Making pastry shells

a technology of pastry shells and shells, applied in the field of culinary arts, can solve the problems of not without certain limitations, relatively sharp bends and corners, baking pans, etc., and achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

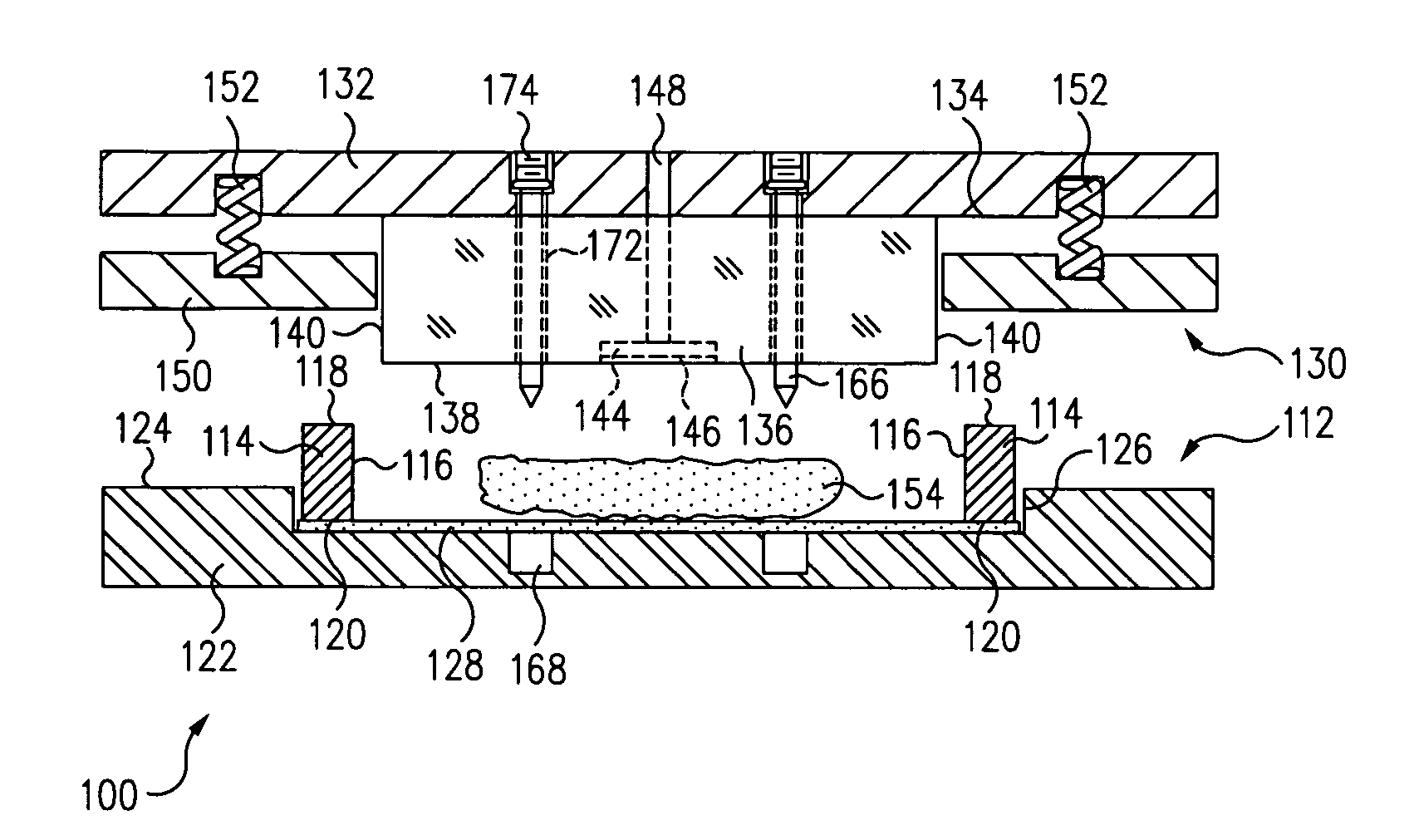

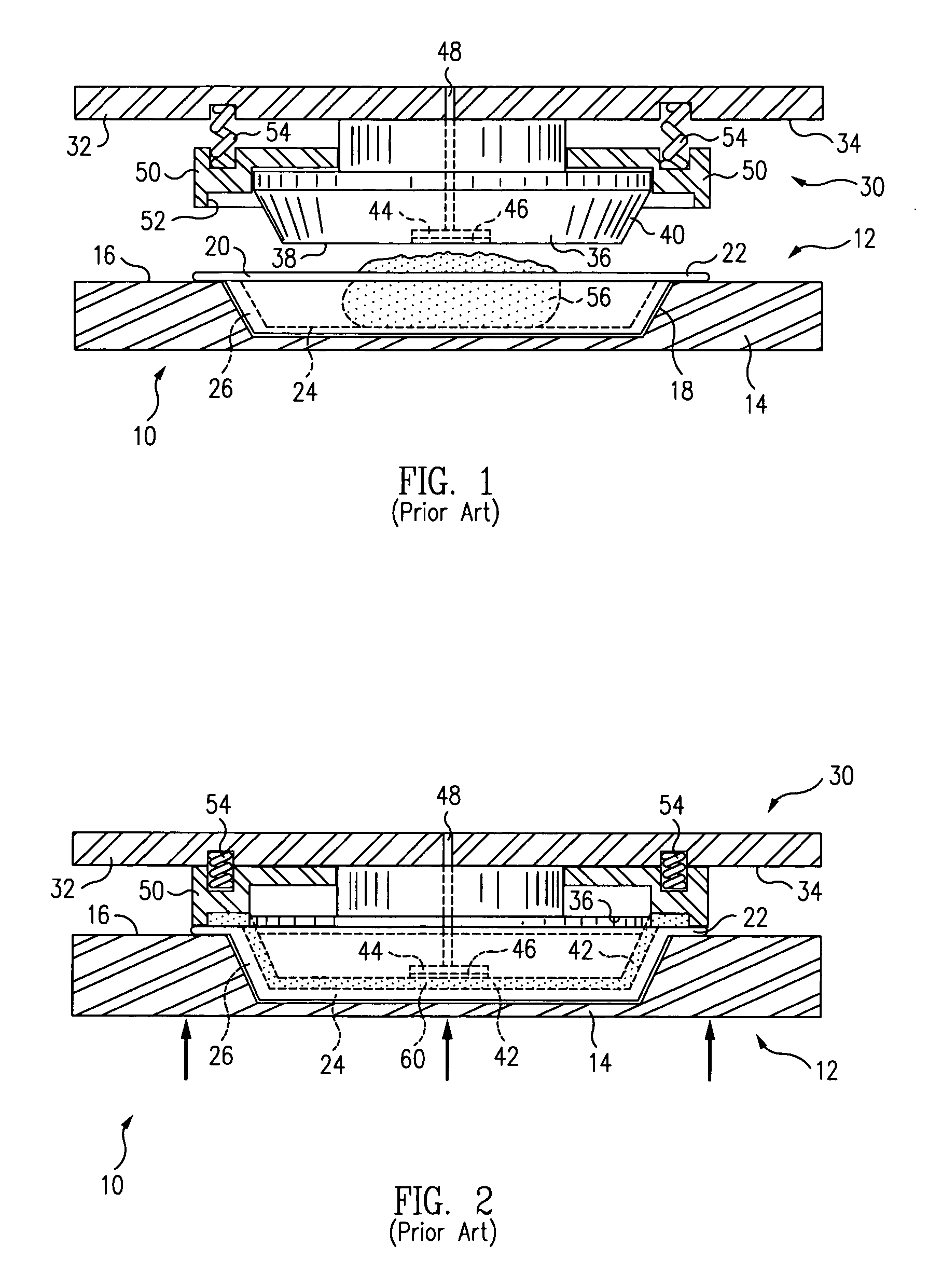

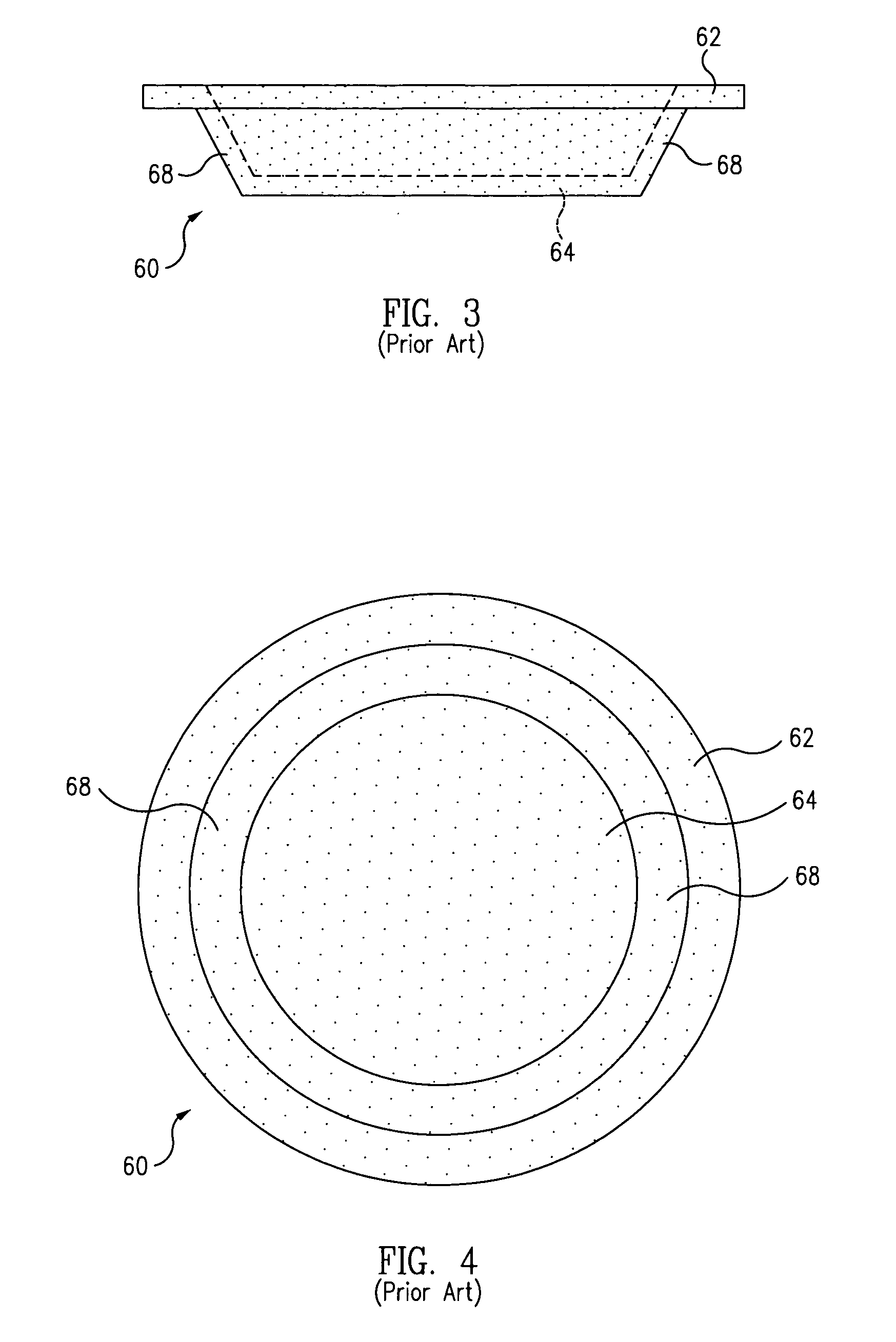

[0027] A prior art apparatus 10 for making pastry shells is illustrated in the partial cross-sectional elevation views of FIGS. 1 and 2. As shown in the figures, the prior art apparatus is seen to comprise two portions, a lower, female die portion 12 and an upper, male die portion 30. A conventional hydraulic press, used to urge the two portions together in a controllable manner to form the conventional pastry crust or shell 60 illustrated in the respective elevation and plan views of FIGS. 3 and 4, is omitted from the figures for clarity.

[0028] The lower, female die portion 12 of the prior art apparatus 10 comprises a lower support plate 14 having a horizontal upper surface 16 containing a recess 18 in which a conventional rimmed, frustoconical baking pan 20 is retained. As may be seen in the figures, the conventional baking pan includes a rim 22, a flat, closed floor or bottom 24, and upwardly flaring, or tapering, side walls 26.

[0029] The upper, male die portion 30 of the appar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com