Patents

Literature

256results about "Housings/shields for recording heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

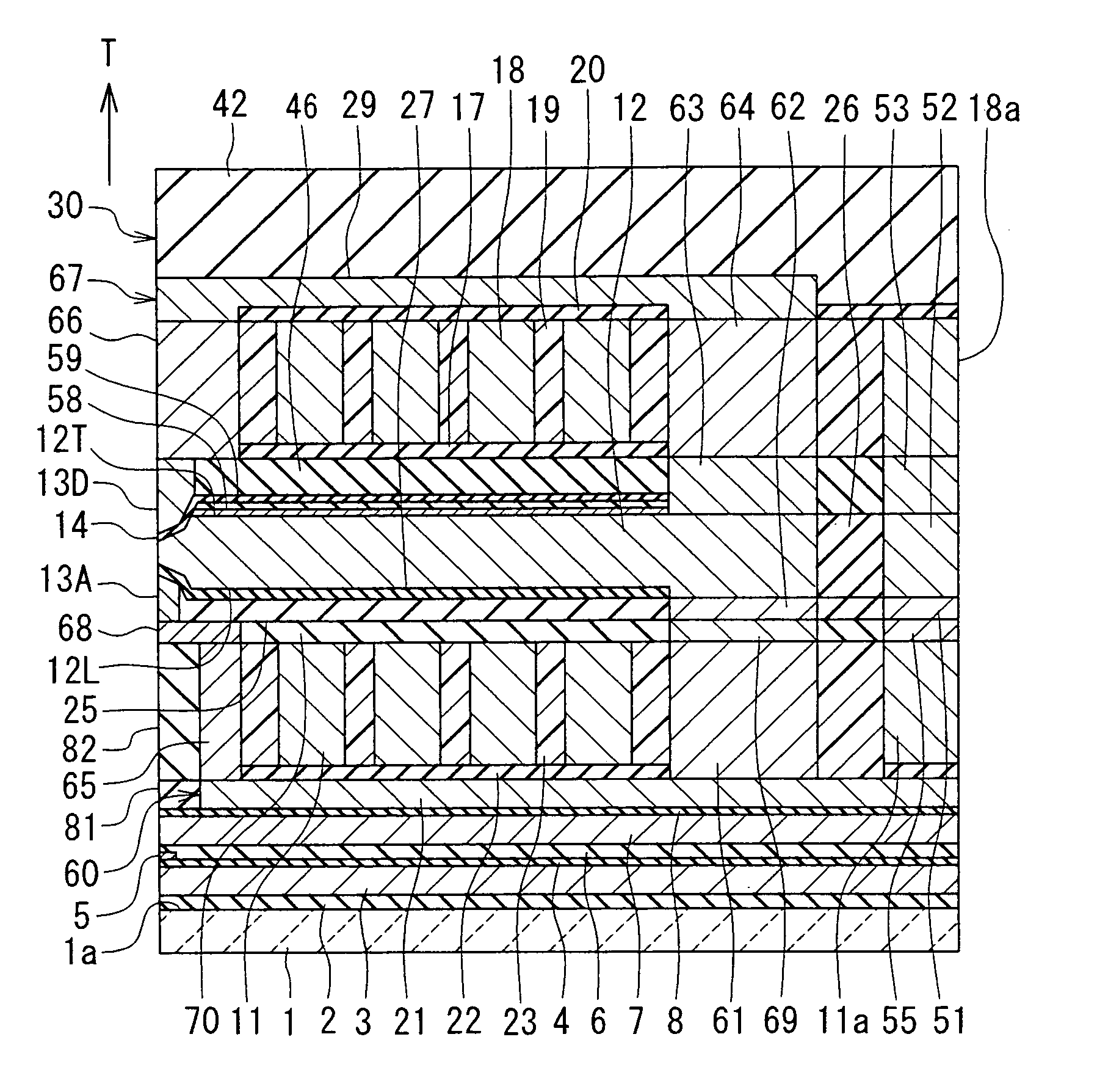

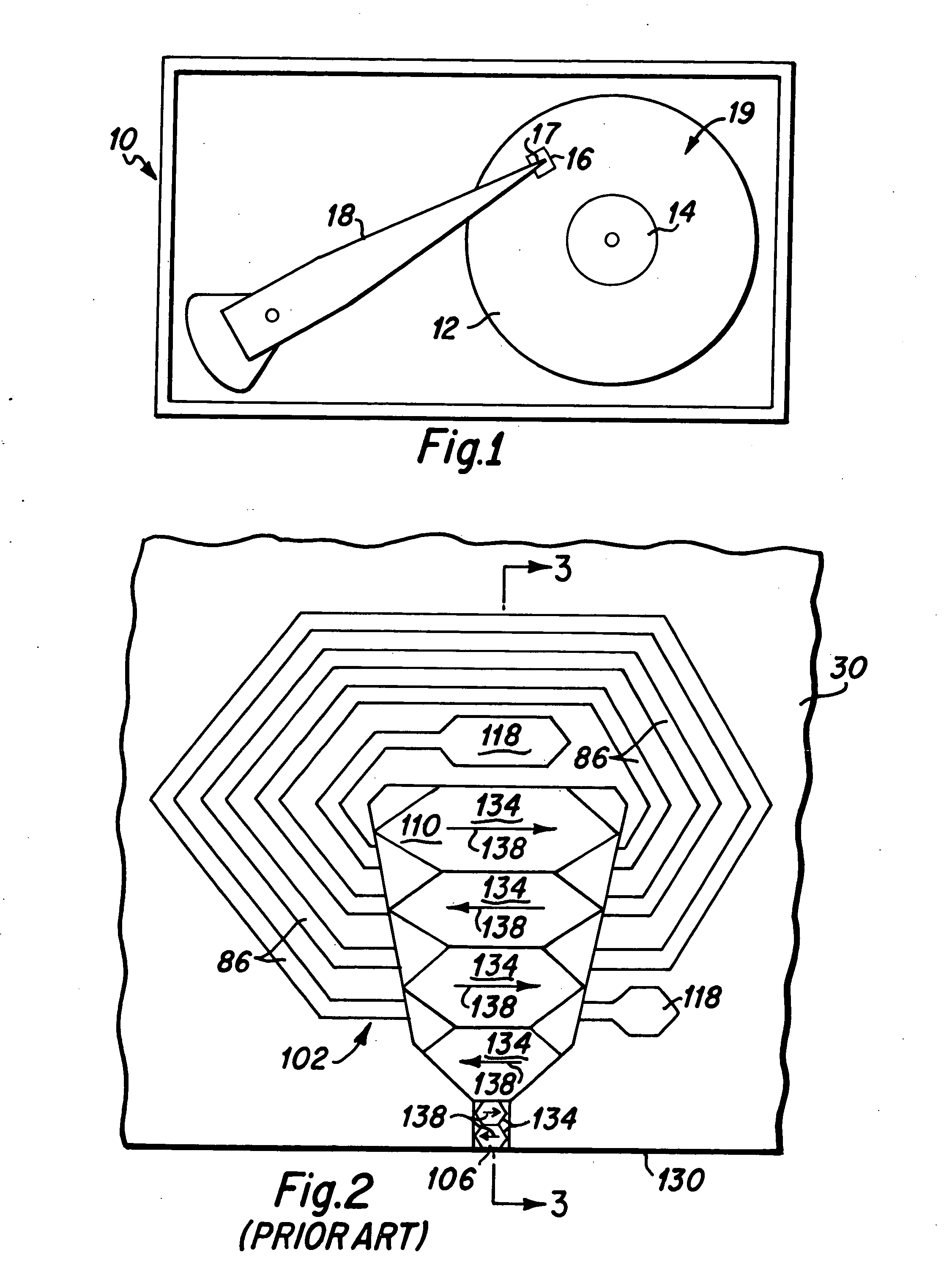

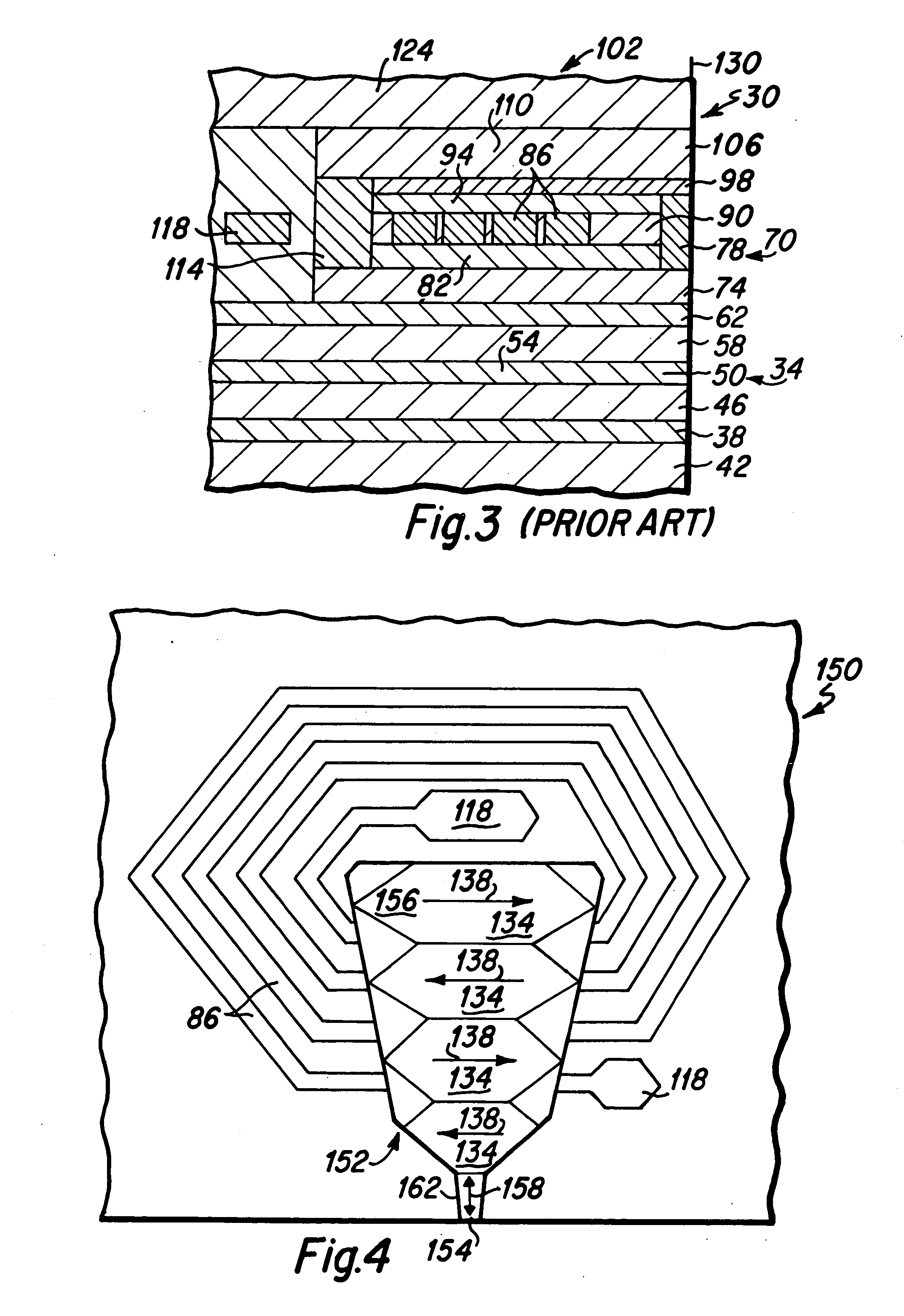

Magnetic head for perpendicular magnetic recording and method of manufacturing same

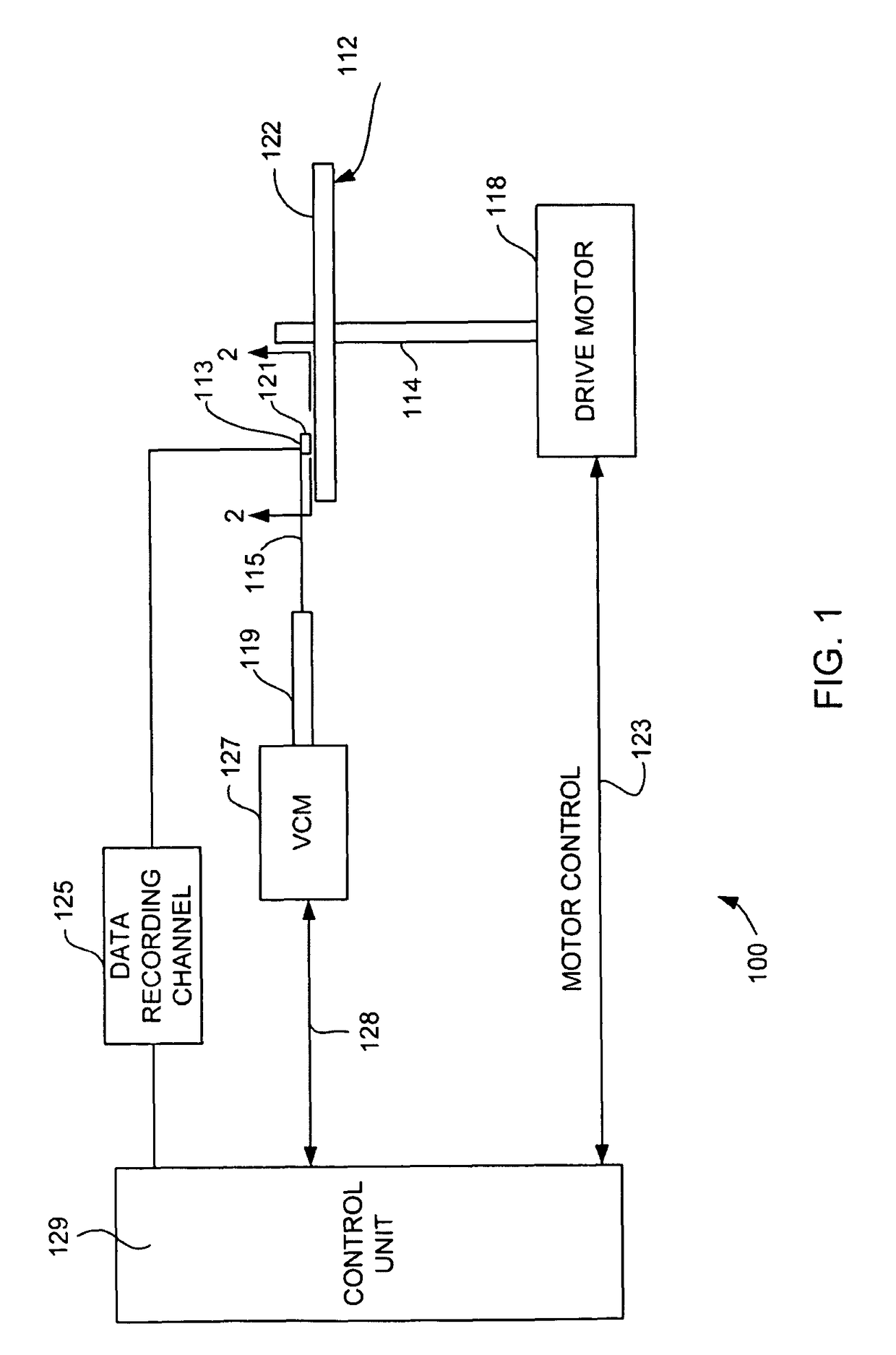

ActiveUS20080088972A1Suppress wide-range adjacent track eraseReduce resistanceConstruction of head windingsManufacture head surfaceRecording mediaElectrical and Electronics engineering

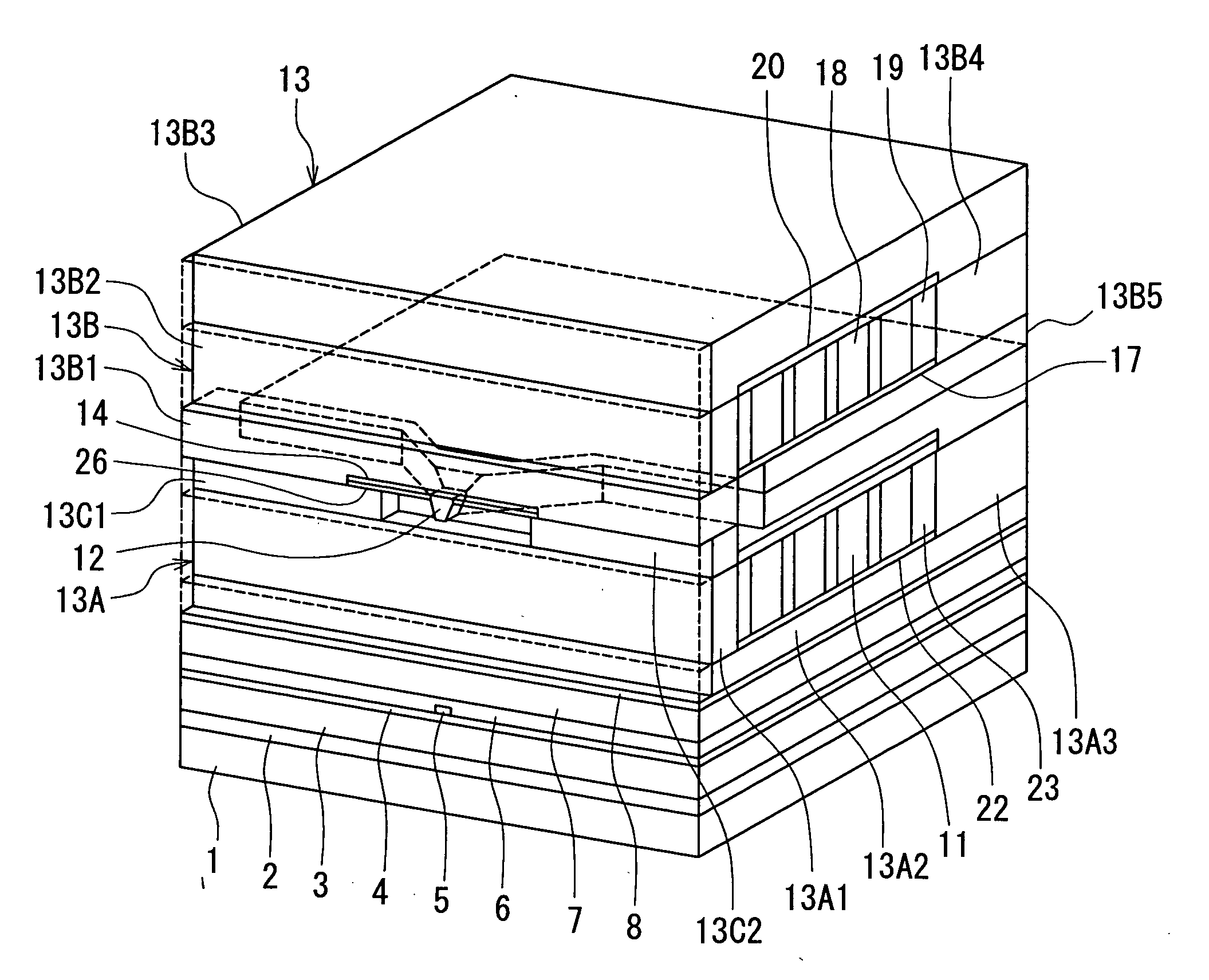

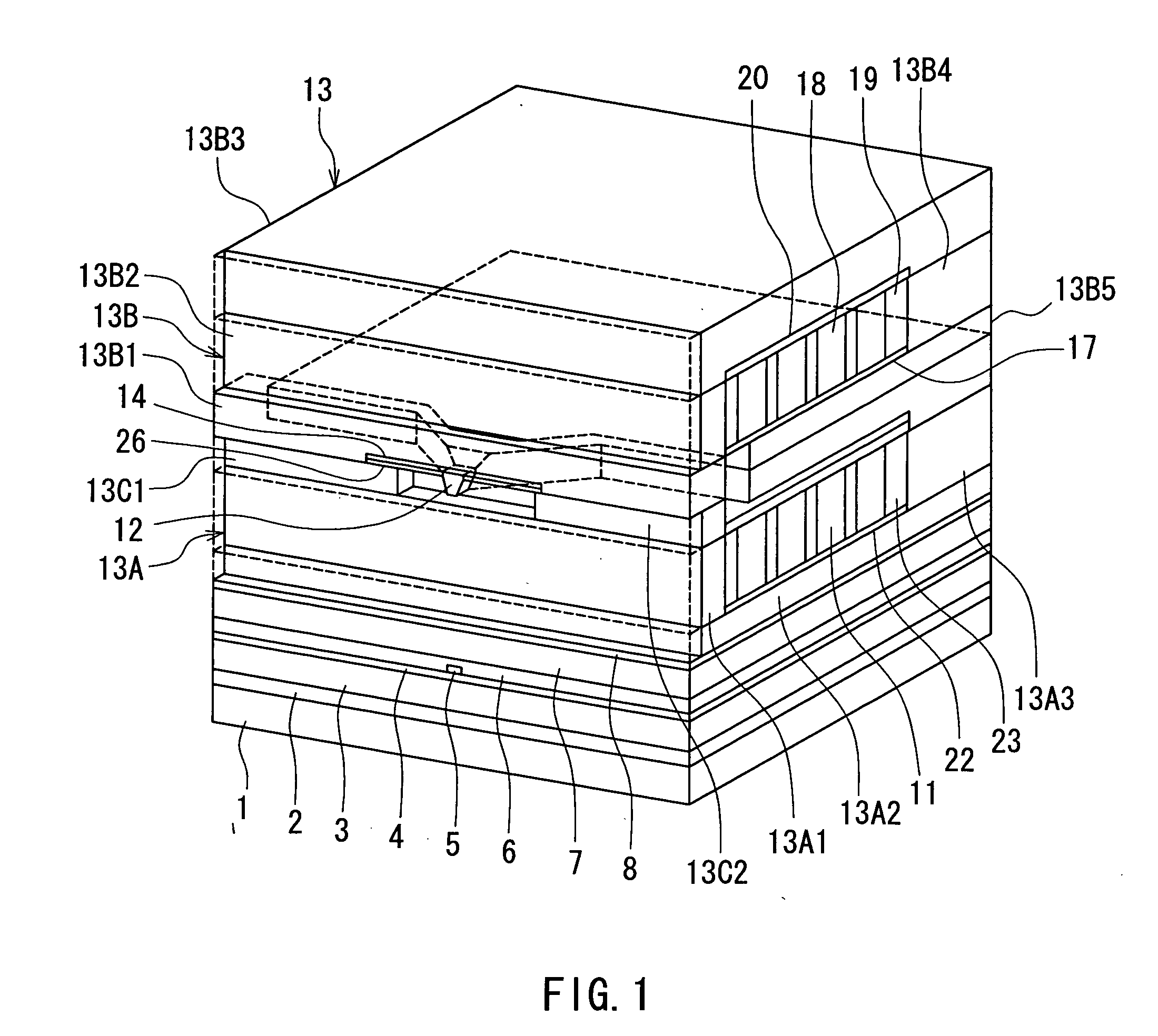

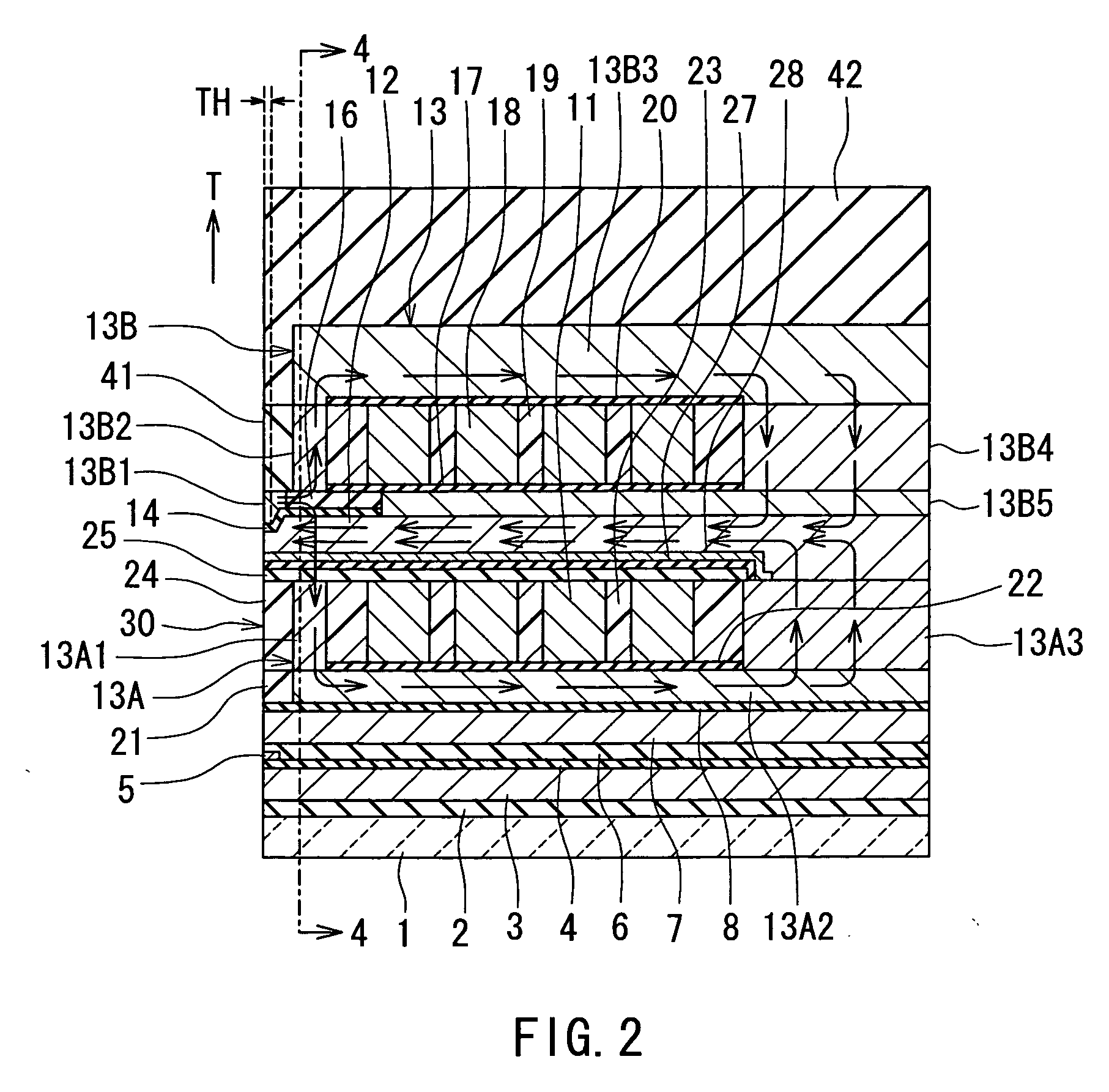

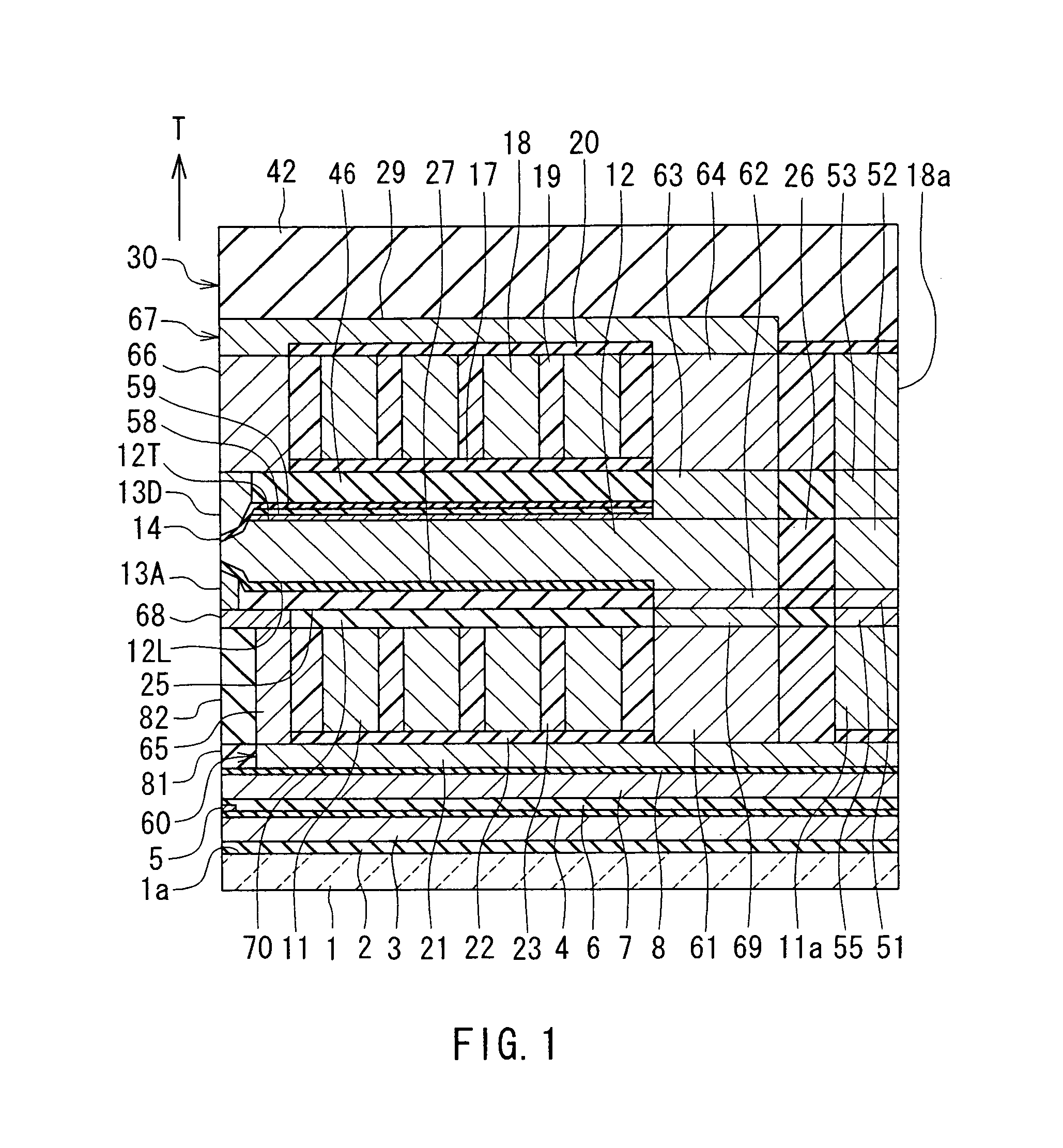

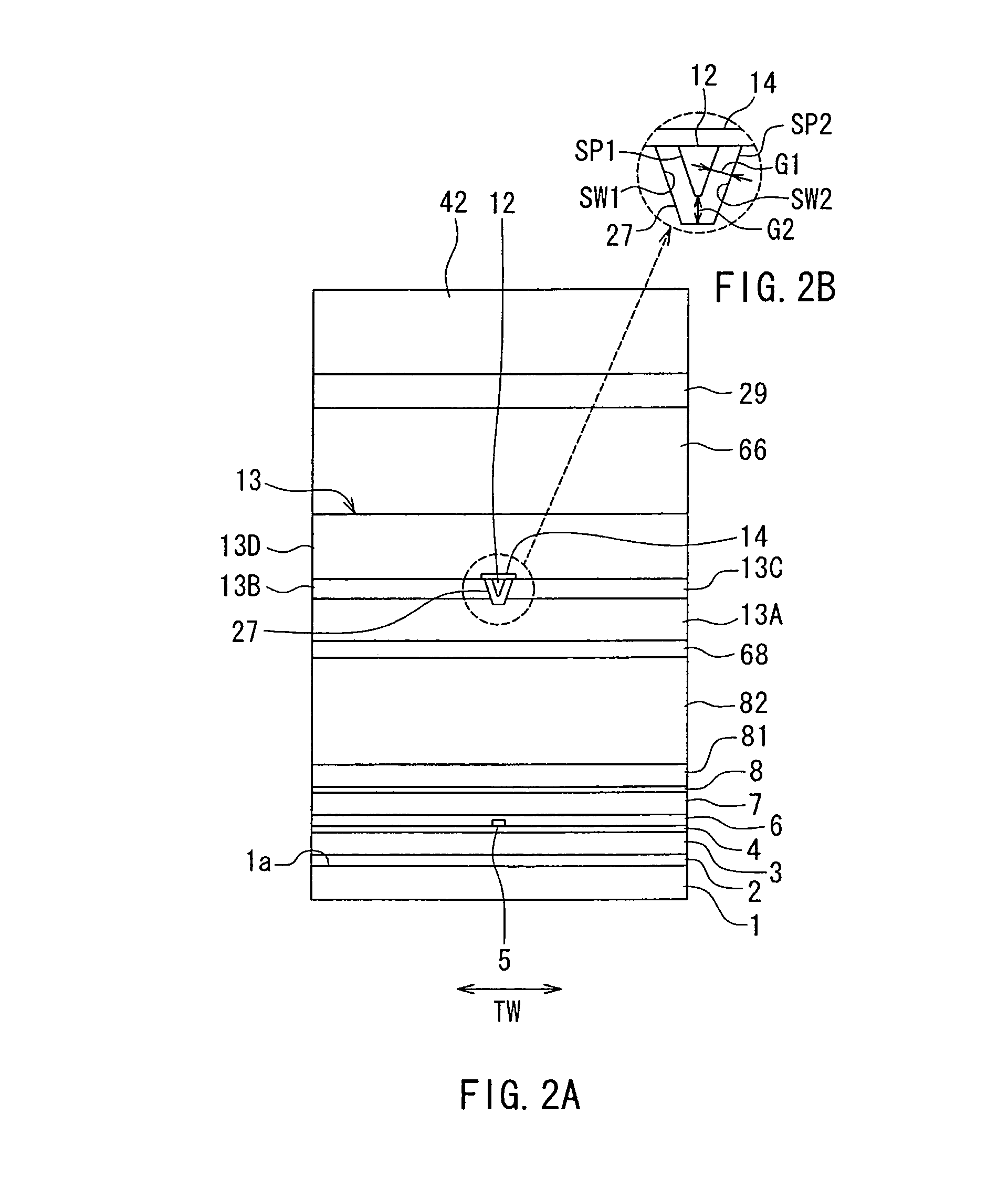

A magnetic head comprises a pole layer, a first coil, a second coil, and a shield. The shield incorporates: a first portion located backward of the pole layer along the direction of travel of a recording medium; a second portion located forward of the pole layer along the direction of travel of the recording medium; and two coupling portions. The first portion has an end face located in a medium facing surface. The two coupling portions couple the first and second portions to each other without touching the pole layer. Part of the first coil passes through a space surrounded by the pole layer and the first portion. Part of the second coil passes through a space surrounded by the pole layer and the second portion.

