Fixing and release systems

a technology of fixing and release system, applied in the direction of electrical/magnetic/electromagnetic heating, couplings, furniture parts, etc., can solve the problems of affecting the repair effect of the element, the fixing method is visible externally, and the common method of fixing is rarely reversible without damage to the element being fixed, etc., to achieve the effect of easy removal for renovation and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

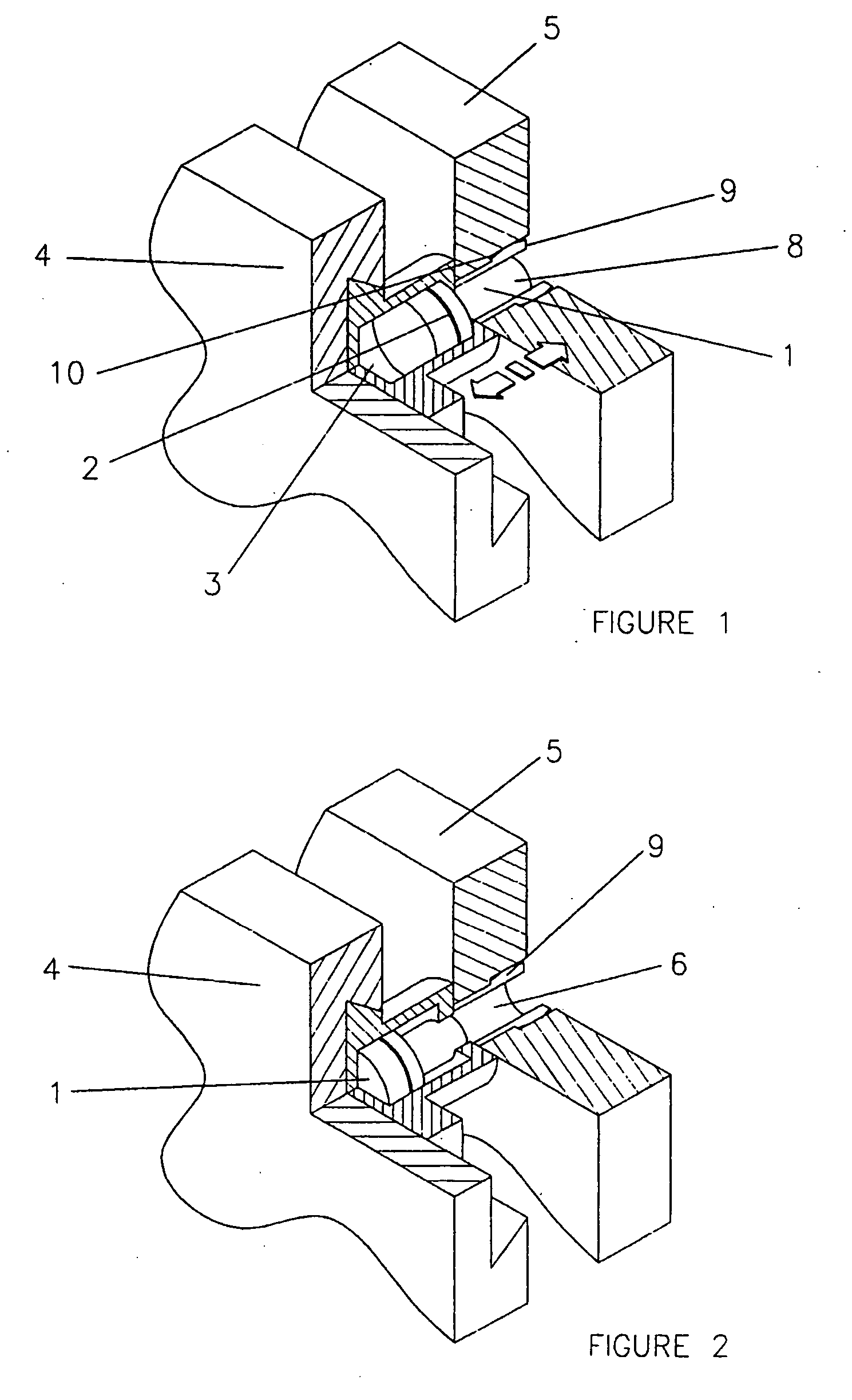

[0143] Referring first to FIG. 1, locking pin 1 is injection moulded from a suitable plastic material and includes a metal strip 2. Locking pin 1 lies in recess 3 between first element 4 and second element 5. Recess 3 has a narrow end 6 which lies within element 5.

[0144] When a magnetic force is applied to locking pin 1, it is caused to move within recess 3 as shown in FIG. 2, so that leg 8 of locking pin 1 is pushed into narrow recess 6, in turn expanding wall 9 so that it locks into the recess 10 provided in element 5.

[0145] Locking pin 1 may be reversed, so that elements 4 and 5 may be released, by the use of magnetic force. Magnetic attraction may be applied for fixing elements 4 and 5 and magnetic repulsion for releasing them, or vice versa. Alternately, the same magnetic force may be applied on opposite sides—for example, on the side near element 4 for fixing and on the side near element 5 for releasing.

