Yarn package supporting bracket for use on a creel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

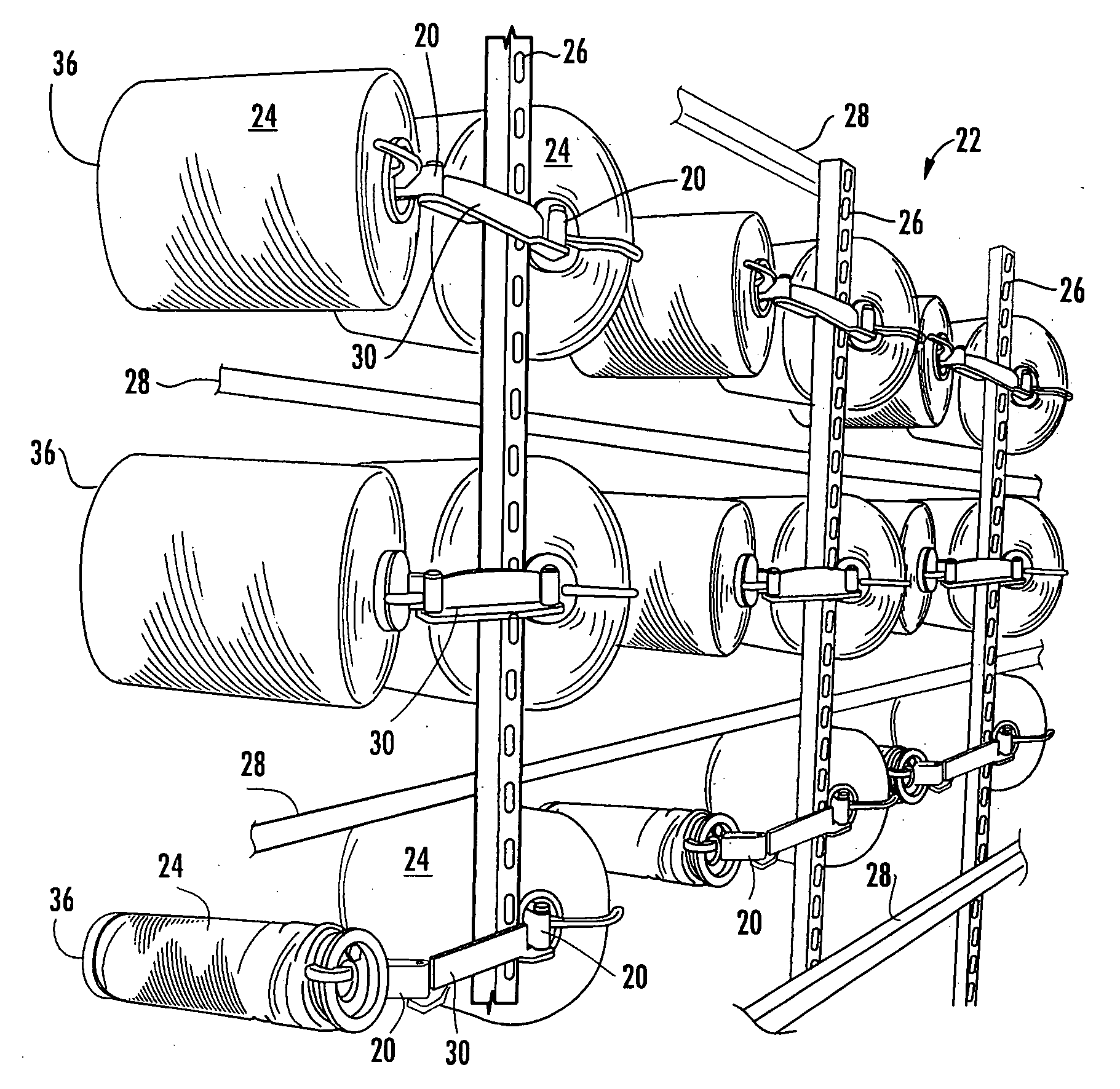

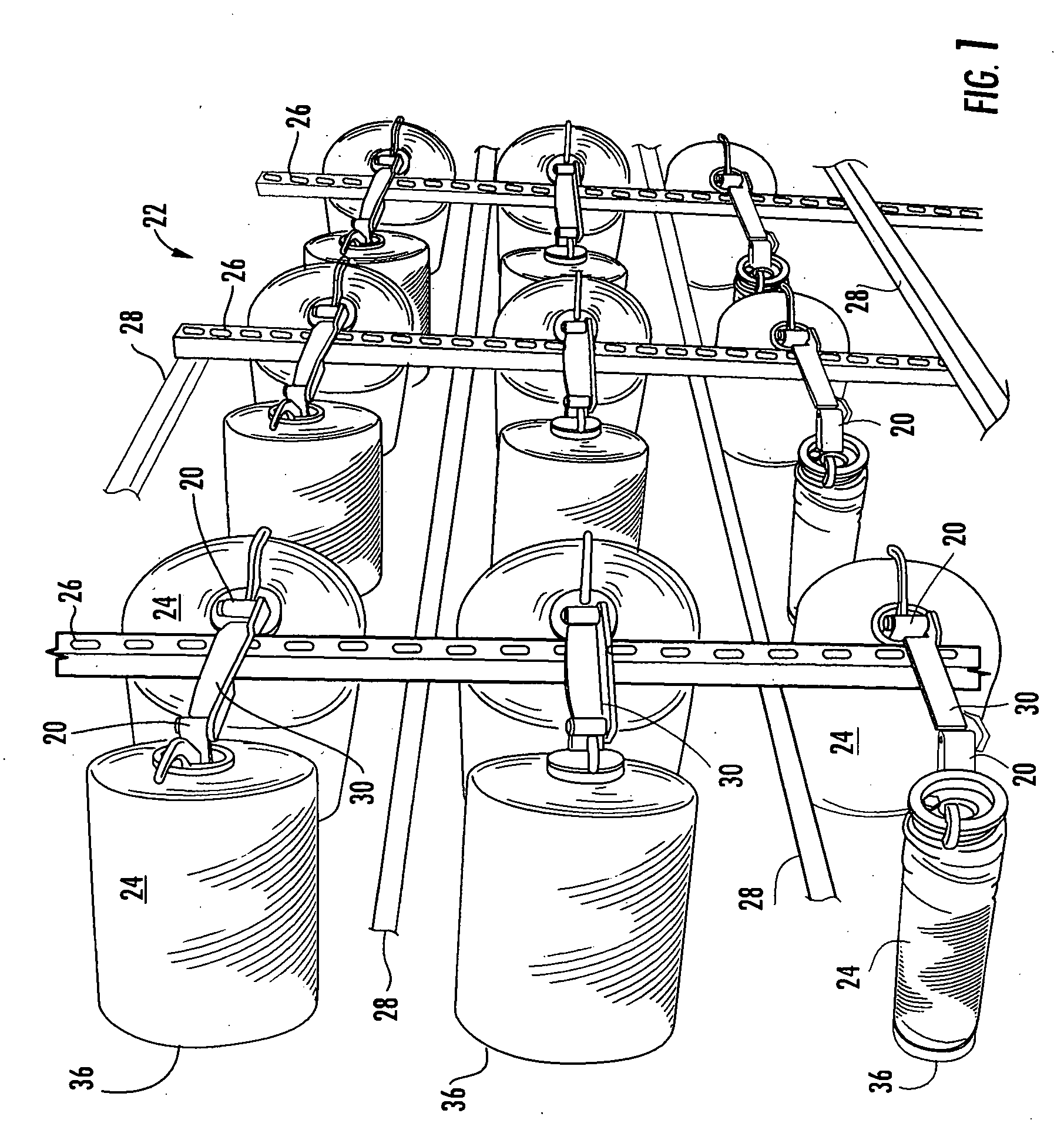

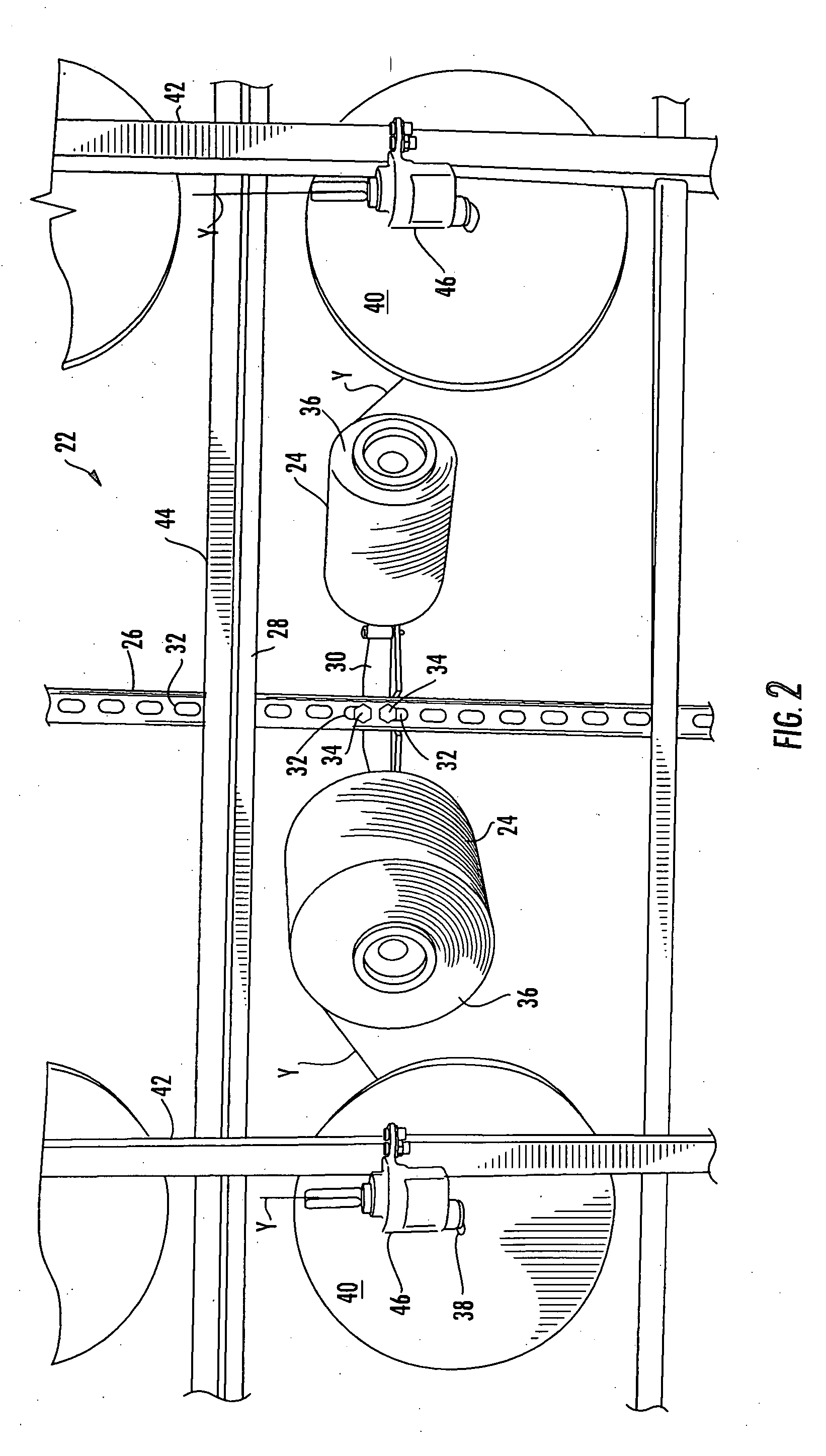

[0020] Referring first to FIG. 1, yarn package supporting brackets 20 are shown mounted on a creel 22 with yarn packages 24 positioned in yarn feeding position. The creel 22 is a frame having vertical and horizontal frame members 26 and 28, respectively. FIG. 1 illustrates only a portion of the rear of a creel 22. Horizontally extending arms 30 are bolted to the vertical frame members 26 in selected mounting holes 32 formed in vertical rows in the vertical frame members 26 by bolts 34.

[0021] In the yarn feeding position illustrated in FIGS. 1 and 2, the yarn packages 24 have there outer faces 36 aimed toward guiding holes 38 in the balloon stopping discs 40 mounted on the vertical frame members 42 at the front of the creel 22. The vertical frame members 42 at the front of the creel 22 are stabilized by horizontal frame members attached thereto.

[0022] Yarn being fed from the yarn packages 24 travels through the holes 38 in the discs 40 and then to and through guides 46, which are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com