Owner:HEADWAY TECH INC +1

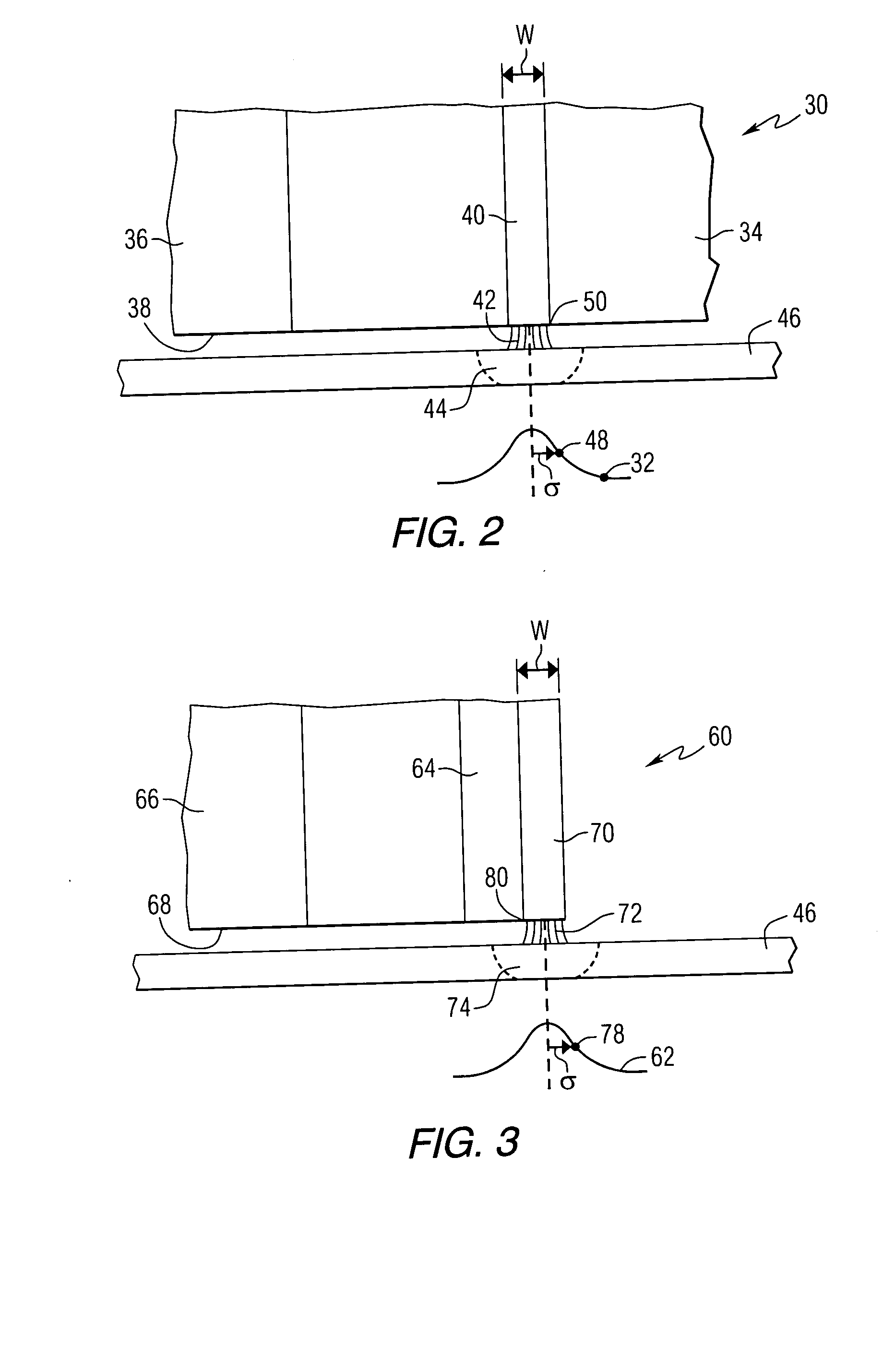

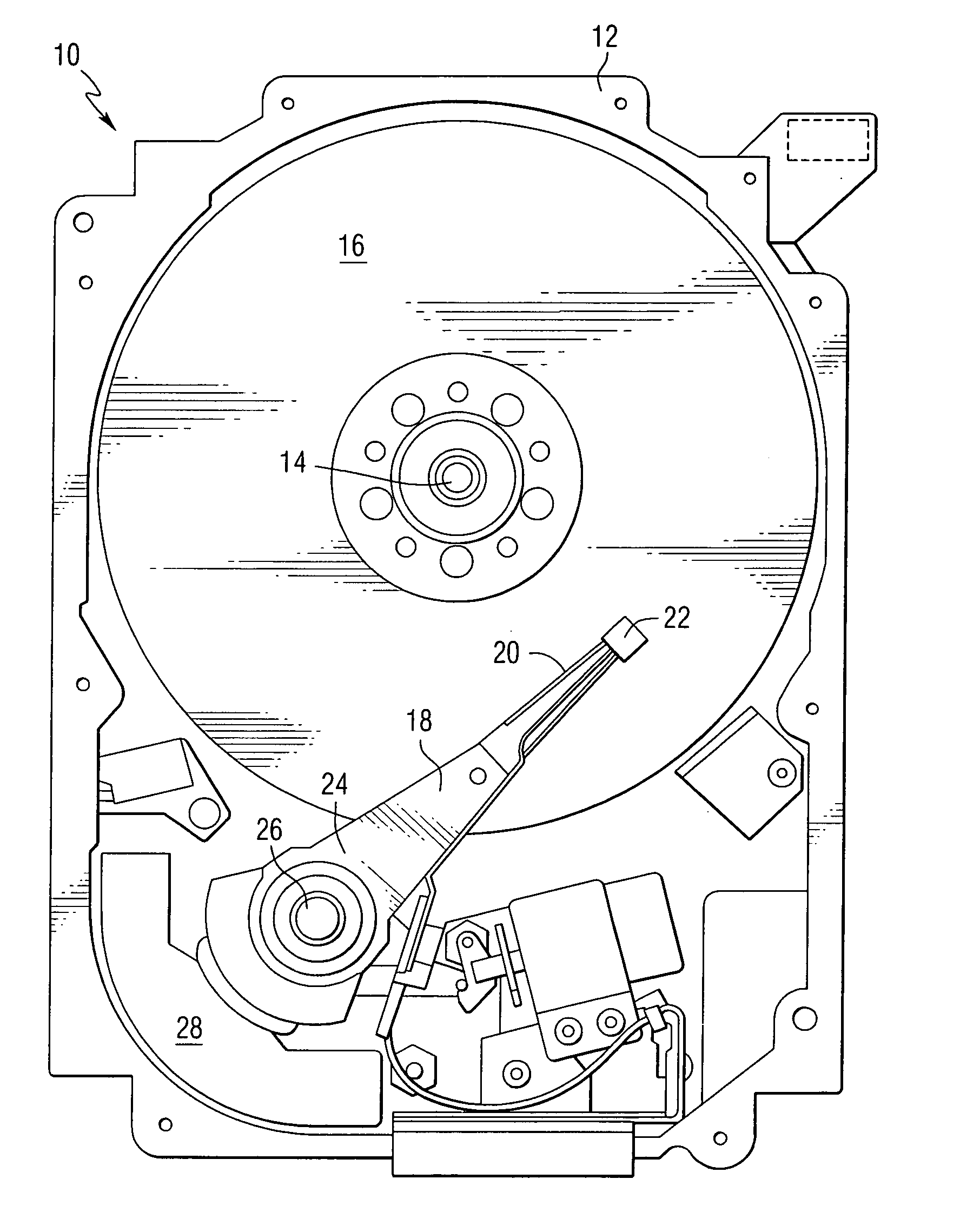

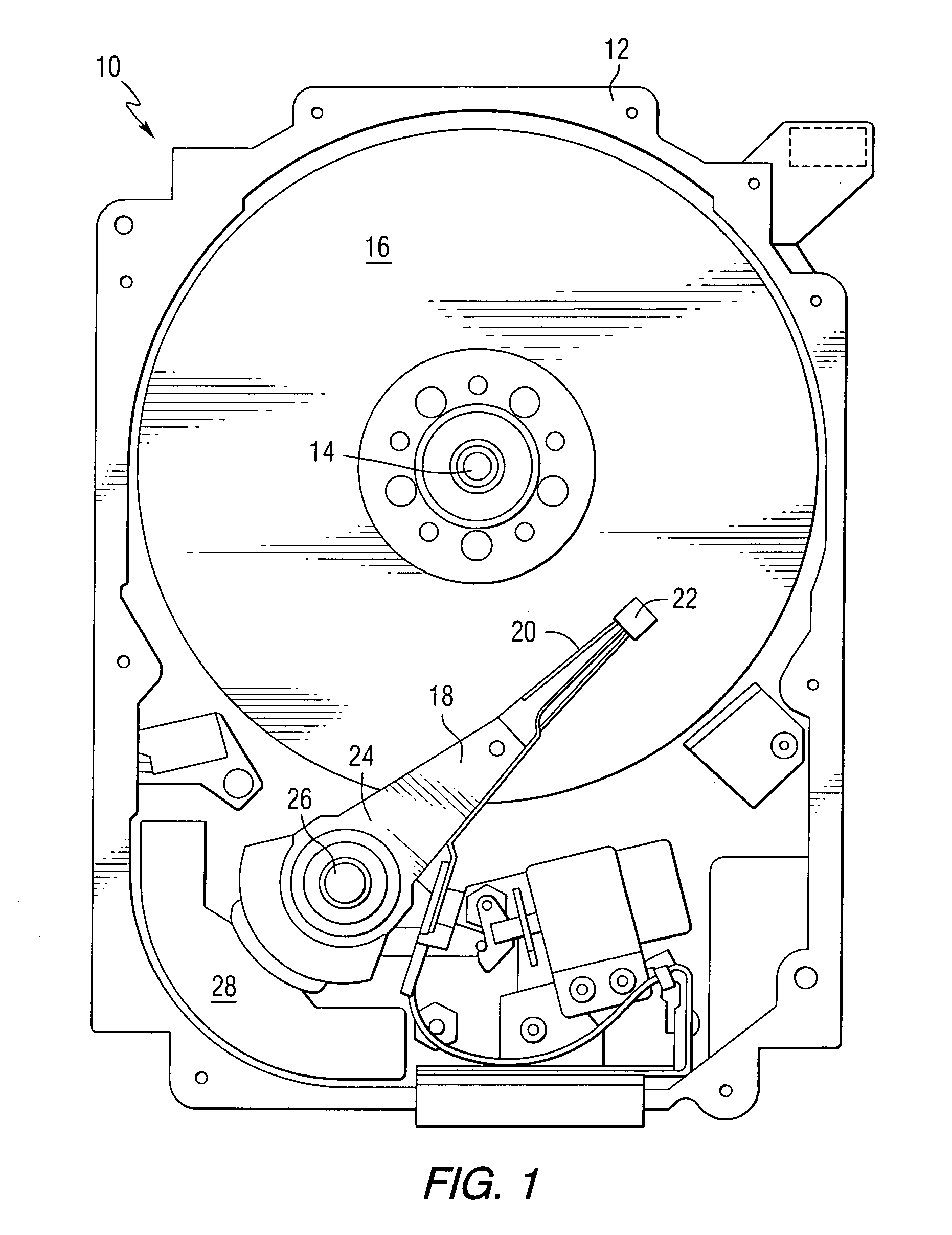

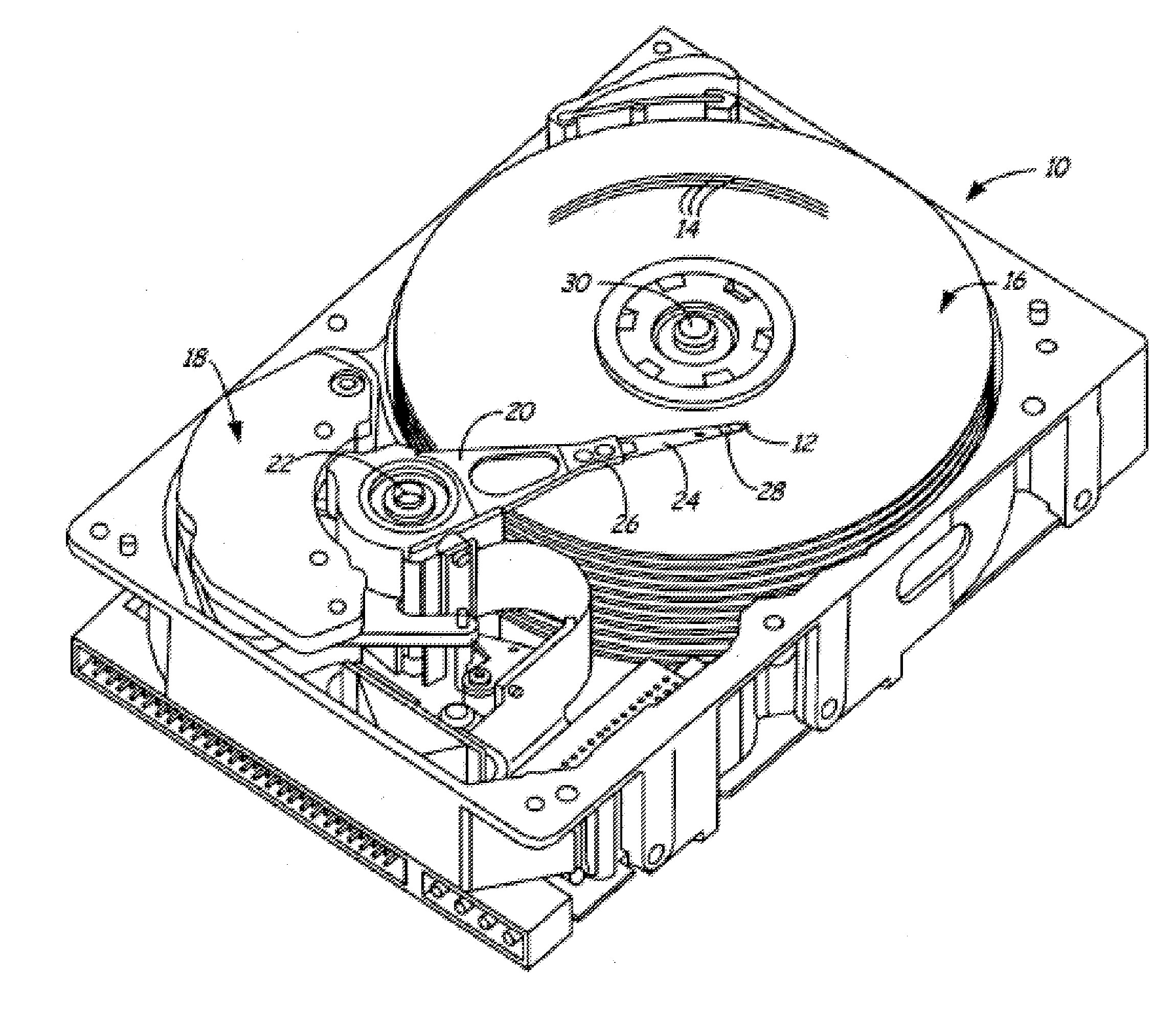

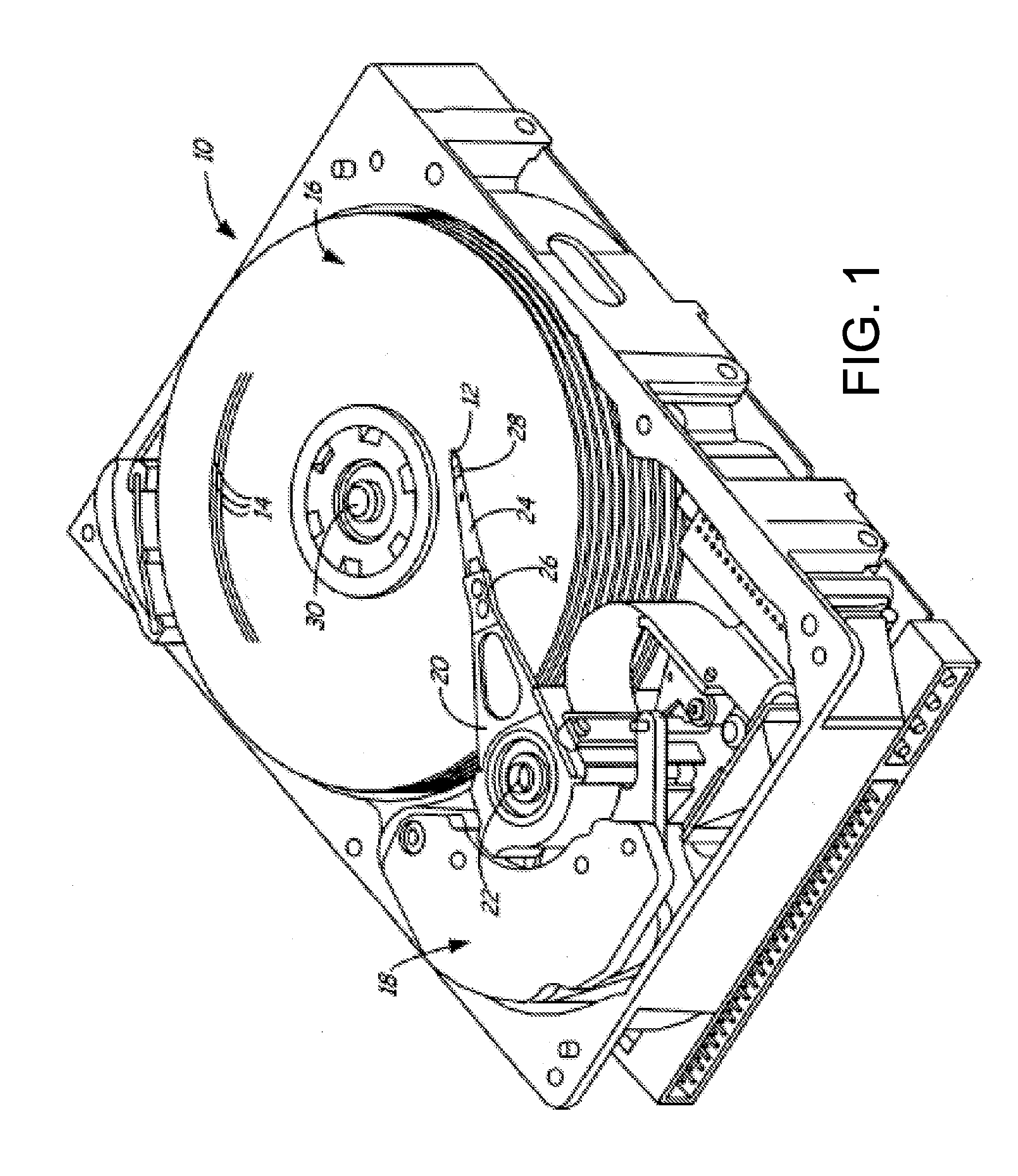

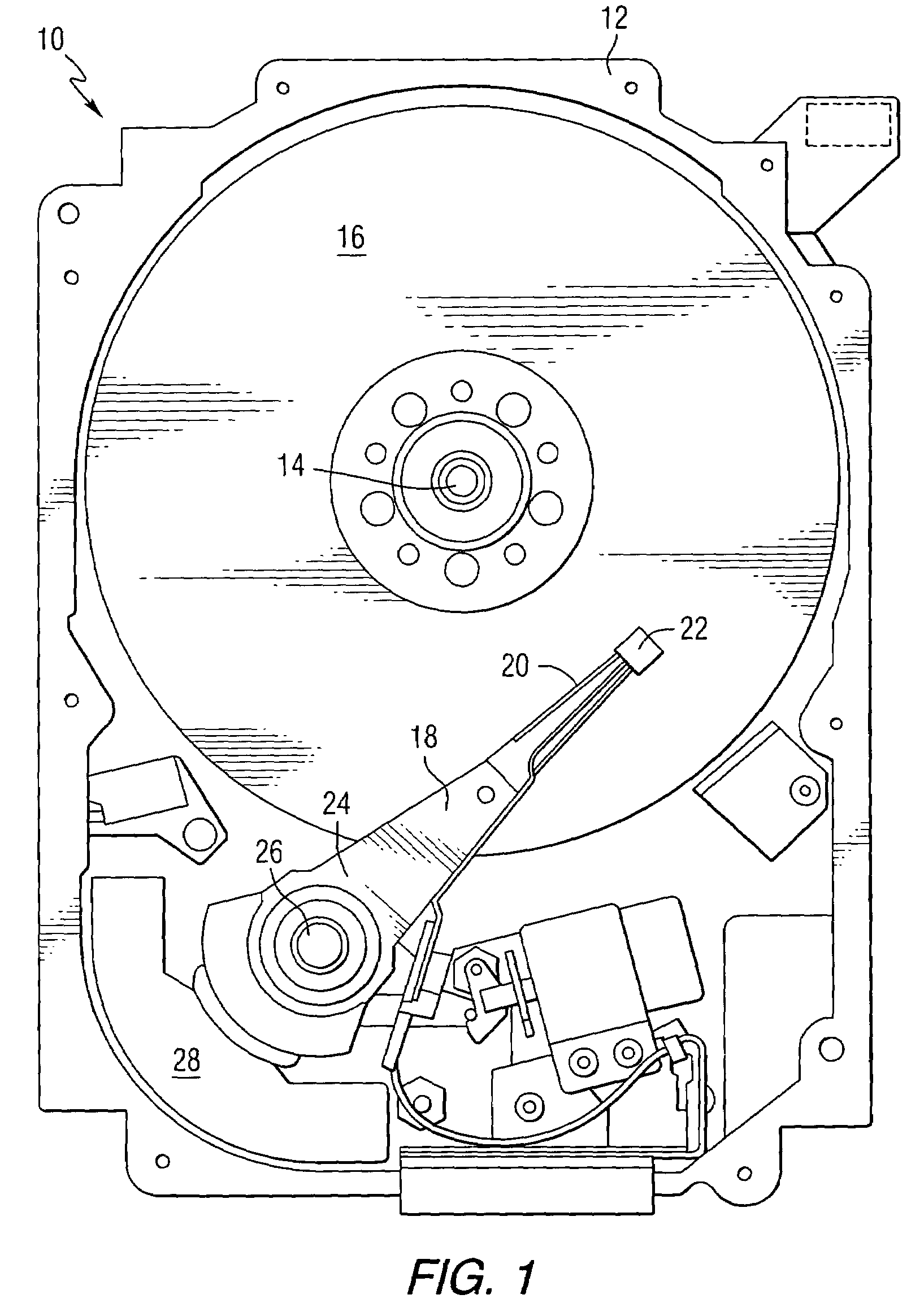

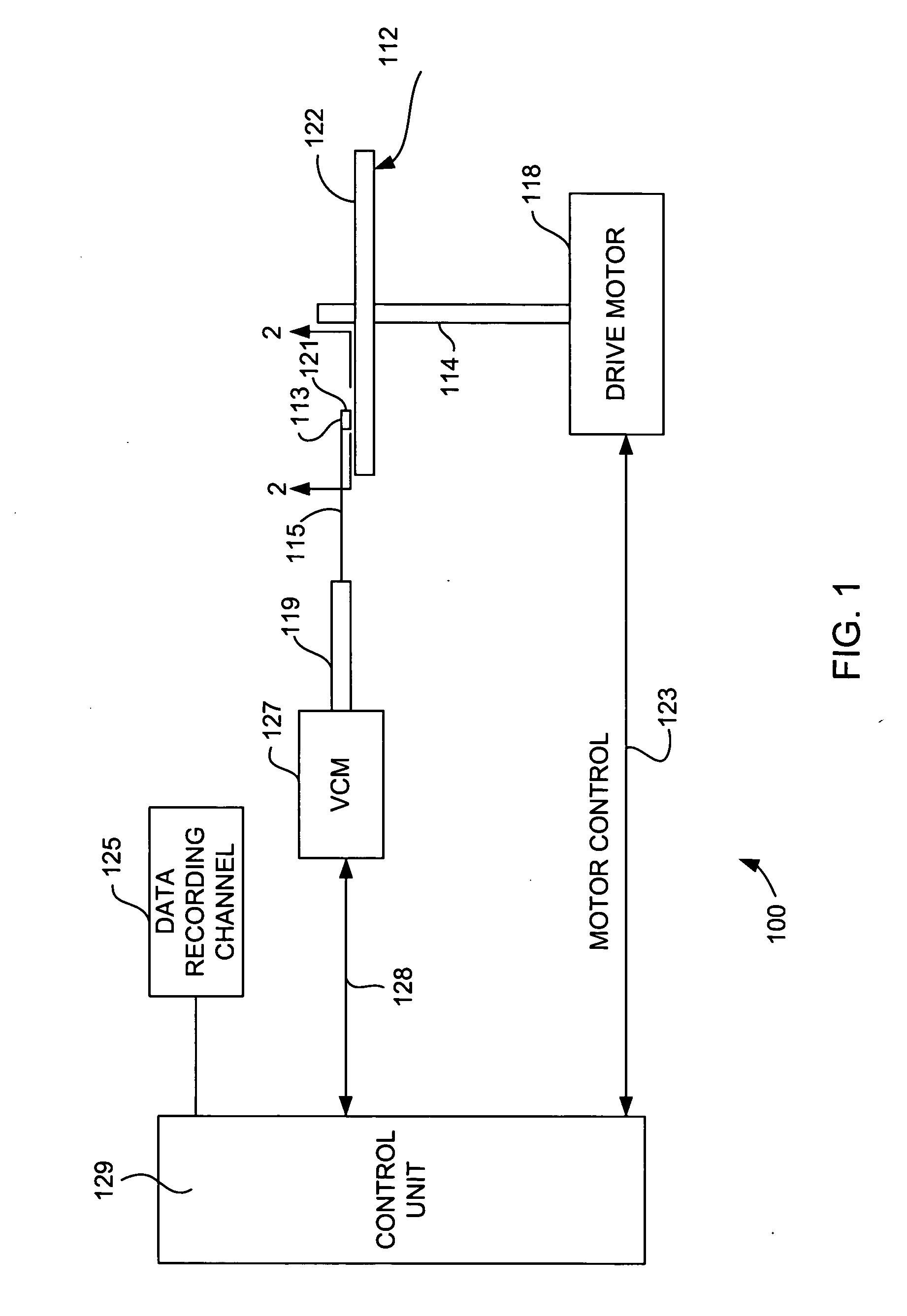

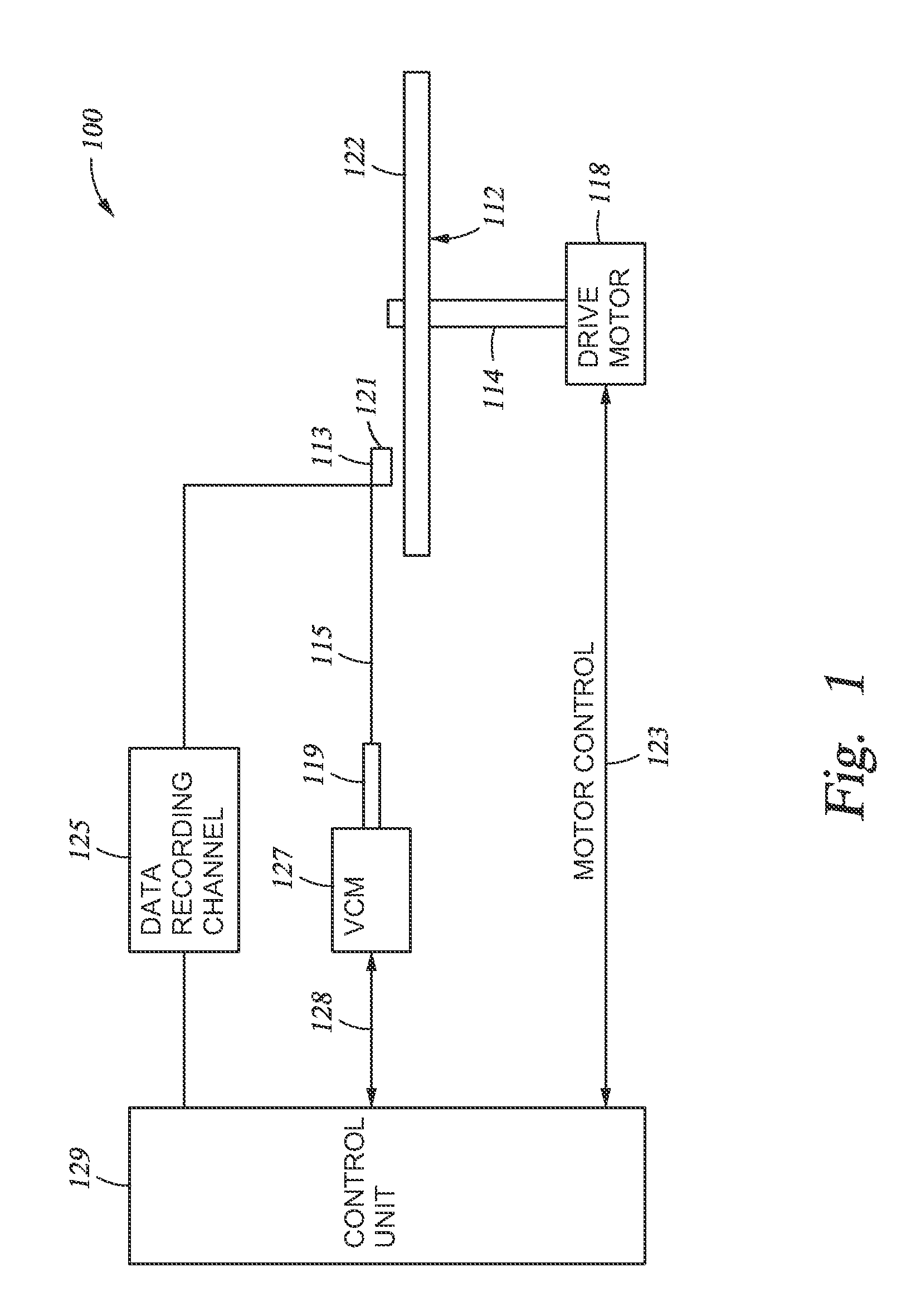

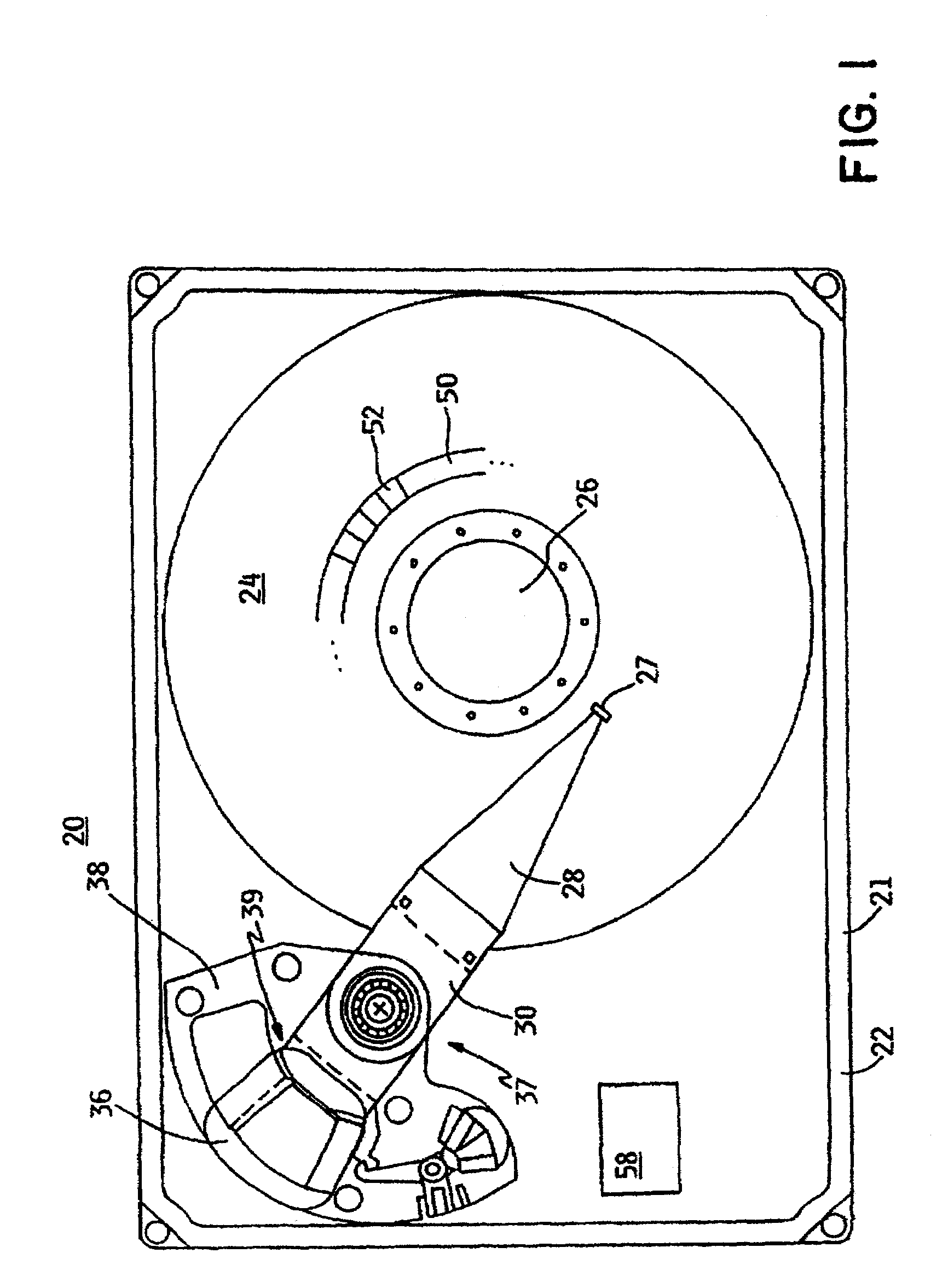

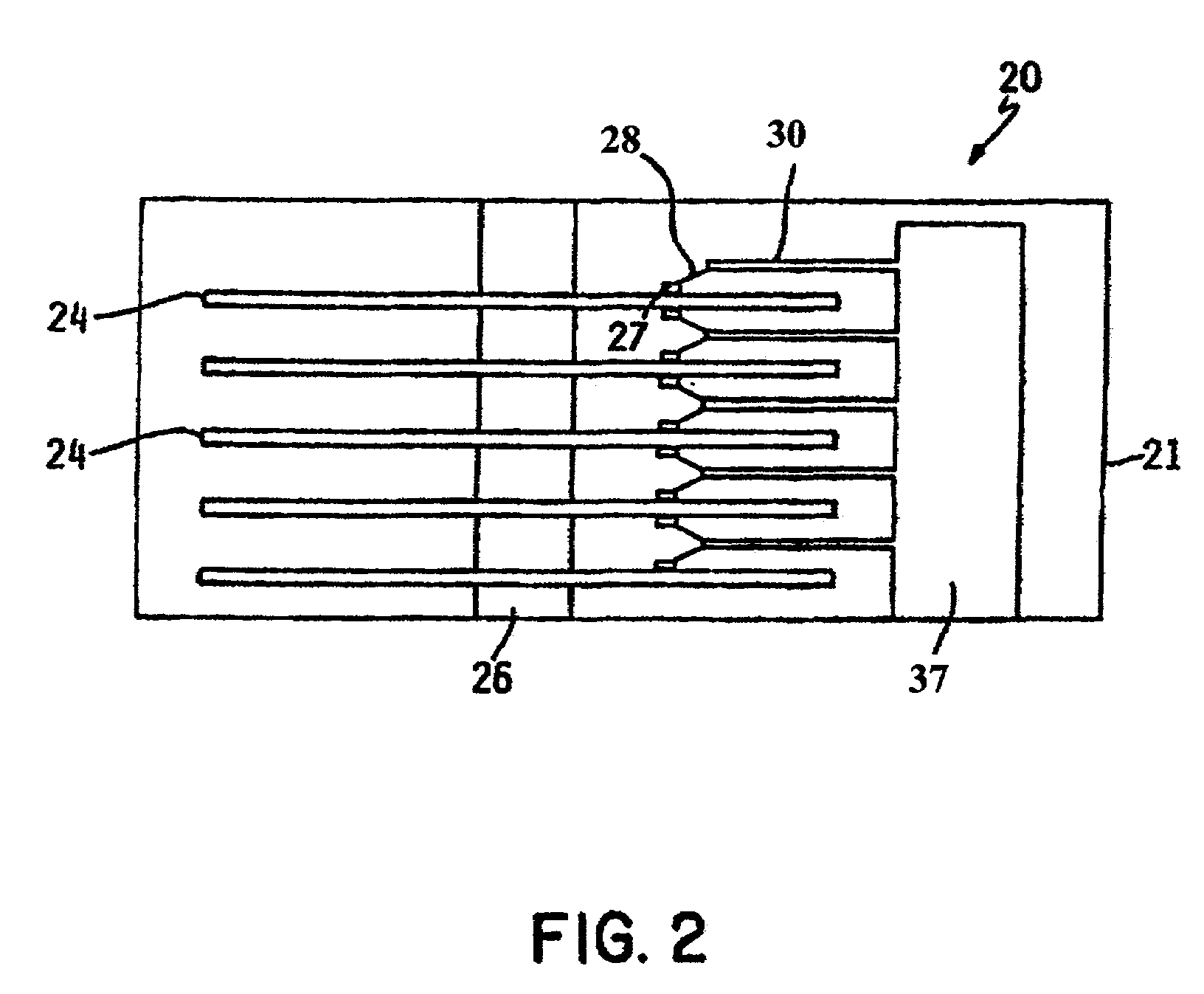

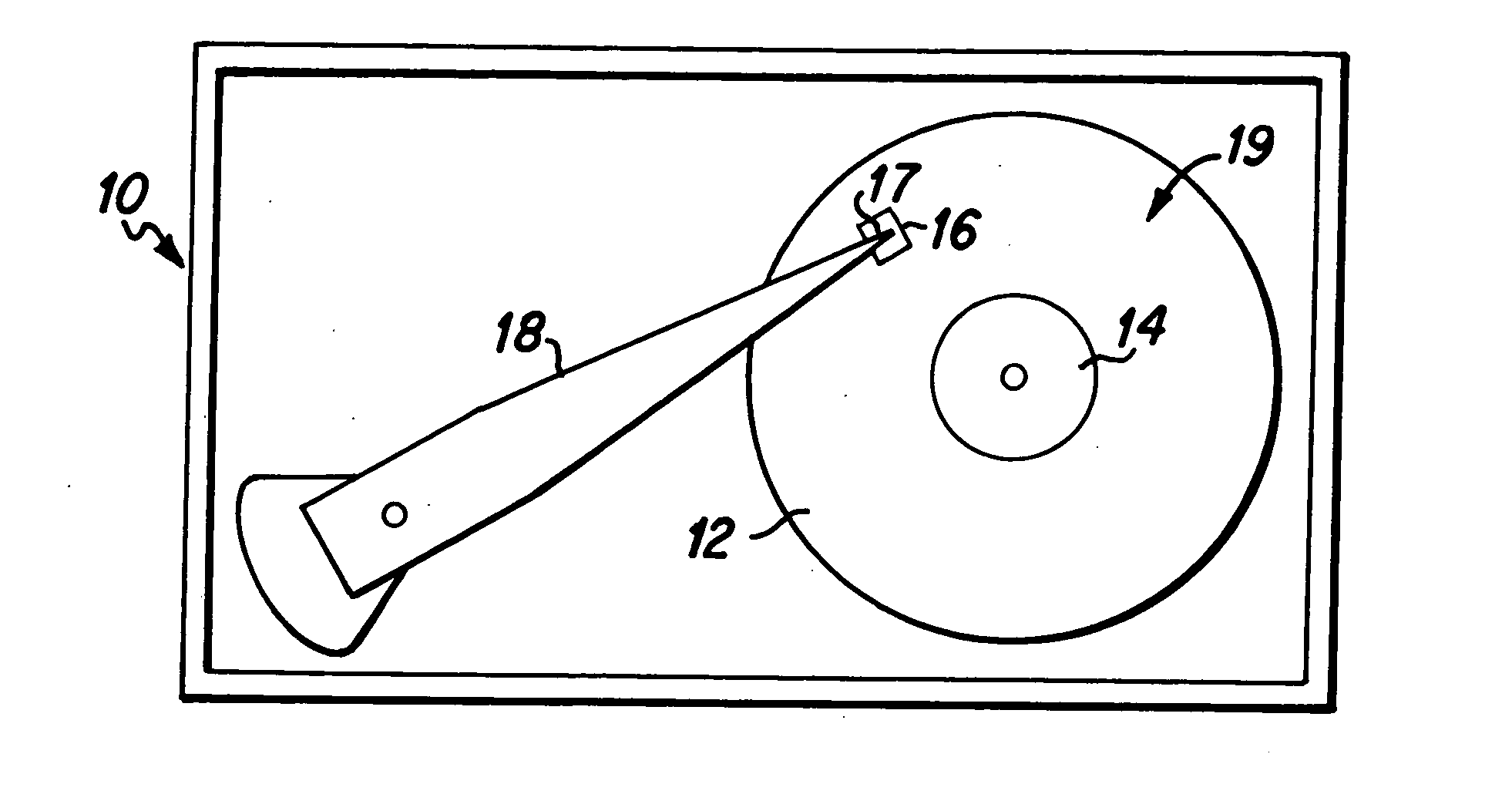

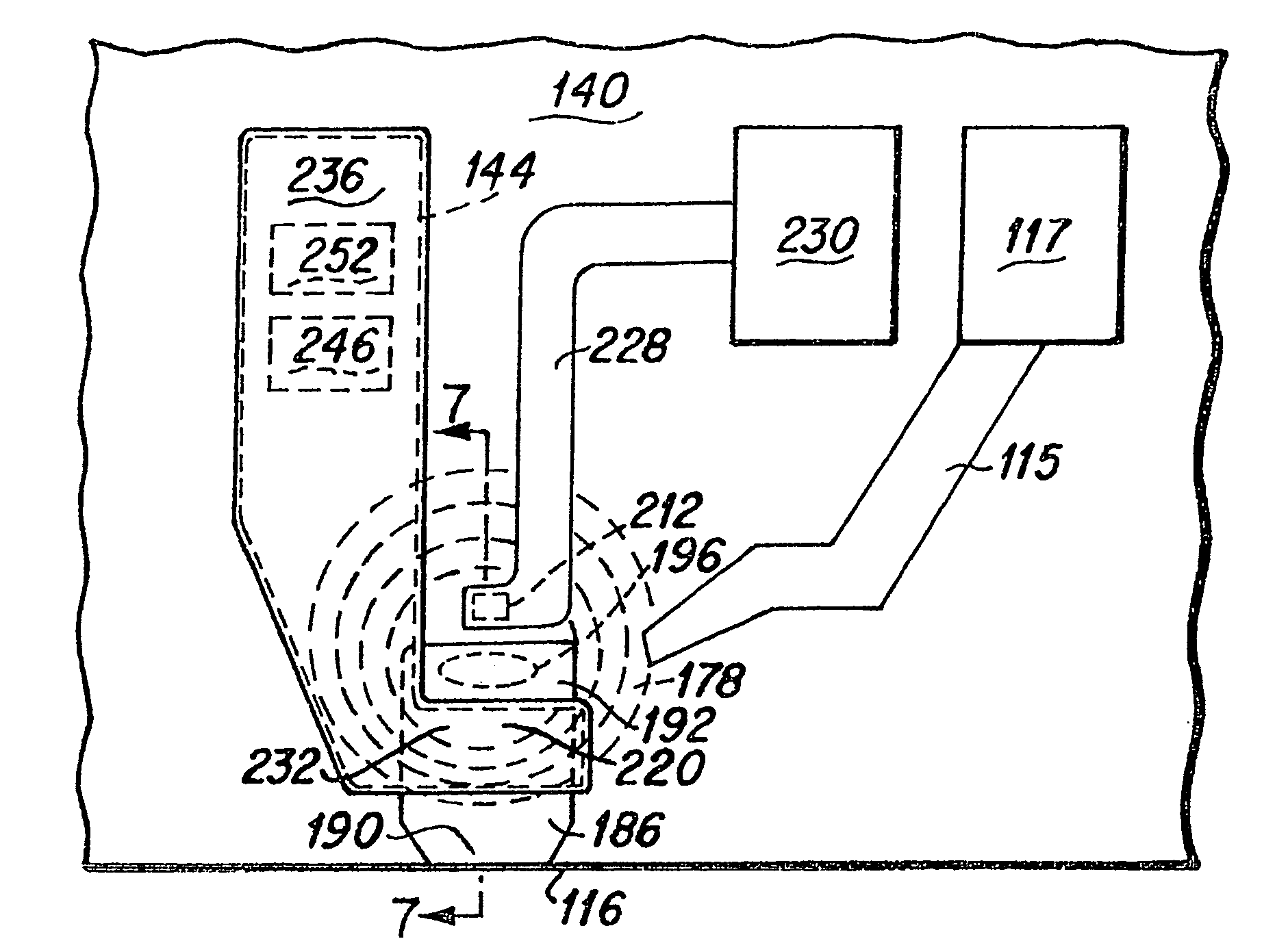

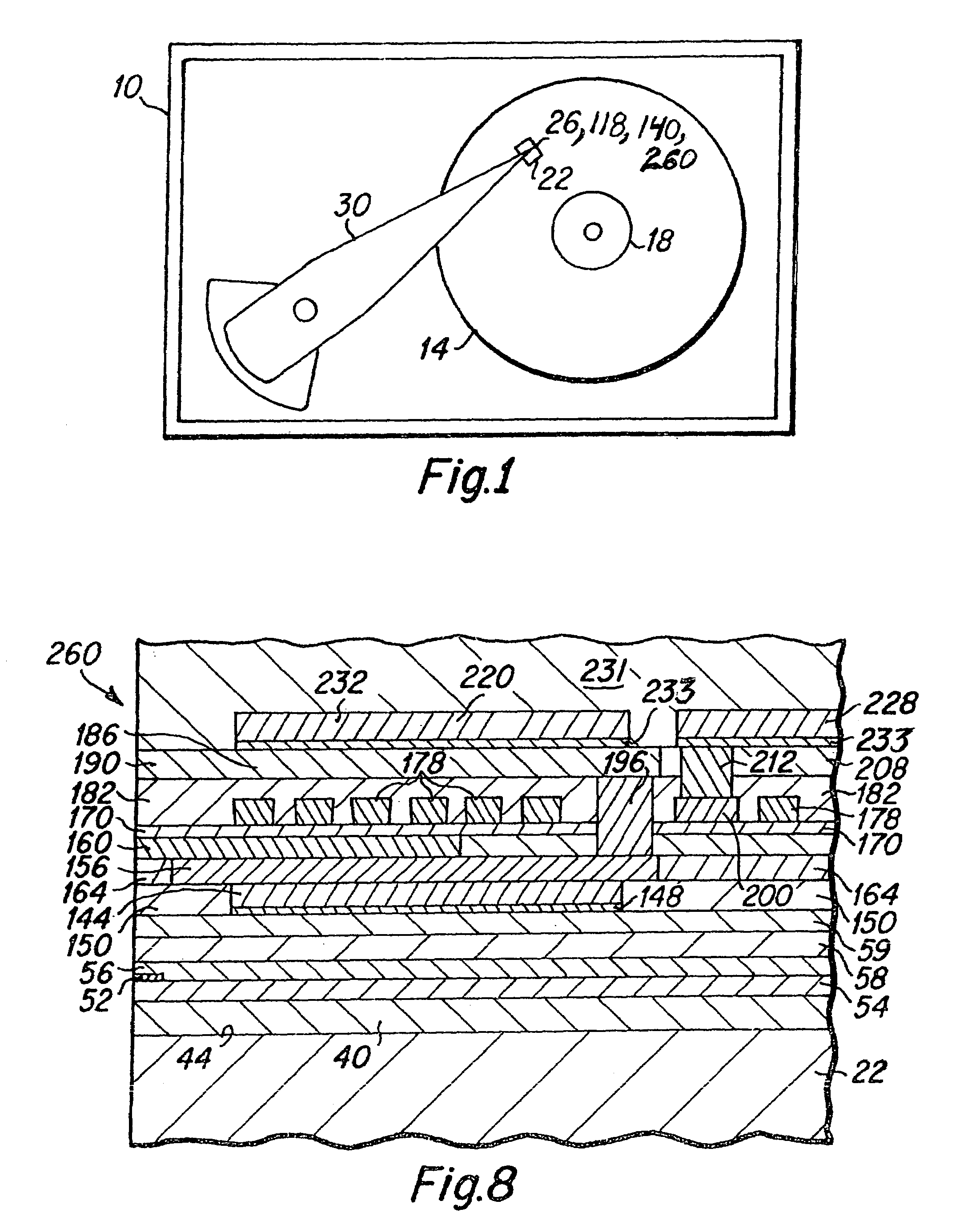

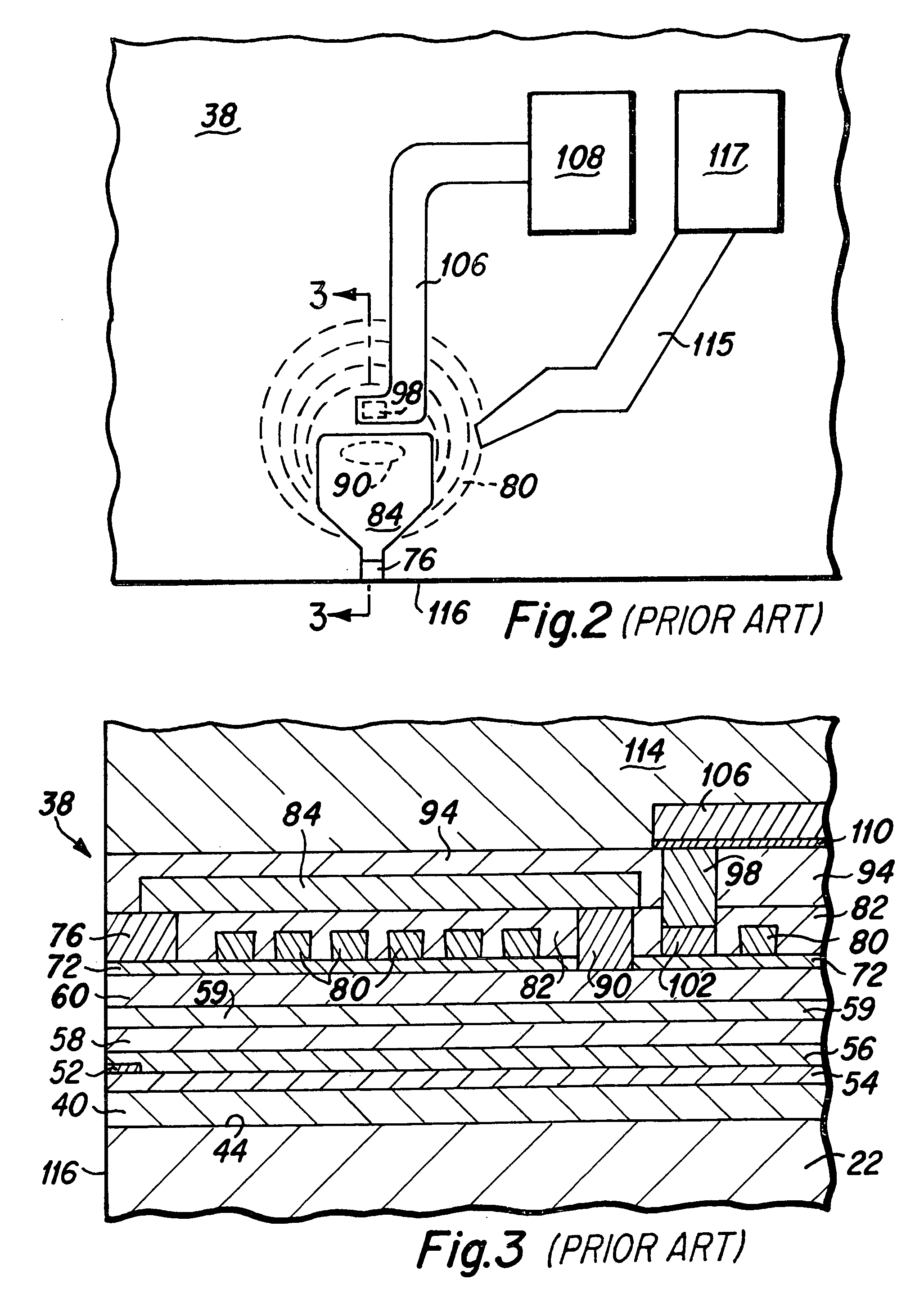

Heat assisted magnetic recording head and method

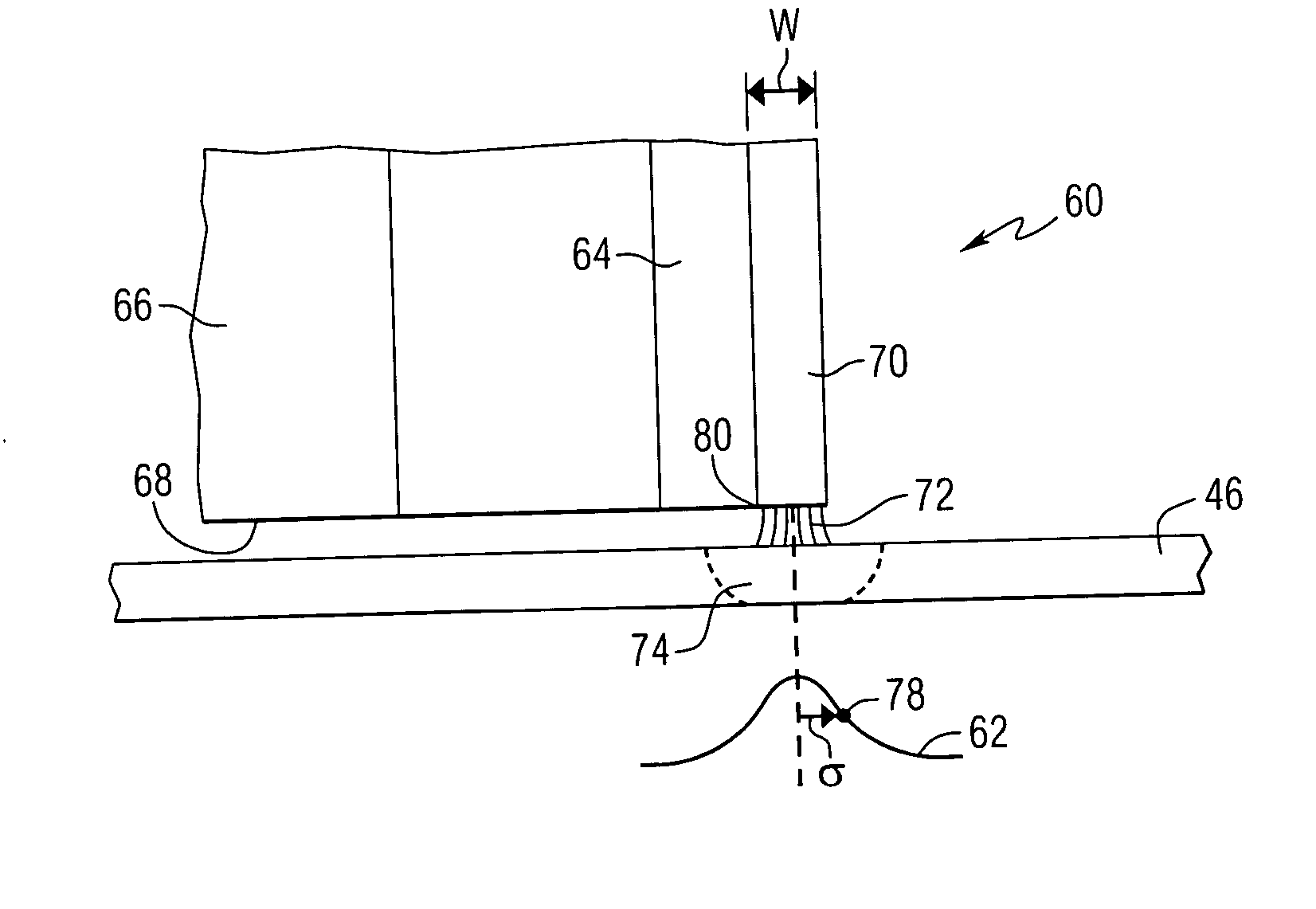

ActiveUS20050052771A1Combination recordingRecord information storageHeat-assisted magnetic recordingMagnetic storage

A magnetic recording head comprises a write pole having a pole tip adjacent to an air bearing surface, a return pole, a near field transducer positioned adjacent to the air bearing surface for producing near field radiation for heating a portion of a magnetic storage medium, wherein a thermal profile of the portion of the magnetic storage medium has a maximum gradient at a location subject to a magnetic write field produced by the write pole. A disc drive that includes the magnetic recording head and a method of recording using the magnetic recording head are also provided.

Owner:SEAGATE TECH LLC

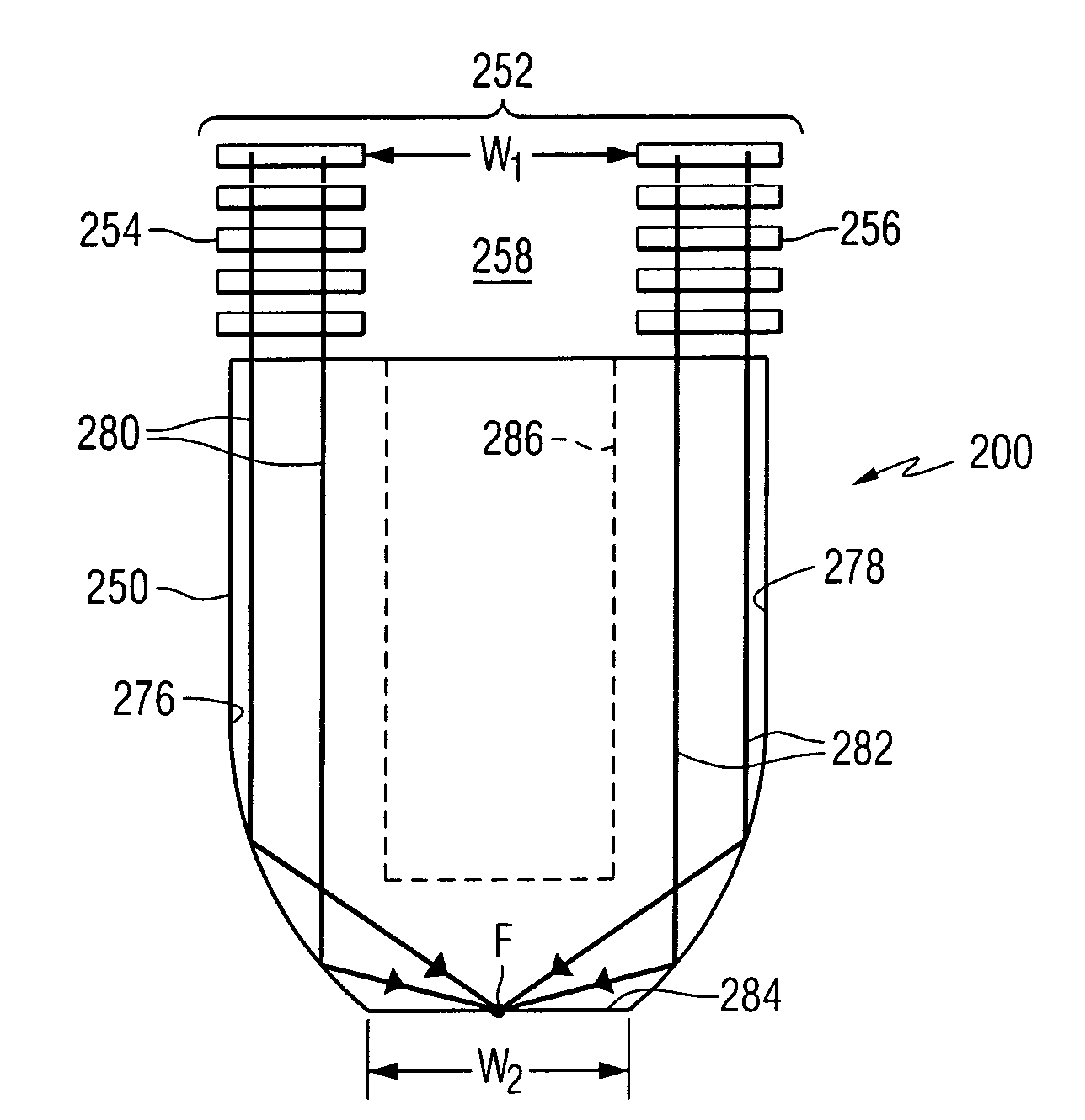

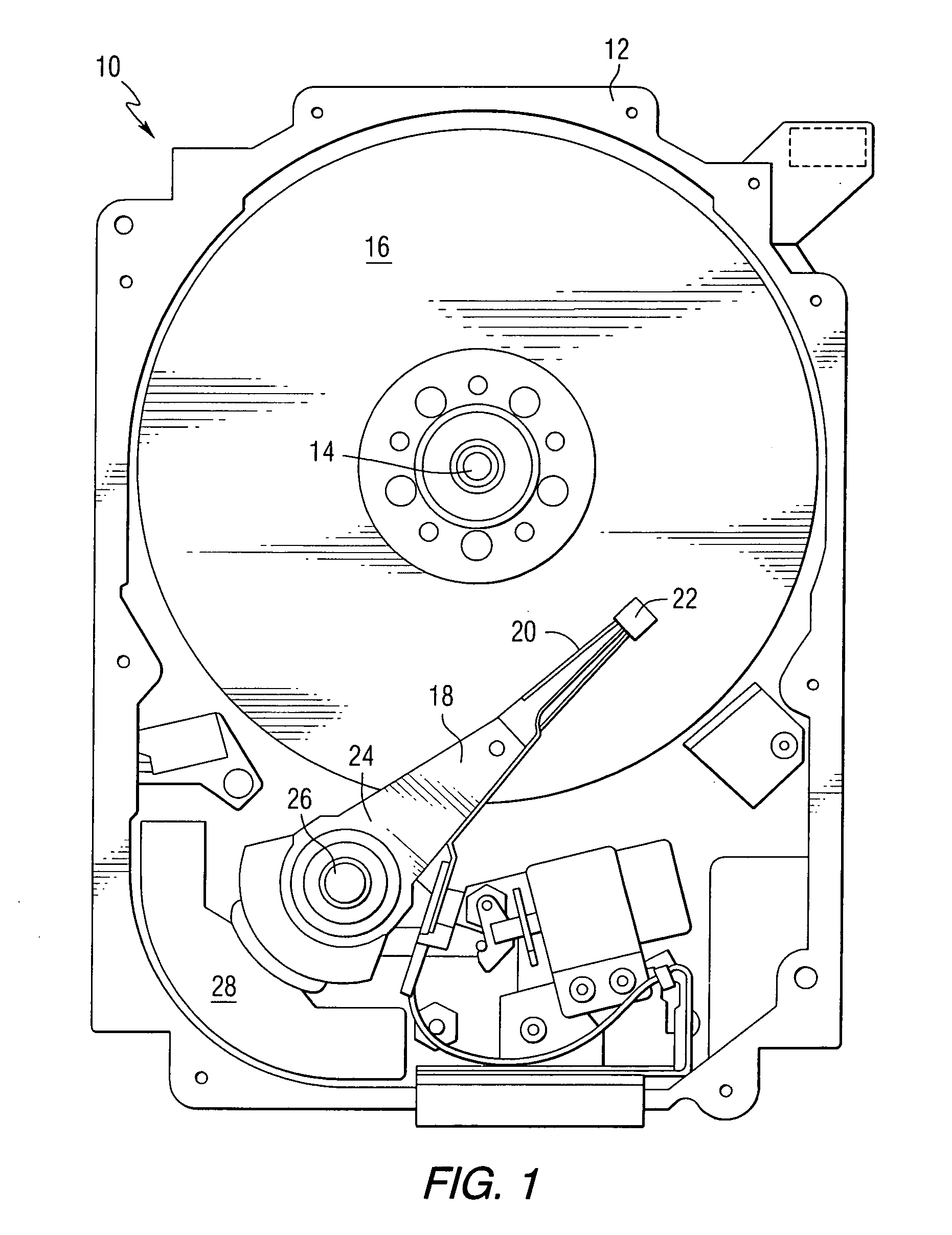

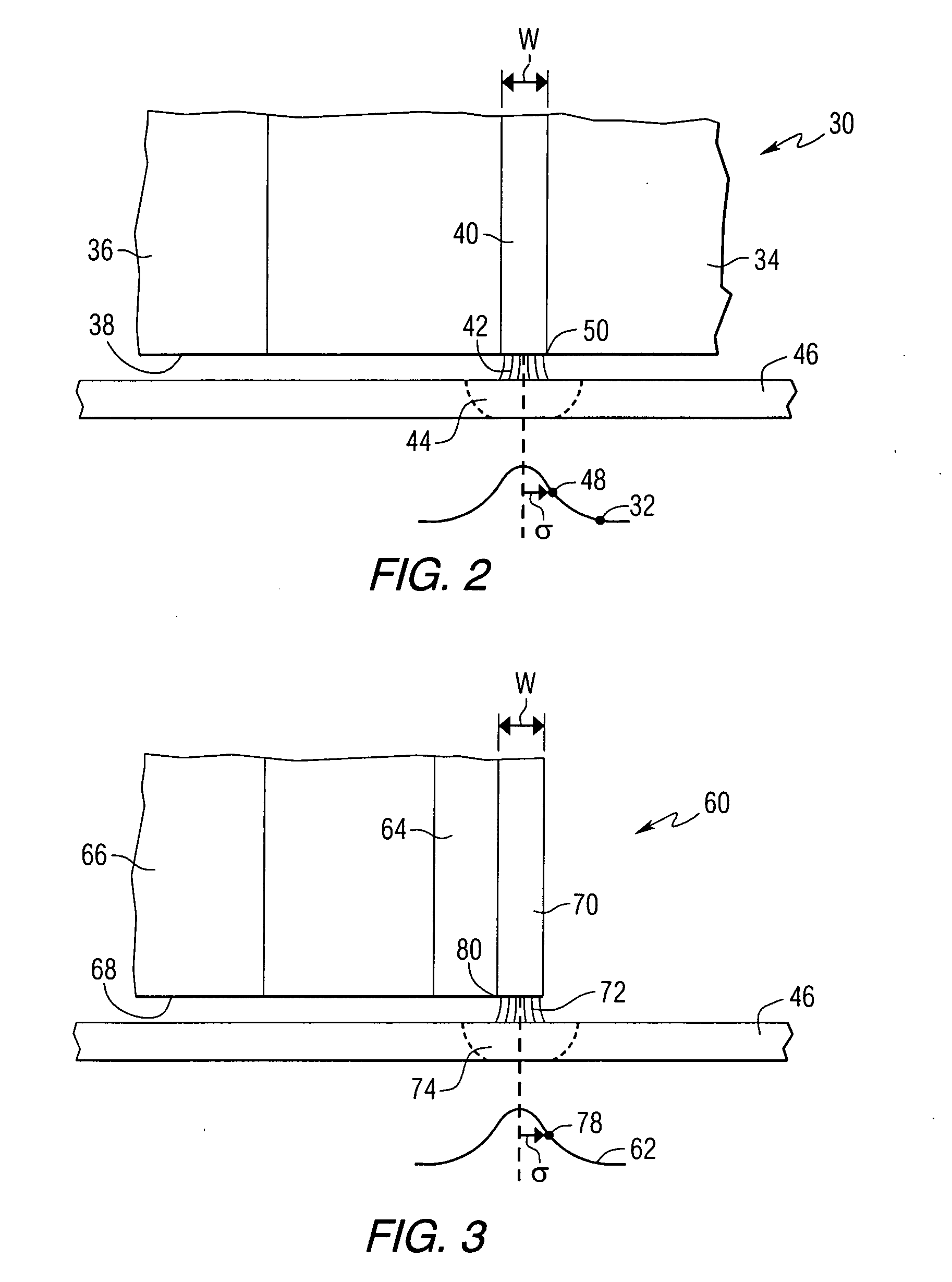

Diffraction grating

