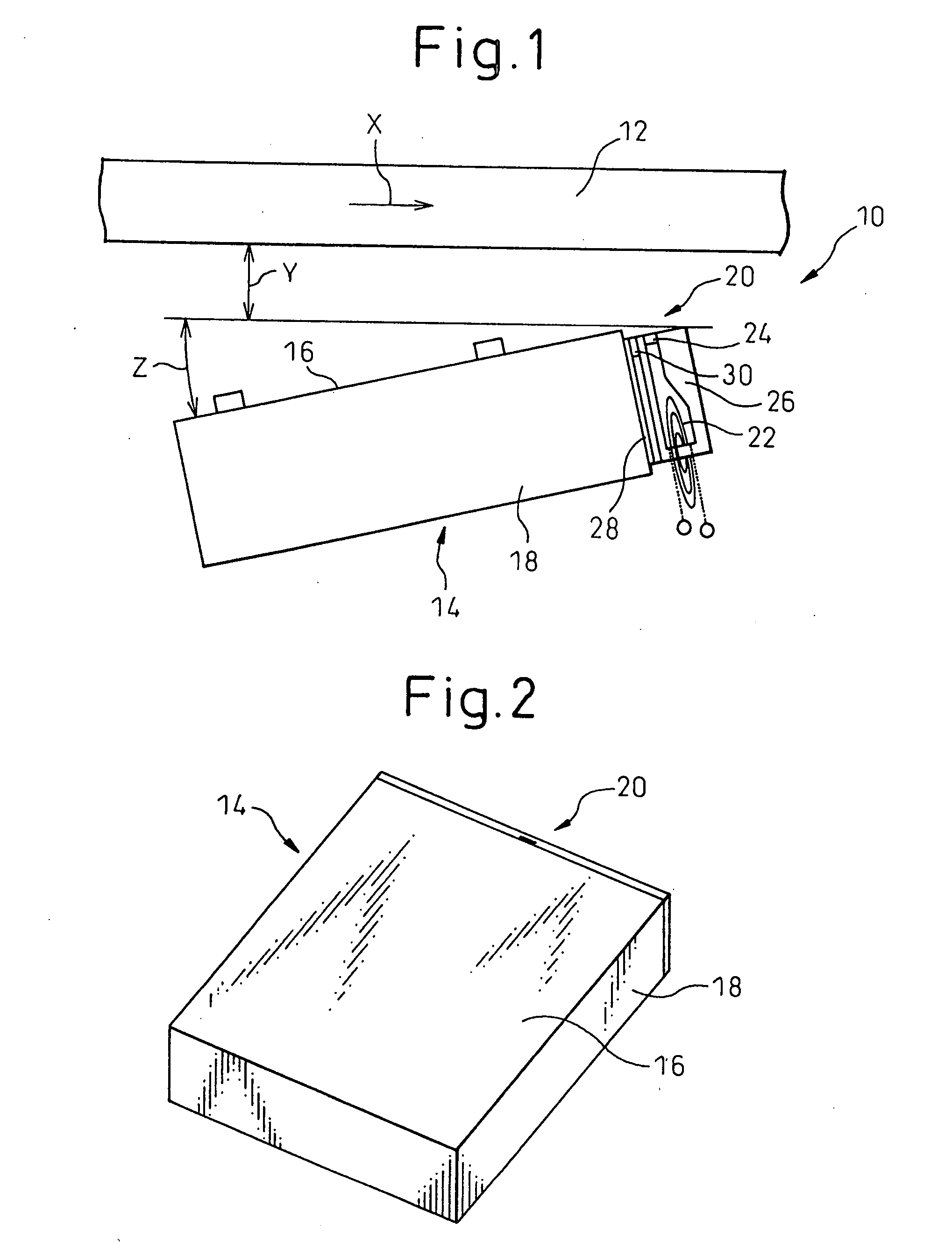

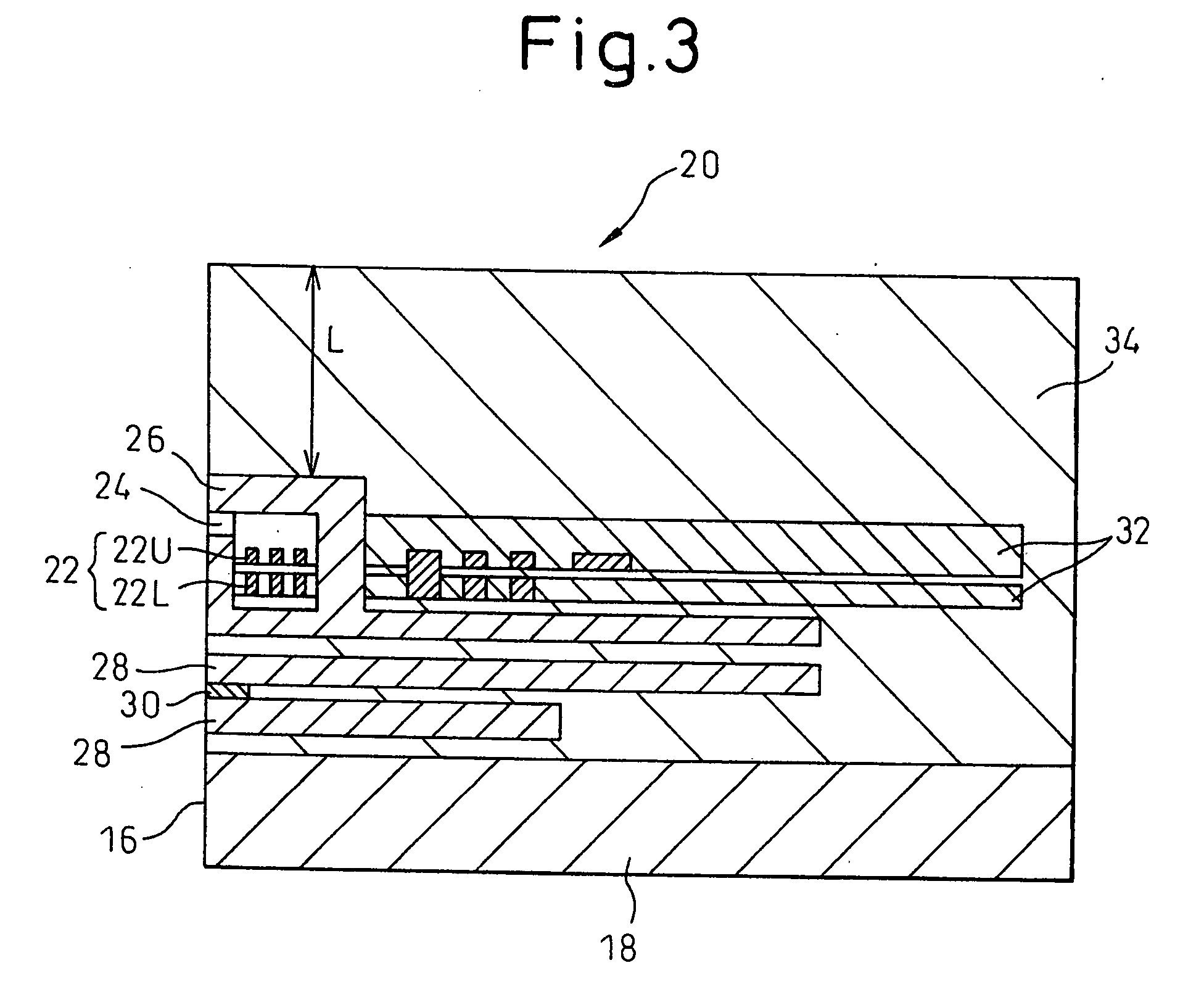

[0039] The preferred embodiment of the present invention will now be explained with reference to the accompanying drawings. FIG. 1 is a schematic view illustrating a part of a magnetic disk apparatus according to an embodiment of the present invention. FIG. 2 is a perspective view illustrating the magnetic head slider.

[0040] The magnetic disk apparatus 10 includes magnetic disks 12 and magnetic head sliders 14. The magnetic head slider 14 has a floating surface 16 and a floating rail (not shown). In operation, the disk rotates in the direction shown by the arrow X, and the magnetic head slider 14 floats with respect to the disk 14 with the floating amount Y and the pitch angle Z. The floating amount Y is approximately 10 nm, for example.

[0041] The magnetic head slider 14 comprises a substrate 18 forming a slider body and a magnetic head structure 20 provided on the substrate 18. The magnetic head structure 20 is formed by laminating thin films of several materials. The magnetic he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com