Traditional putter with elevated mass

a putter and mass technology, applied in the field of golf clubs, can solve the problems of reducing affecting the accuracy of the roll, and the ball being launched too high with the old prior art style putter, so as to achieve the required roll distance, and improve the accuracy of the roll. the effect of accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

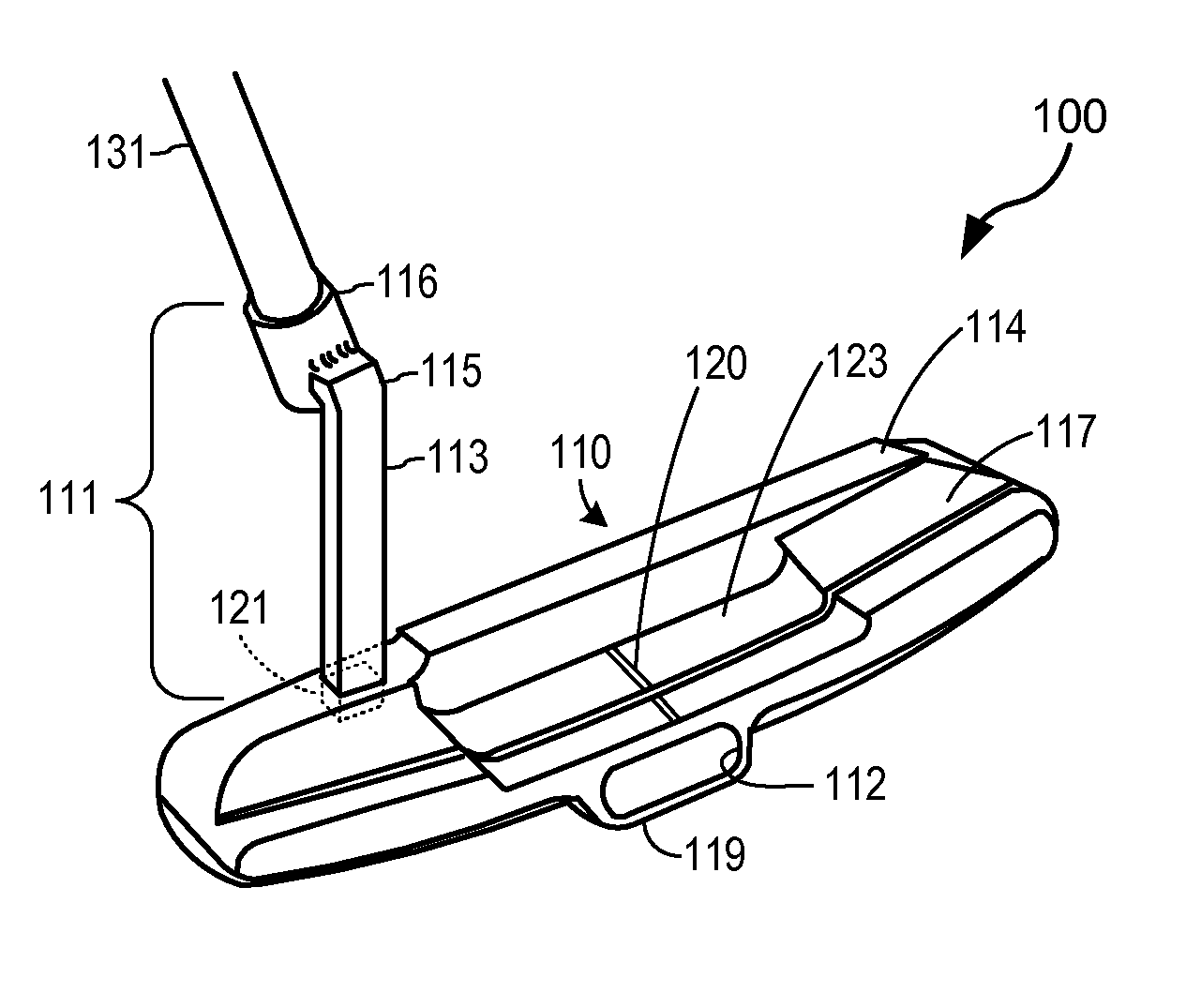

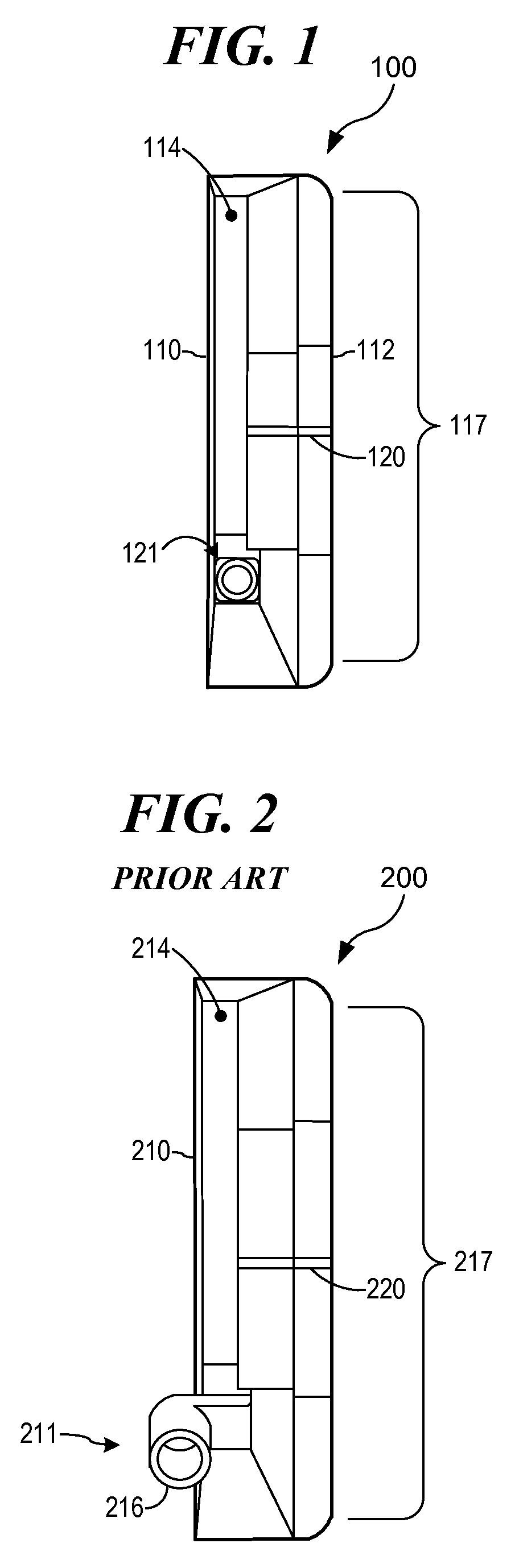

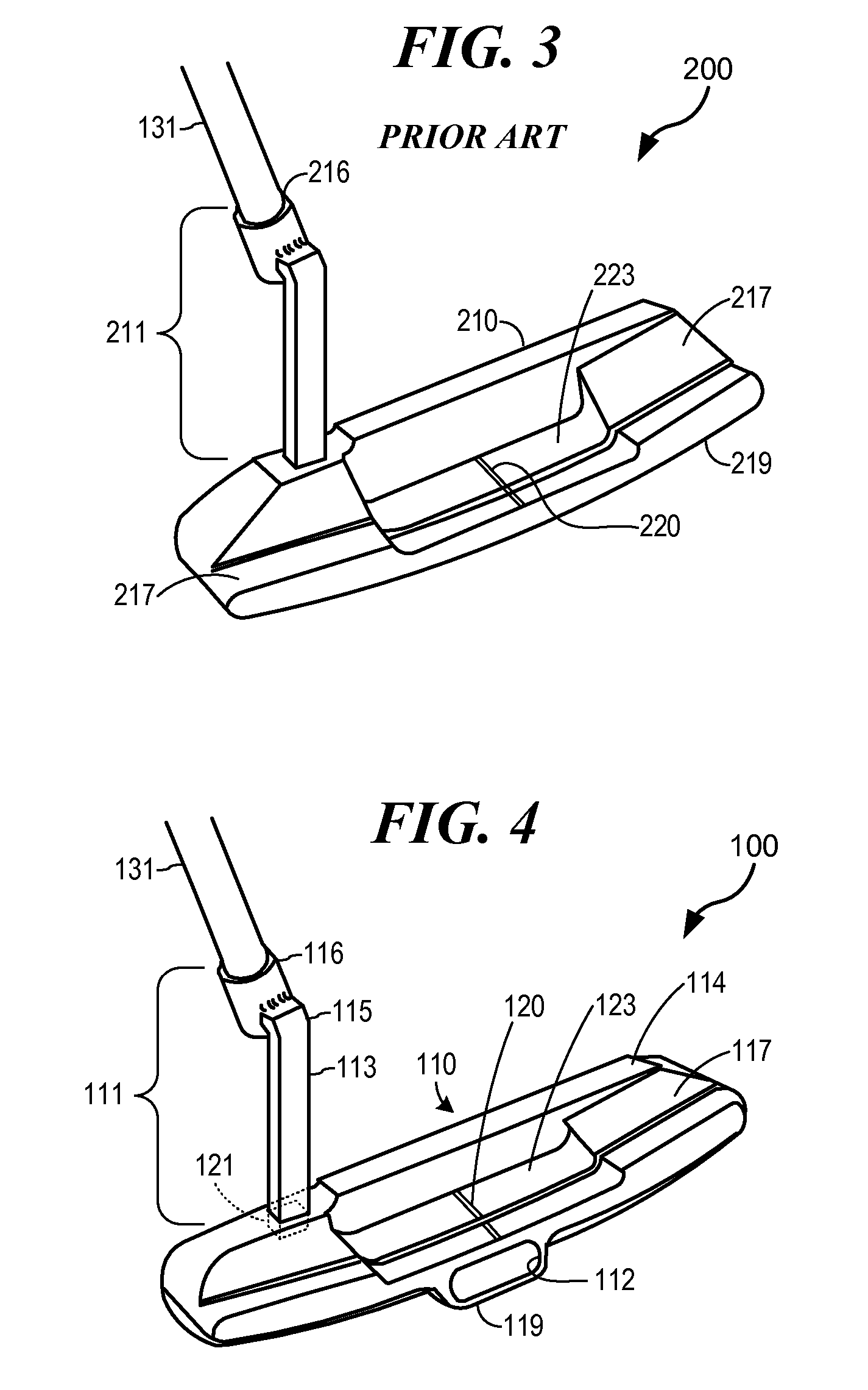

[0024] Referring to FIGS. 1, 4, 7 and 8 of the drawings, the reference numeral 100 generally designates a putter head embodying features of the present invention. The putter head 100 generally comprises a face portion 110, the cavity box sole 112 and elevated flange portion 117, a top-line portion 114, and a hosel or “gooseneck” portion 111 with an opening 116.

[0025] The golf club head 100 is shown in a finished state such that the top-line portion 114 includes an optional alignment mark 120 and the face portion 110 includes optional milled grooves and / or punch marks or other surface treatment as permitted by the USGA and R&A Rules. Preferably, the golf club head 100 in a finished state has been sanded, painted and / or plated and polished as desired.

[0026] In one embodiment a metal billet is CNC machined, bead blasted, nickel plated, finished, polished, painted in the engraved areas, assembled with a modular hosel 111, a shaft 131 and a grip (not shown). In one embodiment, the stoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com