Diffraction gratings for coupling an electromagnetic wave into a planar waveguide are disclosed. The diffraction grating may include a first diffraction grating and a second diffraction grating slanted relative to one another. Alternatively, the diffraction grating may include a first diffraction grating and a second diffraction grating spaced apart to form a gap therebetween.

Owner:SEAGATE TECH LLC

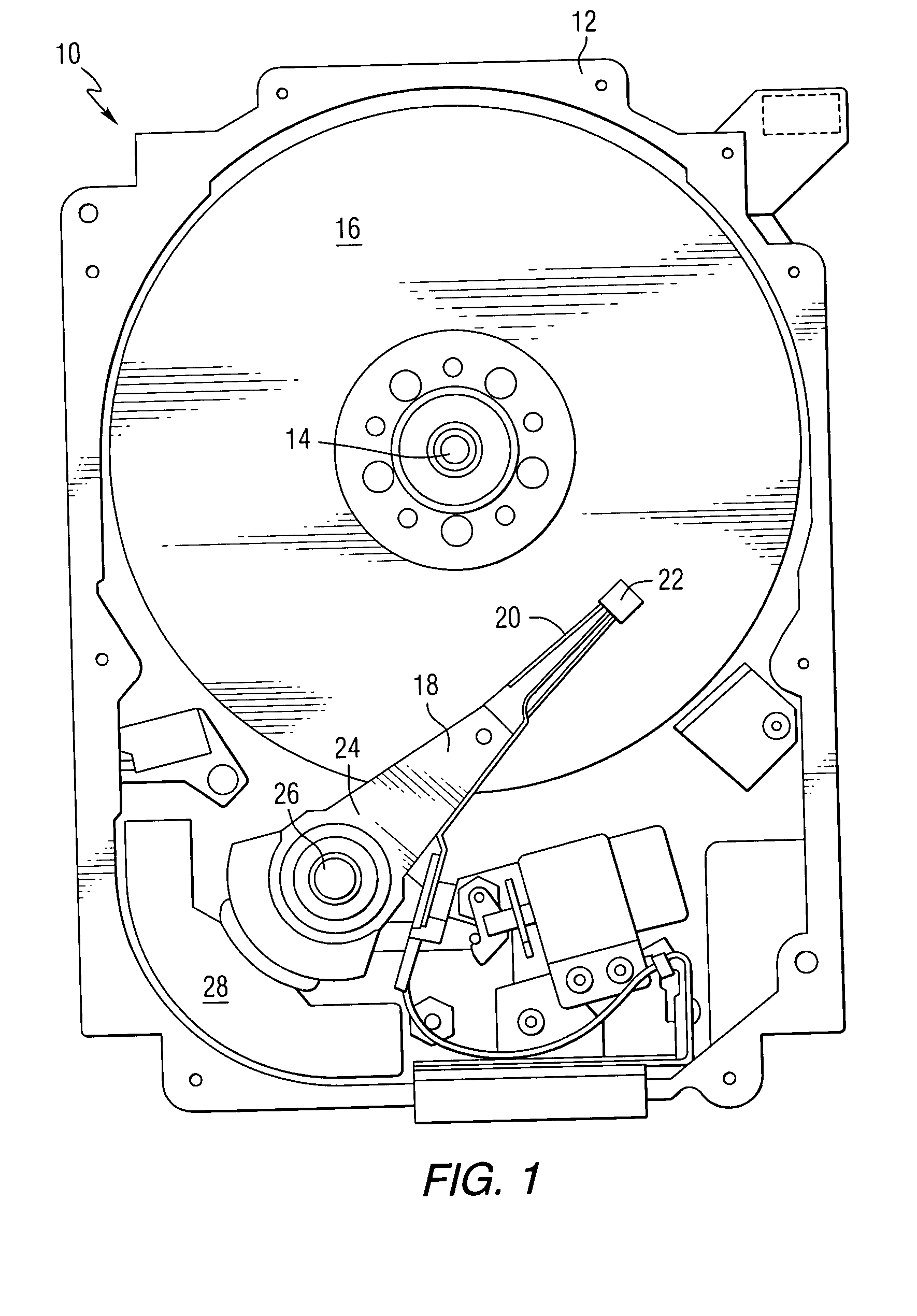

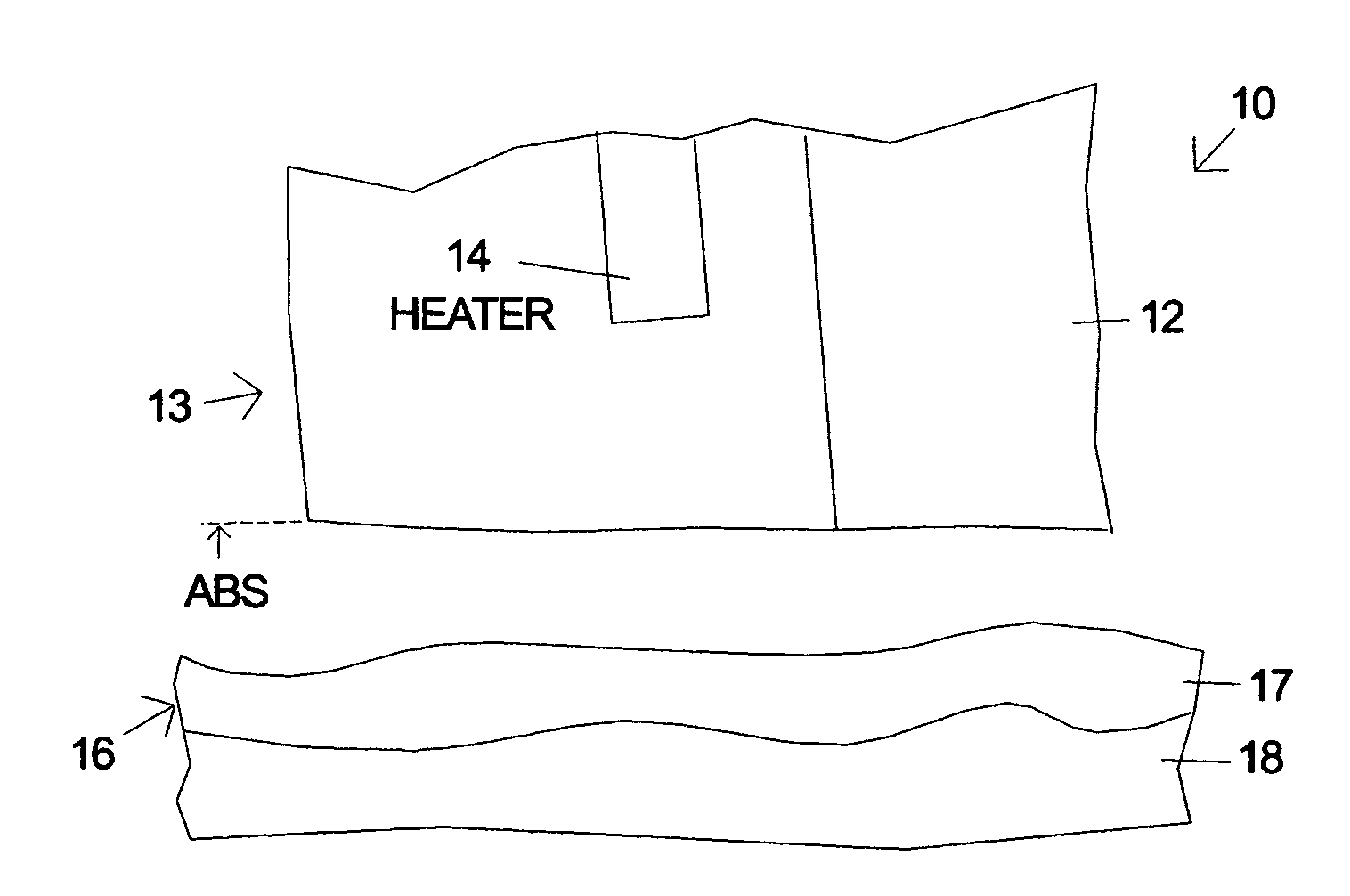

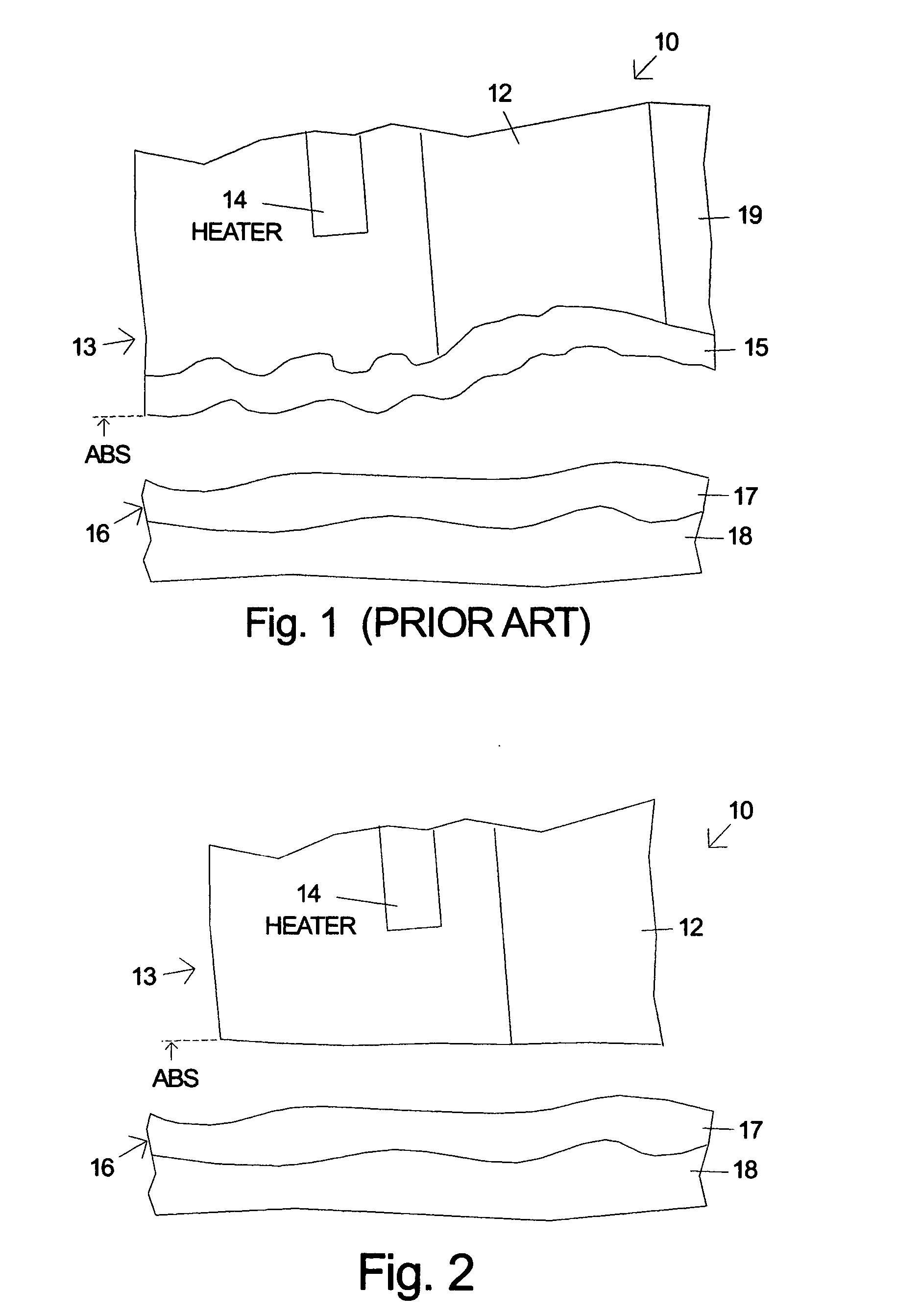

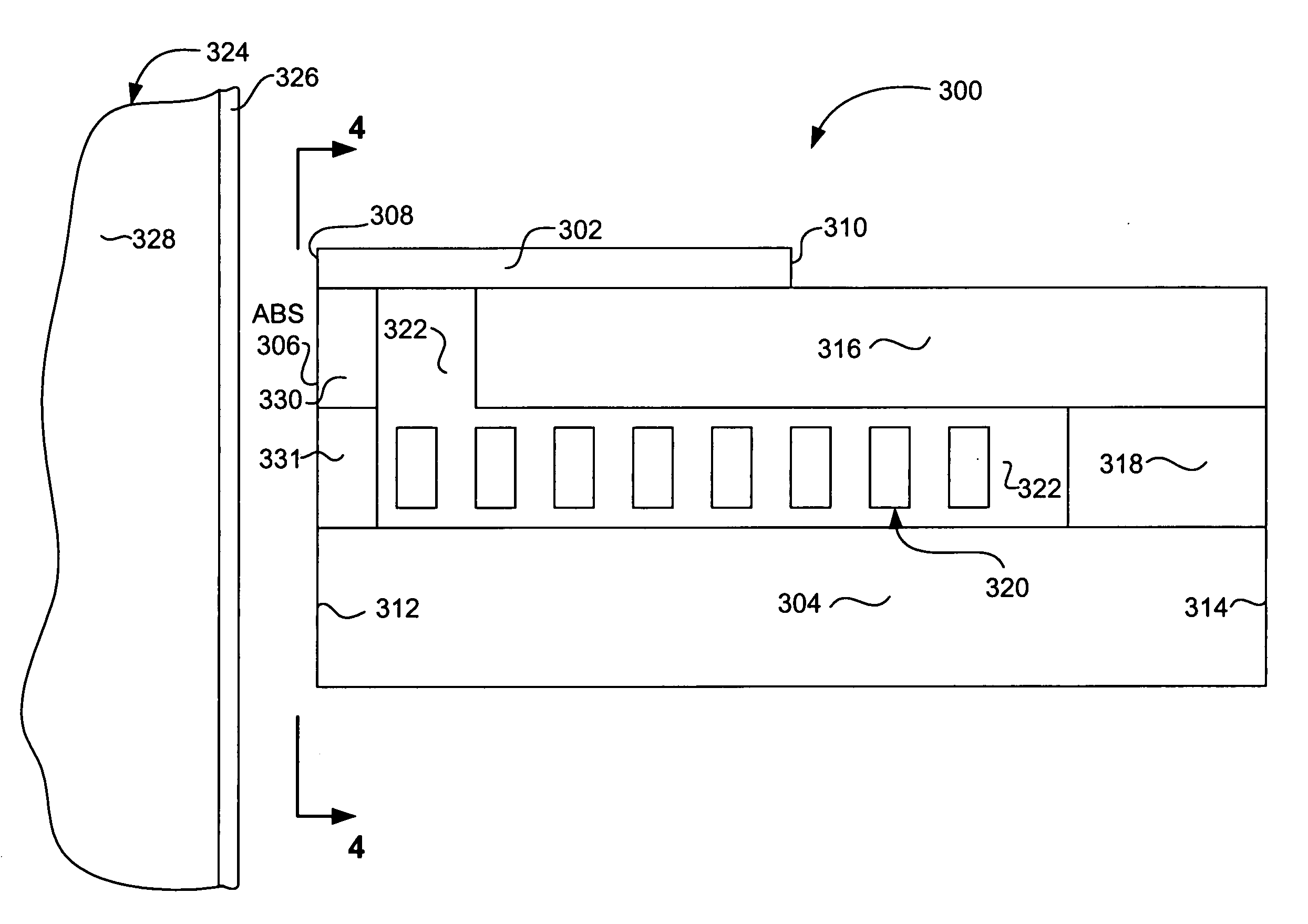

Disk drive slider design for thermal fly-height control and burnishing-on-demand

InactiveUS20060092570A1Reduced risk of corrosionAvoid corrosionElectrical transducersDriving/moving recording headsEngineeringFlying height

Owner:WESTERN DIGITAL TECH INC

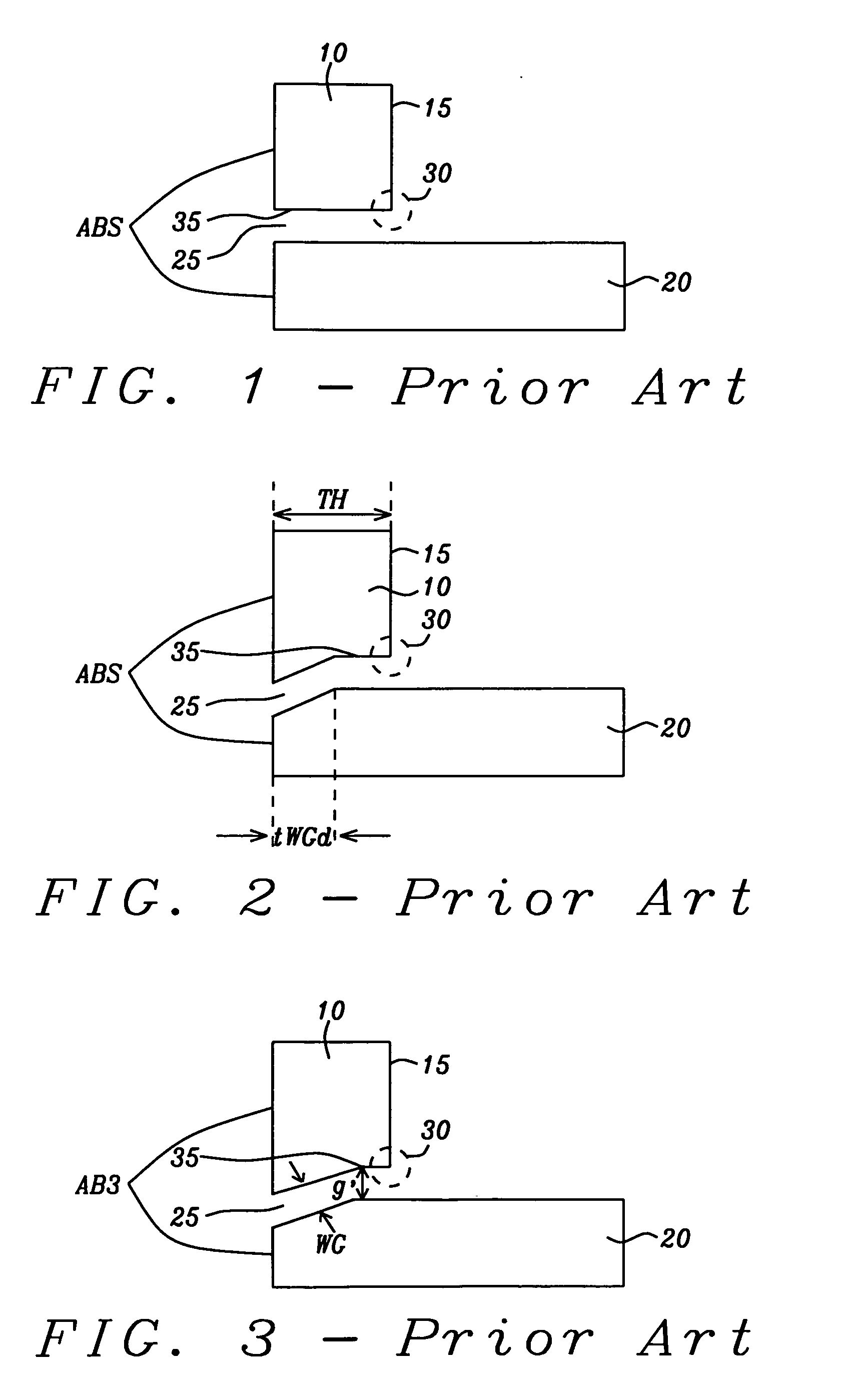

Perpendicular write head having a modified wrap-around shield to improve overwrite, adjacent track interference and magnetic core width dependence on skew angle

ActiveUS8120874B2High strengthShorten the trackManufacture head surfaceRecord information storageLeading edgeSkew angle

A magnetic write head for perpendicular magnetic data recording. The write head includes an wrap around trailing shield structure for improved write field strength, reduced skew related adjacent track interference and magnetic core width. The trailing wrap around shield includes a side shield that is separated from sides of the write pole by a side gap that is narrower near the leading edge of the write pole and wider near the trailing edge of the write pole.

