Gas gun having pressure driving device

a driving device and gas gun technology, applied in the field of compressed gas guns, can solve the problems of increasing manufacturing costs, and achieve the effect of reducing the manufacturing cost of compressed gas guns and simplifying the manufacturing process of compressed gas guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

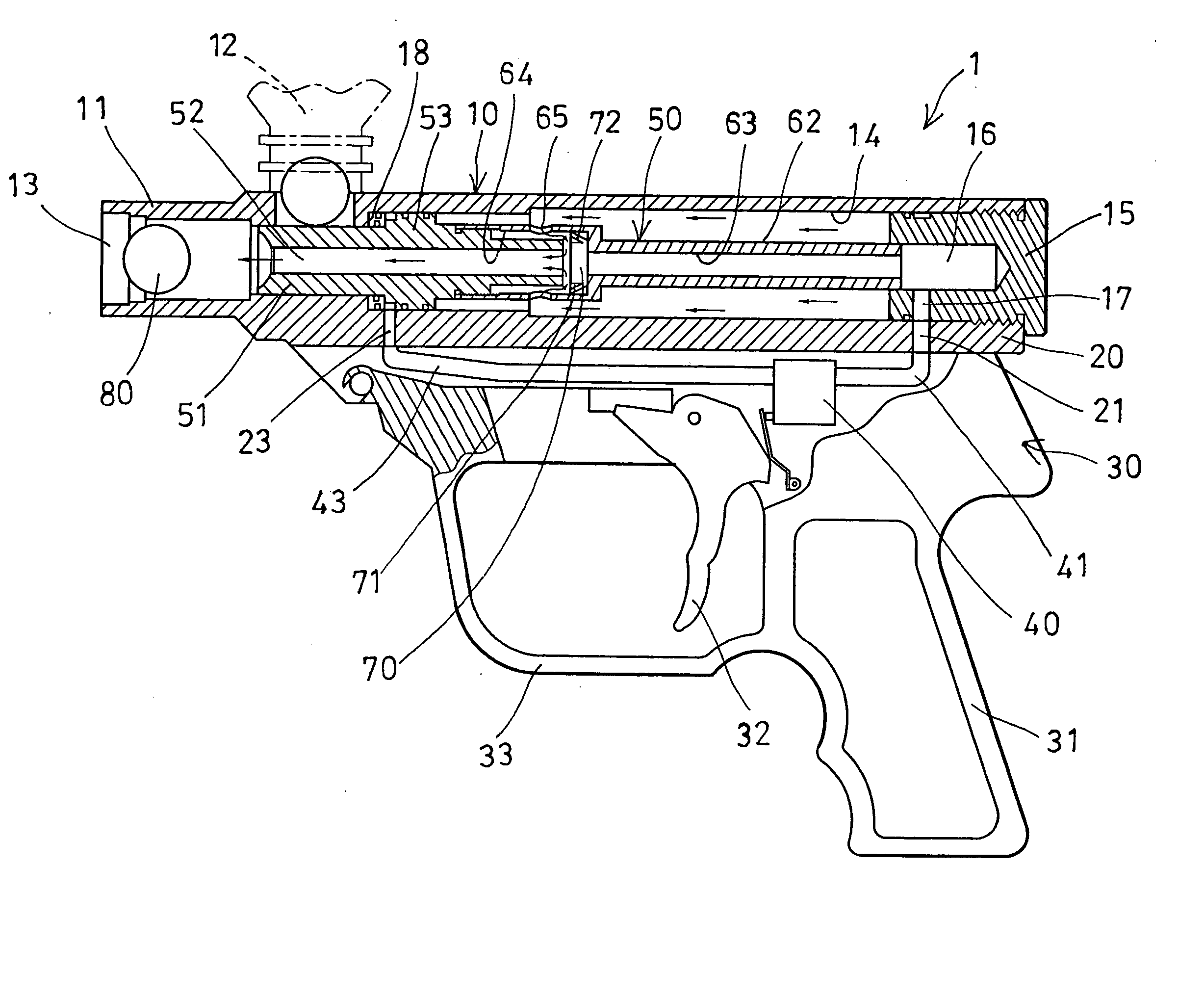

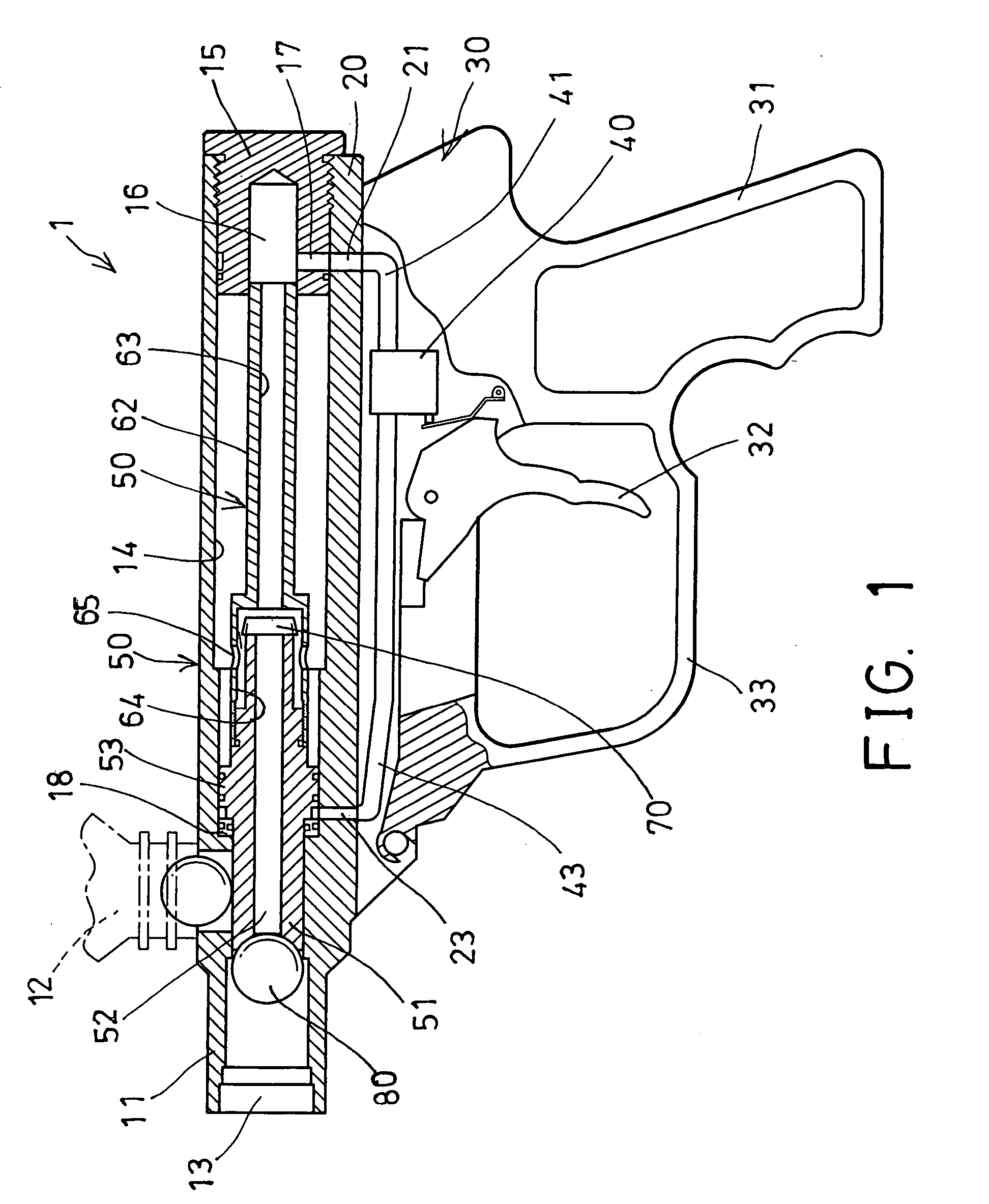

[0022] Referring to the drawings, and initially to FIGS. 1-2, a compressed gas gun 1 in accordance with the present invention comprises an upper housing 10, and a lower housing 30 having a hand grip 31 extended downwardly therefrom for being grasped or held by the users. The upper housing 10 includes a barrel 11 provided or extended forwardly therefrom, and a projectile feed tube 12 attached to the barrel 11 and opened into the barrel 11 for feeding or supplying projectiles 80 into a bore 13 of the barrel 11 one at a time. The bore 13 may be formed in the barrel 11 and / or in the upper housing 10.

