Self spotting barbell press

a self-spotting and barbell press technology, applied in the field of self-spotting barbell press, can solve the problems of significant danger of serious injury, weight lifting without spotter, and danger, and achieve the effect of eliminating and reducing the need for spotter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In the following description, terms such as horizontal, upright, vertical, above, below, beneath, and the like, are used solely for the purpose of clarity in illustrating the invention, and should not be taken as words of limitation. The drawings are for the purpose of illustrating the invention and are not intended to be to scale.

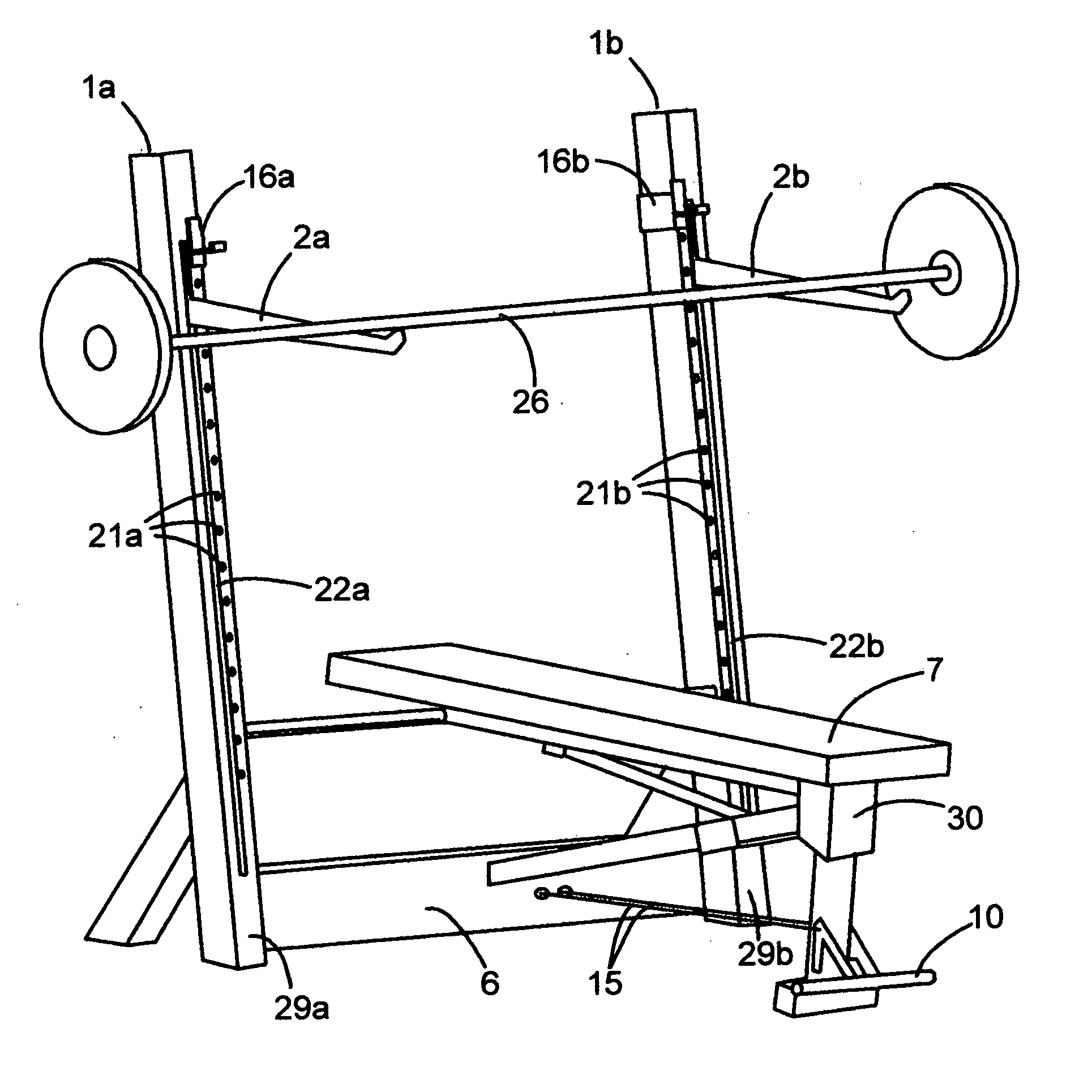

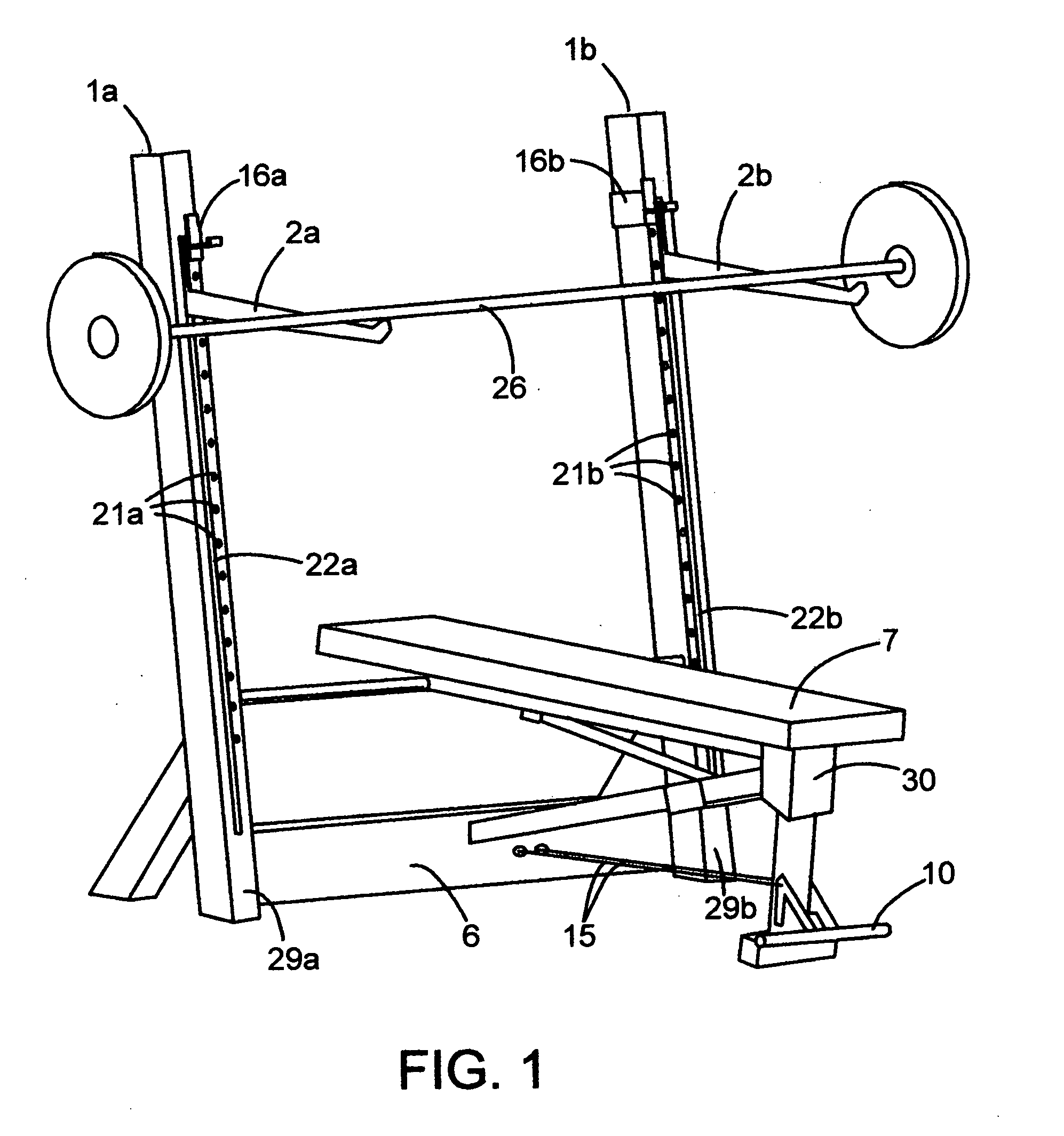

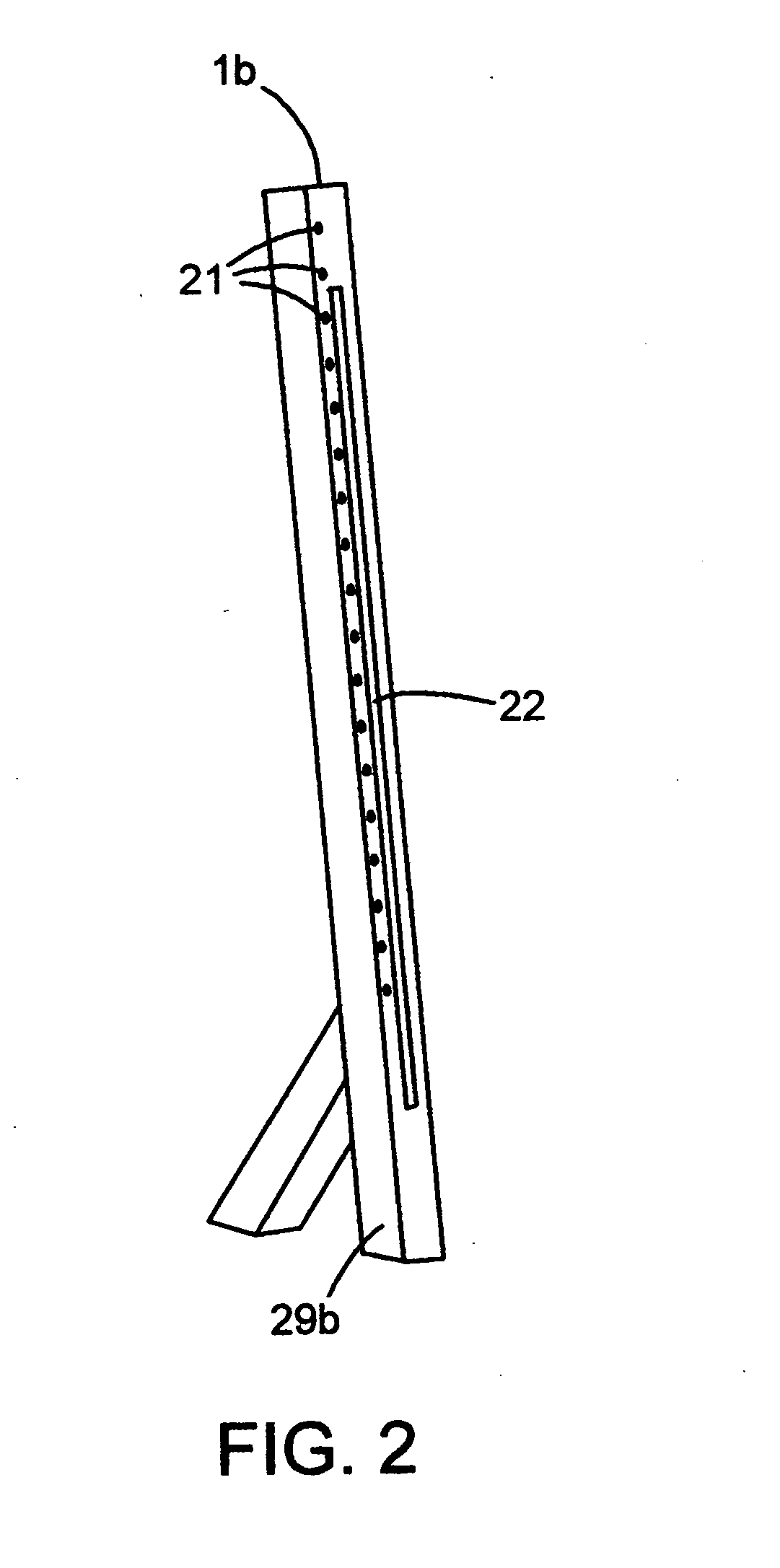

[0080]FIG. 1 shows a composite drawing of the device. There are two uprights (1a, 1b) parallel to each other and tilted slightly away from the longer side of the seat (7). Two adjustable weight rests (16a, 16b) are located on the inner side of each upright. Protruding from the front of each upright (1a, 1b) is a lifting arm (2a, 2b) that extends perpendicular to gravity, and in the direction of the seat (7) and adjustable seat frame (30). Each upright (1a, 1b) has a support (29a, 29b) and is connected to the other via a cross bar (6). Mounted to the cross bar (6) is an accumulator (8) (see FIG. 6) and a hydraulic cylinder (9) (see FIG. 6). Attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com