Owner:WESTERN DIGITAL TECH INC

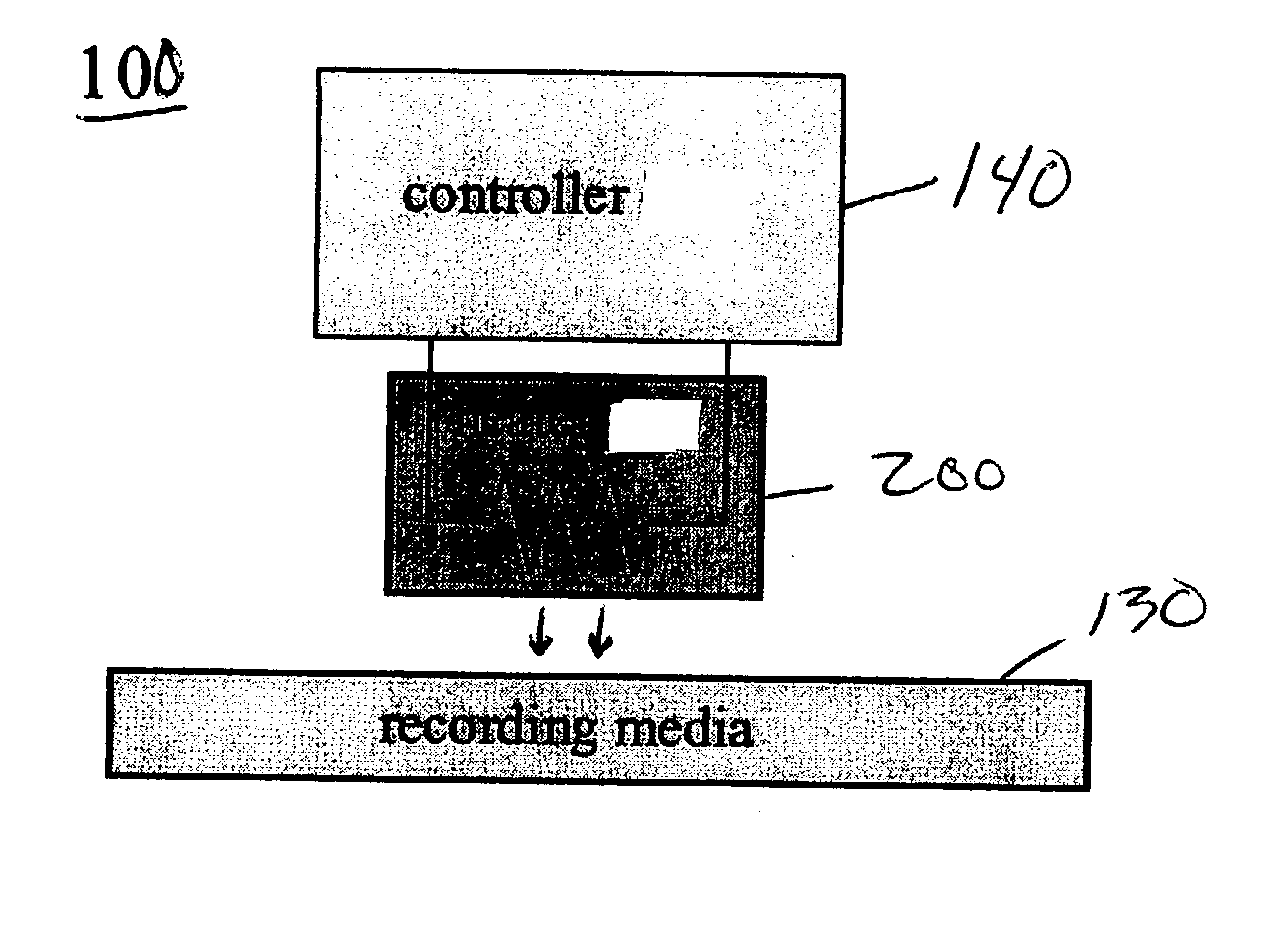

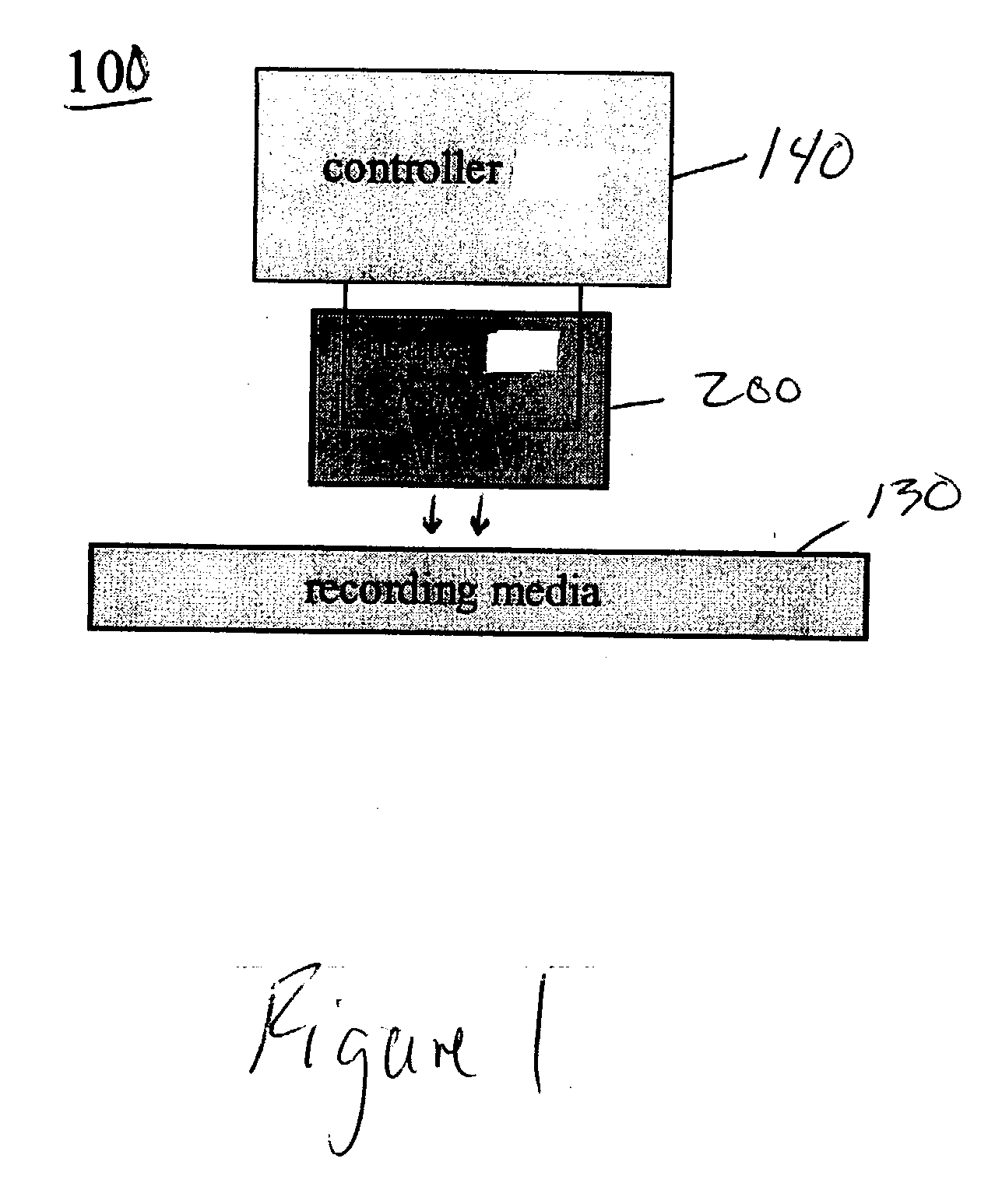

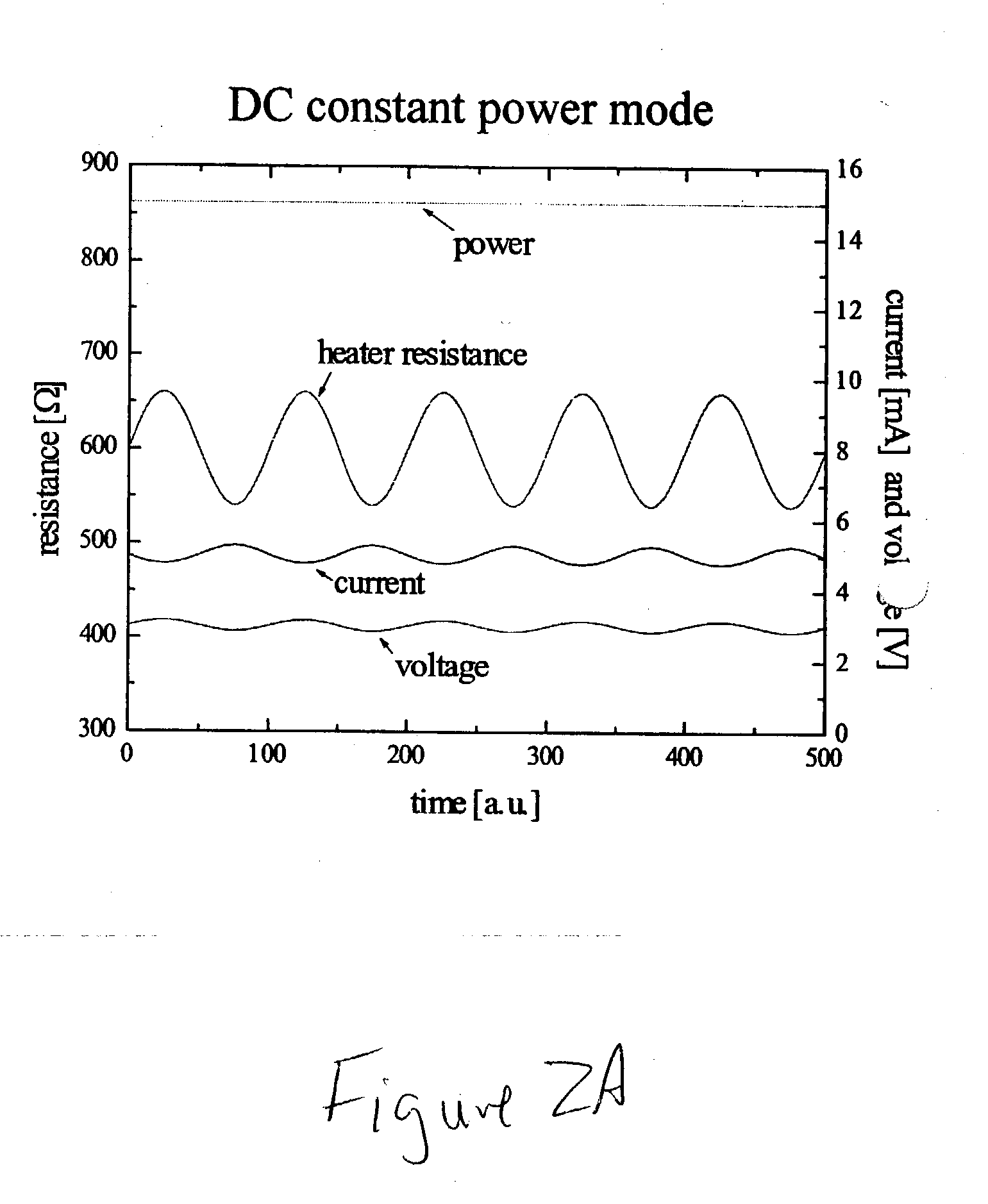

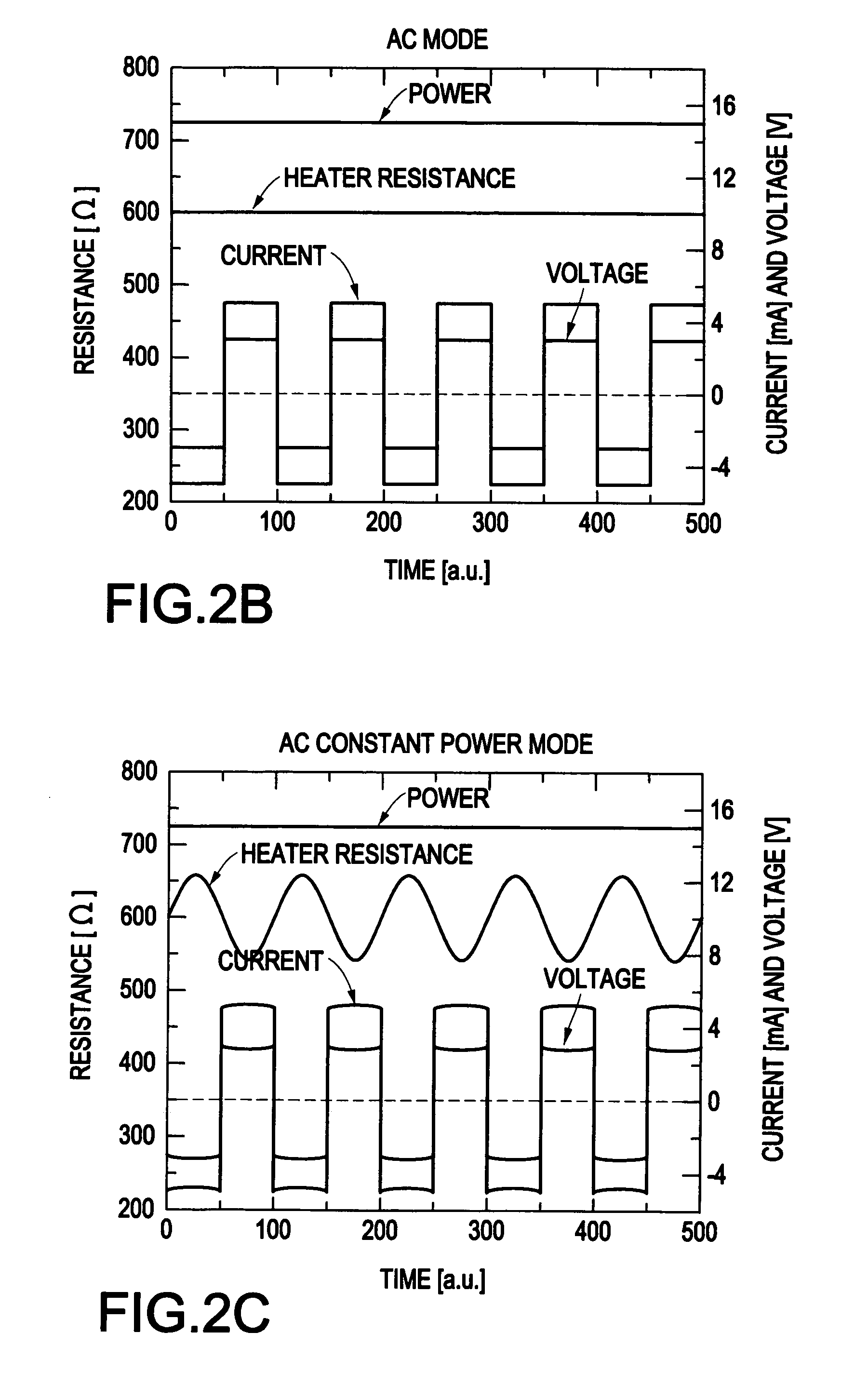

Assembly for thermal and/or thermally-assisted information processing

InactiveUS20040190175A1Manufacture head surfaceRecord information storageInformation processingElectrical polarity

An information processing assembly includes at least one heater suitable for information processing, and a controller for controlling the at least one heater by at least one of adjusting a power to the at least one heater to match a target power level, and changing a polarity of an electrical current supplied to the heater.

Owner:WESTERN DIGITAL TECH INC

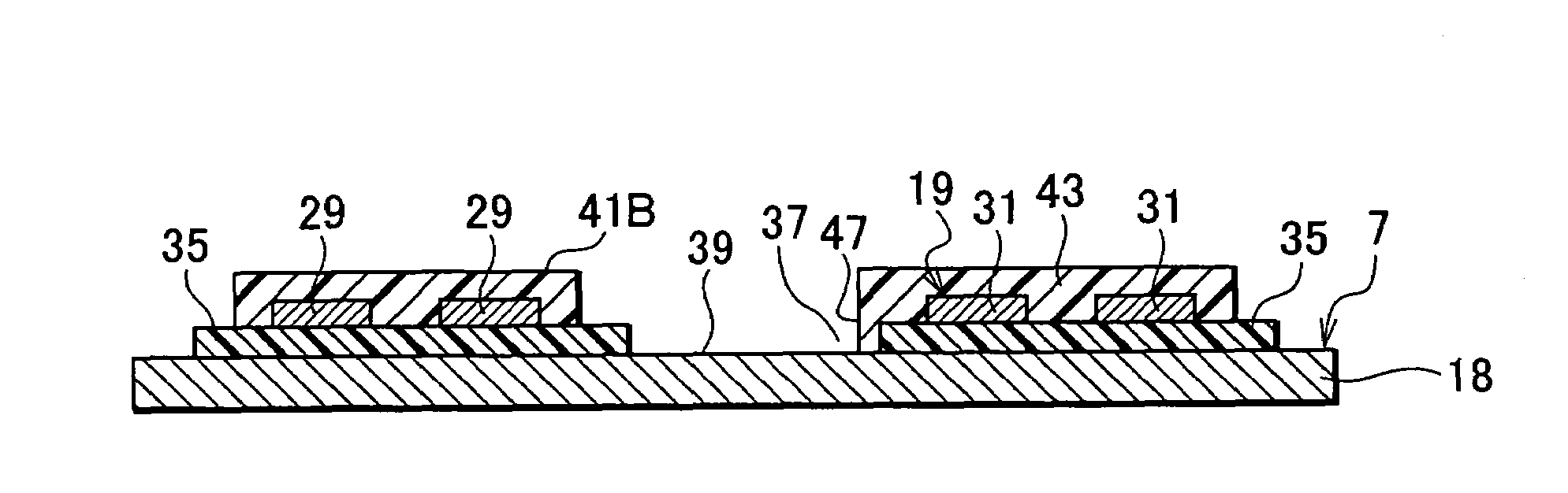

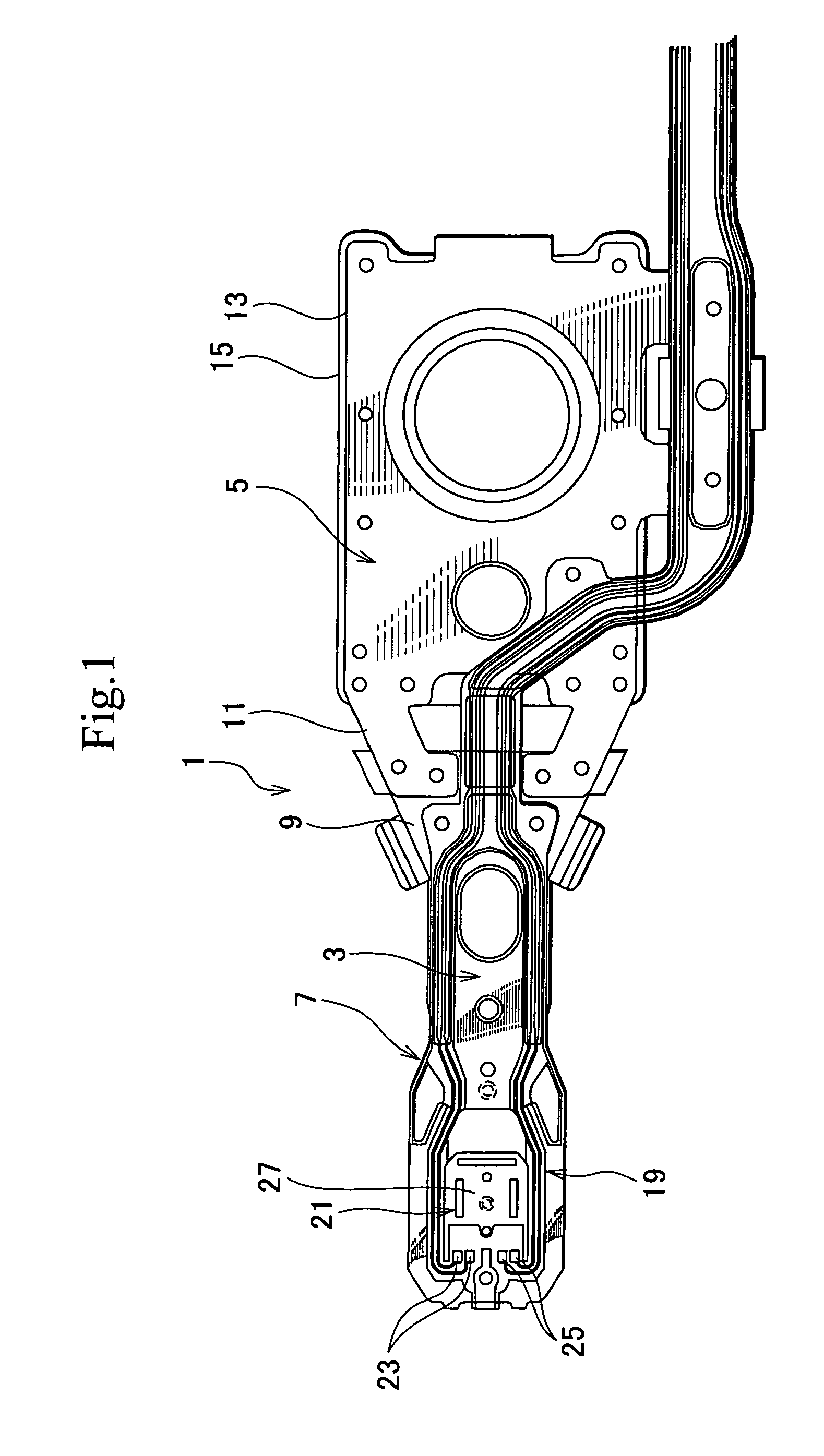

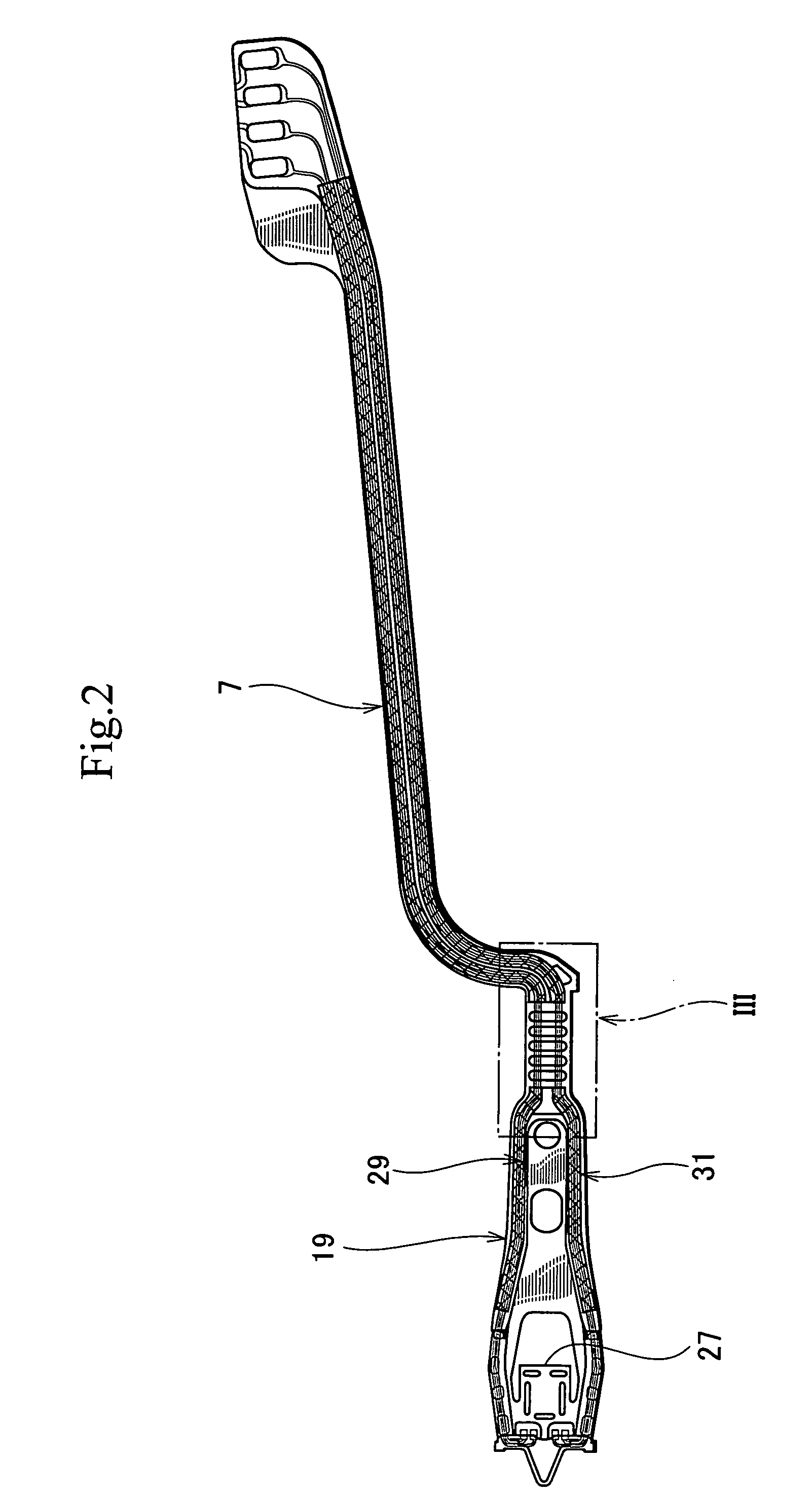

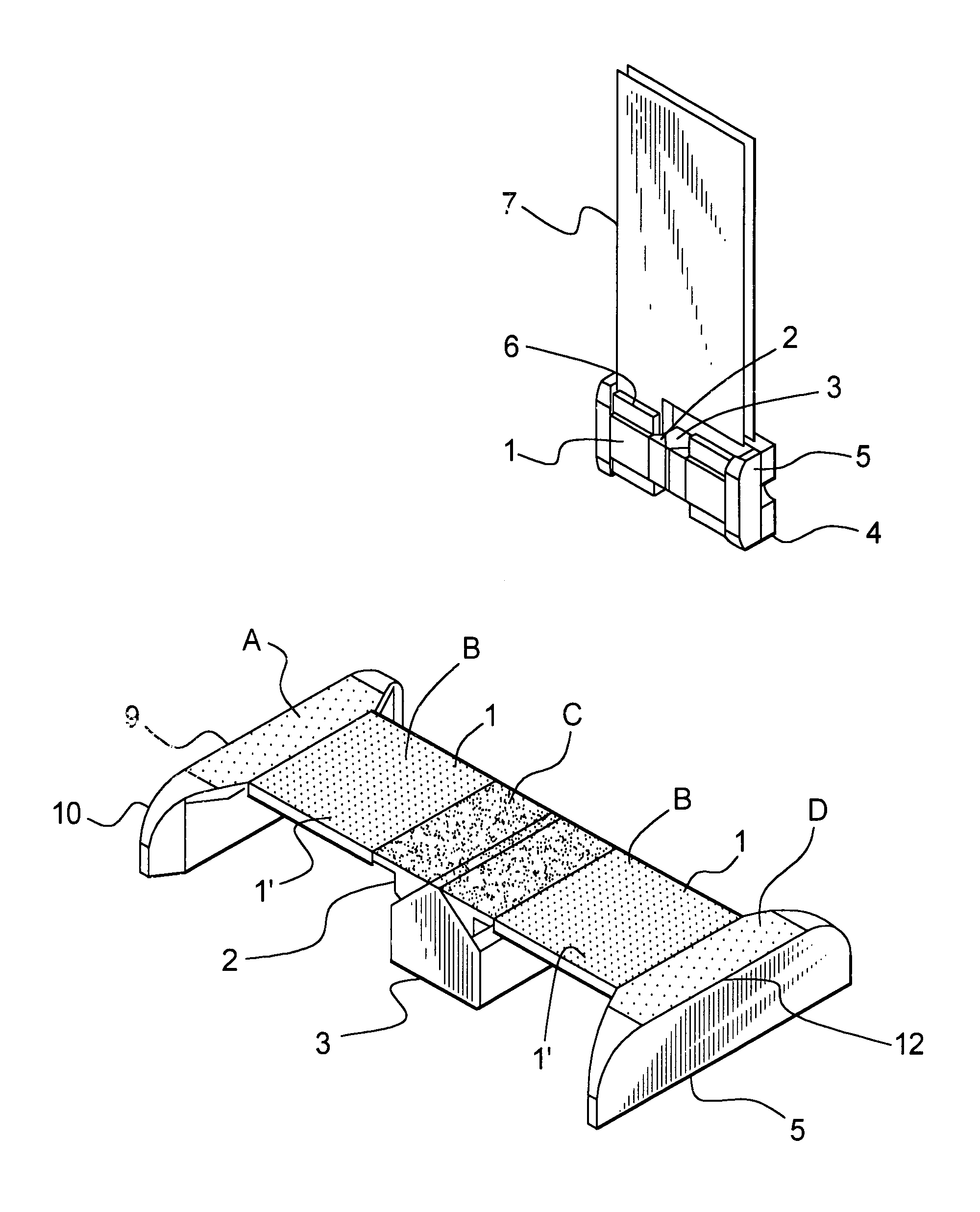

Head suspension having wiring disposed in contact with slightly conductive flexible resin

ActiveUS7692899B2Avoid damageAvoid destructionElectrical connection between head and armHigh voltage circuit adaptationsEngineeringElectrostatic discharge

A head suspension prevents a read element from electrostatic discharge damage without employing a static electricity remover or without increasing the number of manufacturing processes. The head suspension has a load beam to apply load to a head that writes and reads data to and from a hard disk, a flexure made of a conductive thin substrate attached to the load beam and supporting the head, an insulating base layer made of flexible resin and formed on the substrate of the flexure, write wires and read wires connected to the head and formed on the insulating base layer, and an insulating cover layer covering the write and read wires on the insulating base layer. The insulating cover layer is made of slightly conductive flexible resin.

