Drives pertaining to a reel changer

a technology of drives and reel changers, applied in the field of drives of reel changers, can solve problems such as the inability to tense the cones, and achieve the effects of preventing friction, high functionality, and reducing the cost of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

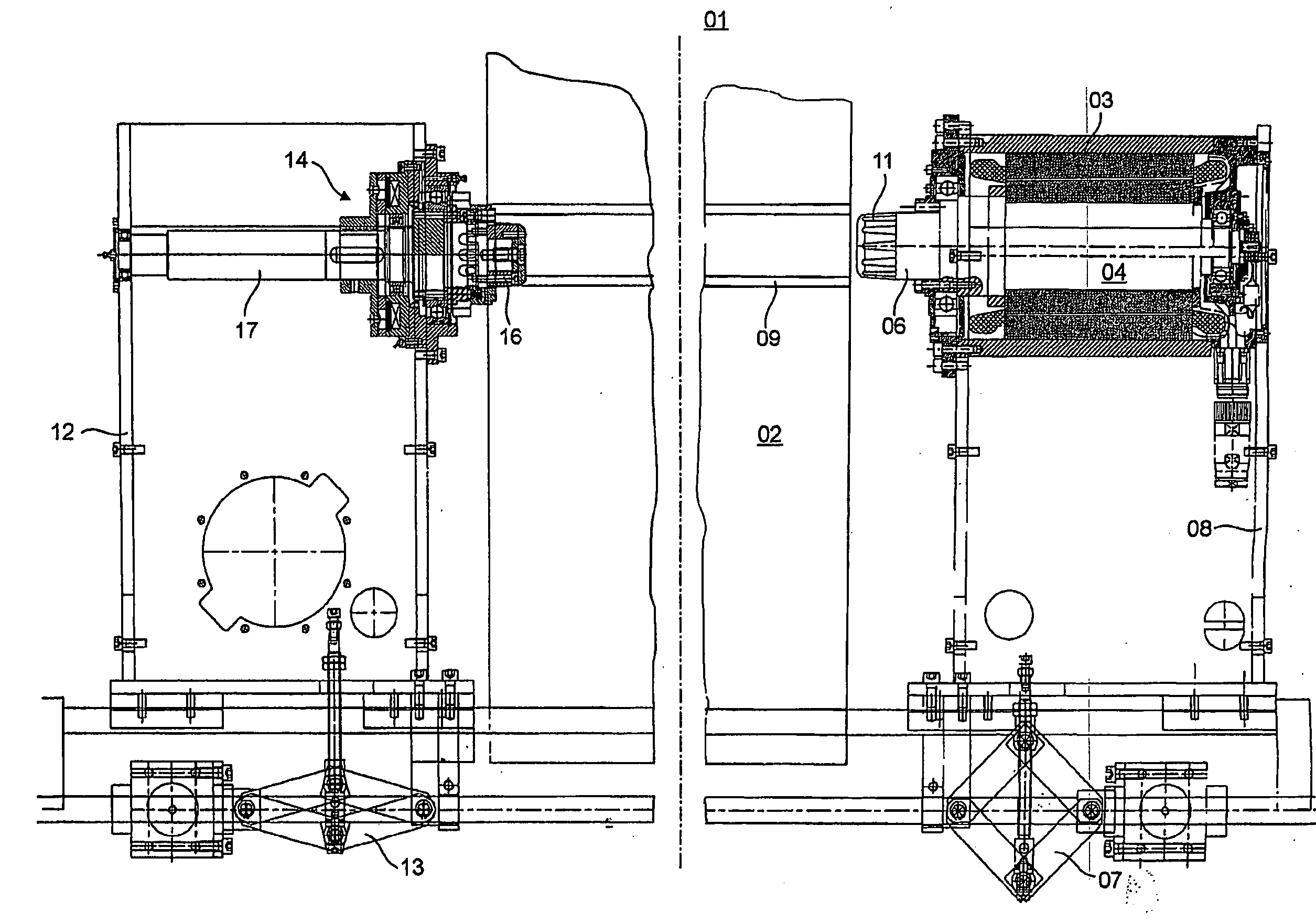

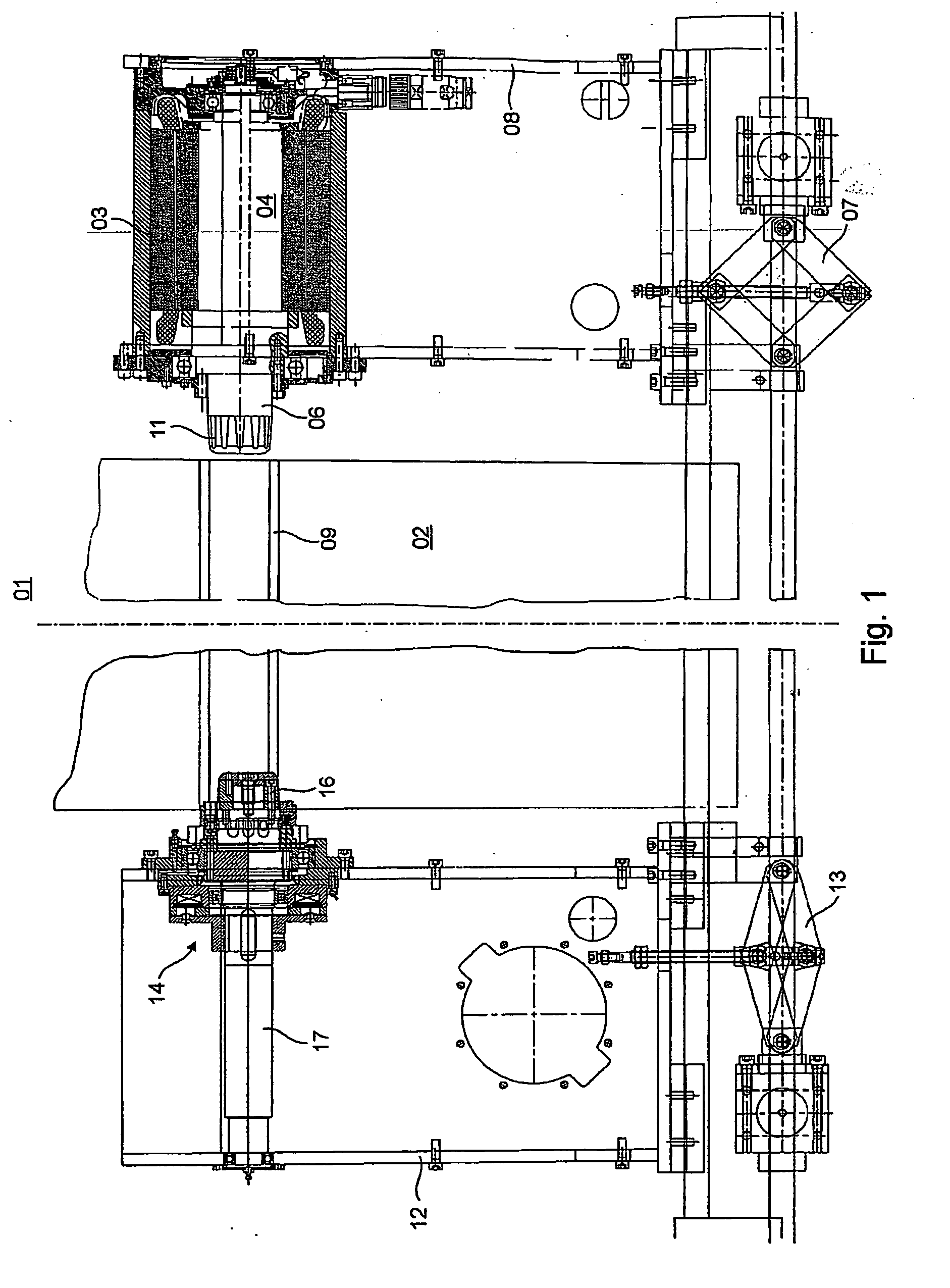

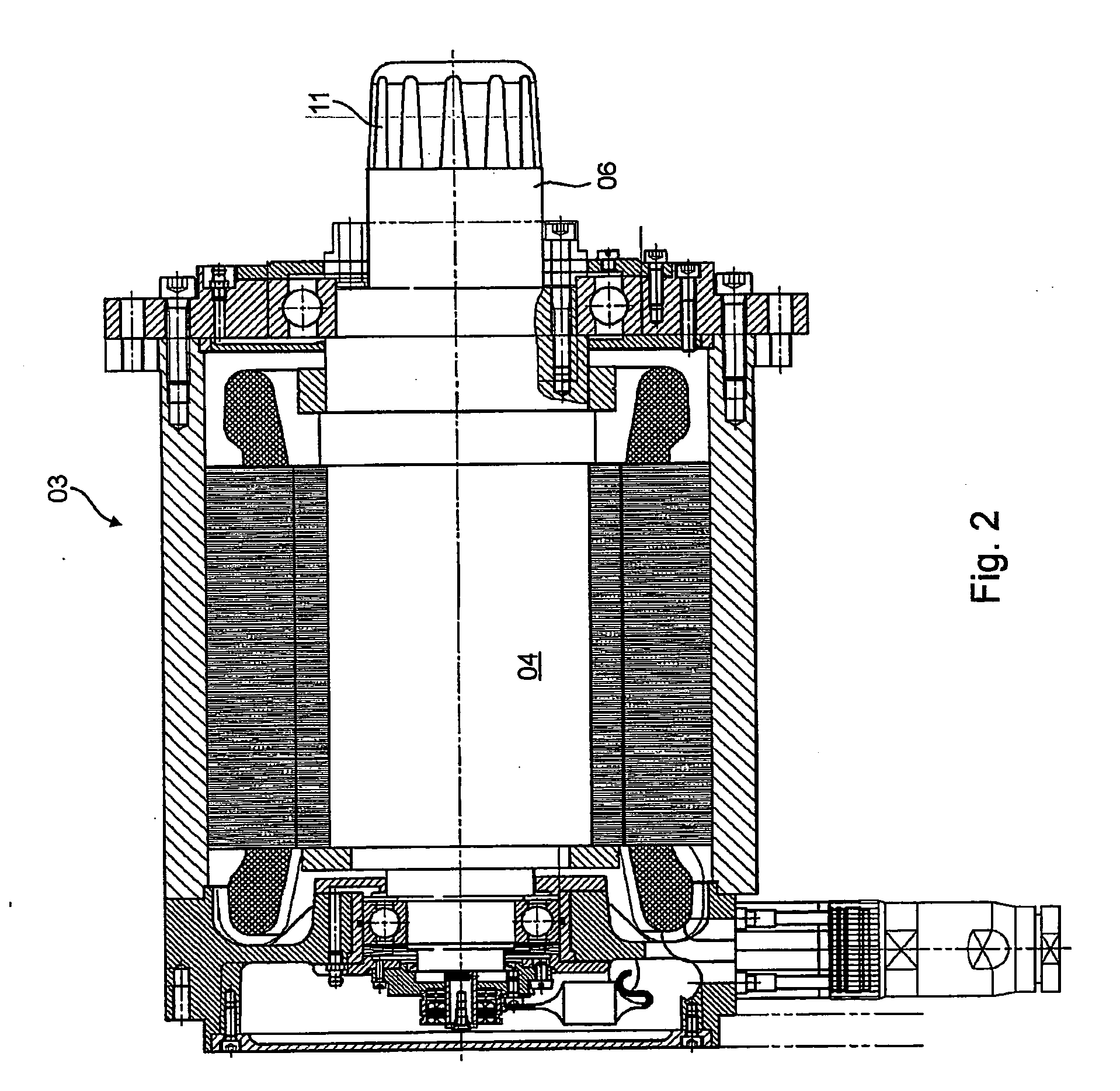

[0043] Referring initially to FIG. 1, there is shown a partial cross-sectional view of a reel changer 01, and in particular a reel changer for a rotary, web-fed printing press, for use in supporting a supply reel 02 having a width, of for example, from 300 mm to 1000 mm, and upon which a material web, such as, in particular, a web of printable material, has been wound. For the purpose of driving the supply reel 02, a motor 03, and in particular a synchronous motor 03, has been provided on one side of the supply reel 02. The synchronous motor 03 has a drive shaft 04 that protrudes past the housing of the synchronous motor 03 on a side of the motor which is facing the supply reel 02. This protruding side of the drive shaft 04 serves as a receiving unit 06, upon which the supply reel 02 may be rotationally supported.

[0044] An axial adjustor 07, which, as may also be seen in FIG. 1, is embodied in the manner of a scissor lever mechanism, supports a bracket 08 that is mounted in a shift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com