Tool holder with a locking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

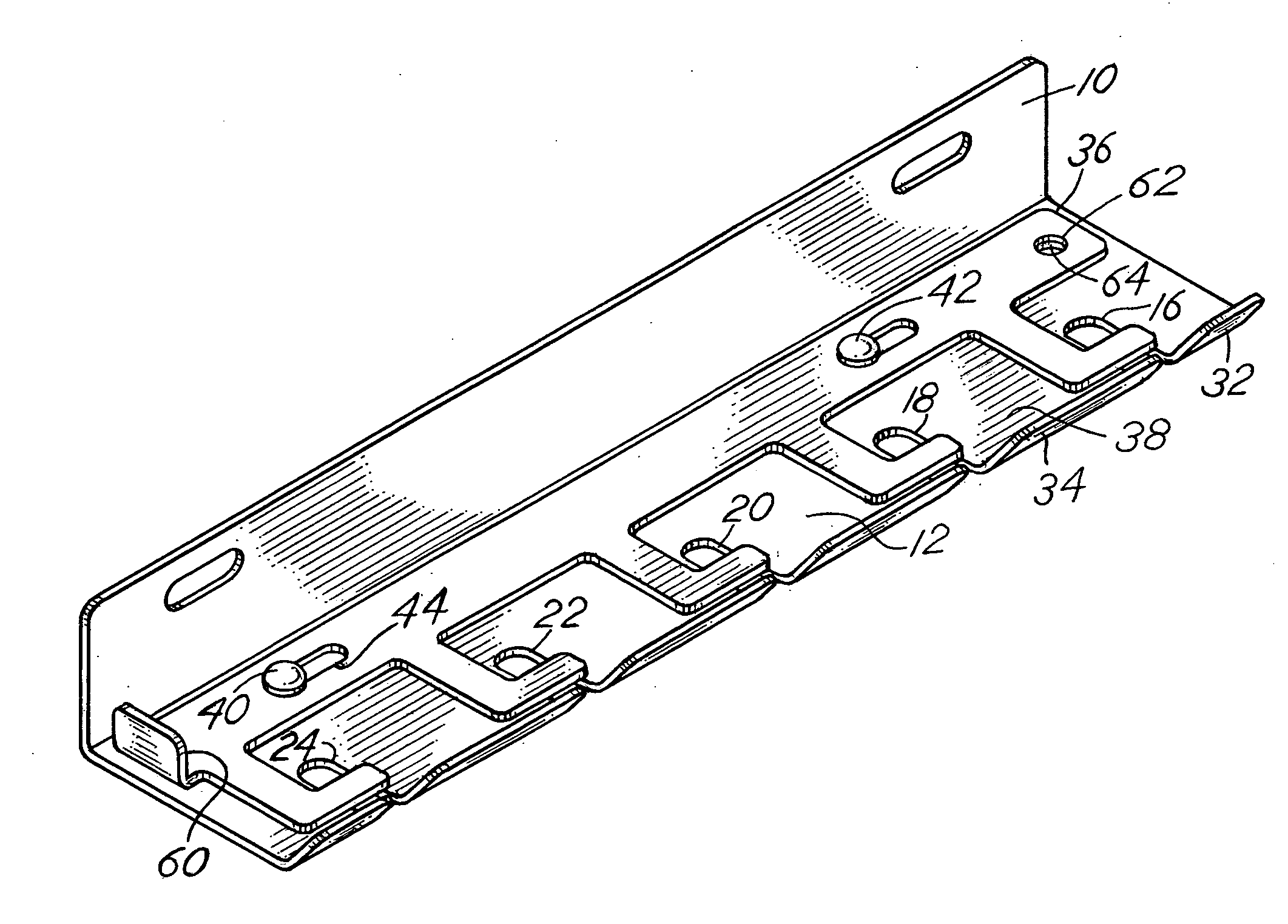

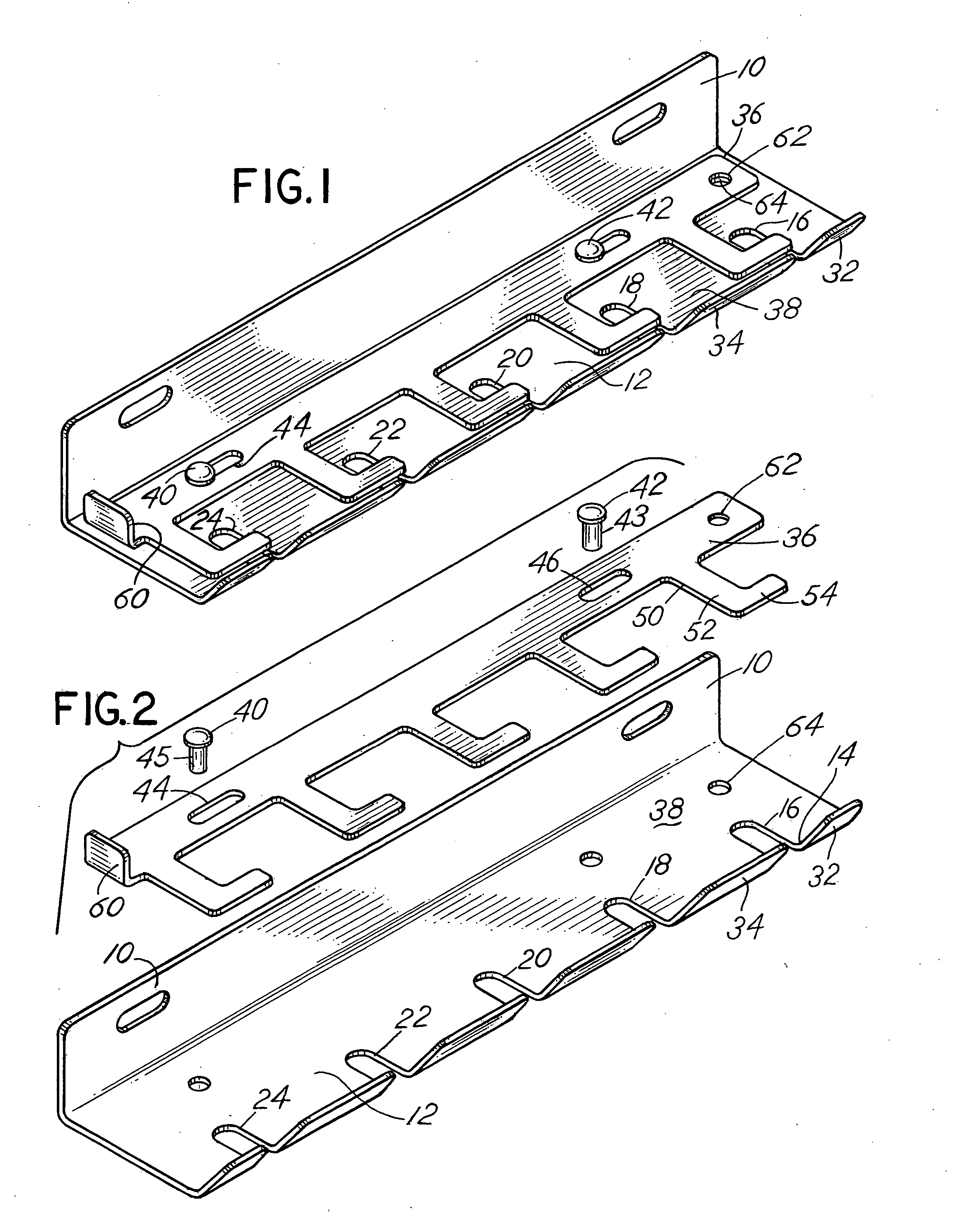

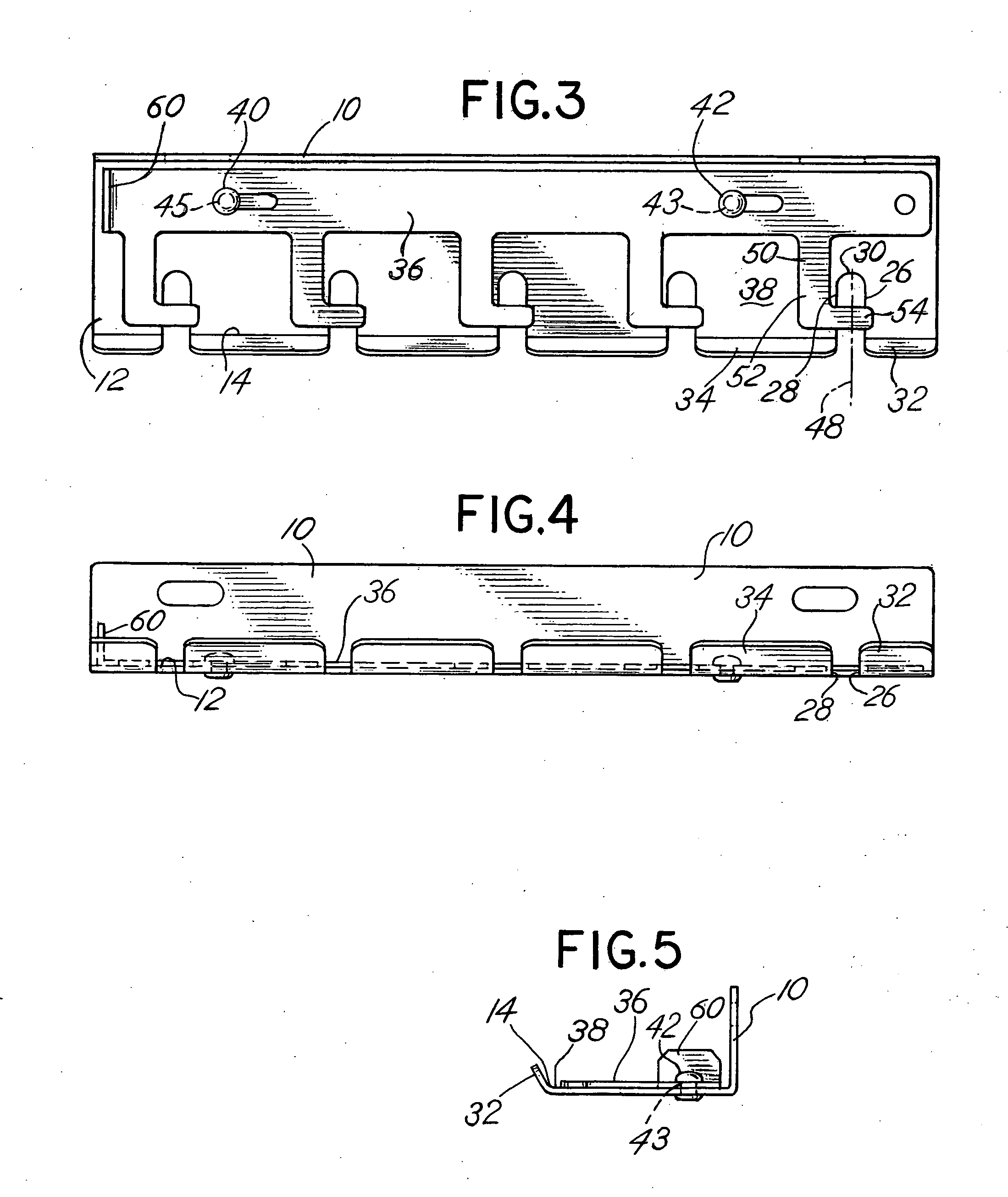

[0026] Referring to the figures, a first embodiment depicted in FIGS. 1-5A is comprised of a sheet or cast metal construction and includes a back mounting plate 10 with a generally integral, transversely extending tool support plate 12 projecting forwardly from the back mounting plate 10. The back mounting plate 10 and the forwardly extending tool support plate 12 are typically fabricated from a formed sheet steel material, although the component parts may be cast or otherwise formed, and may be formed separately and attached together by welding, for