Owner:NHK SPRING CO LTD

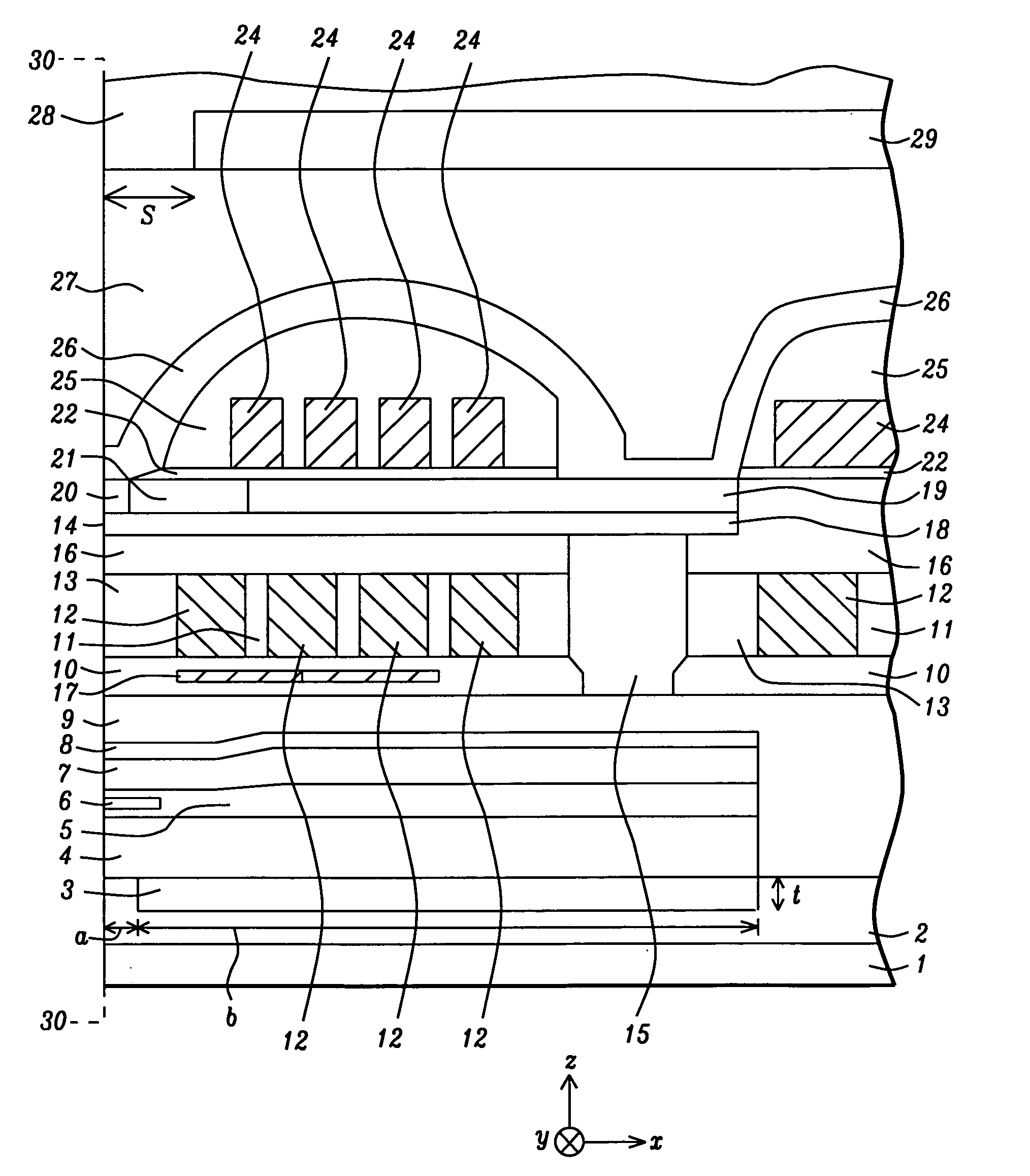

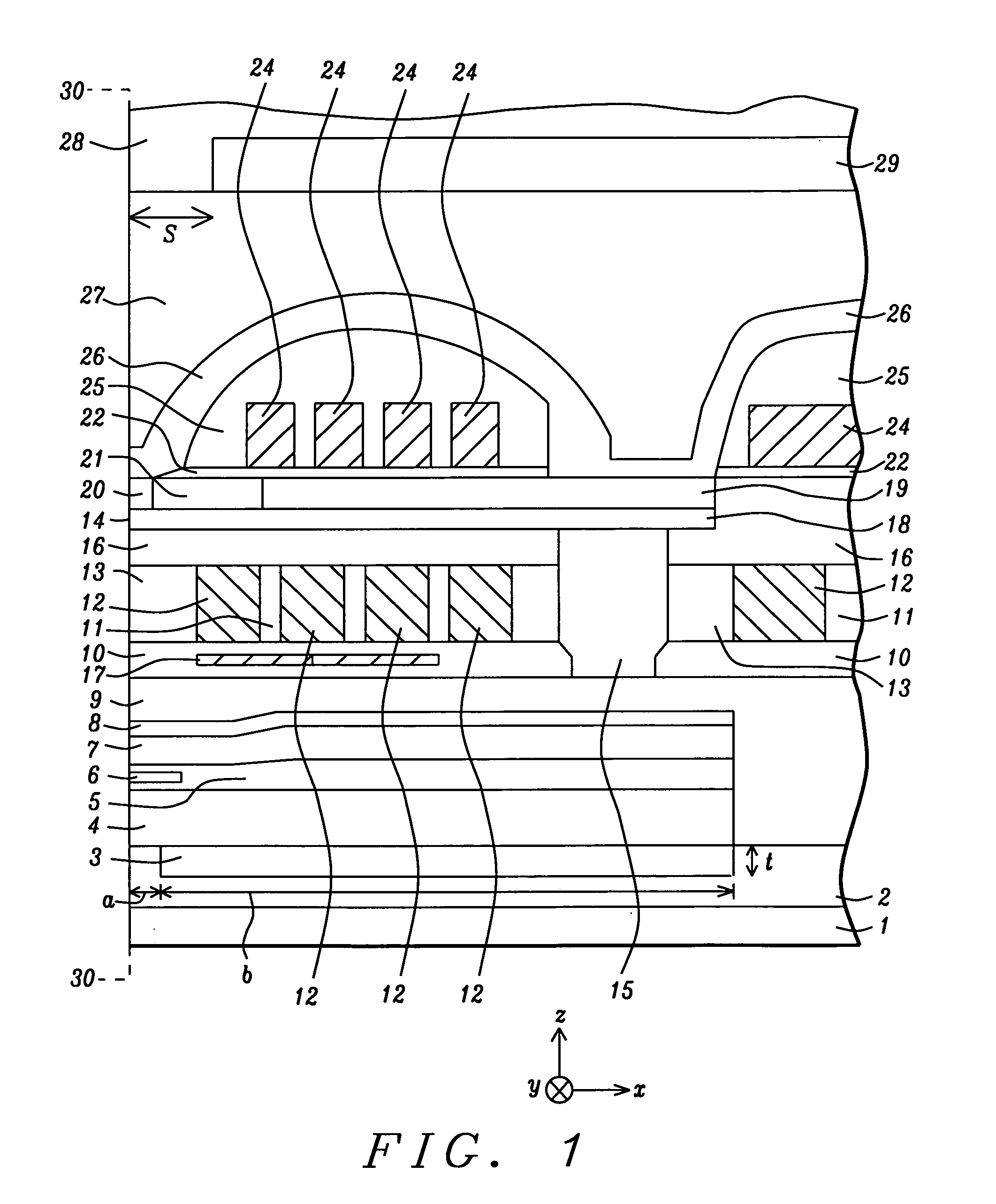

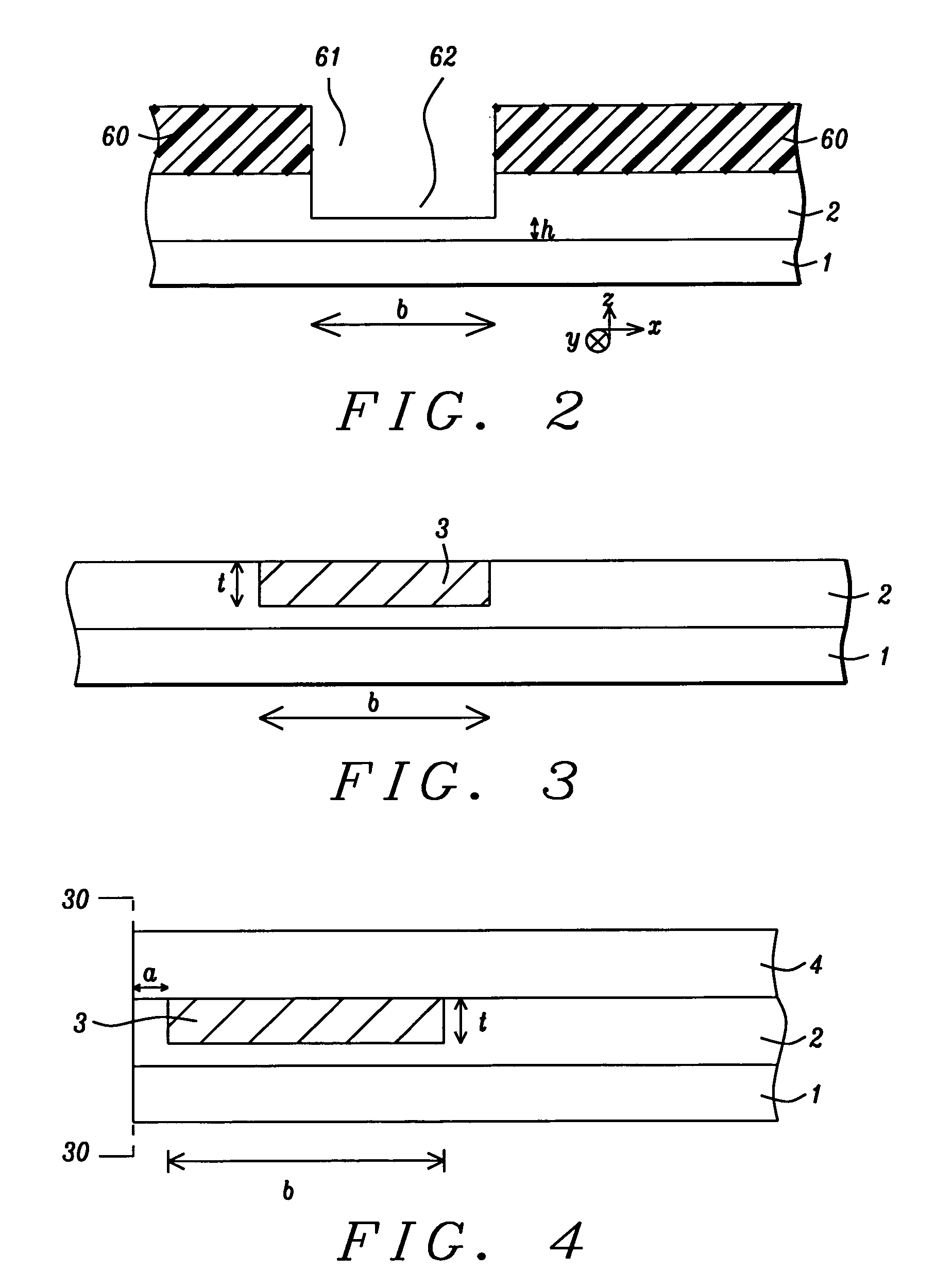

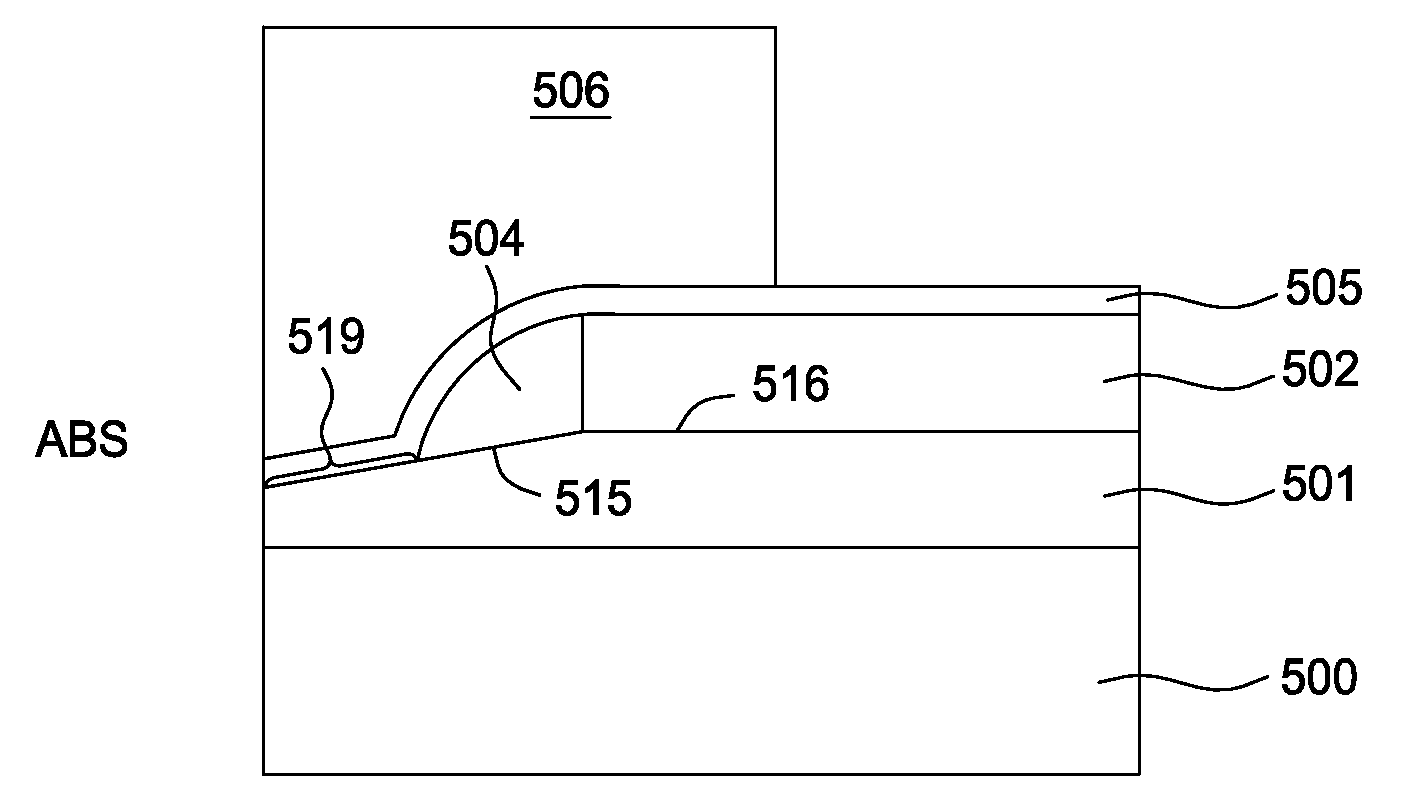

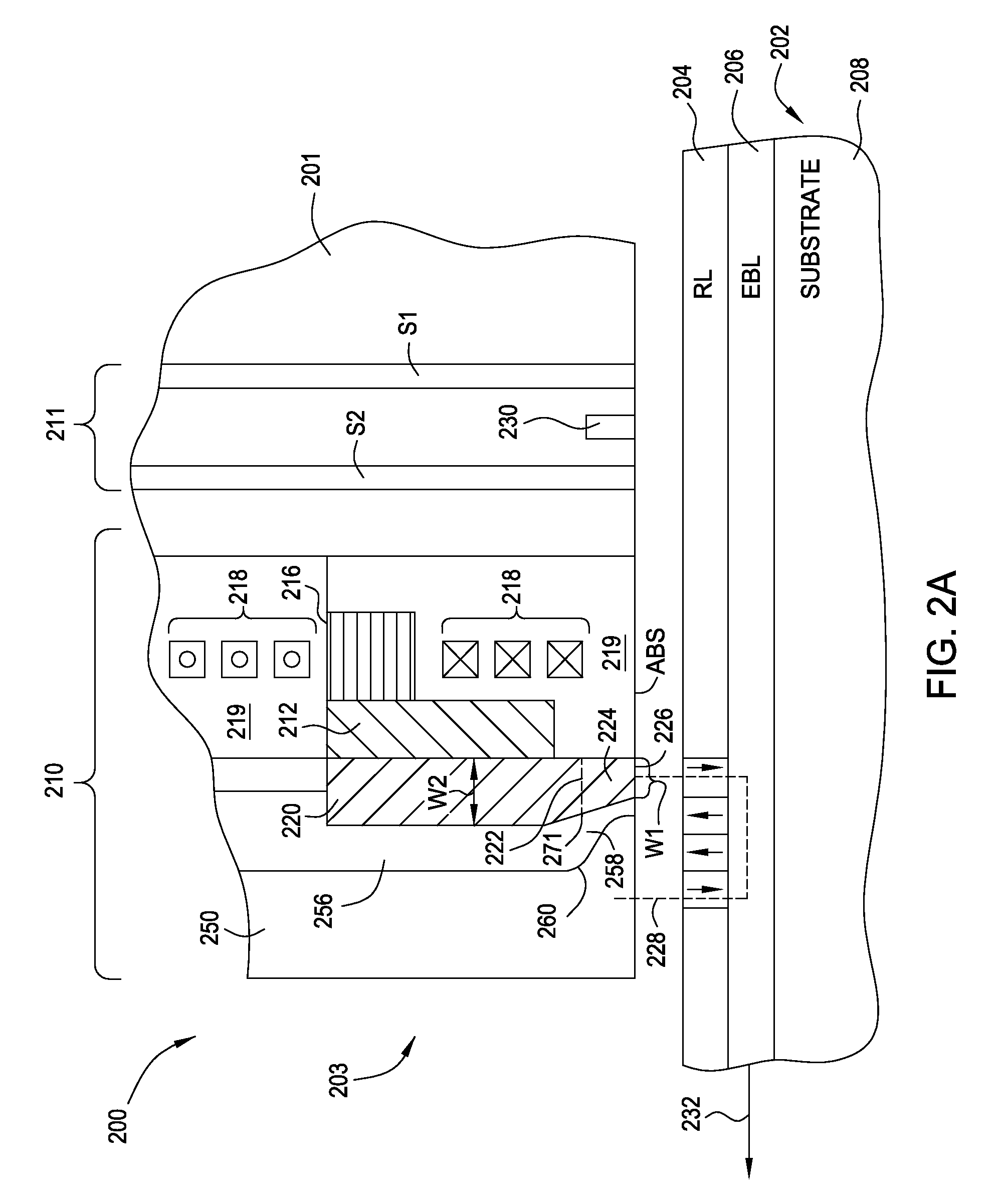

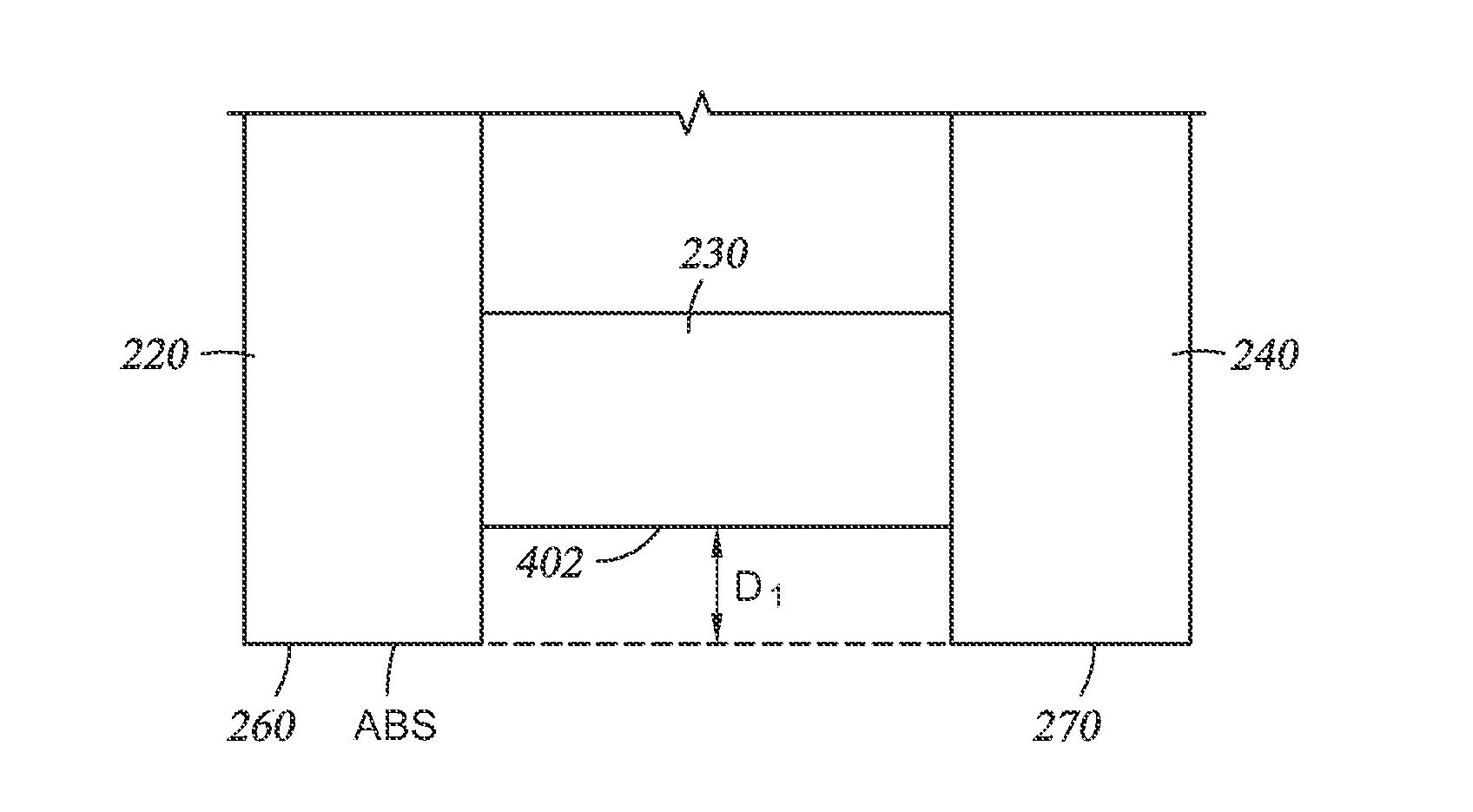

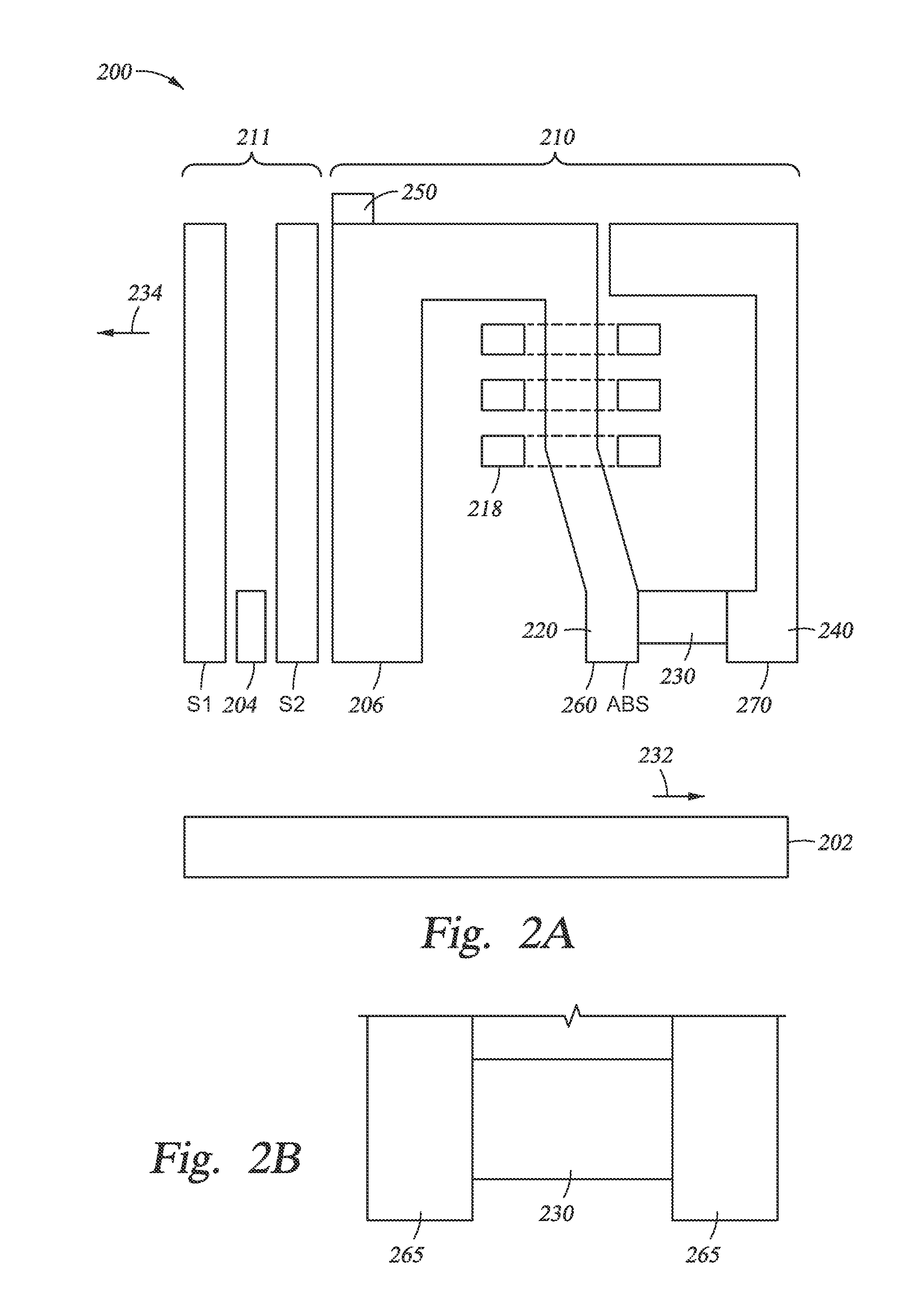

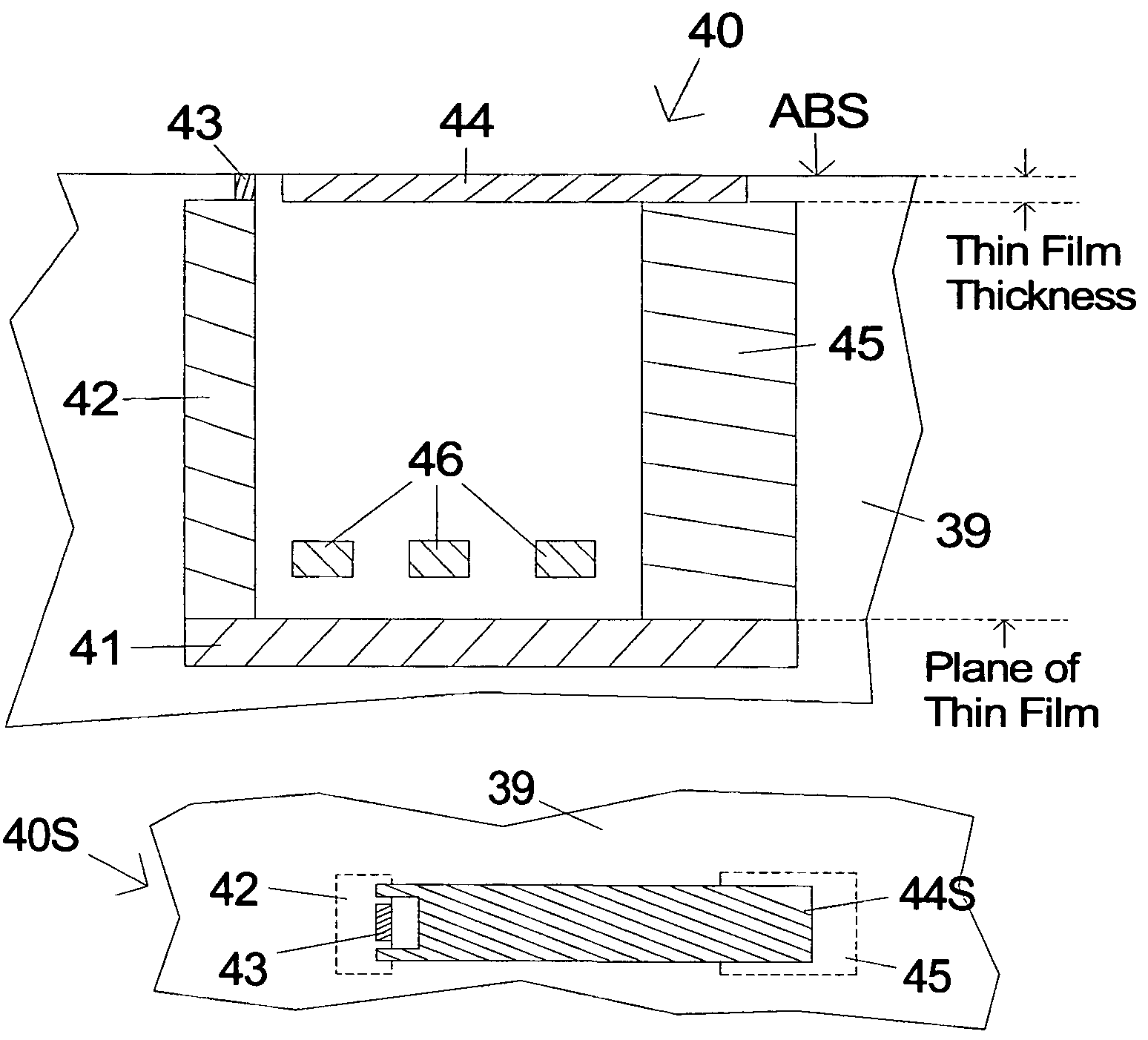

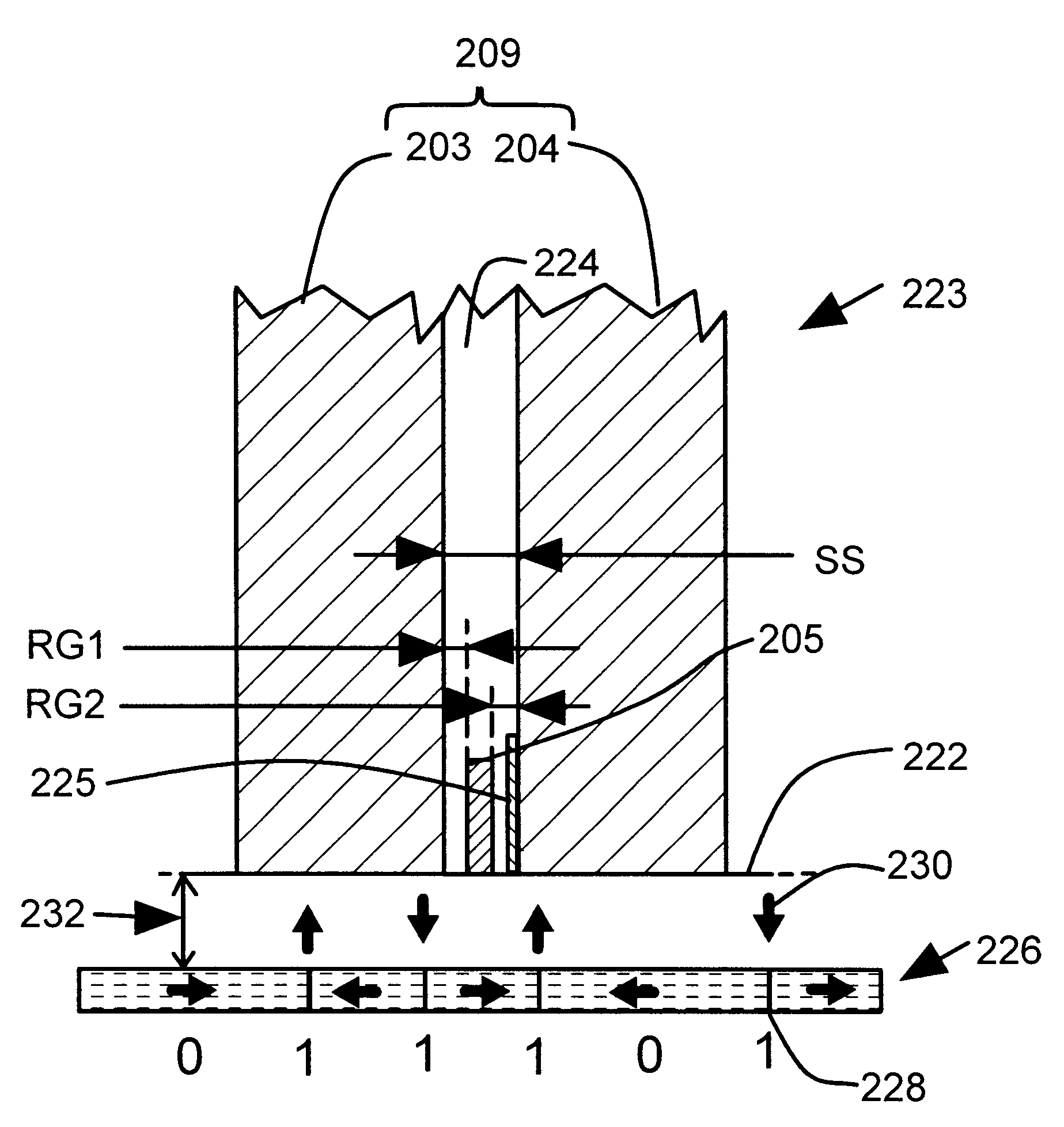

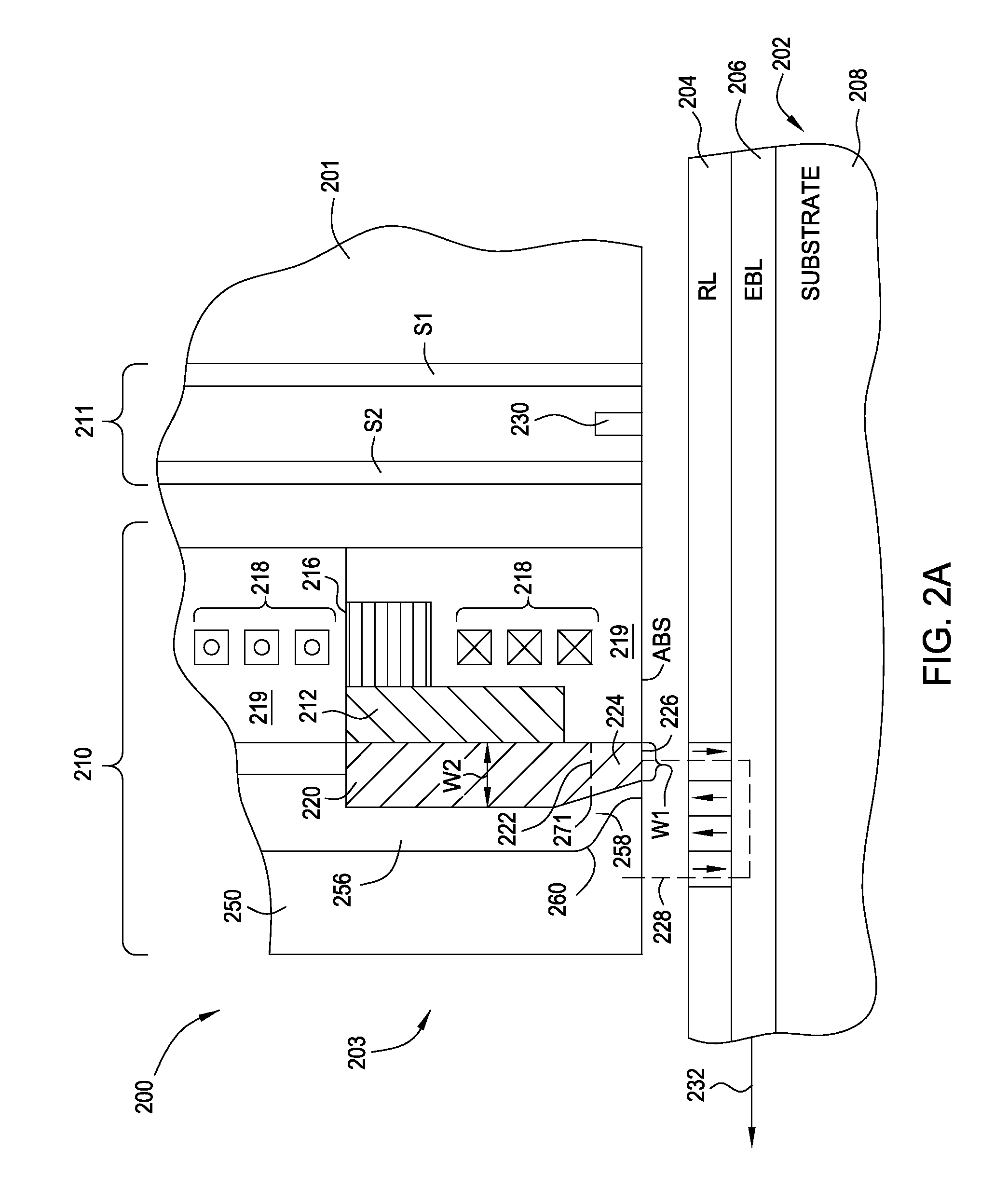

Insertion under read shield for improved read gap actuation in dynamic flying height

ActiveUS20100309581A1Efficient read gap (RG) actuationAvoid having adverse magnetic effectConstruction of head windingsRecord information storageEngineeringFlying height

A read / write head is disclosed wherein a non-magnetic layer made of a metal is inserted in the read head on a side opposite to the S1 shield with respect to the sensor. The non-magnetic layer is preferably Cu and is recessed from the ABS to prevent corrosion. A preferred design has a 1 to 5 micron thick non-magnetic insertion layer that extends a distance of 3 to 100 microns along a plane that is perpendicular to the ABS. RG efficiency is enhanced significantly and RG gamma ratio is improved to 1.0 so that a smaller difference in RG, WG, and min-fly point can be achieved at touchdown detection and in normal read / write operations. These results lead to an optimal dynamic performance for a given spacing target and enhanced read gap protrusion at a given heater power. S1 / S2A thickness can be independently optimized for magnetic performance consideration only.

Owner:HEADWAY TECH INC

Diffraction grating

ActiveUS20050135008A1Record information storageRecording/reproducing/erasing methodsWaveguideDiffraction grating

Diffraction gratings for coupling an electromagnetic wave into a planar waveguide are disclosed. The diffraction grating may include a first diffraction grating and a second diffraction grating slanted relative to one another. Alternatively, the diffraction grating may include a first diffraction grating and a second diffraction grating spaced apart to form a gap therebetween.

Owner:SEAGATE TECH LLC

Magnetic head for perpendicular magnetic recording with shield around main pole

ActiveUS8493687B2Function increaseReduce distanceConstruction of head windingsRecord information storageCouplingEngineering

A magnetic head includes a shield, and first and second return path sections. The shield has an end face that is located in a medium facing surface to wrap around an end face of a main pole. The shield includes a bottom shield, two side shields, and a top shield. The first return path section includes a yoke layer, and first and second coupling layers that magnetically couple the bottom shield and the yoke layer to each other. The first coupling layer is magnetically connected to the bottom shield. The second coupling layer magnetically couples the first coupling layer to the yoke layer. No end faces of the second coupling layer are exposed in the medium facing surface. The second return path section magnetically couples the top shield and the main pole to each other.

Owner:HEADWAY TECH INC +1

Apparatus including modified write pole tip

An apparatus that includes a write element including a write element tip having a leading edge, a trailing edge, and first and second side edges connecting the leading edge to the trailing edge, wherein the trailing edge is non-planar; a trailing shield proximate the trailing edge of the write element; a first side shield proximate the first side edge; and a second edge proximate the second side edge.

Owner:SEAGATE TECH LLC

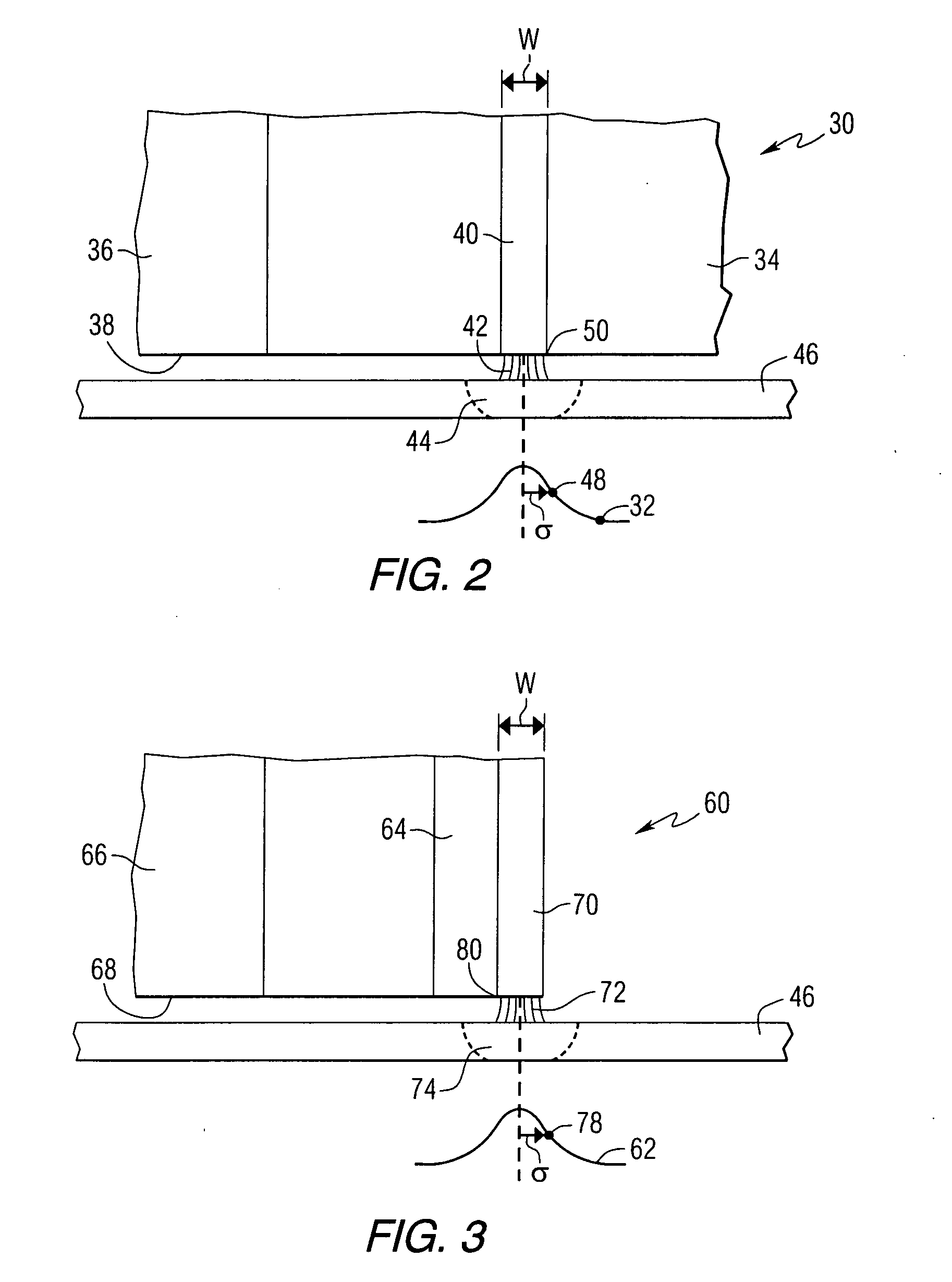

Heat assisted magnetic recording head and method

ActiveUS7155732B2Record information storageRecording/reproducing/erasing methodsHeat-assisted magnetic recordingMagnetic storage

A magnetic recording head comprises a write pole having a pole tip adjacent to an air bearing surface, a return pole, a near field transducer positioned adjacent to the air bearing surface for producing near field radiation for heating a portion of a magnetic storage medium, wherein a thermal profile of the portion of the magnetic storage medium has a maximum gradient at a location subject to a magnetic write field produced by the write pole. A disc drive that includes the magnetic recording head and a method of recording using the magnetic recording head are also provided.

Owner:SEAGATE TECH LLC

Flux shunt structure for reducing return pole corner fields in a perpendicular magnetic recording head

InactiveUS20060245108A1Improve protectionSufficient magnetic separationManufacture head surfaceHeads using thin filmsEngineeringMagnetic shield

A magnetic head for use in a perpendicular recording system having a novel shield structure that provides exceptional magnetic shielding from extraneous magnetic fields such as from a write coil, shaping layer or return pole of the write head. The magnetic head includes a write pole, a return pole and a magnetic shield that is magnetically connected with the return pole near the ABS and extends toward the write pole. The shield is formed with a notch at its edge closest to the write pole. The notch assures adequate physical, magnetic, and electrical separation between the write pole and the shield, while allowing un-notched portions of the shield to provide additional magnetic shielding.

