Method of producing overwrap material, and a pack furnished with the material produced

a technology of which is applied in the field of producing overwrapping material and packing material, and to a pack furnished with the material produced, can solve the problems of difficult dislodge and pack damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

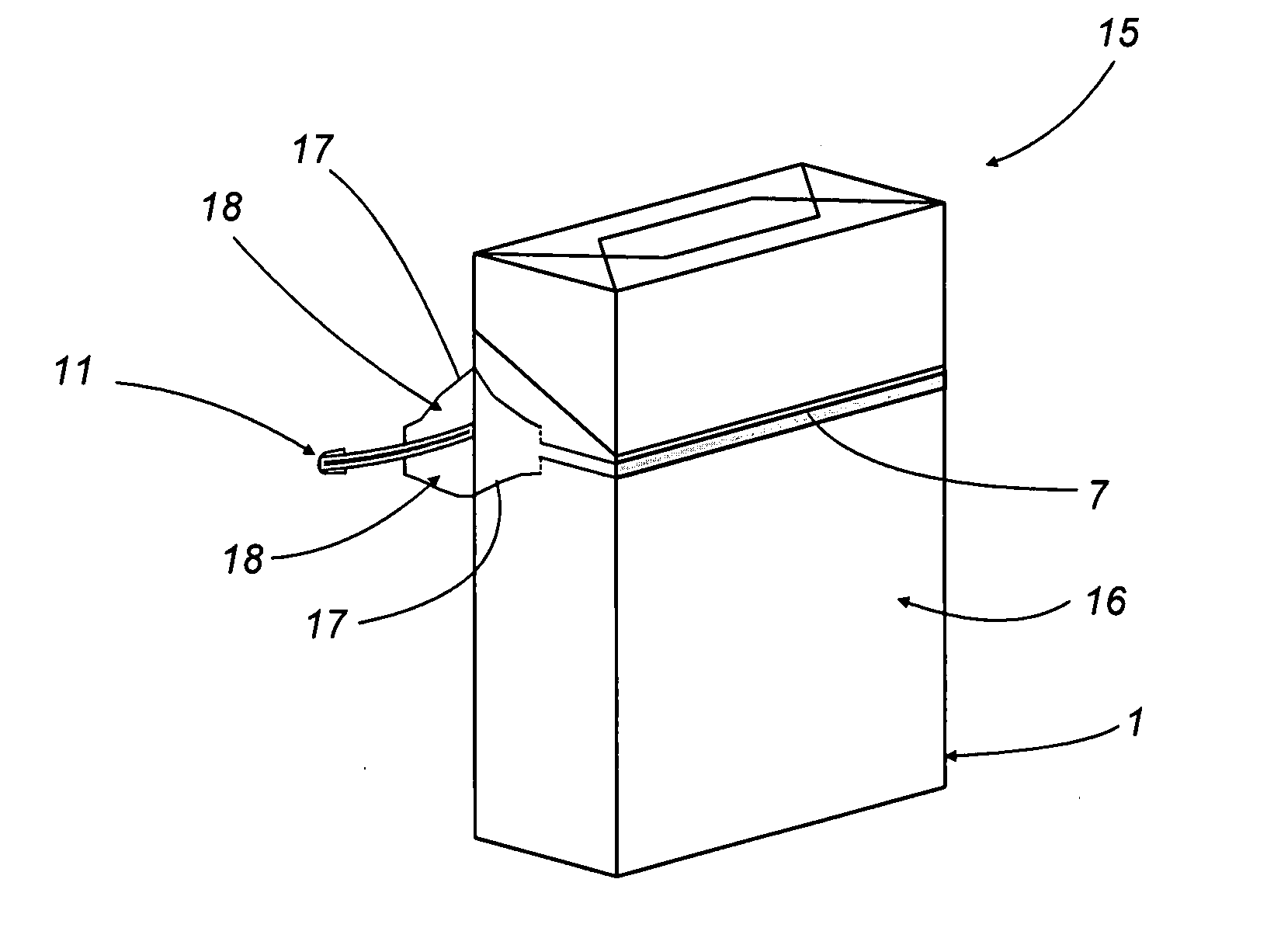