example. The tool support plate 12 includes a forward side 14 with a plurality of slots, such as slots 16, 18, 20, 22 and 24 extending from the forward side 14 toward the back mounting plate 10. The slots 16, 18, 20, 22 and 24 are generally equally sized, generally parallel and equally spaced. However, the slots may be uniquely sized in length and width and uniquely spaced one from the other. The distance of the inward extent of the slo...

second embodiment

[0031] the device comprises an elongated, L-shaped support panel 102 including a horizontal portion 103 with a vertical back plate 104 depending therefrom. The back plate 104 includes a plurality of apertures 105 that receive fasteners 41 to secure the support panel 102 to a tool cart or similar supporting structure. The back plate 104 terminates at a lower edge with a U-shaped channel 106 positioned thereon. The horizontal portion 103 terminates at an upwardly turned retaining lip 107 and includes a plurality of spaced, linear slots 108 thereon. Adjacent an end of the horizontal portion 103 is a locking aperture 109.

[0032] The device also includes a lower locking panel 110 likewise including a second horizontal portion 111 with a vertical portion 112 depending therefrom. An edge of the second horizontal portion 111 includes an upwardly extending U-shaped sleeve 113 that slidably receives the lip on the support panel 102. Likewise, a lower edge 120 of the vertical portion 112 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com