Owner:WESTERN DIGITAL TECH INC

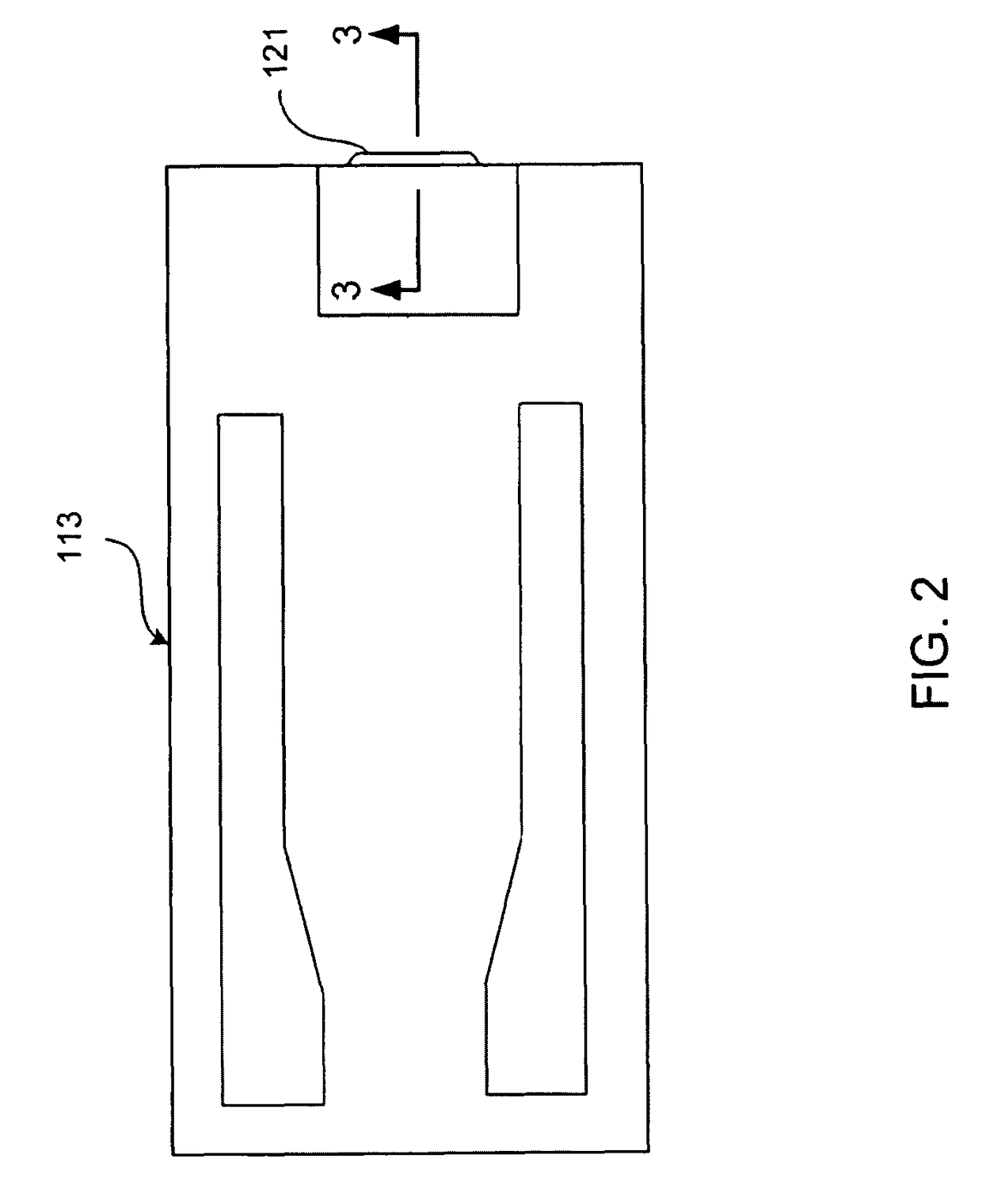

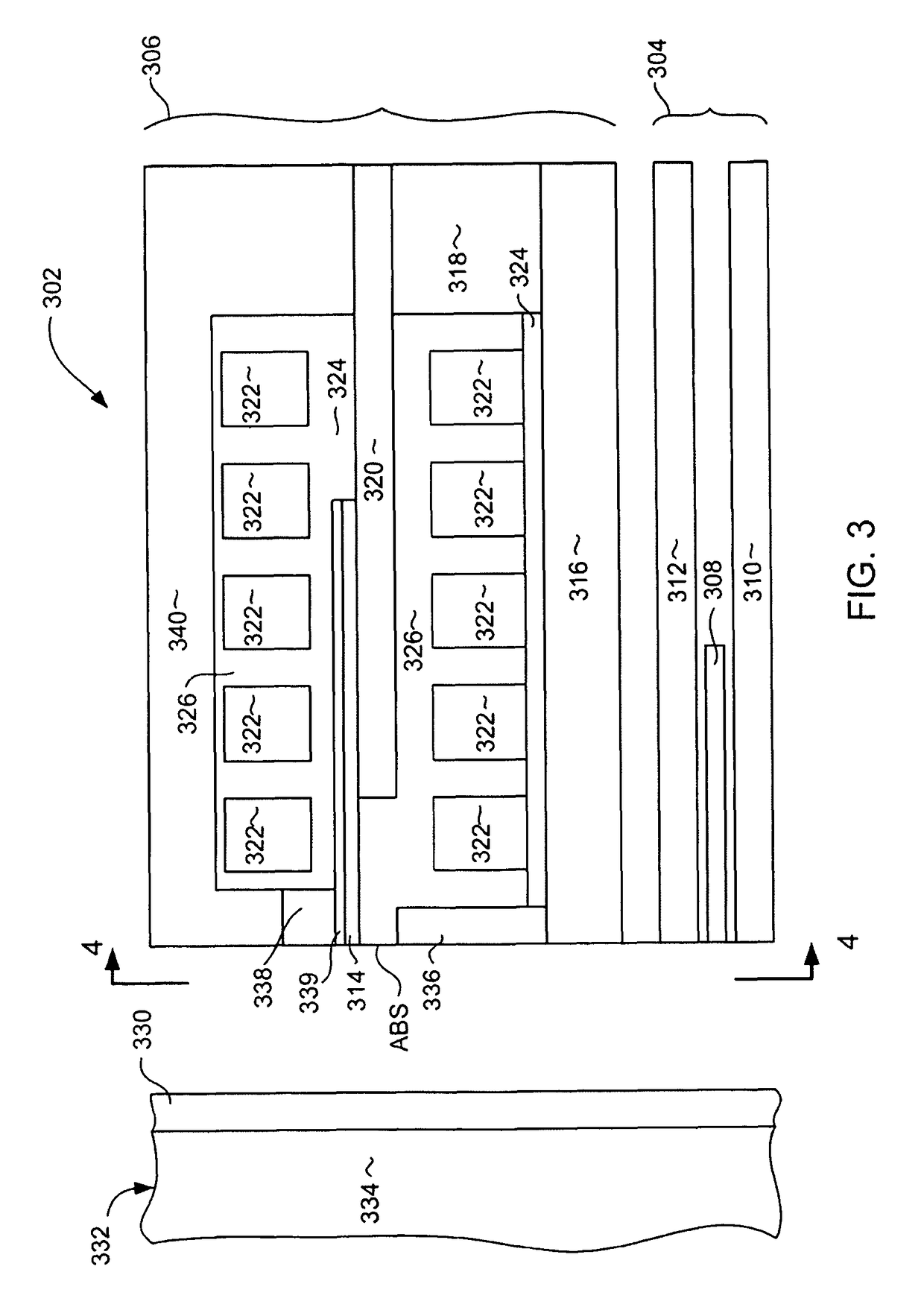

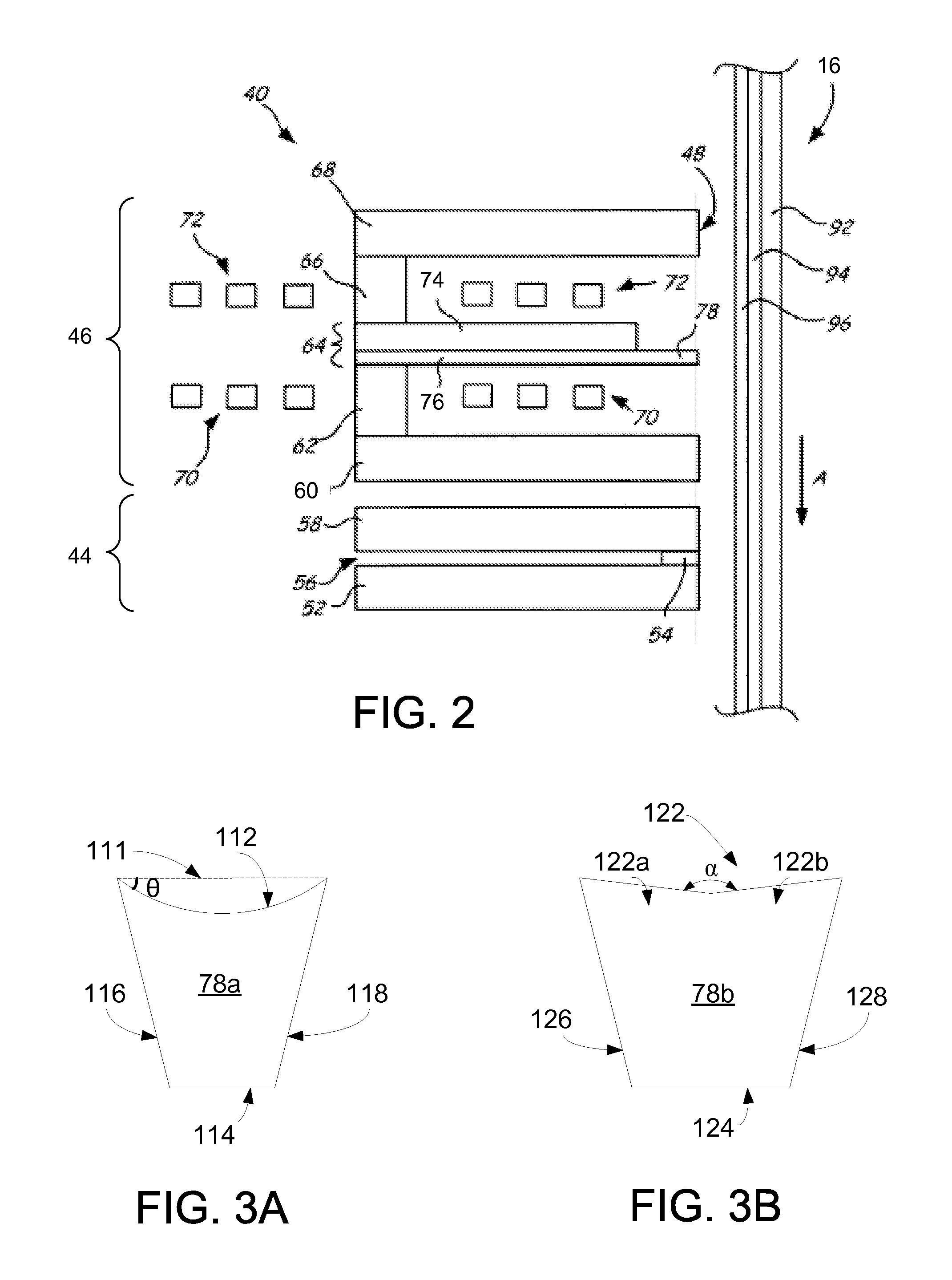

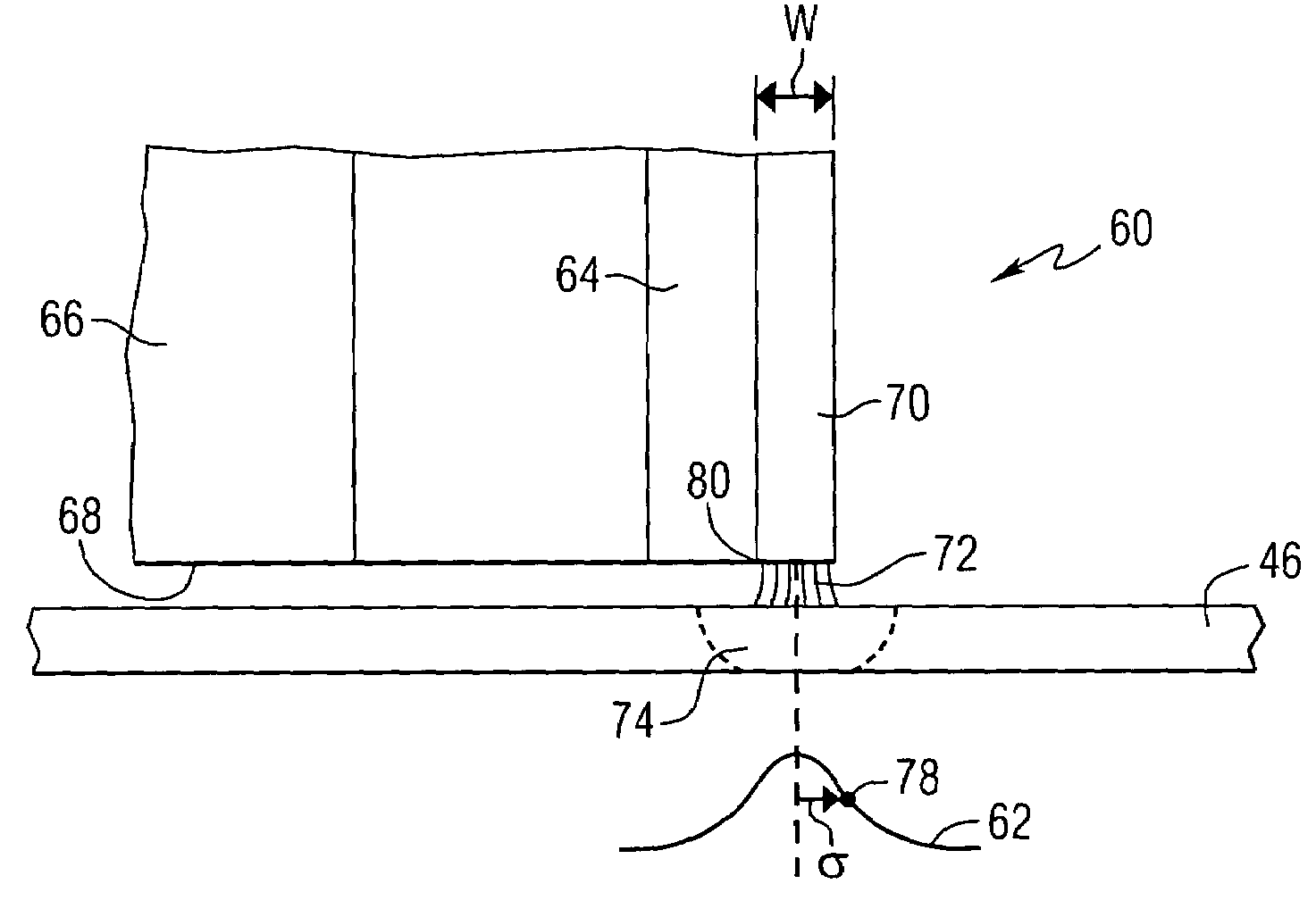

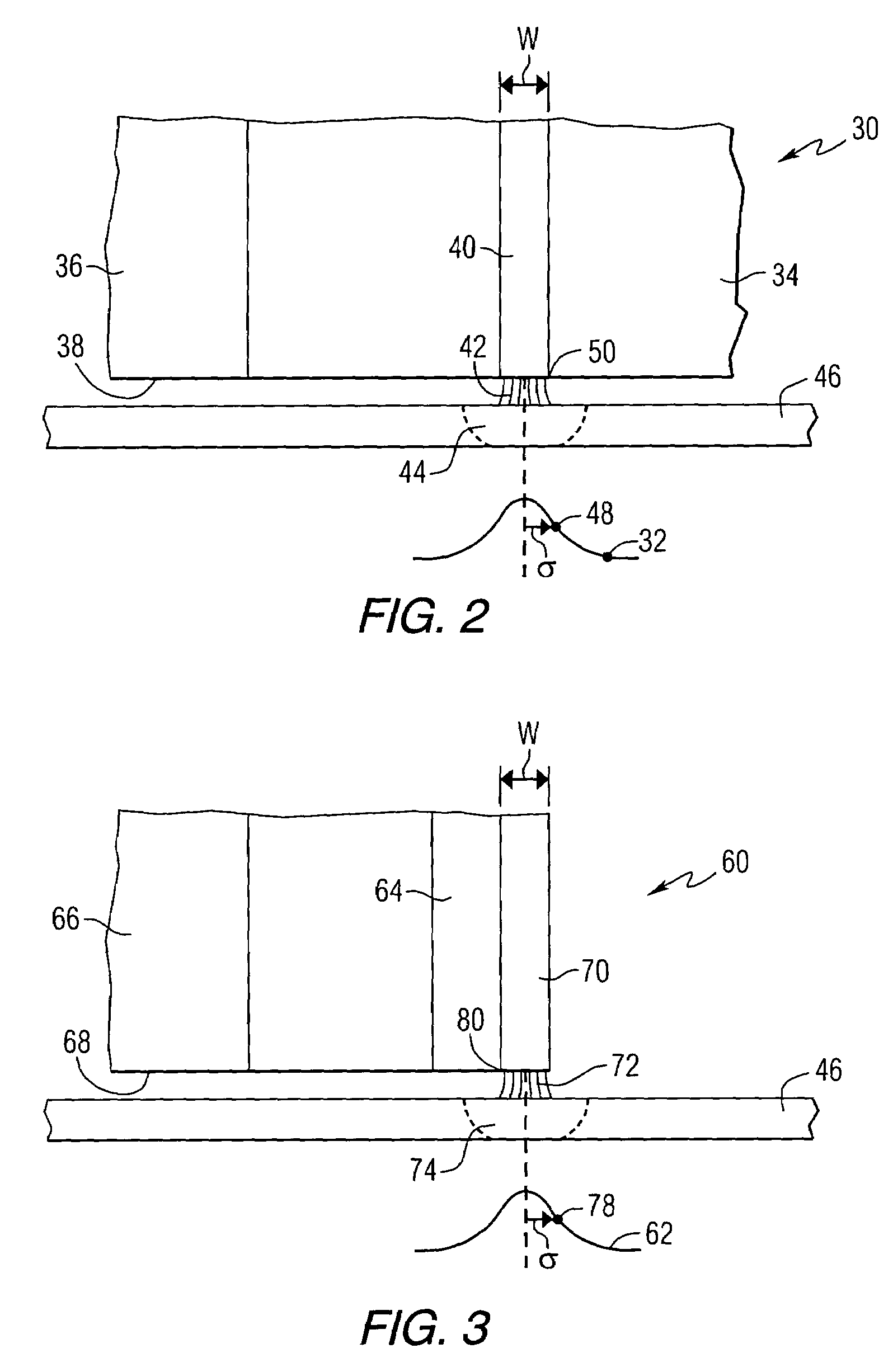

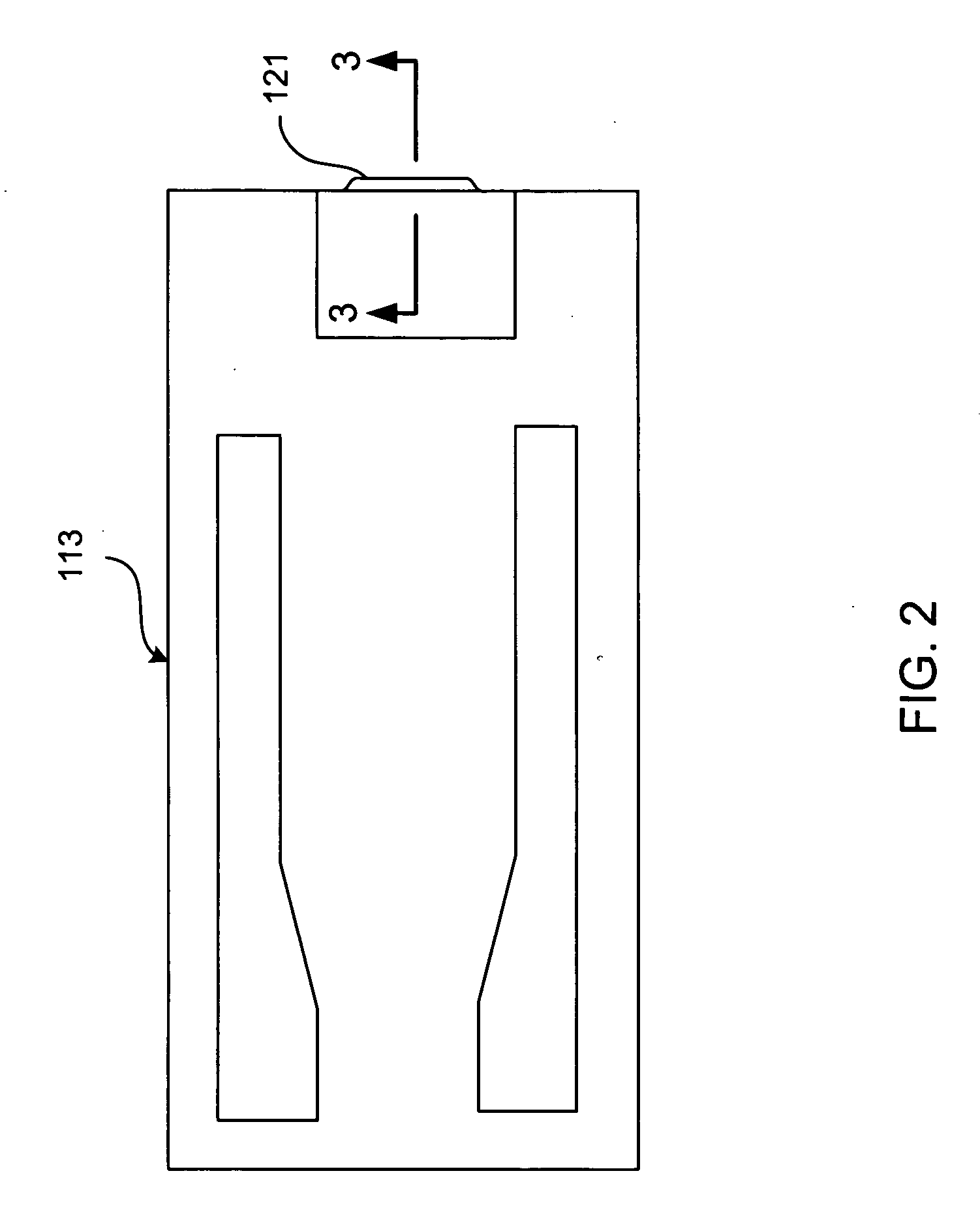

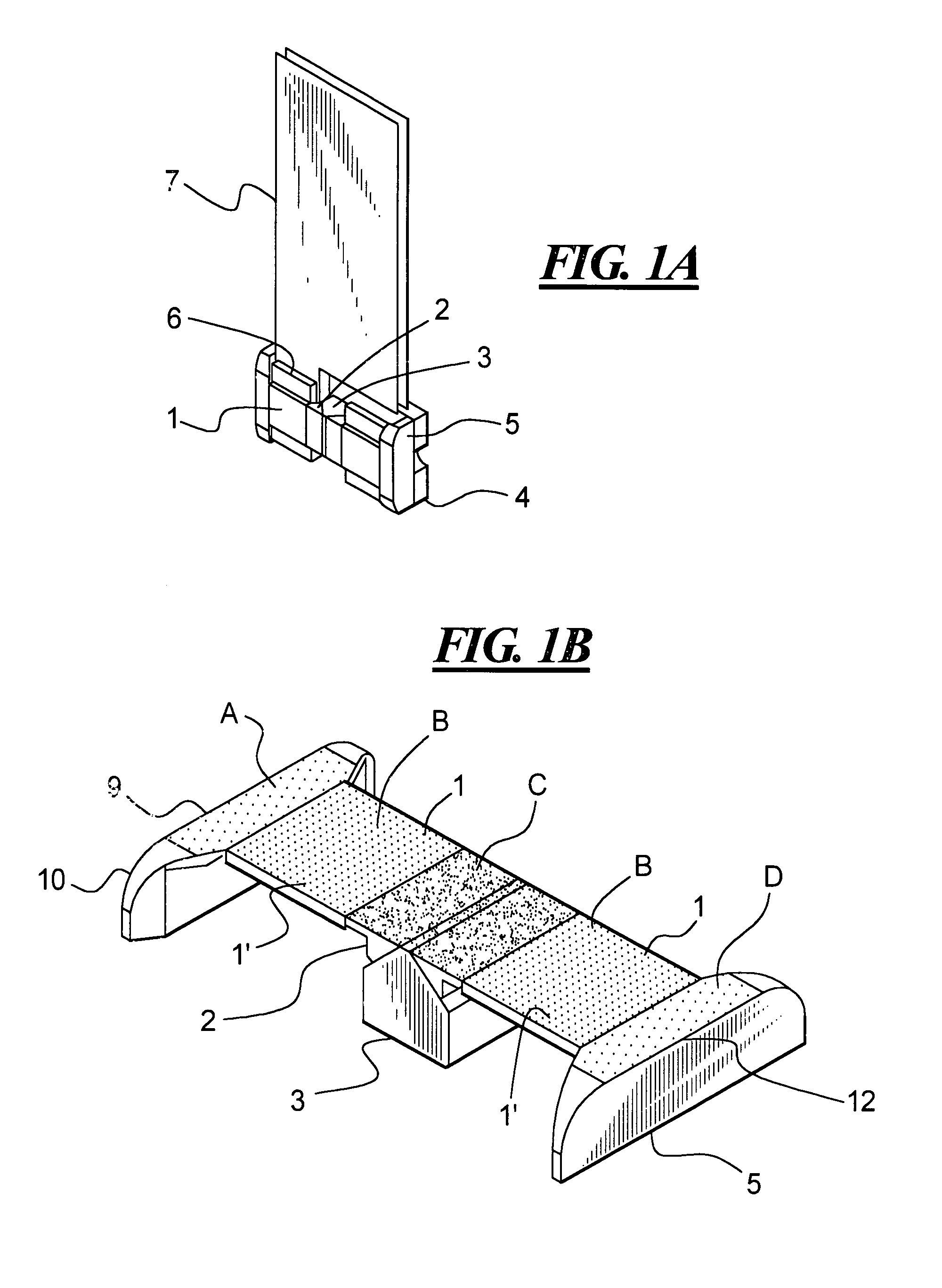

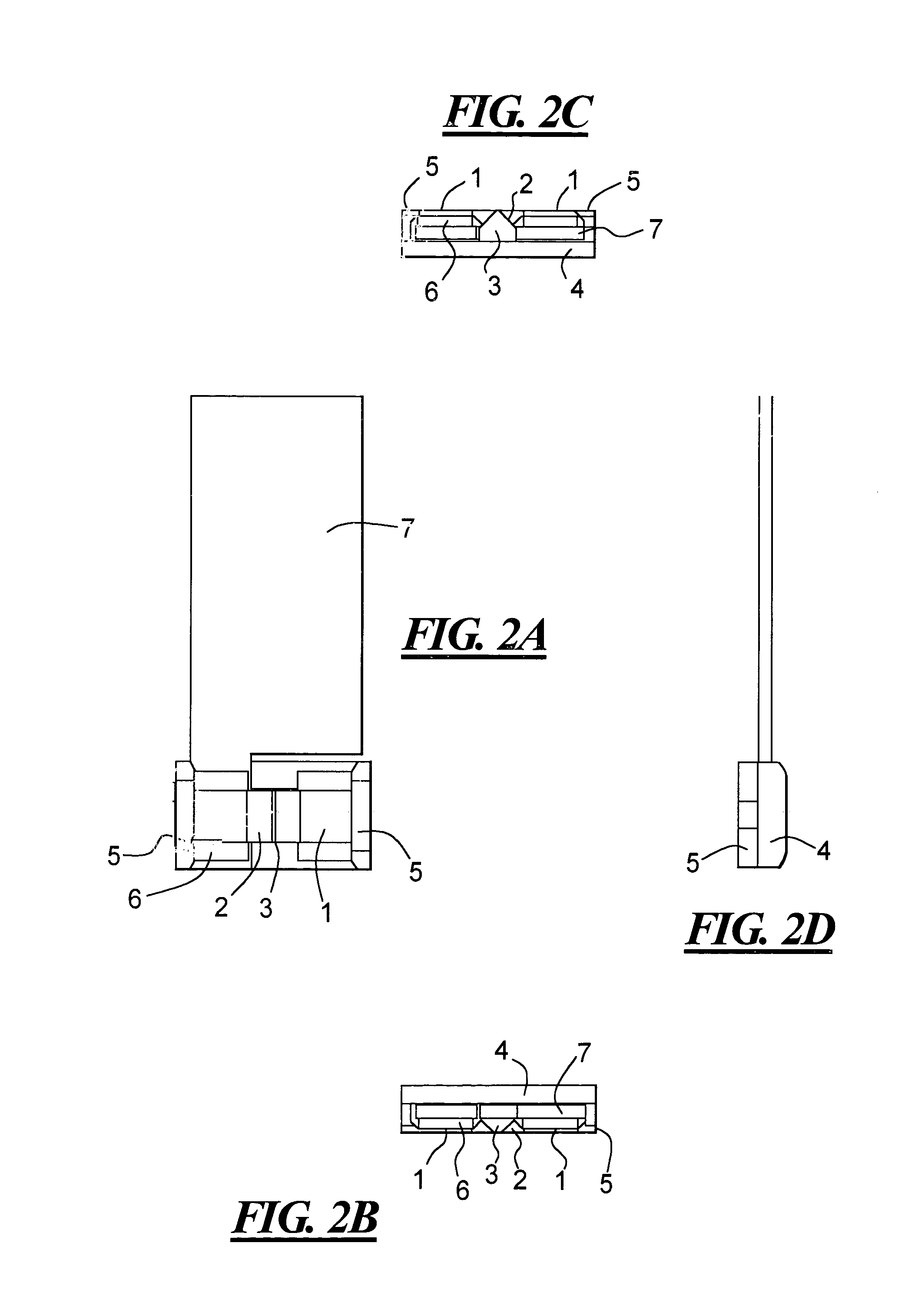

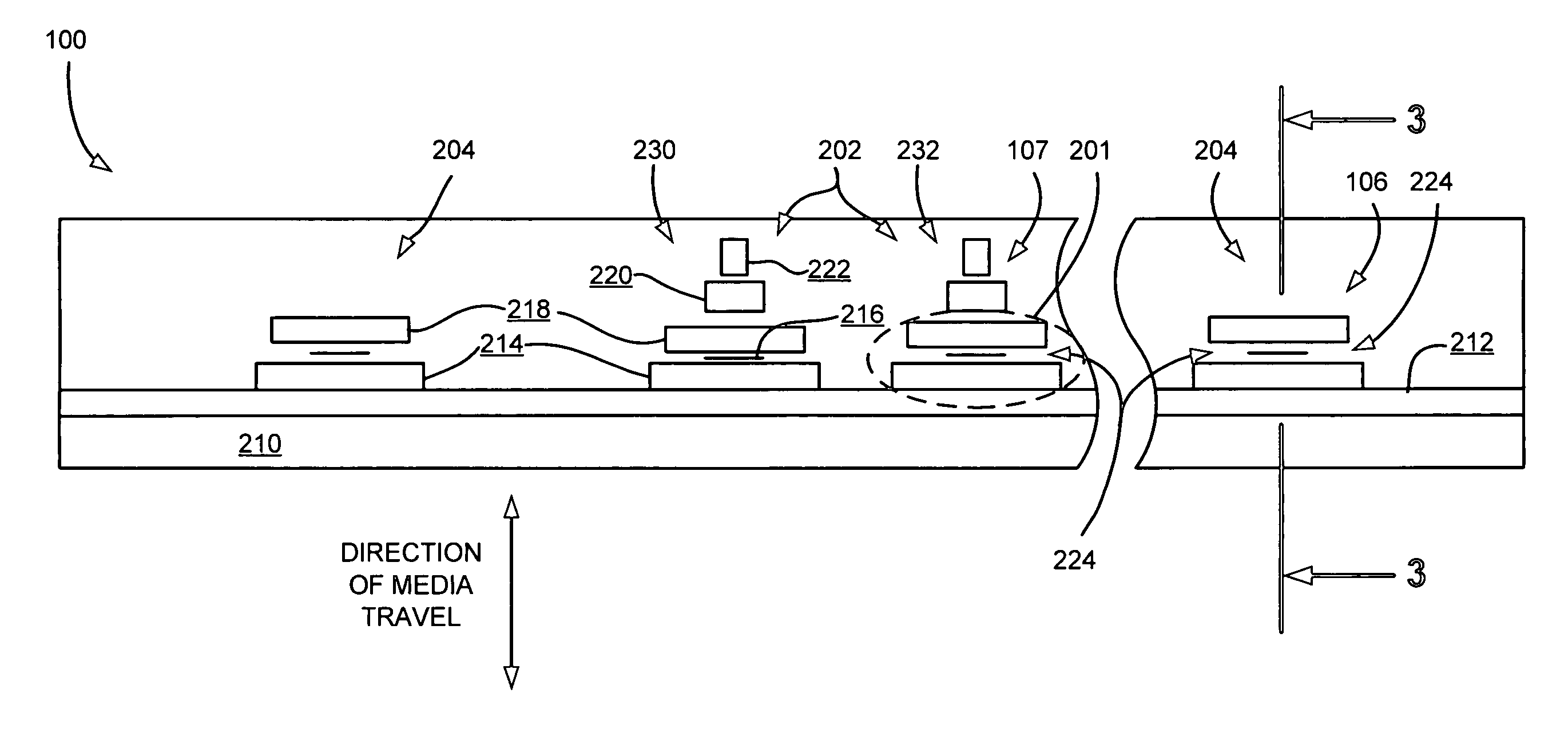

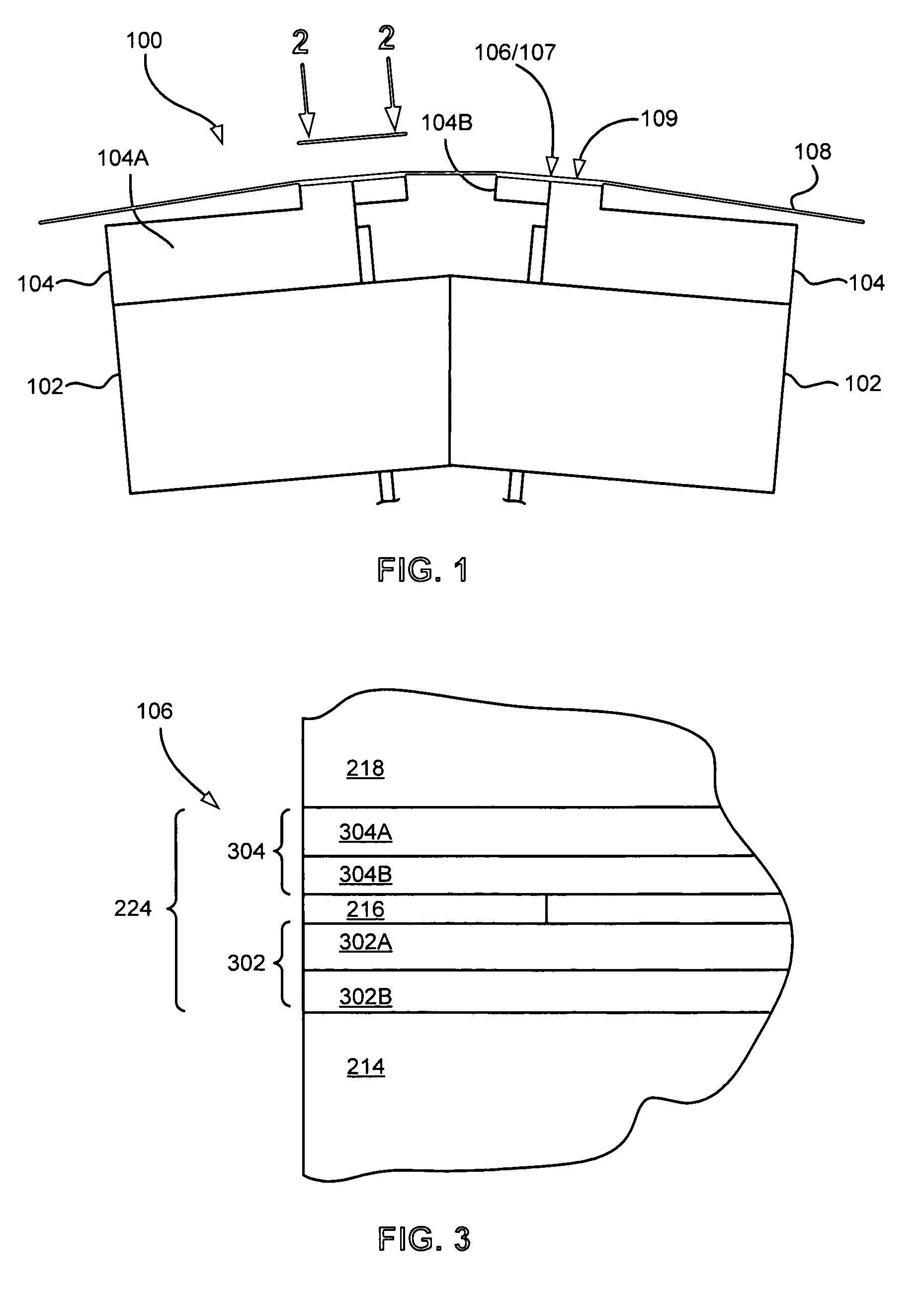

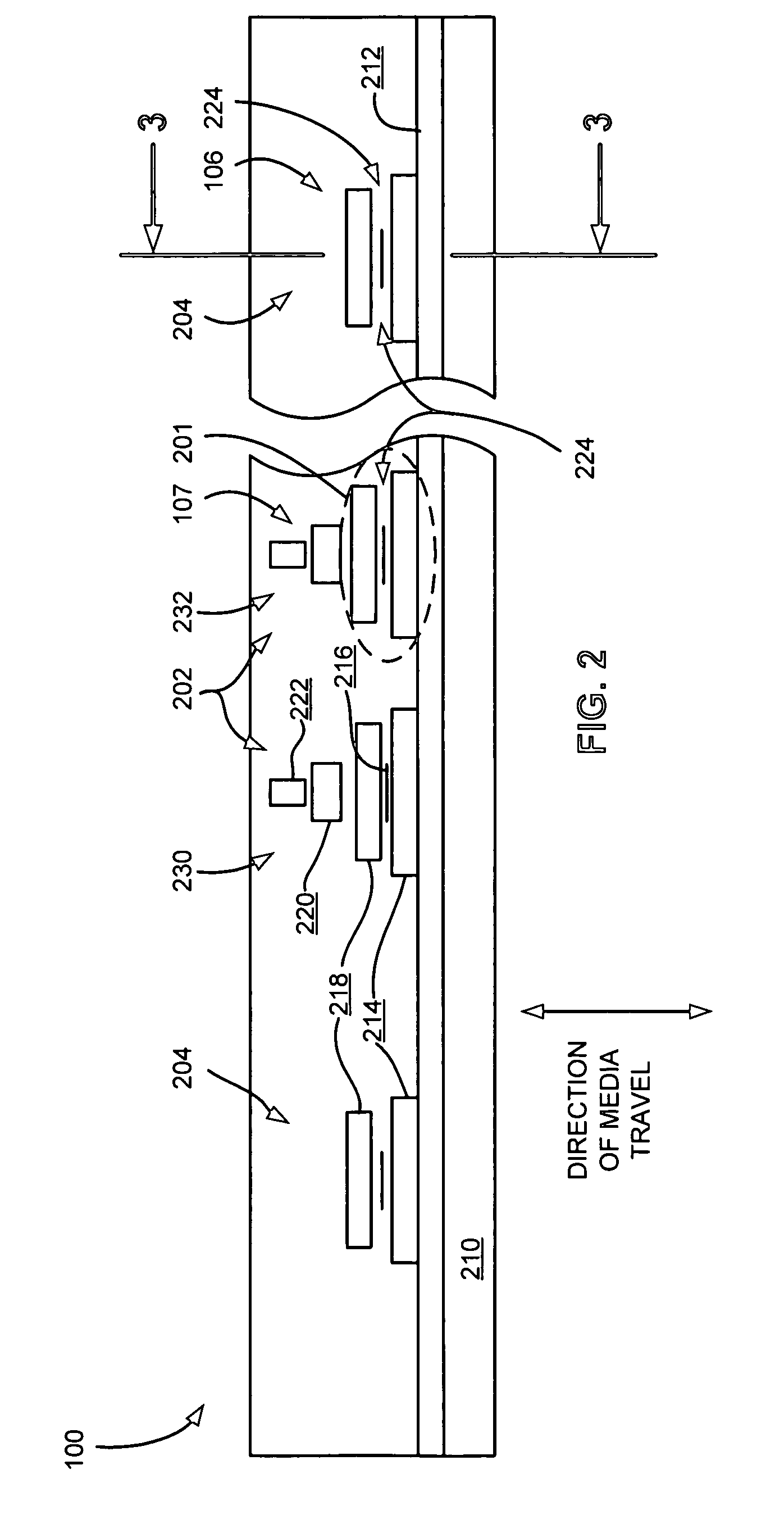

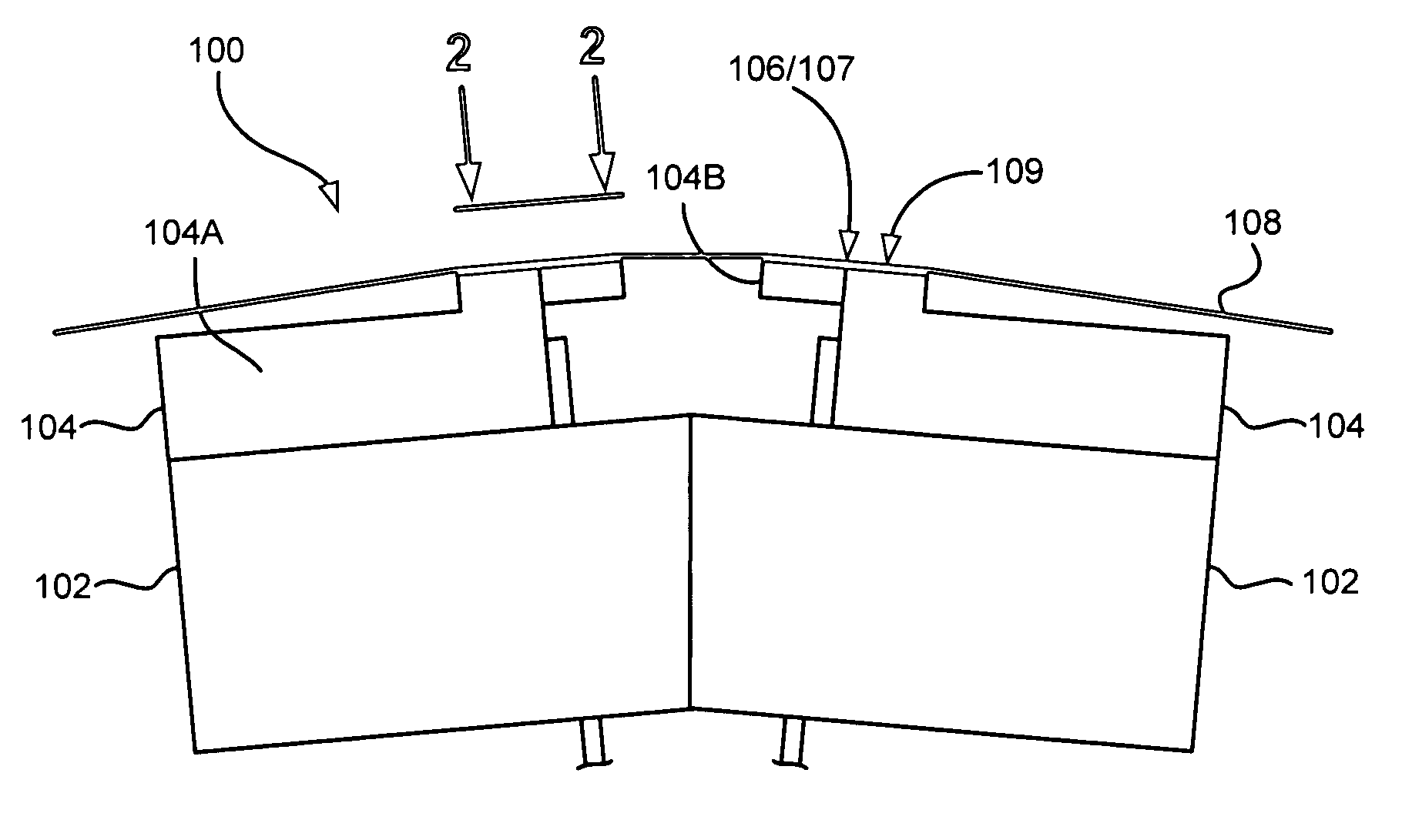

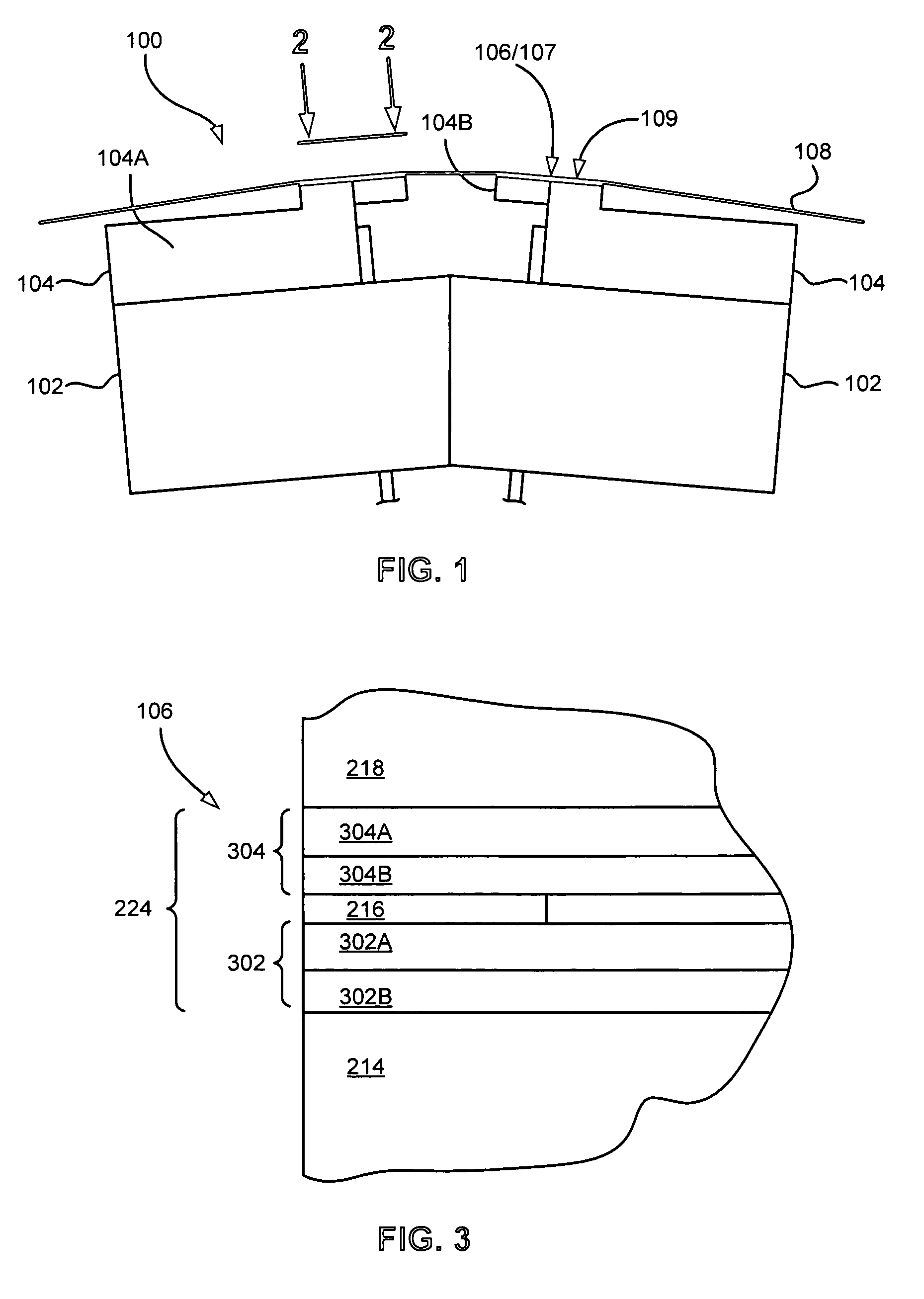

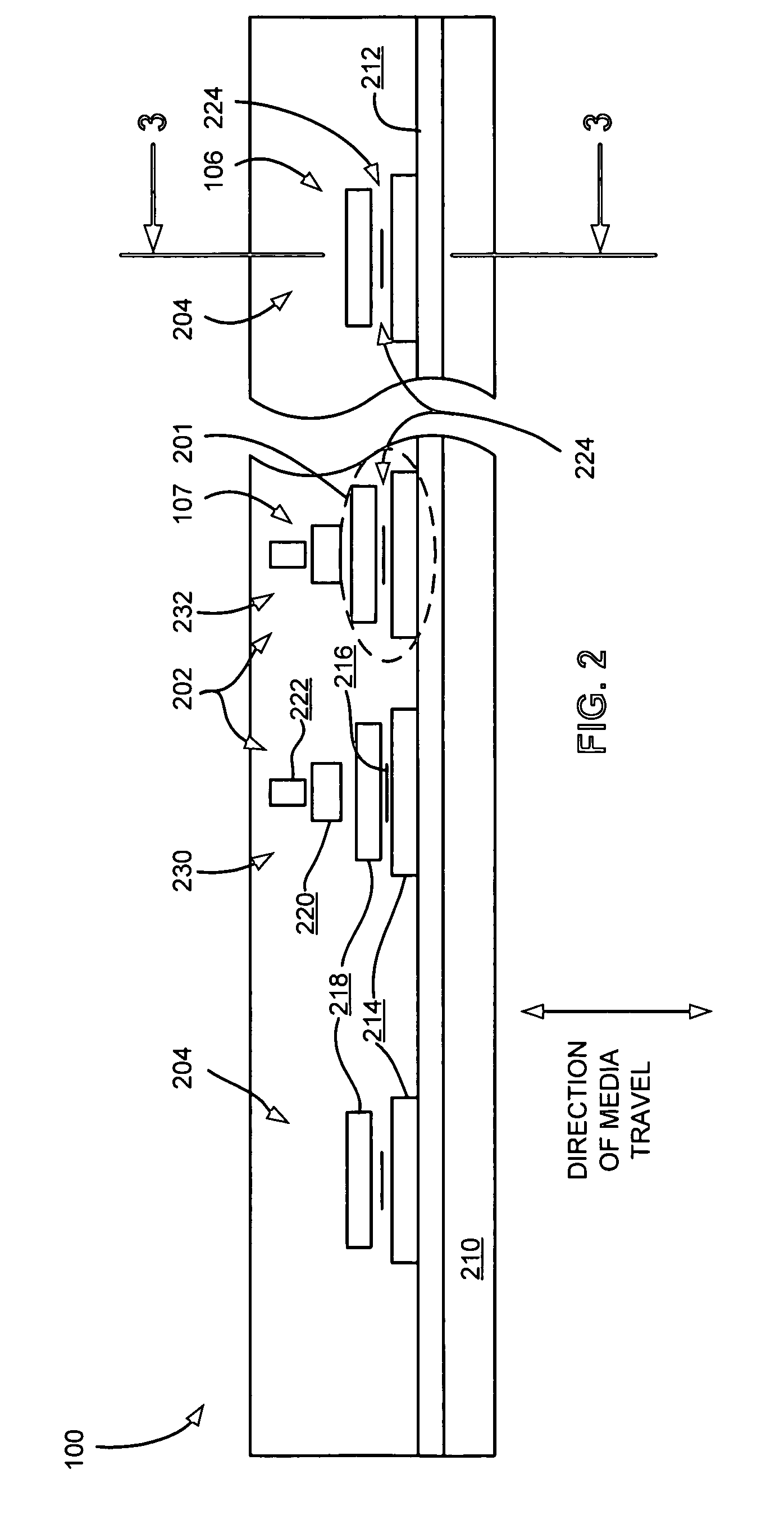

Write/read head assembly with wear parts

InactiveUS6972931B2Alignment for track following on tapesRecord information storageMagnetic tapeEngineering

A read / write head of a magnetic tape drive is provided, where the matrix write head is provided as a part of an overall flat structure that utilizes the atmospheric pressure to hold the tape against the operational surface of the write head. The read head portion is provided to enable reading of the data immediately after it is written. The present head structure permits writing and reading of written data in both tape travel directions. The matrix write head portions are on chips and wear parts are in the upstream direction with respect to the tape travel from the write head. The wear parts provide a shape edge over which the tape moves. The read head is either optical or magnetic and is between two portions of the write head.

