Sheet metal decoiling device and multi-coil decoiling system

a decoiling device and coil technology, applied in the field of metal building construction, can solve the problems of significant safety problems, significant dangers, and the nature of feed materials, sheet metal, coils to unroll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail of exemplary embodiments of the invention, as illustrated in the accompanying drawings. Whenever possible, similar reference numbers will be used throughout the drawings to refer to the same or like parts.

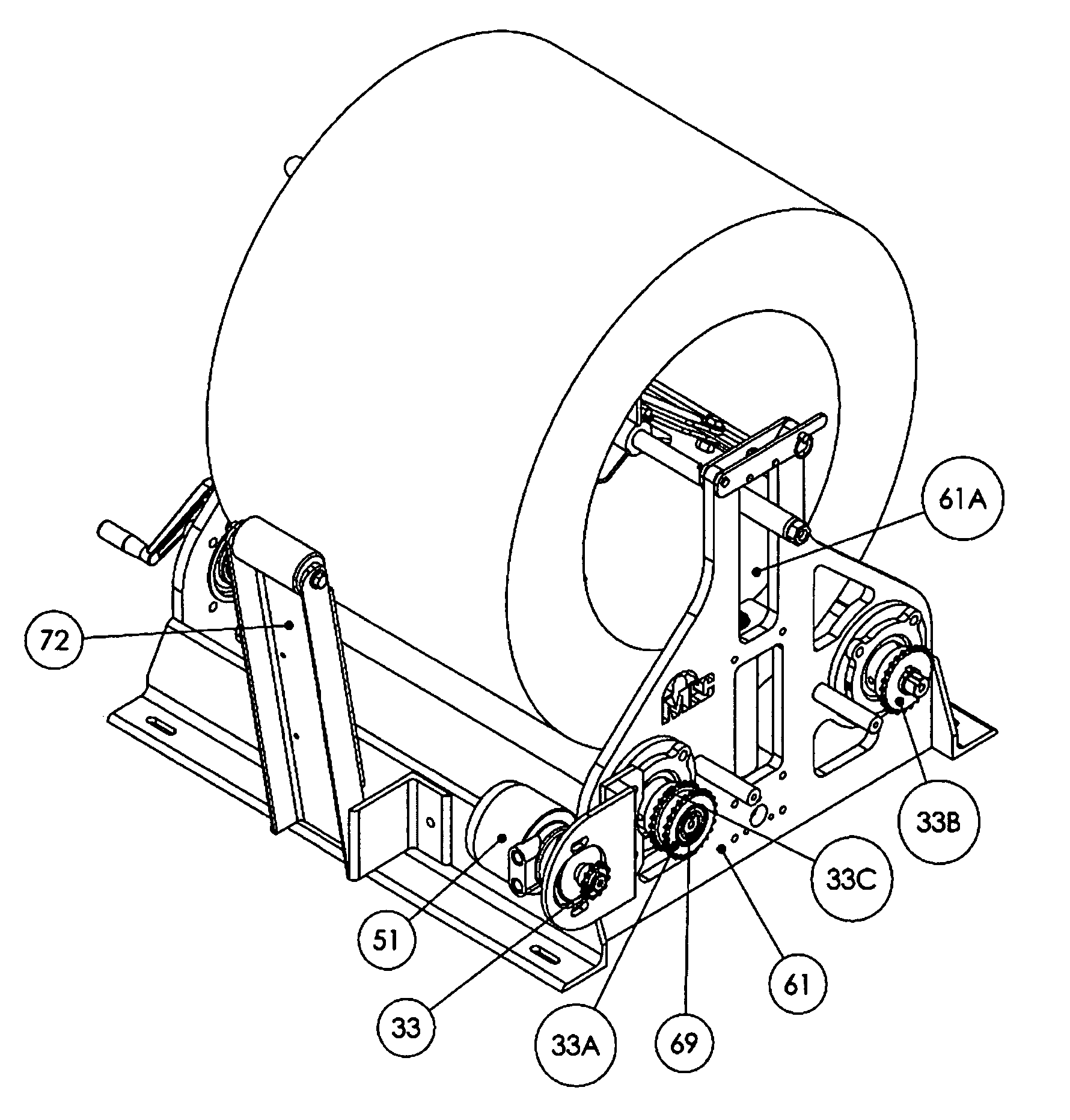

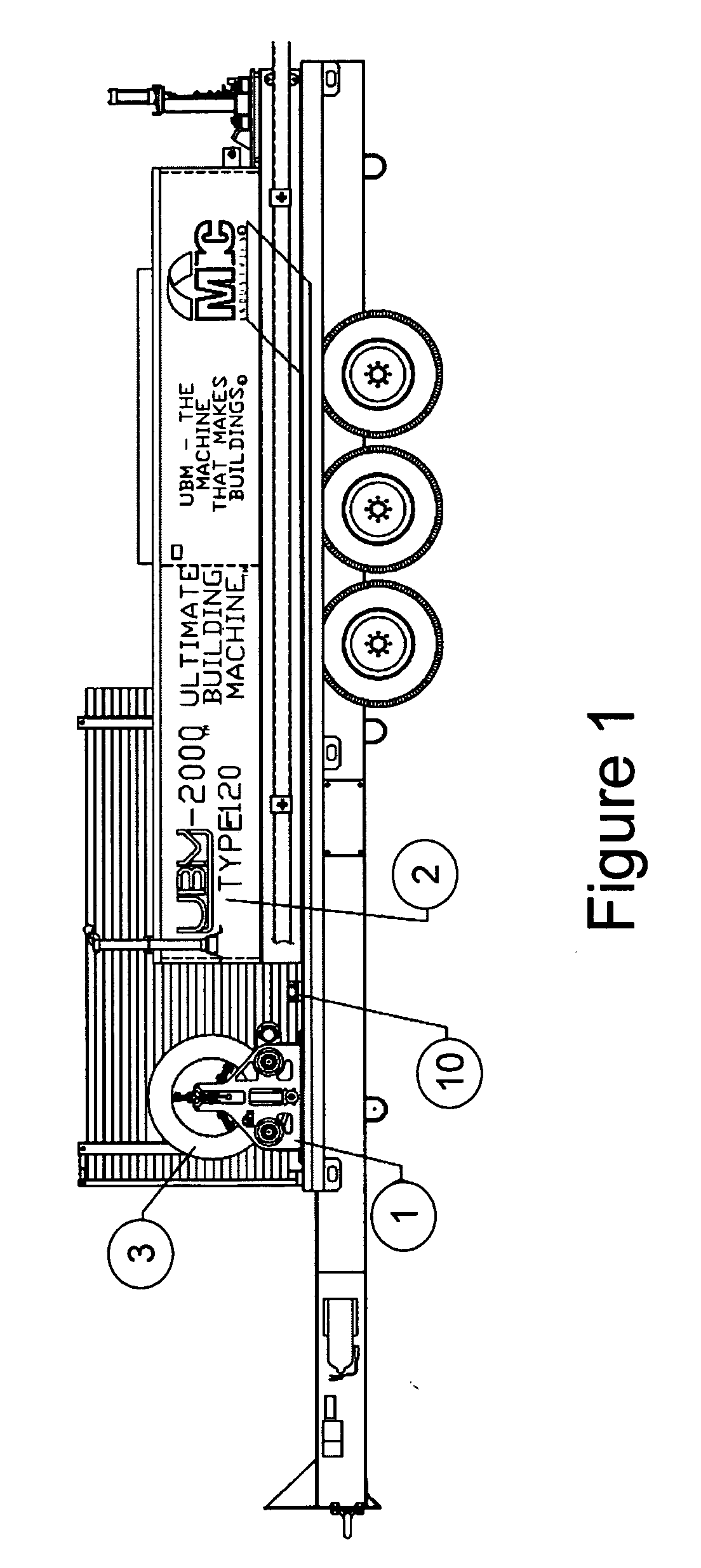

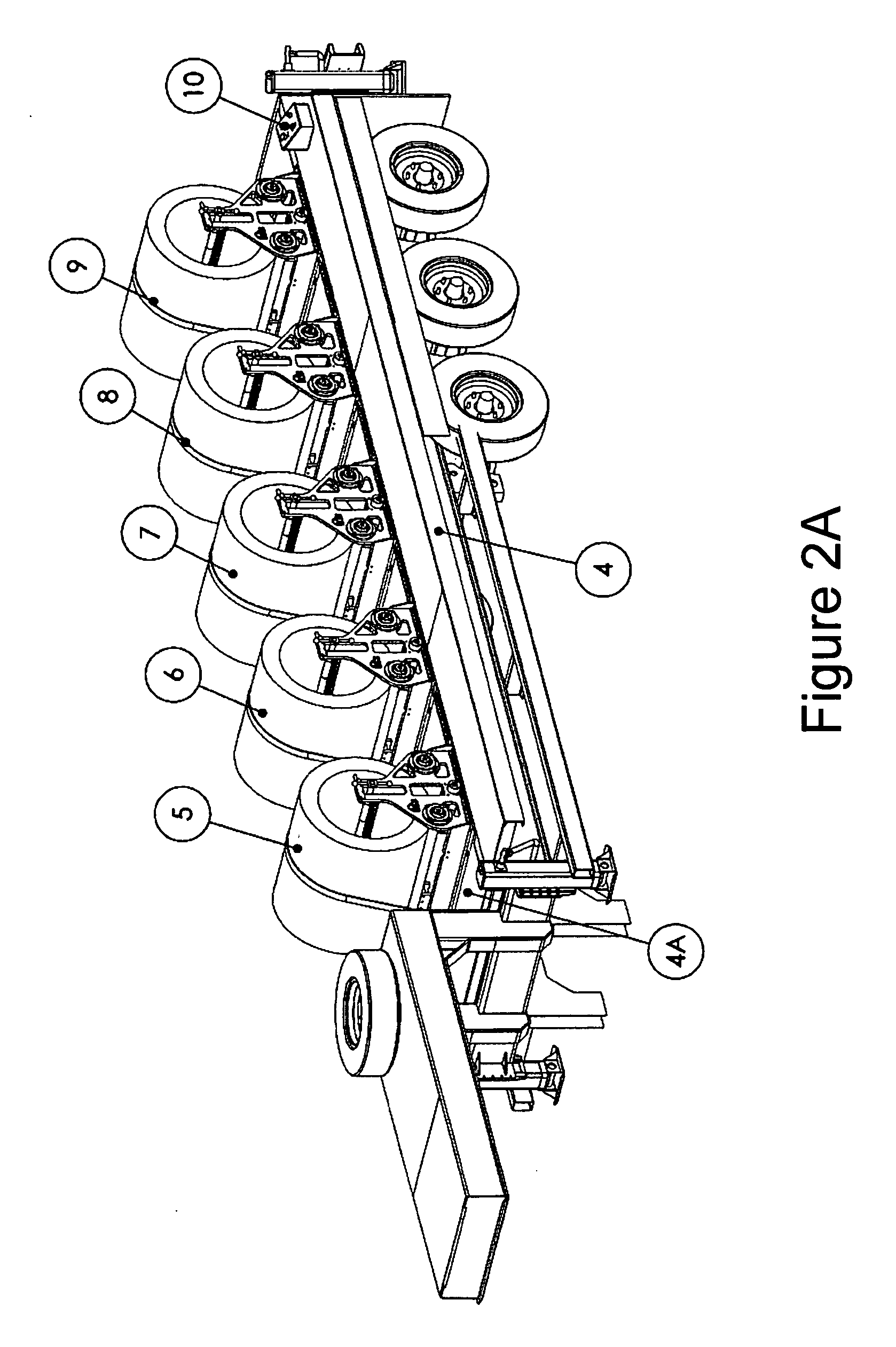

[0040]FIG. 1 shows a left-side view of an exemplary decoiling device 1 mounted on a support member of a self-contained building machine 2. The decoiling device 1 is mounted at the front of the trailer that supports the self-contained building machine 2. A coil 3 of sheet material (e.g., steel) is mounted on the decoiler 1 so that sheet material from the coil 3 can be fed into the building machine 2 for a roll-forming operation. An operator can employ the control panel 10 to control the decoiler's electrical and / or hydraulic mechanisms. The decoiling device 1 could be manually operated, instead of electrically or hydraulically operated, if desired, to suit the needs of the customer. The control panel 10 permits the operator one-handed con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| displacement | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com