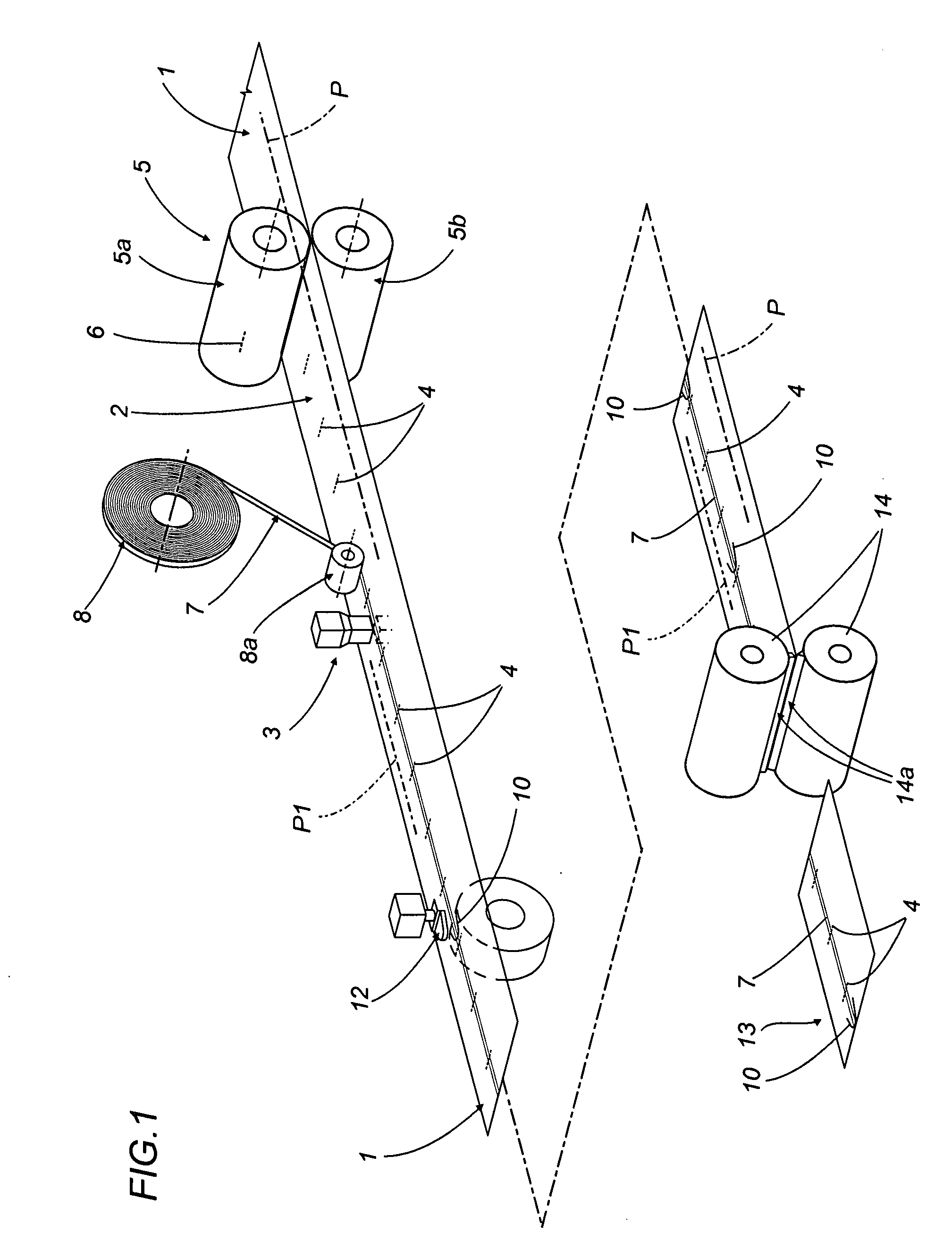

[0021]With reference to FIG. 1, the invention relates to a method of producing overwrap material 1.

[0022]In a first step of the method, a continuous strip of preferably transparent and heat-shrinkable overwrap material 1 is caused to advance along a predetermined feed path “P” in a predetermined direction “A”.