Owner:TANDBERG DATA

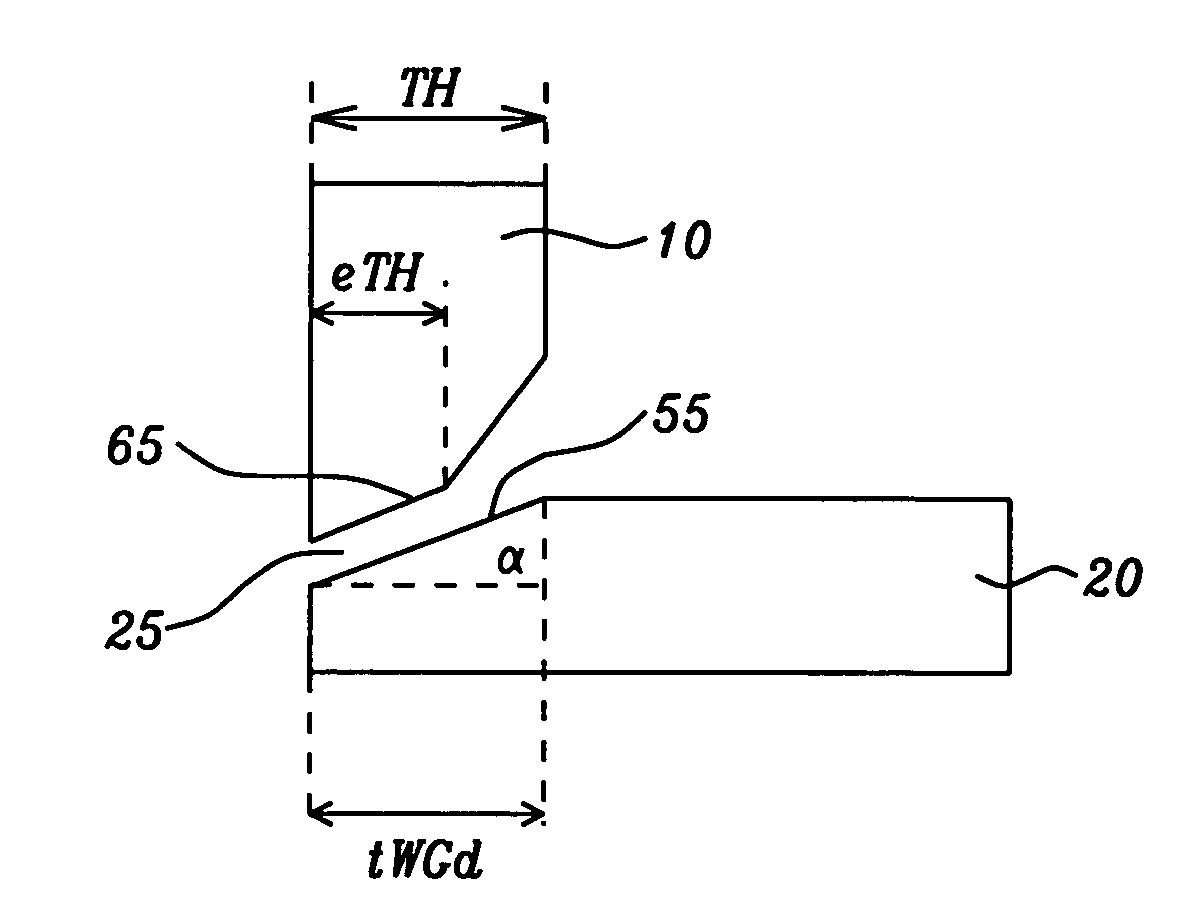

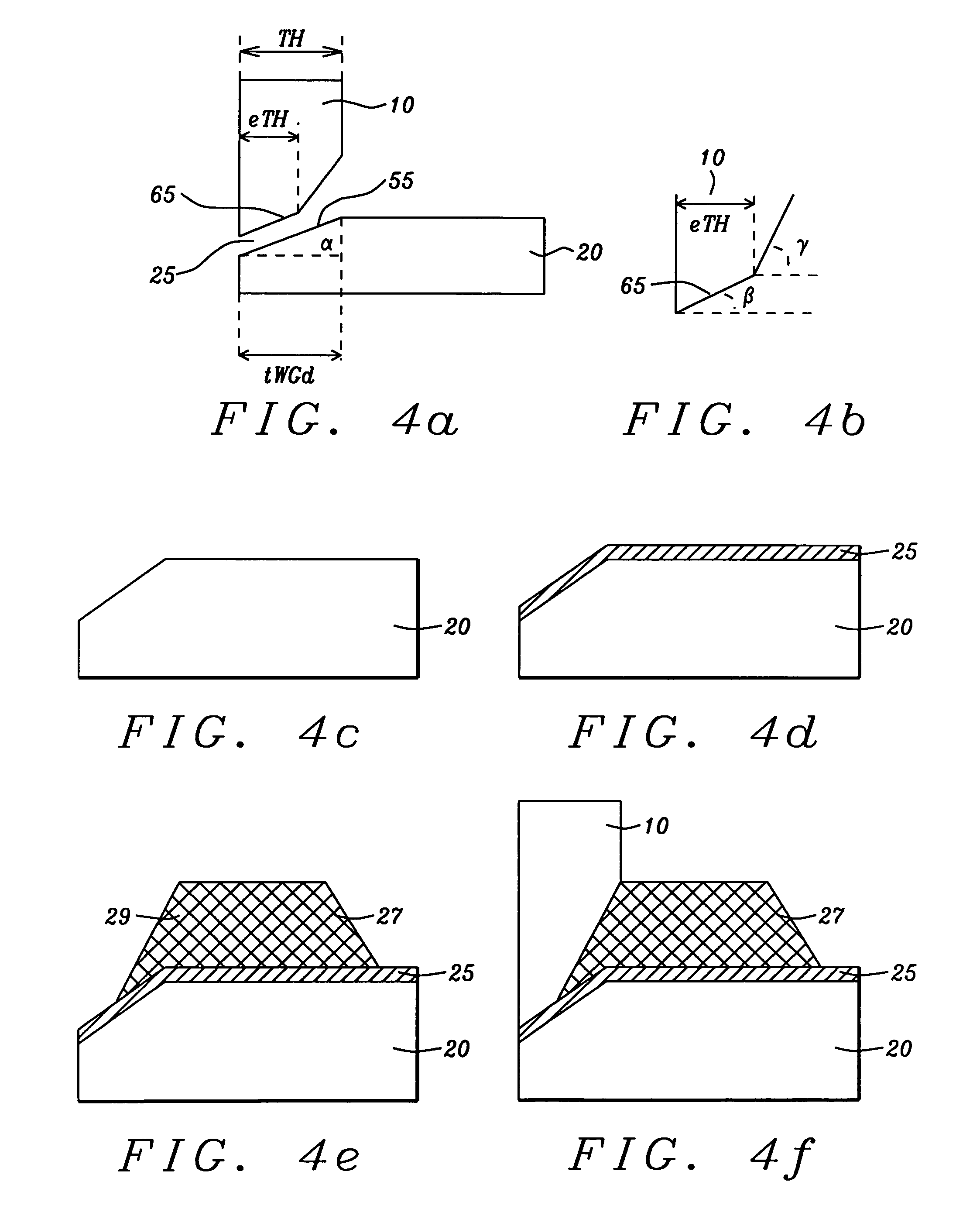

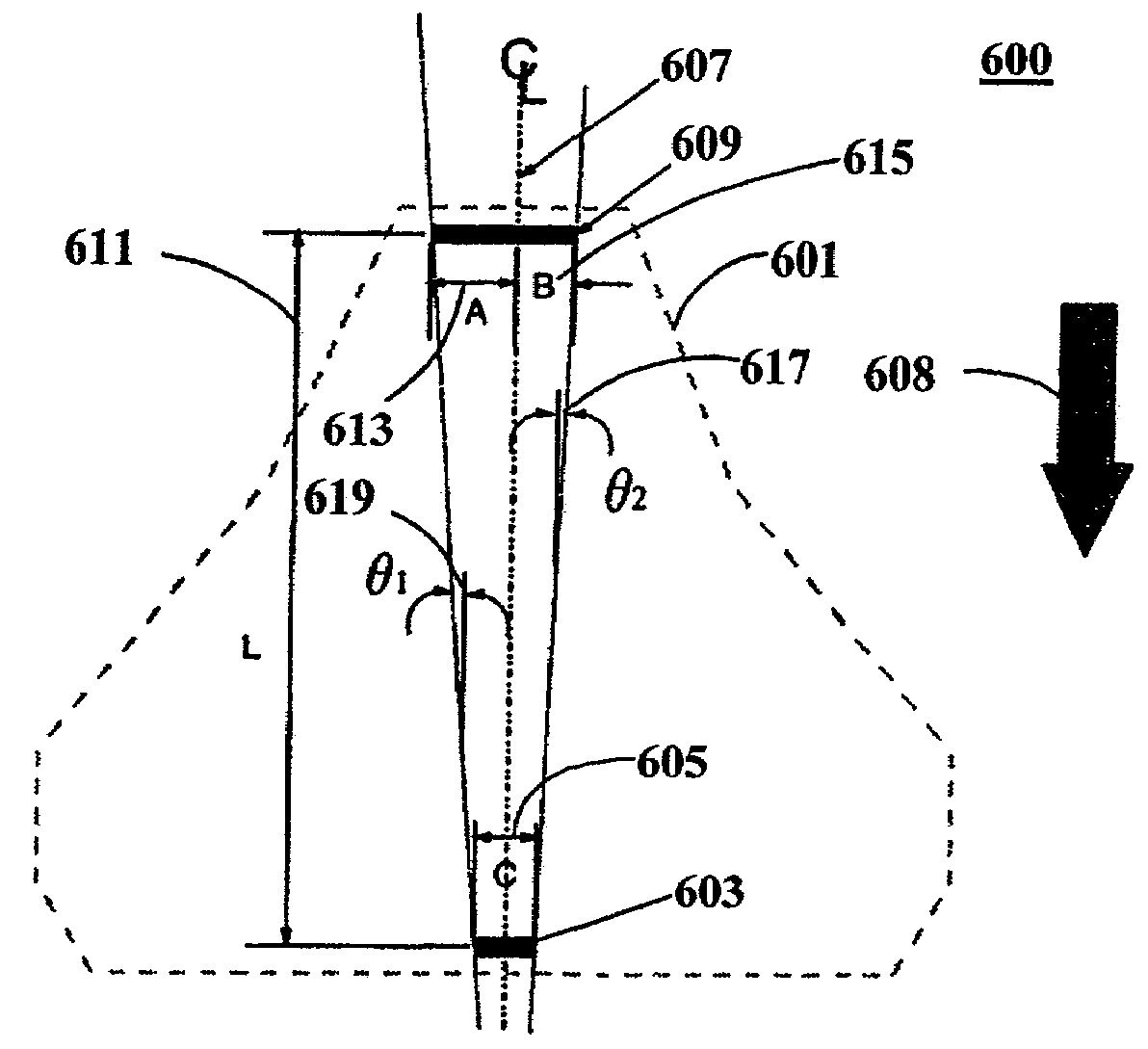

PMR writer having a tapered write pole and bump layer and method of fabrication

Methods for fabrication of tapered magnetic poles with a non-magnetic front bump layer. A magnetic pole may have a tapered surface at or near an air bearing surface (ABS), wherein a thickness of the write pole increases in a direction away from the ABS. A non-magnetic front bump layer may be formed on the tapered surface of the magnetic pole and away from the ABS. The front bump layer may increase the separation distance between a shield layer and the magnetic pole near the tapered surface, thereby improving the performance of the write head.

Owner:WESTERN DIGITAL TECH INC

Writer shields with modified shapes for reduced flux shunting

ActiveUS20120044598A1Improve performanceEnhances write fieldConstruction of head windingsRecord information storageEngineeringElectrical and Electronics engineering

A perpendicular magnetic recording (PMR) head is fabricated with a configuration of leading edge shields and trailing edge shields that reduce the leakage of flux between the main pole and the shields. The reduction of leakage is achieved by eliminating the sharp 90° corner between the backside surfaces of the shields and the surfaces adjacent to the main pole. In one embodiment the corner is replaced by two successive acute angles, in another embodiment it is replaced by a rounded surface. In a final embodiment, leakage between the pole and trailing edge shield is achieved by shortening the length of the write gap by forming the shield with a double taper.

Owner:HEADWAY TECH INC

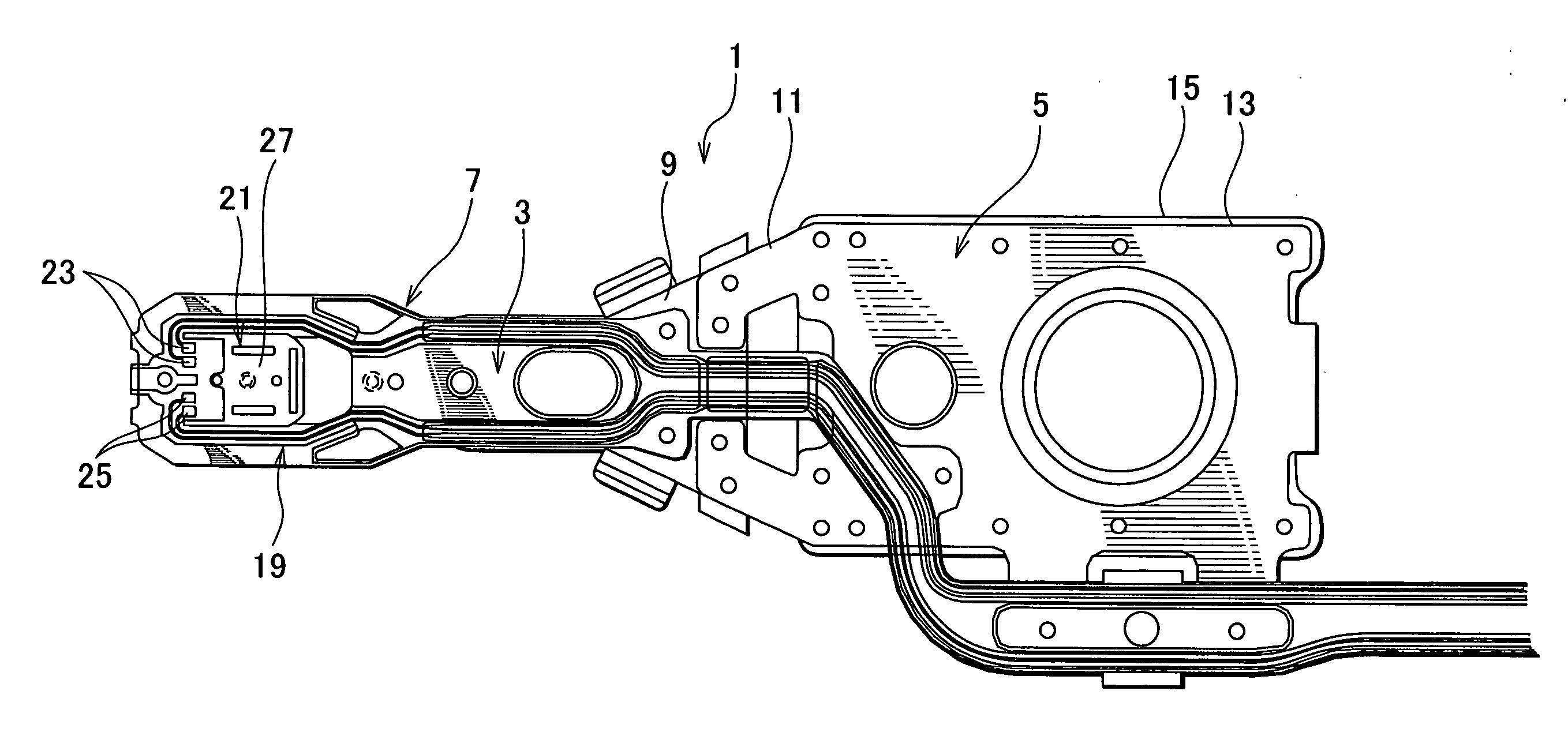

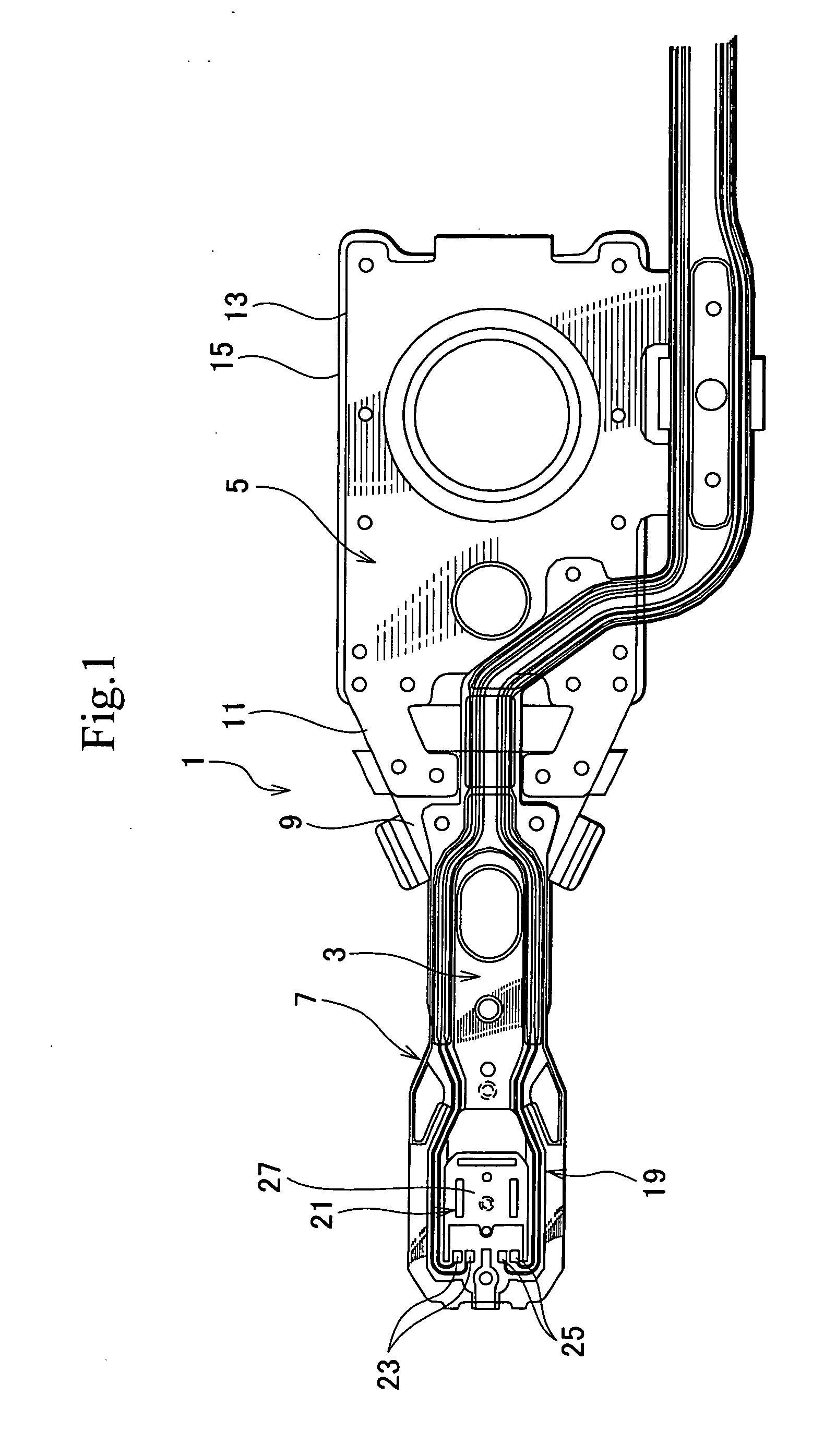

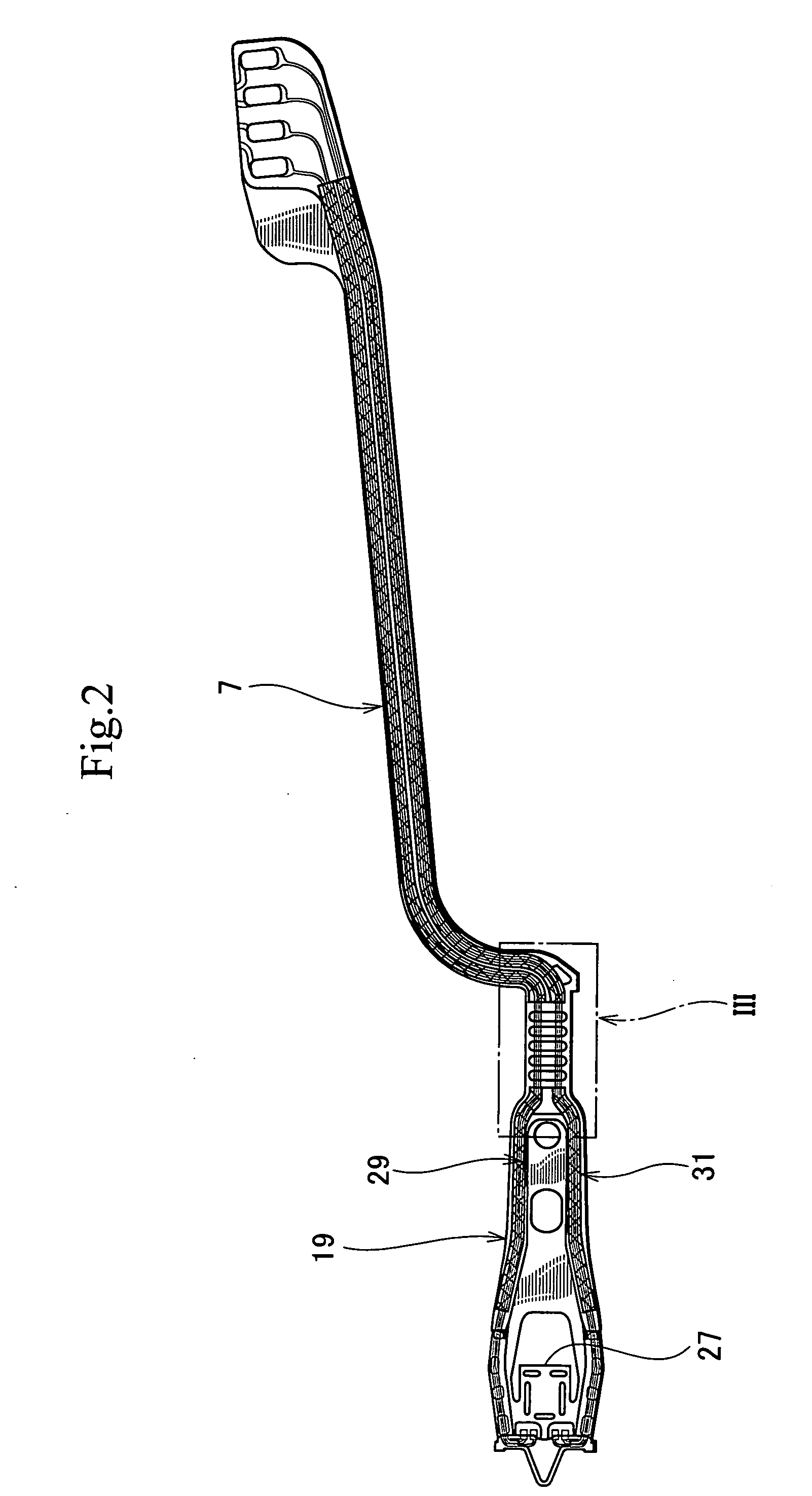

Head suspension

ActiveUS20060190673A1Electrostatic destruction can be preventedPrevent electrostatic dischargeElectrical connection between head and armHigh voltage circuit adaptationsElectrostatic dischargeElectric wire

A head suspension prevents a read element from electrostatic discharge damage without employing a static electricity remover or without increasing the number of manufacturing processes. The head suspension has a load beam to apply load to a head (21) that writes and reads data to and from a hard disk, a flexure (7) made of a conductive thin substrate attached to the load beam and supporting the head, an insulating base layer (35) made of flexible resin and formed on the substrate of the flexure, write wires (29) and read wires (31) connected to the head and formed on the insulating base layer, and an insulating cover layer (41, 43) covering the write and read wires on the insulating base layer. The insulating cover layer (41, 43) is made of slightly conductive flexible resin.

Owner:NHK SPRING CO LTD

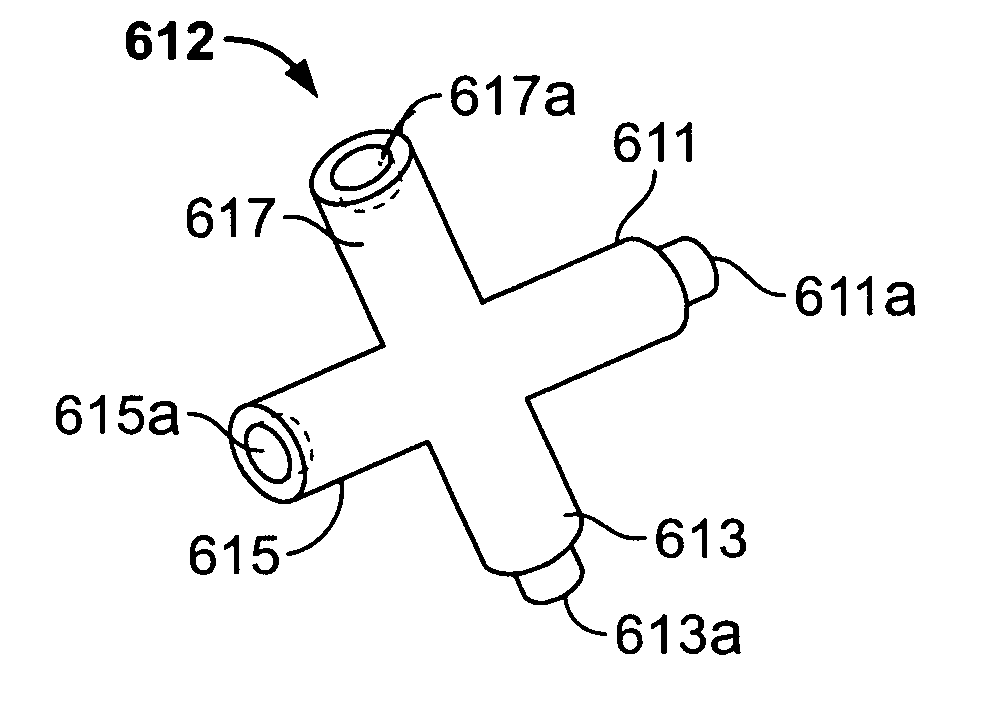

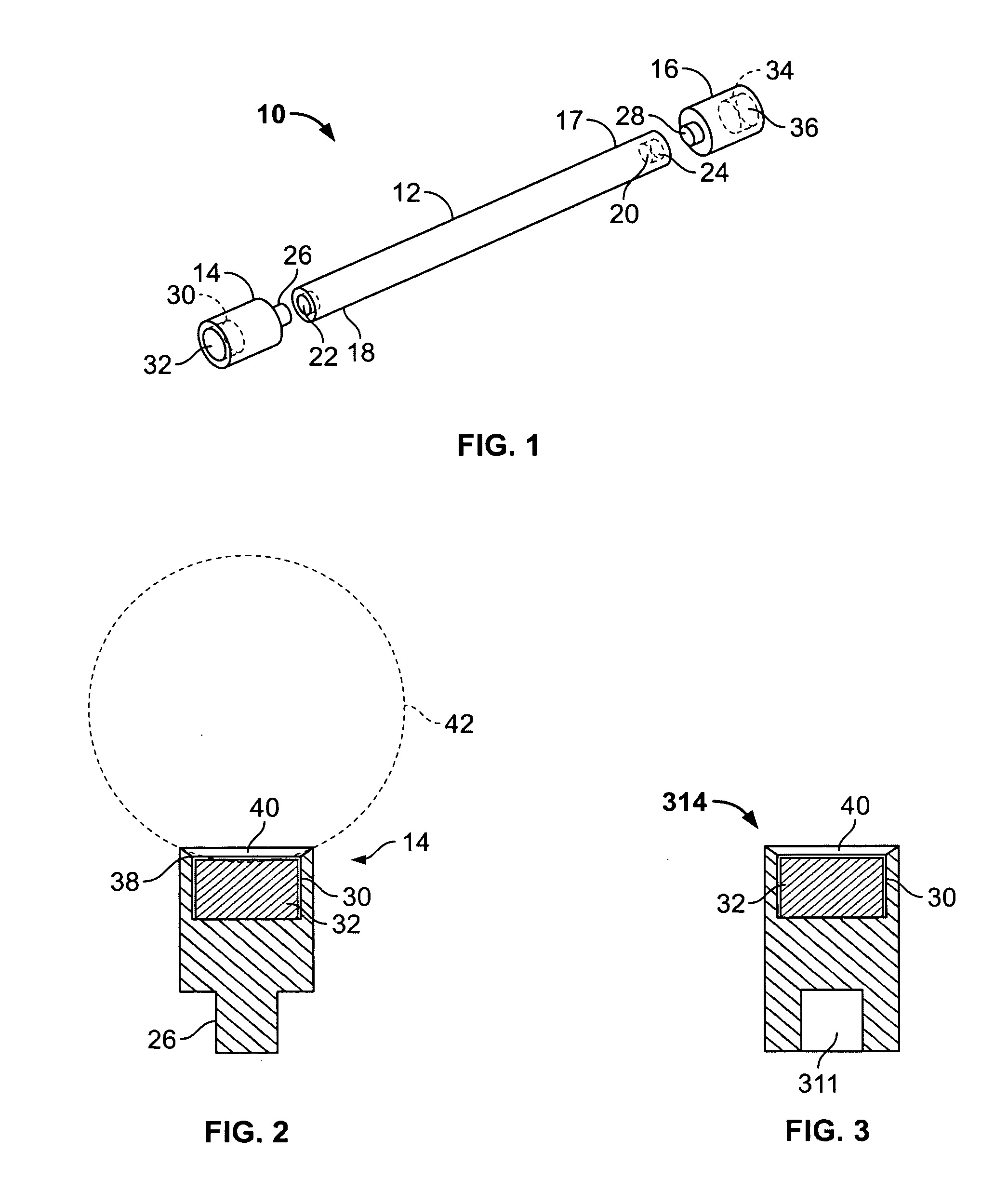

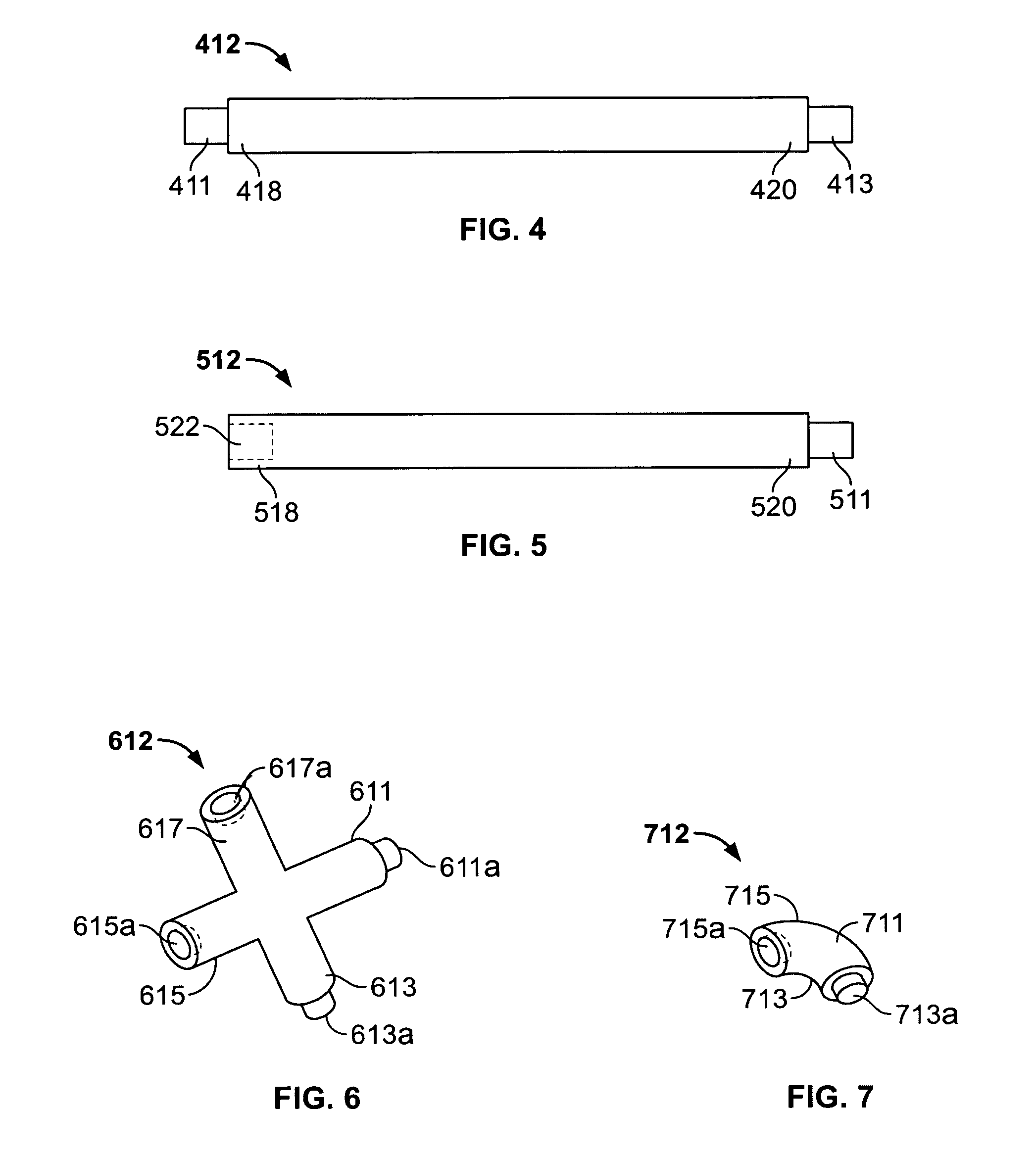

Magnetic construction module with interchangeable magnet holders

InactiveUS20050159076A1Improved structural profileImprove construction flexibilityRecord information storageToysArchitectural engineeringMetal sphere

A magnetic construction module that is suitable for creating a variety of different construction profiles and lengths and that permits the construction of modules where at least some of the members are adapted to be flexible. A rod is attachable to a holder adapted for retaining a magnet. The magnet is retained in a pocket of the holder. The holder can be attached in rods of various lengths, curves, rigidities to conform to the shape desired by the user. An outer surface of the magnet is adapted to provide a magnetic connection to a magnetizeable element such as a metal sphere with which the rod and holder can be operatively associated for a particular construction profile. Moreover, the holder may also be securely, selectively connected to the rod via a male-female connection in order to provide greater construction flexibility.

Owner:ROSE ART INDS +1

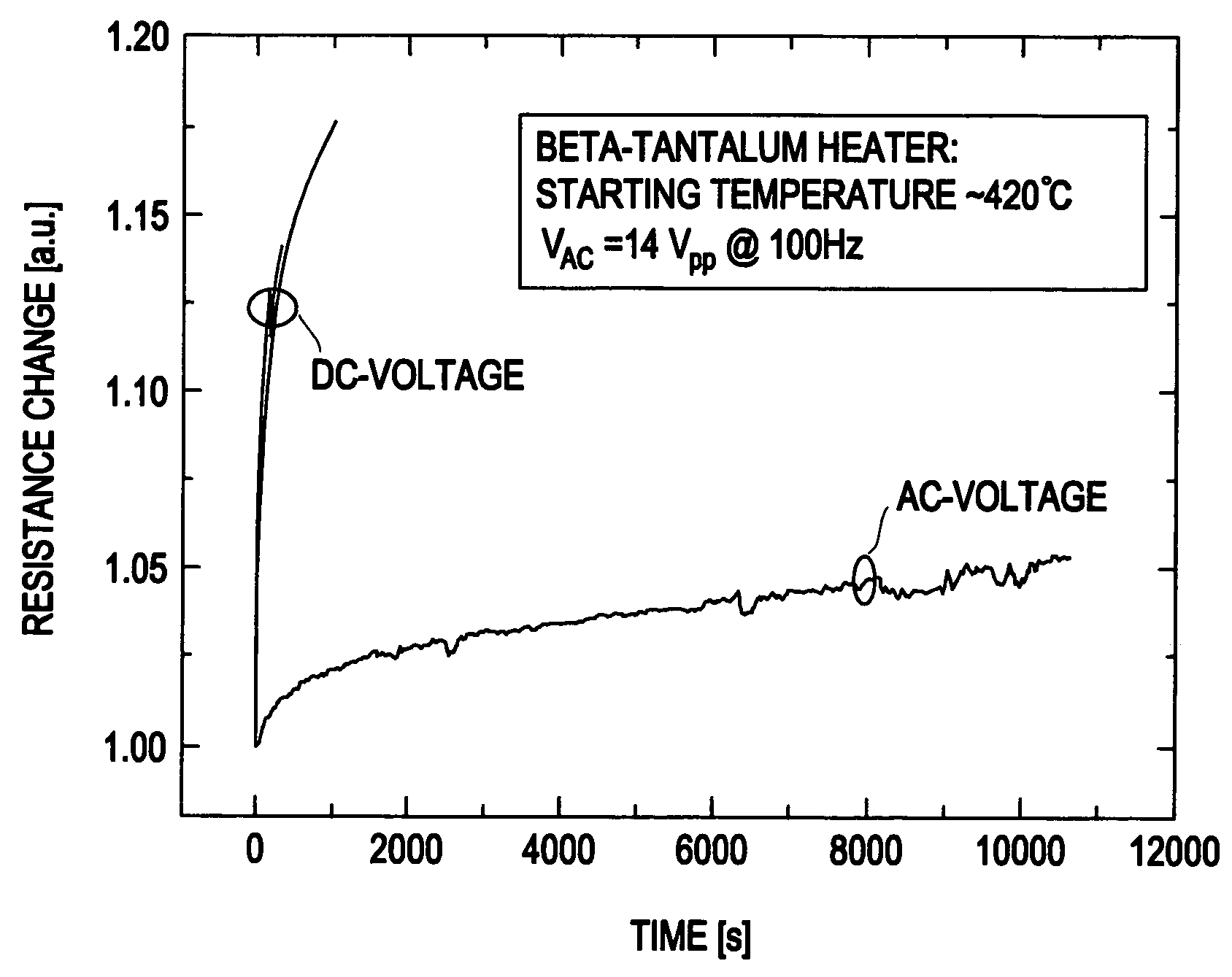

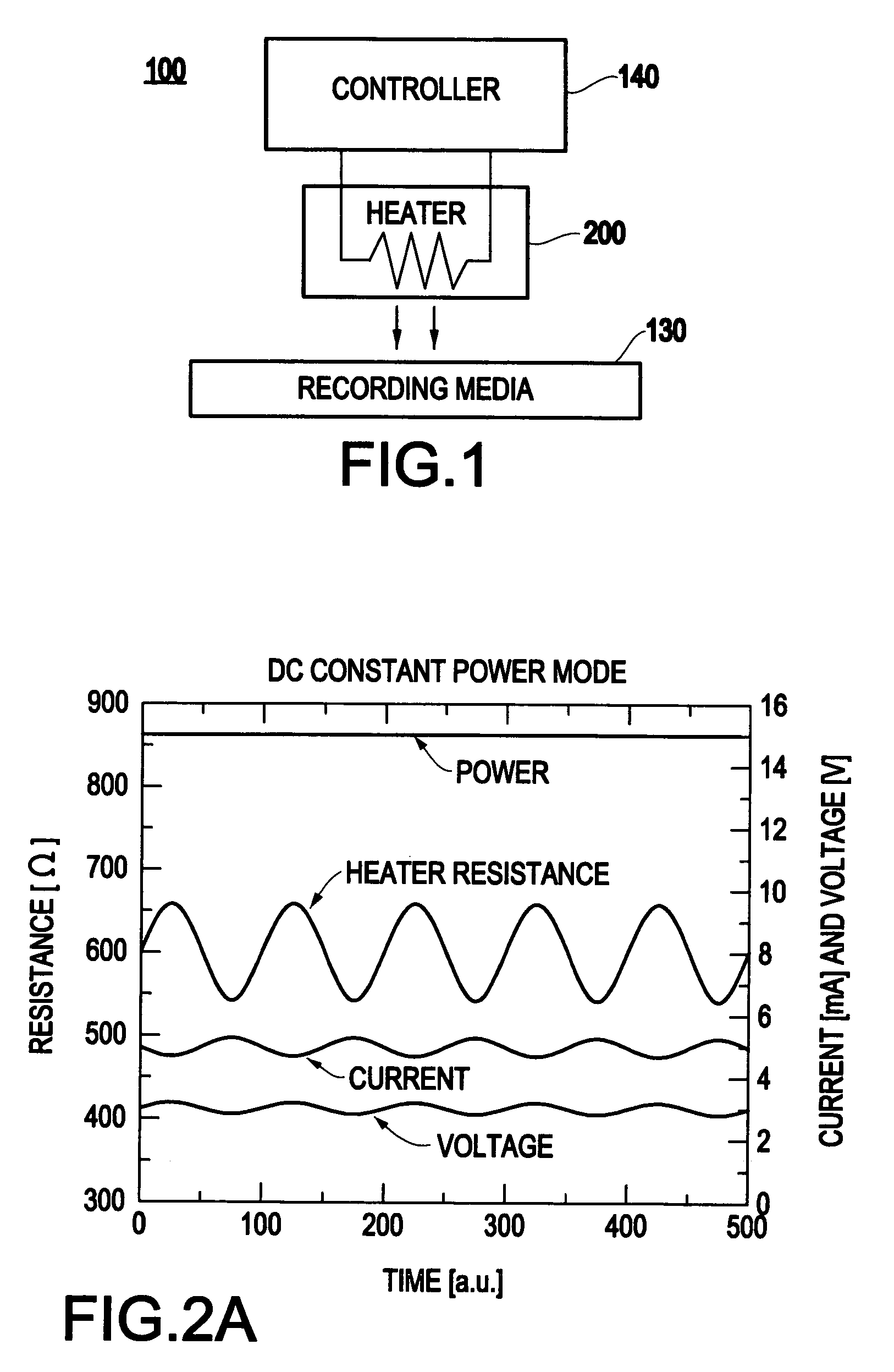

Assembly for thermal and/or thermally-assisted information processing

InactiveUS7130141B2Minimize changesTemperature controlManufacture head surfaceRecord information storageInformation processingElectrical polarity

An information processing assembly includes at least one heater suitable for information processing, and a controller for controlling the at least one heater by at least one of adjusting a power to the at least one heater to match a target power level, and changing a polarity of an electrical current supplied to the heater.