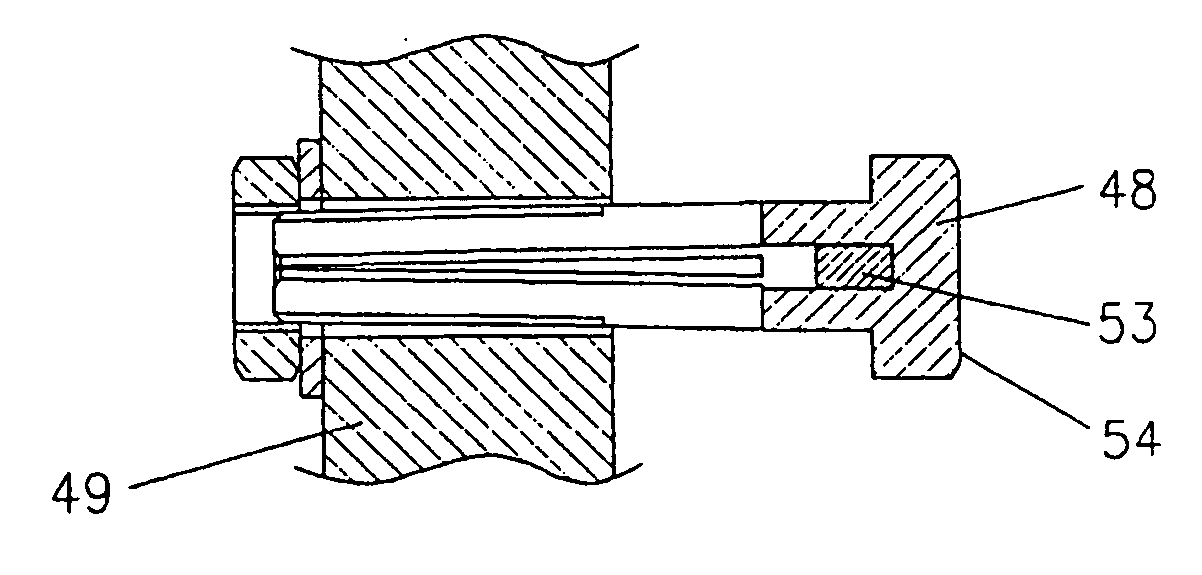

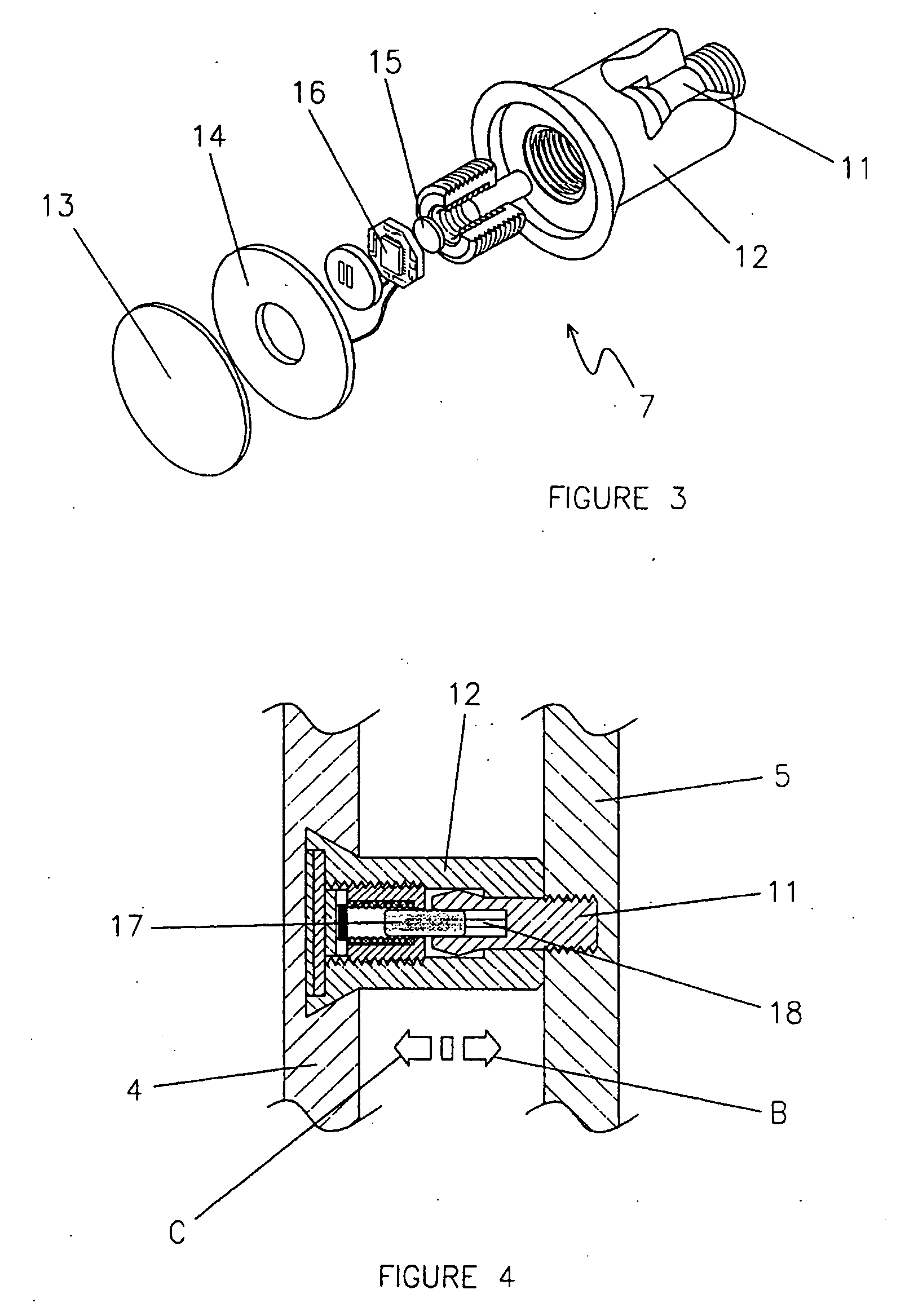

[0146] Turning now to FIG. 3, the connecting means 7 illustrated includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com