Heat activated air shutter for fireplace

a technology of activated air and fireplace, which is applied in the field of fireplaces, can solve the problems of dangerous conditions, soot or unburned carbon deposits, and the steady state operation of a gas fireplace typically takes 30 minutes or more, and achieves the effect of increasing the intake air and reducing the intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be described in detail with reference to certain embodiments thereof as illustrated in the accompanying drawings. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention and how it may be applied to a gas fireplace. It will be apparent, however, to one skilled in the art, that the present invention may be practiced without some or all of these specific details. In other instances, well-known process steps and / or structures have not been described in detail to prevent unnecessarily obscuring the present invention.

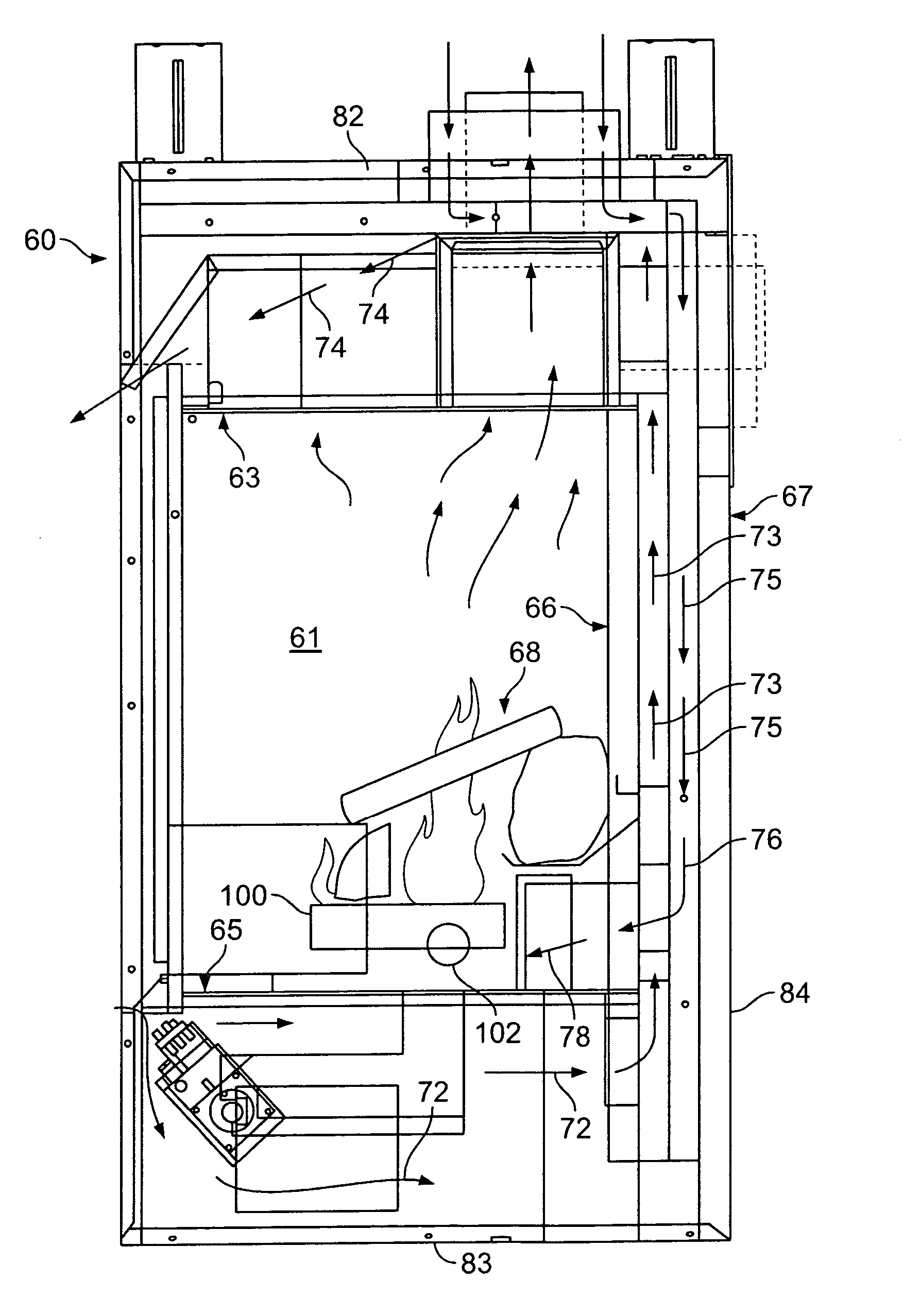

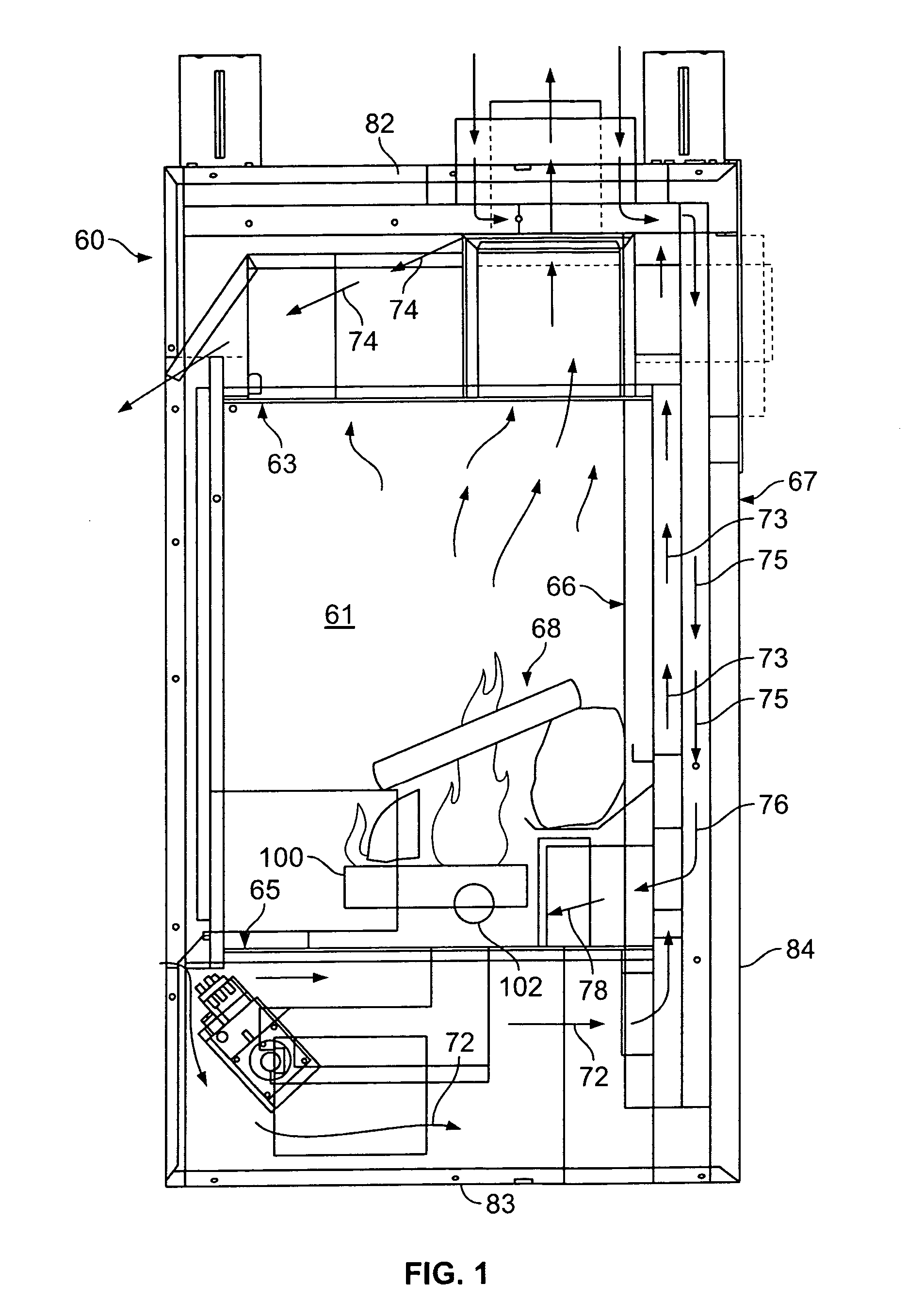

[0041]FIG. 1 illustrates a gas-fueled heating unit, which in a preferred embodiment is a fireplace in accordance with one embodiment of the present invention. Referring to FIG. 1, a gas heating unit 60 includes a combustion chamber 61 with sidewalls (not shown), a rear wall 66 and top and bottom walls 63 and 65. Simulated logs, e.g., ceramic gas logs 68 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com