Owner:WESTERN DIGITAL TECH INC

Mamr head with recessed sto

ActiveUS20150092292A1Record information storageRecording/reproducing/erasing methodsAir bearingSpin torque oscillators

Embodiments of the present invention generally relate to a microwave assisted magnetic recording (MAMR) head. The MAMR head includes a main pole, a trailing shield, and a spin torque oscillator (STO) disposed between the main pole and the trailing shield. The STO is recessed from an air bearing surface.

Owner:WESTERN DIGITAL TECH INC

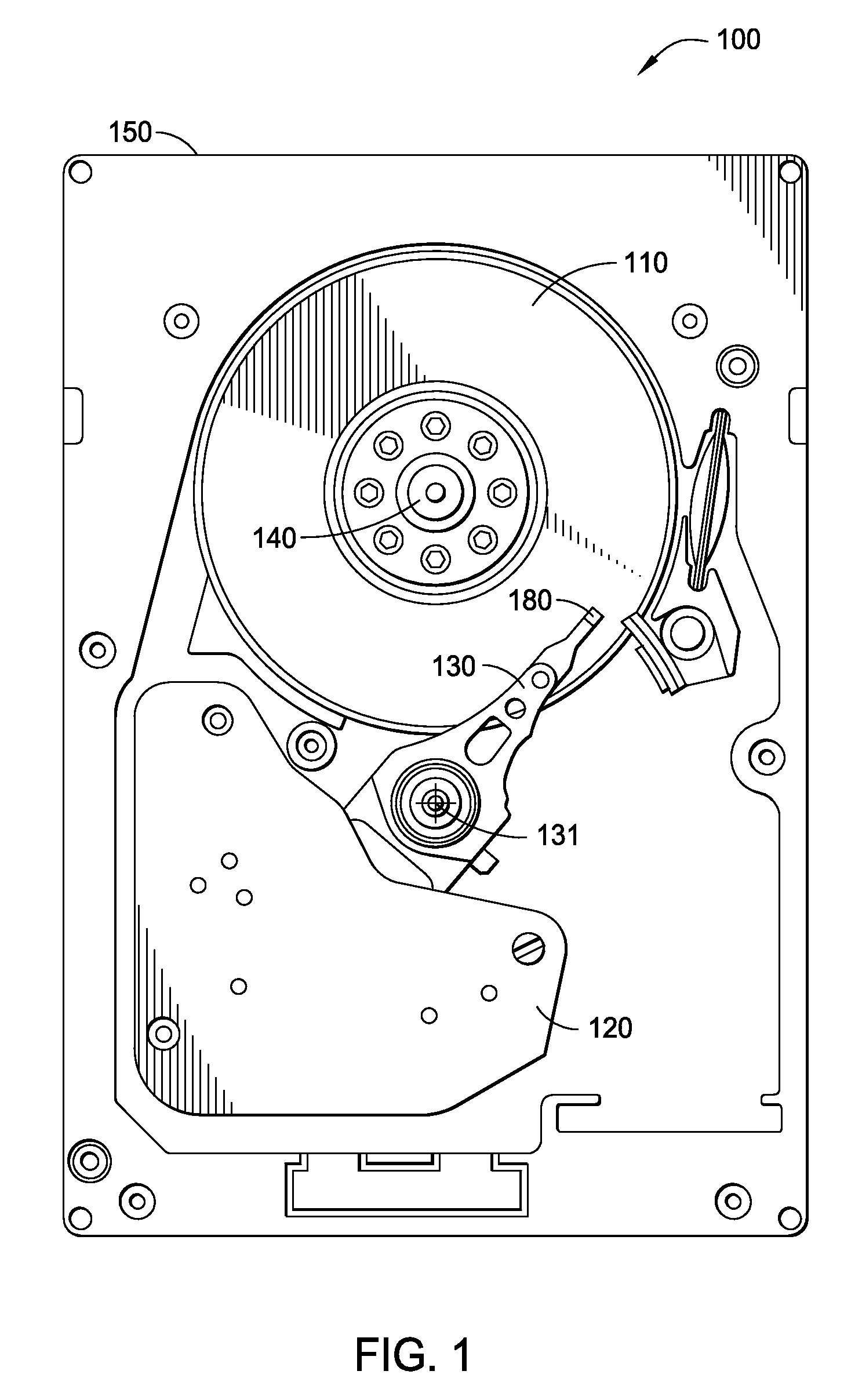

Apparatus for look-ahead thermal sensing in a data storage device

InactiveUS7027263B2Addressing slow performanceDisc-shaped record carriersRecord information storageLeading edgeEngineering

A slider having leading and trailing edges is configured to fly on an airbearing above a data storage disk rotating from the leading edge to the trailing edge. Read and write heads are mounted on the slider proximate the trailing edge. An auxiliary thermal sensor is mounted on the slider, but preferably nearer the leading edge. Forward placement of the sensor allows it to sense mechanical defects before they reach the heads, thereby permitting a write inhibit operation, for example. The sensor may also be used to detect airbearing modulation. Appropriate action may be taken when unacceptable airbearing modulation is detected, such as notifying the user and / or scrubbing the slider. The sensor is preferably wider than the heads. This allows, for example, an in-situ glide test to be performed faster using the sensor. An arm electronics module is preferably configured to permit concurrent operation of the sensor and heads.

Owner:WESTERN DIGITAL TECH INC

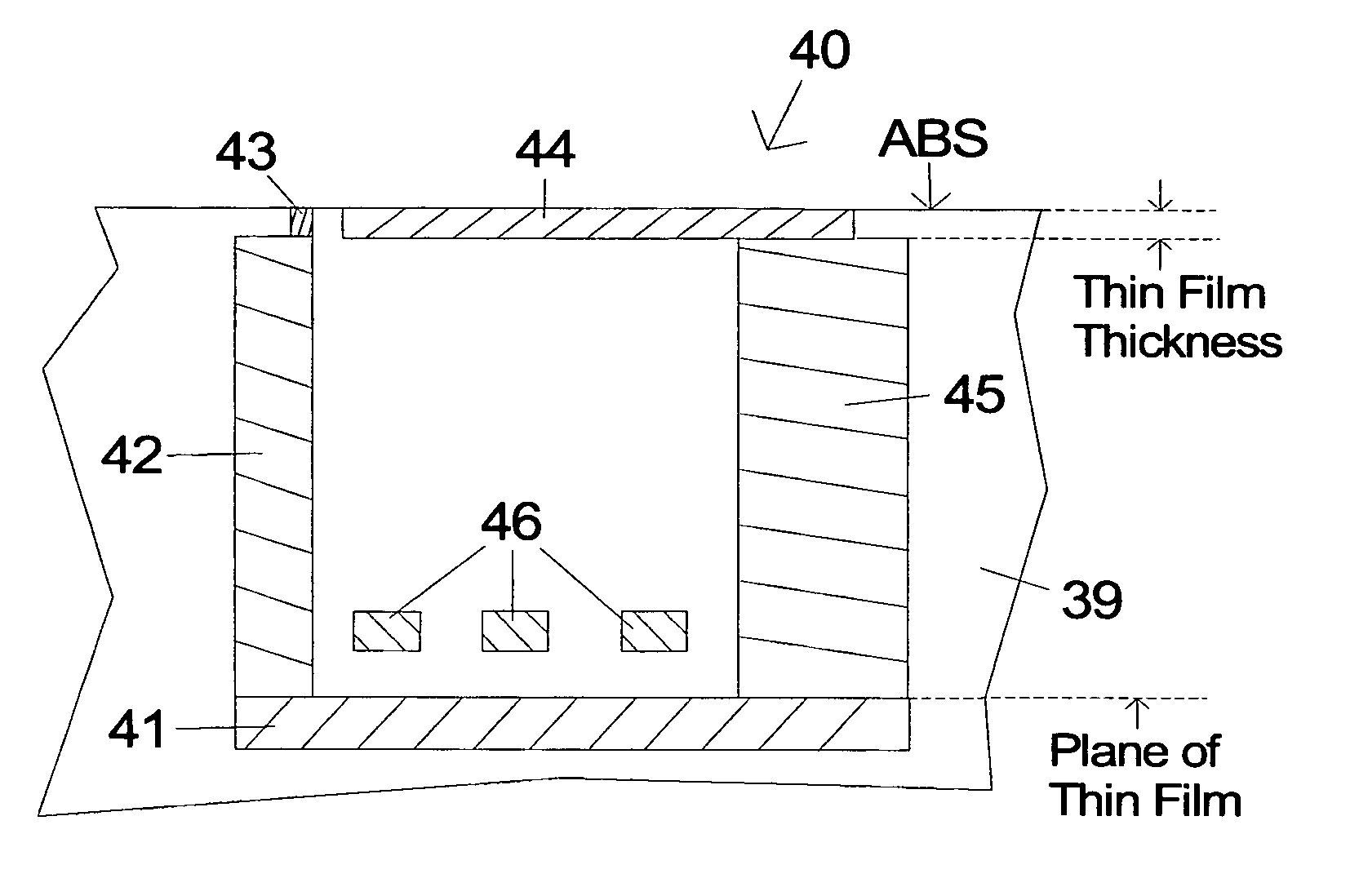

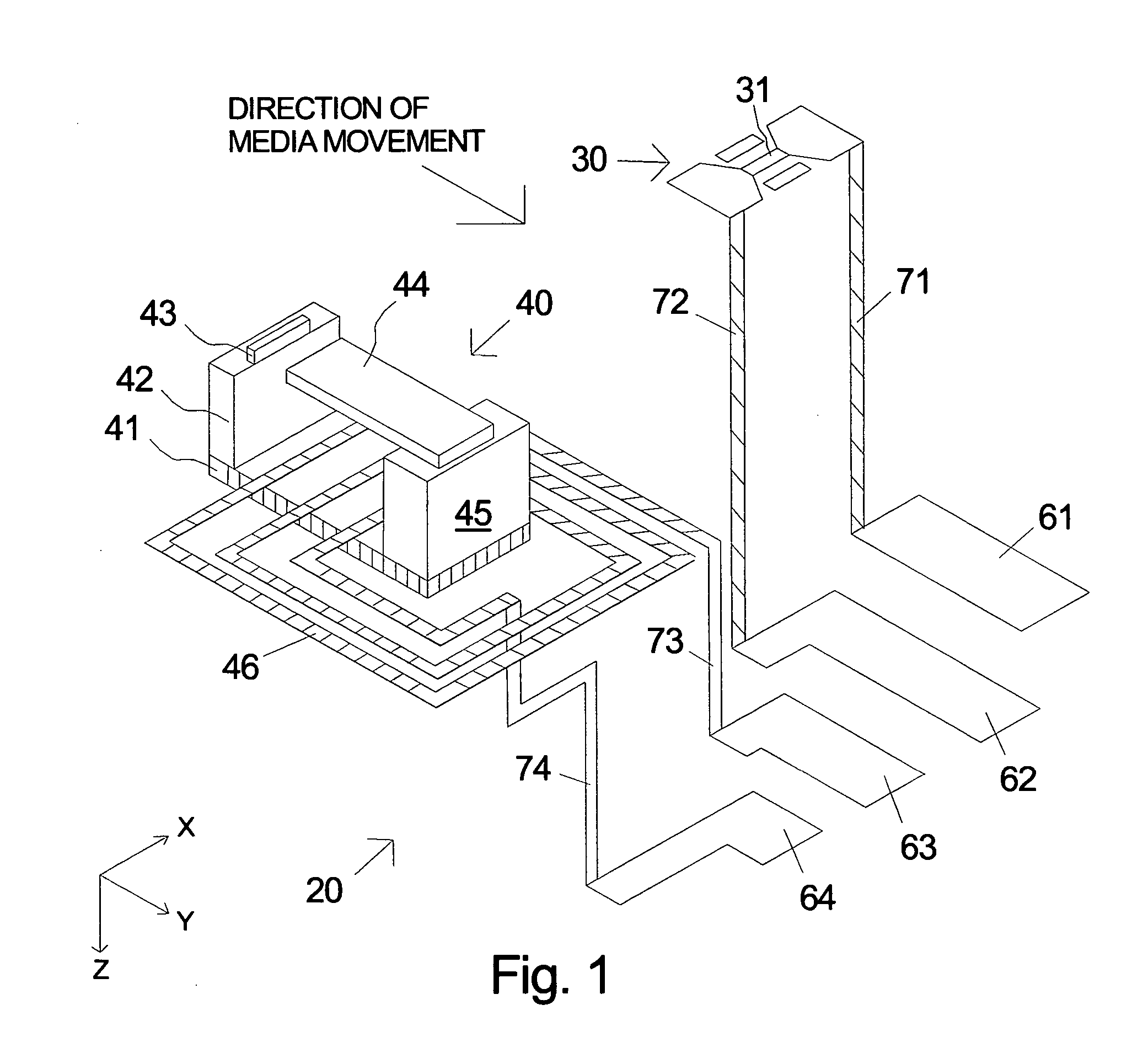

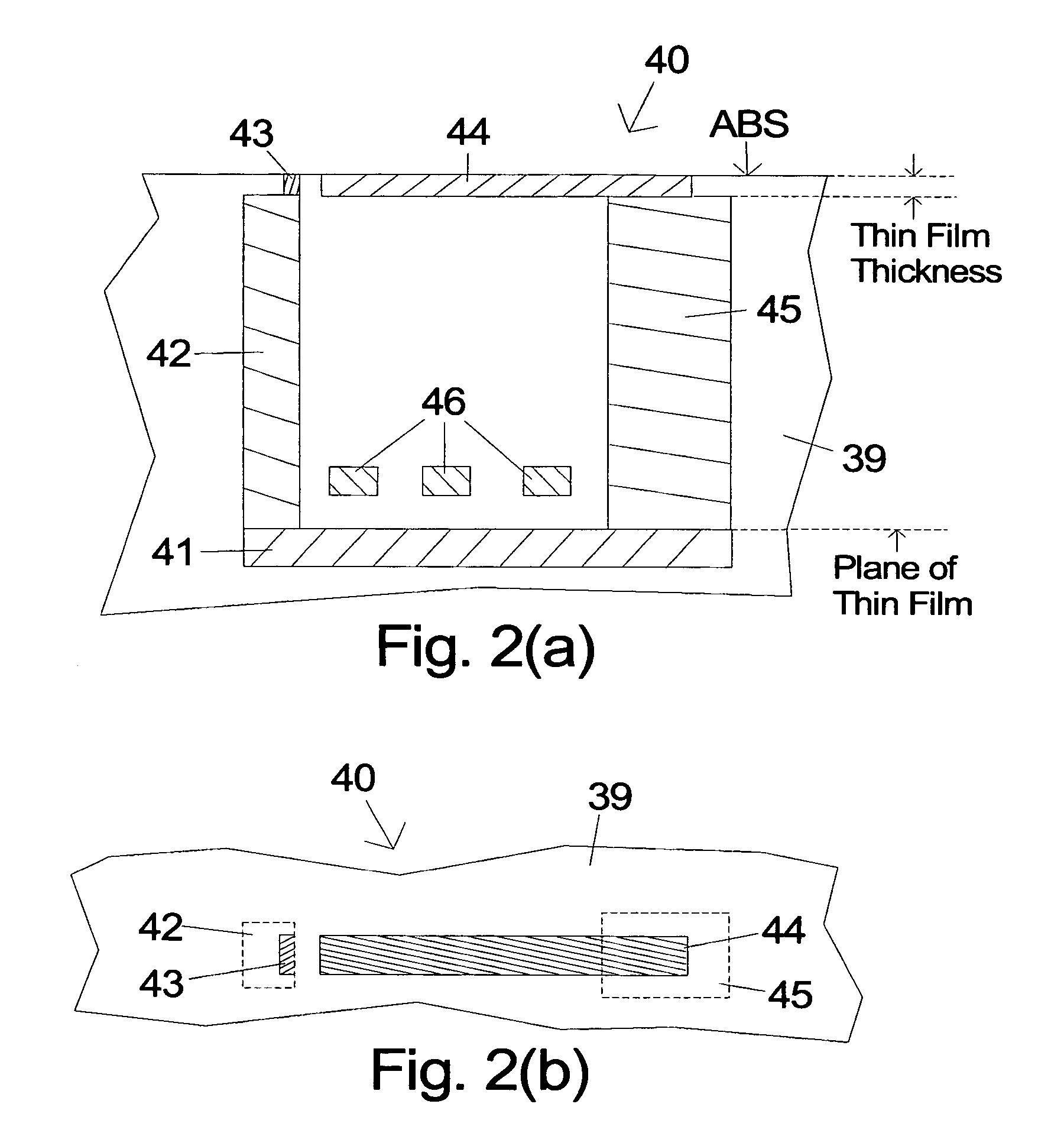

Planar perpendicular recording head

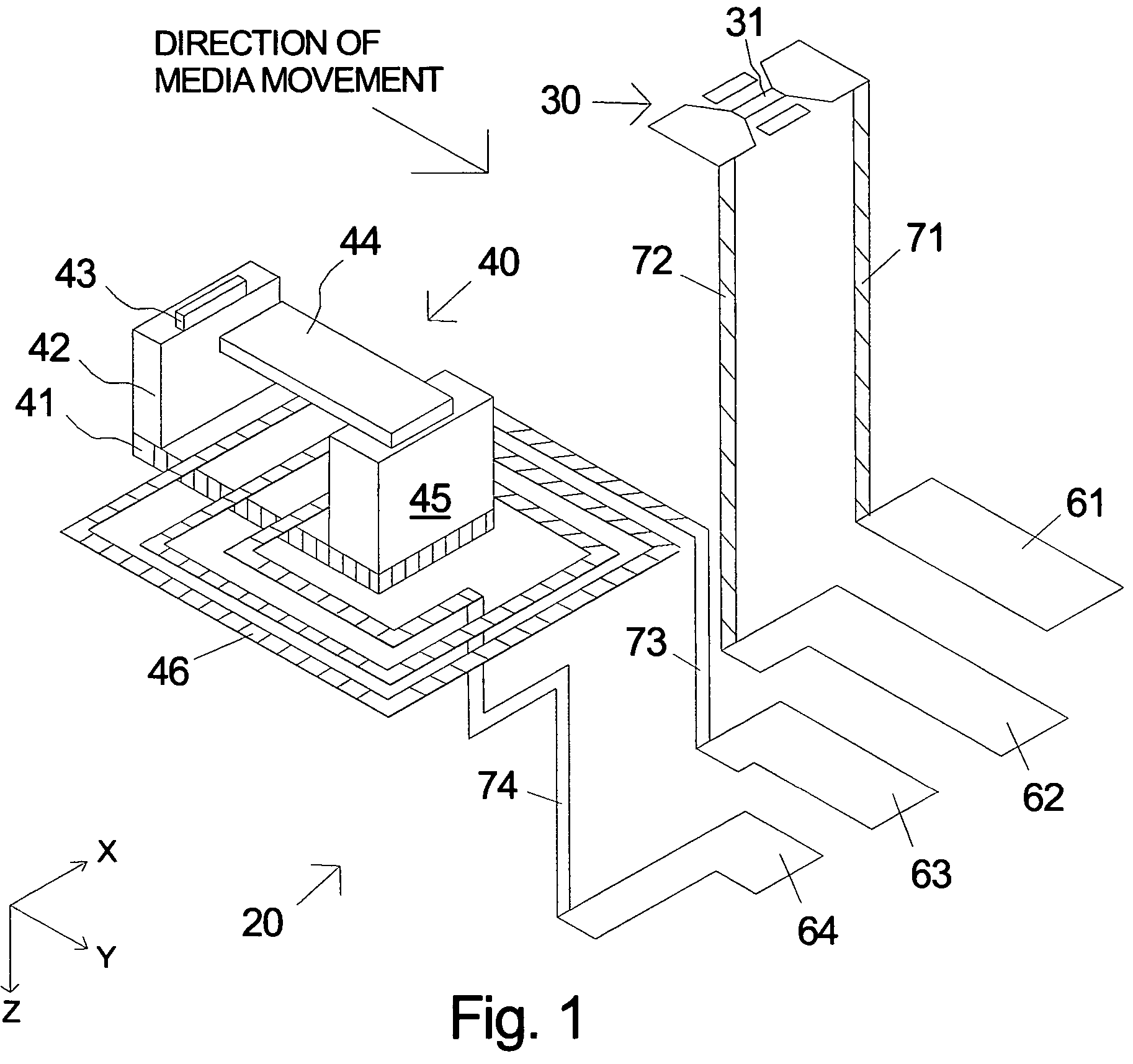

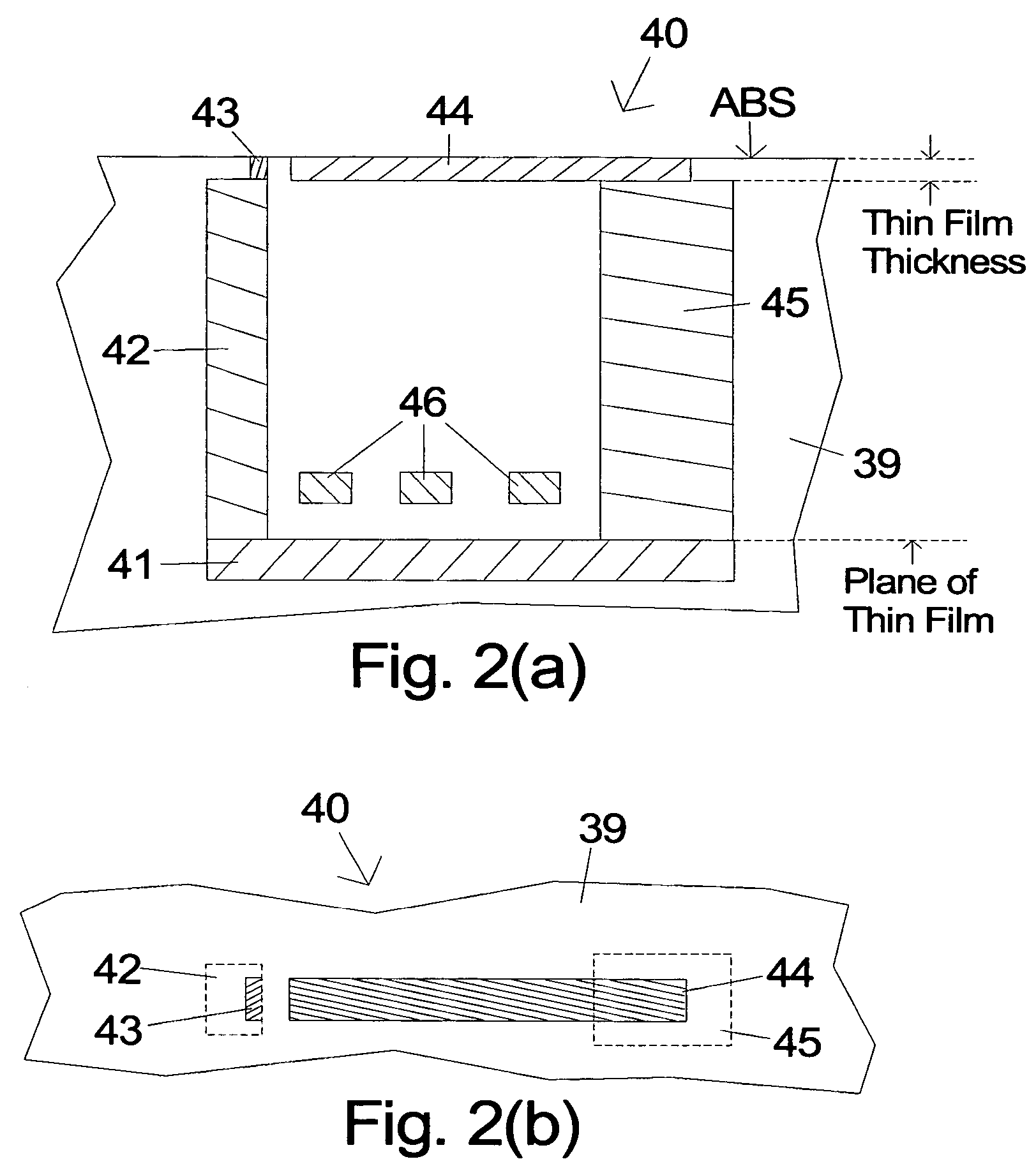

A magnetic head (slider) for perpendicular recording which requires no lapping is described. The head is fabricated with an air bearing surface that is parallel to the wafer surface. The coil and pole pieces are formed from thin films disposed parallel to the air bearing surface. Standard lithographic techniques can be used to define the shapes, gaps and pole piece dimensions. Non-rectilinear shapes can be formed; for example, side shields that conform around the write pole piece region. The thickness of the main and return pole pieces are controlled by the deposition process rather than by lapping. The saw cuts used to separate the individual sliders from the rest of the wafer are perpendicular to the air-bearing surface and do not pass through any critical features.

Owner:WESTERN DIGITAL TECH INC

Magnetic head having selectively defined reader gap thicknesses

InactiveUS20070091505A1Construction of head windingsManufacturing heads with multiple gapsEngineeringElectrical and Electronics engineering

Owner:IBM CORP

Localized pole tip heating device for magnetic head for hard disk drive

ActiveUS20050018347A1Reduce switching speedReduce pole tip stressConstruction of head windingsHeads using thin filmsHard disc driveMagnetization

The magnetic head is formed with a narrow pole tip, and a pole tip heating element is fabricated to reduce the pole tip stress and increase its permeability, such that the magnetization switching speed of the pole tip is increased. The heating element is preferably electrically interconnected within the induction coil circuit of the magnetic head, such that the electrical current flowing through the induction coil also flows through the heating element. In a preferred embodiment, the heating element is fabricated above the second magnetic pole. The heating element is preferably formed with a resistance of approximately 0.2 to 1.0 ohms, such that the approximately 40 mA current that flows through the induction coil and the heating element creates a heating energy of the heating element of approximately 0.3 to 1.6 mW. The heating element can be comprised of a variety of materials such as Cu, W, NiFe, NiCr and IrRh.

Owner:WESTERN DIGITAL TECH INC

Magnetic head having selectively defined reader gap thicknesses

InactiveUS7760465B2Construction of head windingsManufacturing heads with multiple gapsEngineeringElectrical and Electronics engineering

Owner:INT BUSINESS MASCH CORP

Non-magnetic metallic layer in a reader gap of a disc drive

InactiveUS6700752B2Construction of head windingsManufacture head surfaceNon magneticElectrical and Electronics engineering

A read / write head with a bottom shield on a slider substrate and a shared shield spaced apart from the bottom shield. A write head is deposited on the shared shield. A read sensor is spaced apart by reader magnetic gaps from the bottom shield and the shared shield. Electrically insulating layers in the reader magnetic gaps form a thermal resistance between the read sensor and the shields. A thermally conducting nonmagnetic layer in a reader magnetic gap reduces the thermal resistance without a corresponding reduction in the reader magnetic gaps.

Owner:SEAGATE TECH LLC

Pmr writer and method of fabrication

Methods for fabrication of tapered magnetic poles with a non-magnetic front bump layer. A magnetic pole may have a plurality of tapered surfaces at or near and air bearing surface (ABS), wherein a thickness of the write pole increases in a direction away from the ABS. A non-magnetic front bump layer may be formed on one or more of the tapered surfaces of the magnetic pole at a distance from the ABS. The front bump layer may increase the separation distance between a shield layer and the magnetic pole near the tapered surface, thereby improving the performance of the write head.

Owner:WESTERN DIGITAL TECH INC

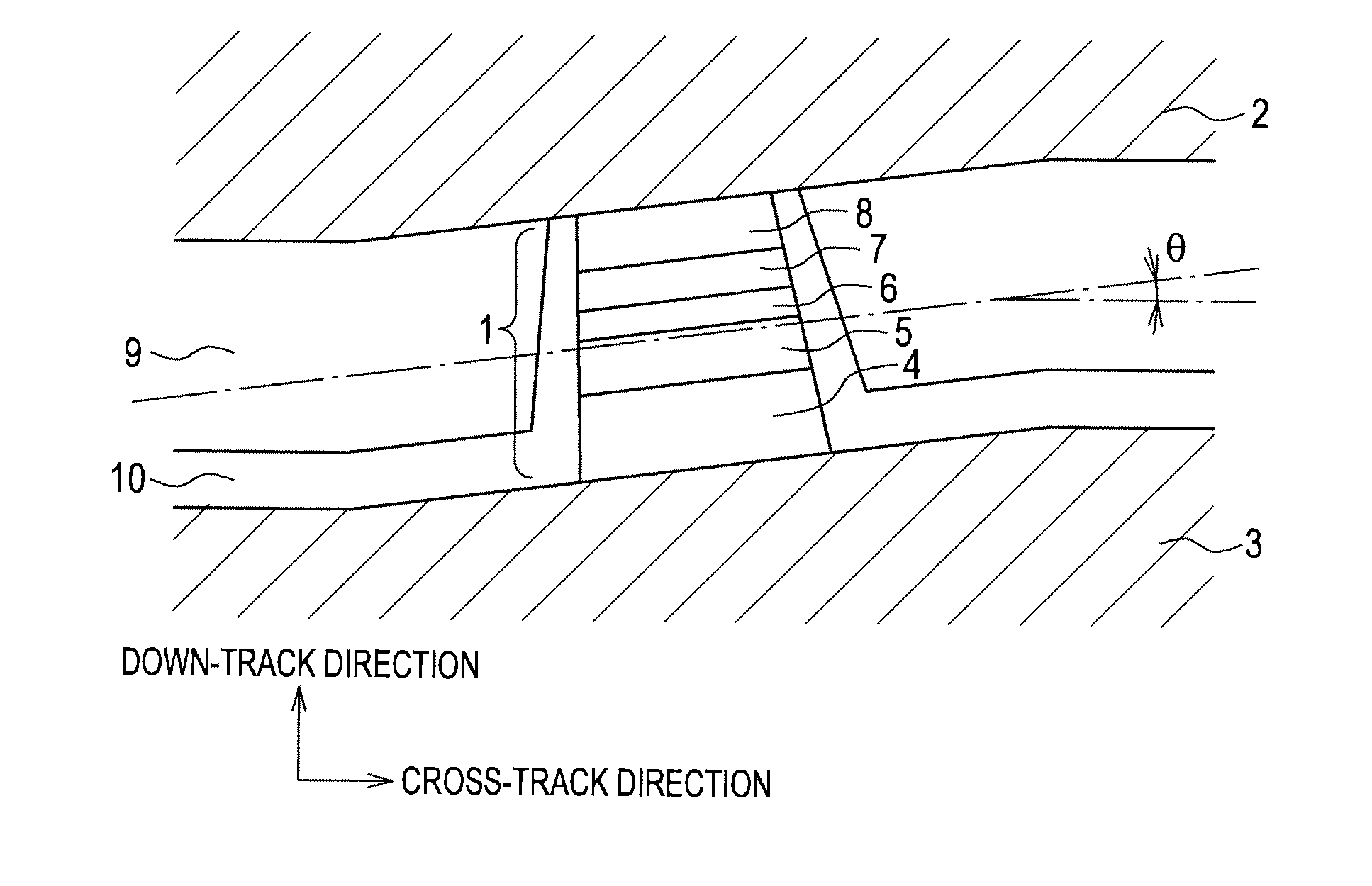

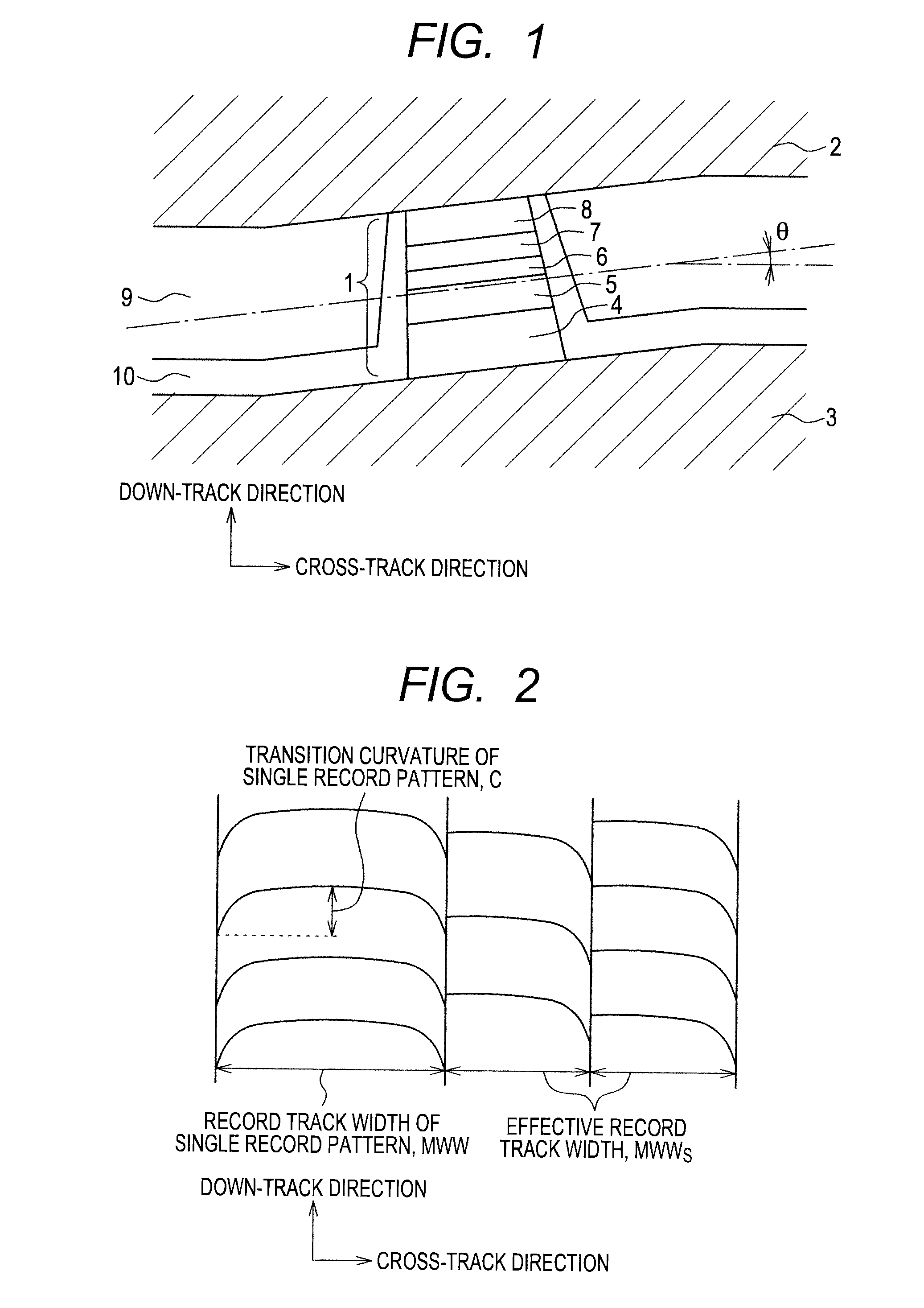

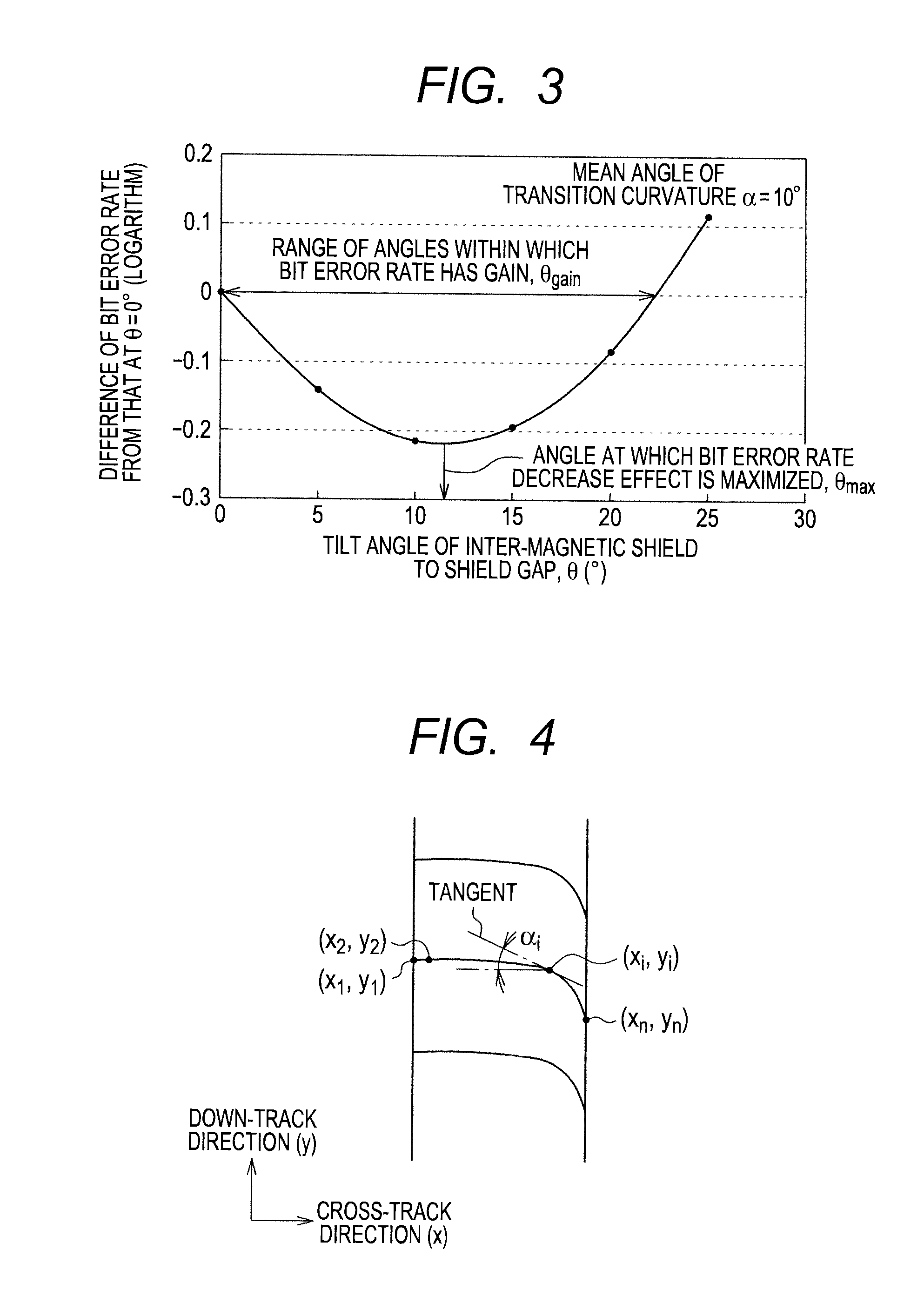

Magnetic head and magnetic disk drive to be used for shingled recording method

InactiveUS20110292545A1Declining signal resolutionReduce signal to noise ratioConstruction of head windingsRecord information storageSignal-to-noise ratio (imaging)Image resolution

In a magnetic head to be used for a shingled recording method, degradation of a signal resolution and a decrease in a signal-to-noise ratio which are caused by an asymmetrical inter-bit transition curvature are prevented, and a low bit error rate is realized. A magnetic head includes a recording head and a reproducing head. The reproducing head includes a pair of magnetic shields and a sensor sandwiched between the pair of magnetic shields. The gap between the magnetic shields is formed so that the longitudinal direction thereof gets inclined by a certain angle with respect to a cross-track direction in line with the shape of a curvature of an inter-bit transition on an effective record track in a record pattern recorded on a recording medium.

Owner:HITACHI LTD

Planar perpendicular recording head

A magnetic head (slider) for perpendicular recording which requires no lapping is described. The head is fabricated with an air bearing surface that is parallel to the wafer surface. The coil and pole pieces are formed from thin films disposed parallel to the air bearing surface. Standard lithographic techniques can be used to define the shapes, gaps and pole piece dimensions. Non-rectilinear shapes can be formed; for example, side shields that conform around the write pole piece region. The thickness of the main and return pole pieces are controlled by the deposition process rather than by lapping. The saw cuts used to separate the individual sliders from the rest of the wafer are perpendicular to the air-bearing surface and do not pass through any critical features.

Owner:WESTERN DIGITAL TECH INC

Magnetic head having heat sink structure

InactiveUS7193817B2Improve cooling effectComponent is quite sensitiveConstruction of head windingsHeads using thin filmsElectricityMagnetic poles

Owner:WESTERN DIGITAL TECH INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com