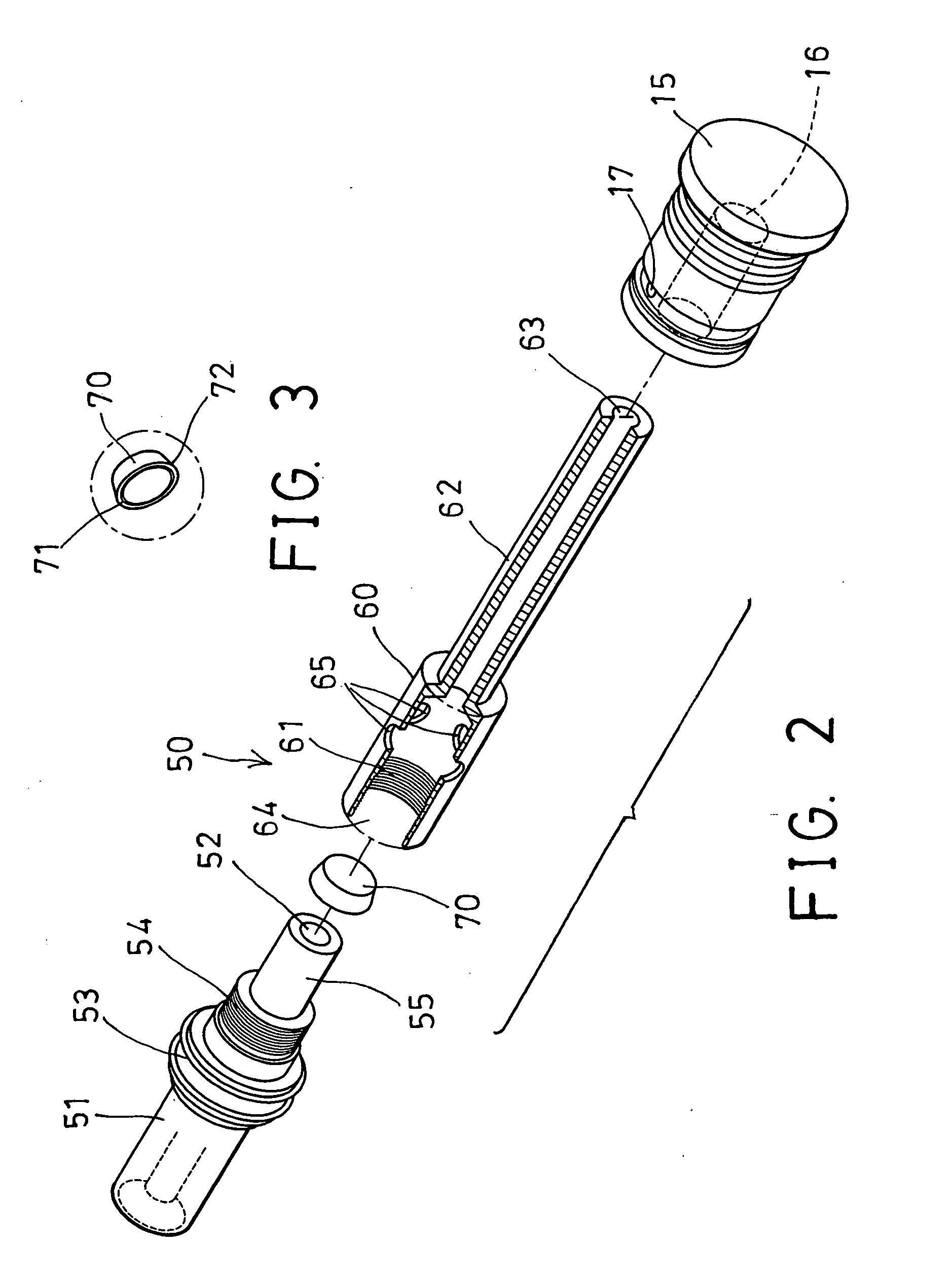

[0023] A loading device 50 includes a loading bolt 51 slidably disposed or engaged in the upper housing 10 or in the bore 13 of the barrel 11, and movable to engage with the projectile 80 that is supplied or fed into the barrel 11 (FIGS. 1, 4) and for feeding or loading the projectile 80 forwardly toward a firing position (FIG. 4). The loading bolt 51 includes a passage 52 formed therein an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com