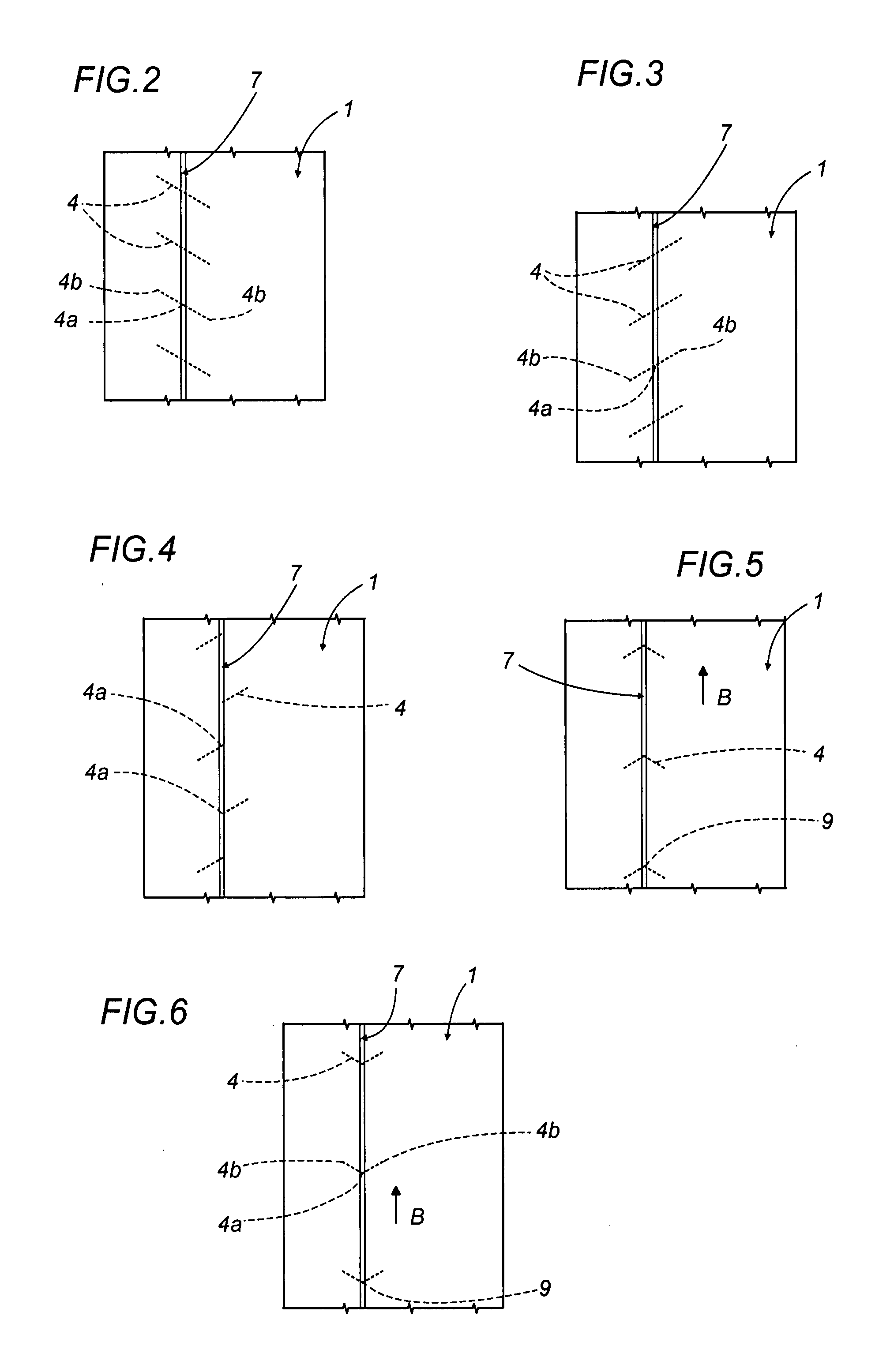

[0023]In a further step, a predetermined area 2 of the advancing strip 1 is provided with at least one slit or incision 4 having a geometrical component transverse to the aforementioned direction “A”.

[0024]Advantageously, the step in question involves creating a succession of such slits 4 through the agency of suitable cutting or punching means 5 composed of a main roller 5a carrying a blade 6, and a matching anvil roller 5b. The two rollers 5a and 5b are set in contrarotation about respective axes extending transversely to the aforementioned feed direction “A”.

[0025]The blade 6 presents a profile selected according to the shape of the slit 4 and strikes against the anvil rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| transverse dimensions | aaaaa | aaaaa |

| longitudinal dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com