Device and a process for applying a preparation fluid to an advancing thread

a technology of preparation fluid and thread, applied in the direction of textile treatment with outlet contect, transportation and packaging, spraying/projecting, etc., can solve the problems of preparation fluid getting, and achieve the effect of avoiding contamination of the environment of the housing, avoiding threading of eyes, and simple manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

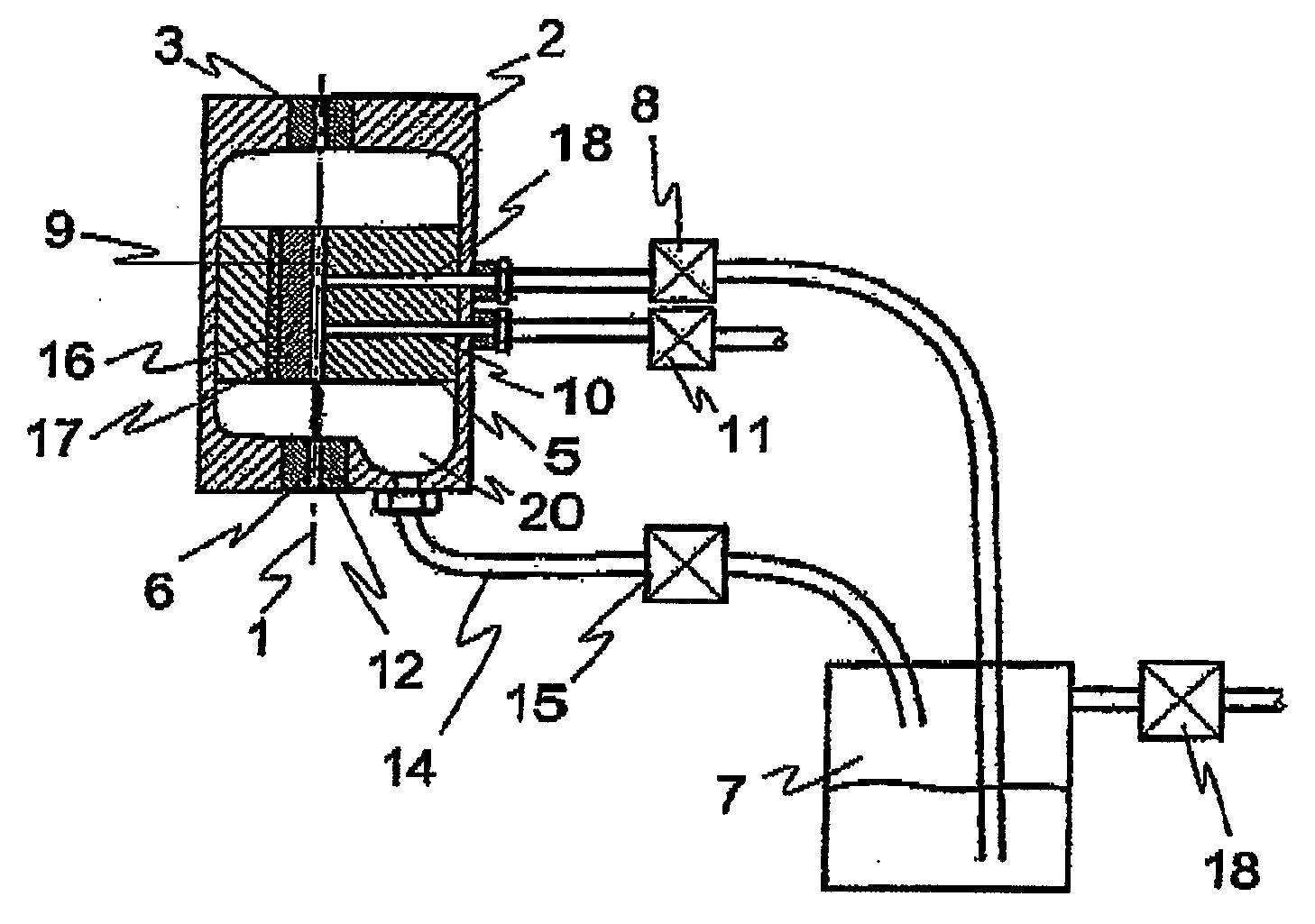

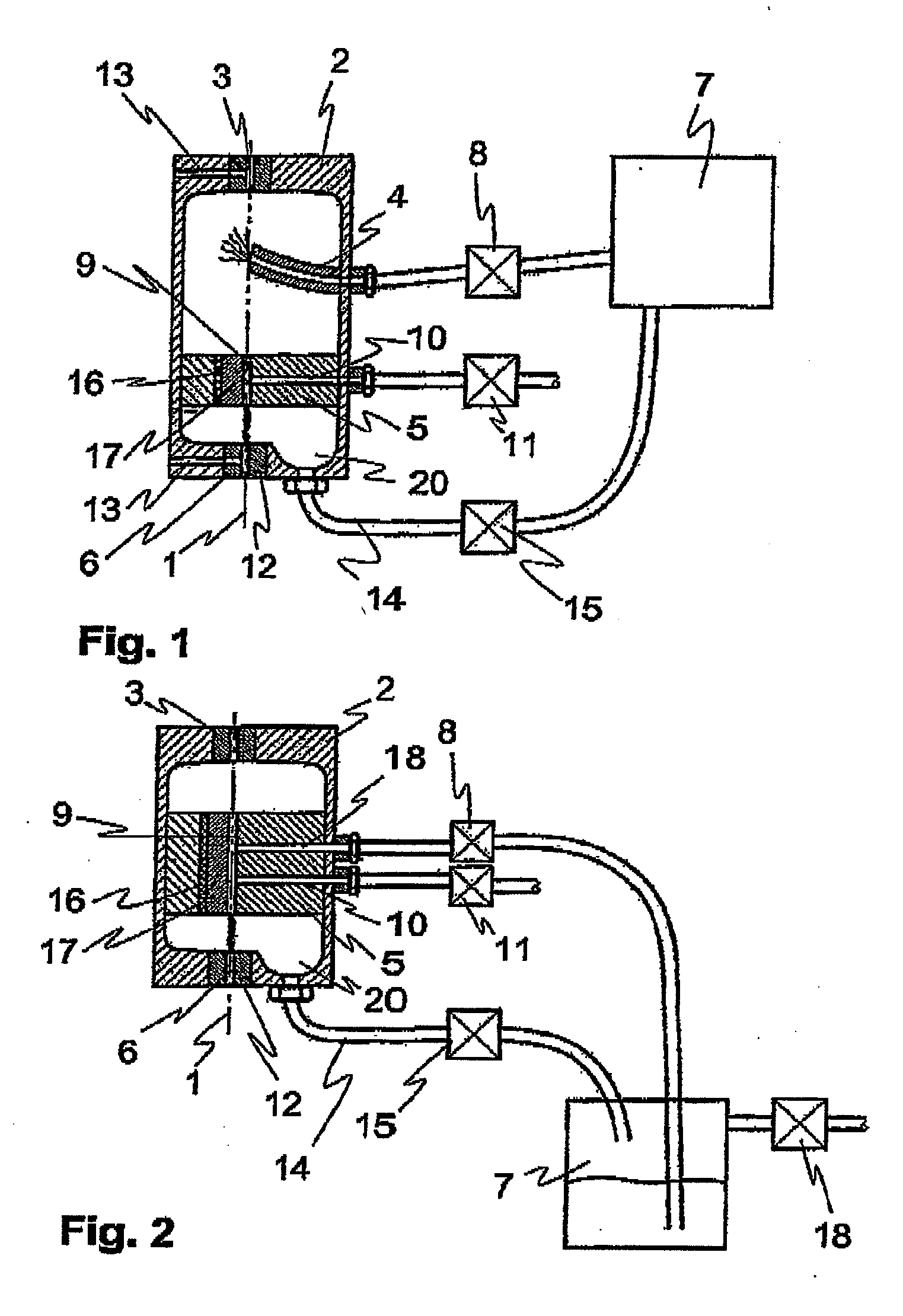

[0040]FIG. 1 shows a complete device for applying a preparation to an advancing thread or yarn in accordance with the invention. A thread 1 runs through a thread inlet opening 3 of a housing 2, is moistened in the preparation device 4, here a pin oiler, with oil as the preparation agent, and is subsequently swirled in a swirling device 5. Due to the swirling there is a uniform mixing and moistening of the individual filaments of the thread 1 with the oil. After the swirling, the thread 1 exits the housing 2 at the other end through an outlet opening 6.

[0041] The oil supply from an oil container 7 is controlled with an oil regulator 8. The thread 1 is tangent to the preparation device 4 and is pressurized with oil which flows out of a supply orifice of the preparation device 4. The embodiment of the preparation device 4 can be according to the present state of the art as generally known. In the direction of the run of the thread after the preparation device 4 the swirling device 5 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| spinning speeds | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com