Motor assembly structure

a technology of motor assembly and assembly structure, which is applied in the direction of positive displacement liquid engine, pump, machine/engine, etc., can solve the problems of high manufacturing cost, complicated assembly of above components, and high manufacturing cost, so as to facilitate the assembly procedure of the motor assembly structure, and reduce the number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

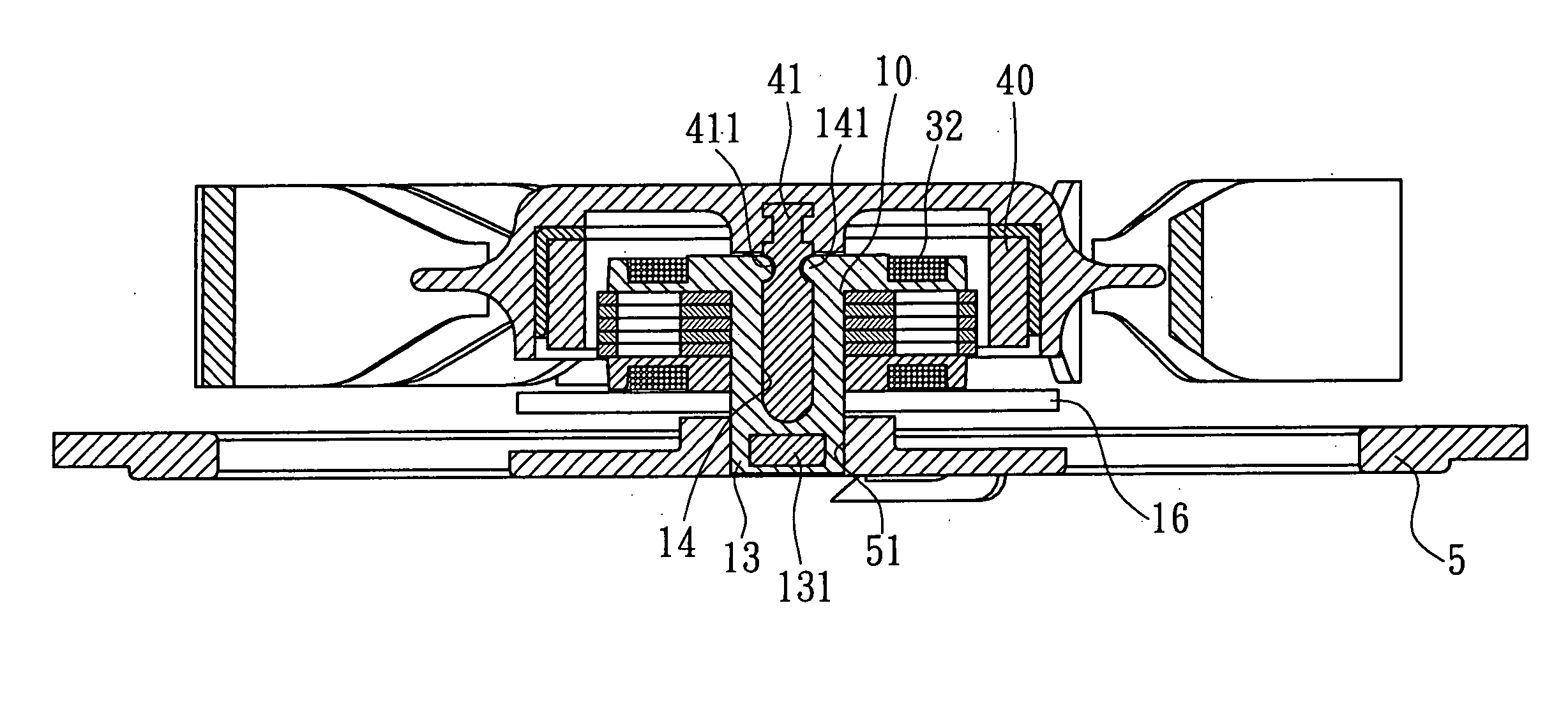

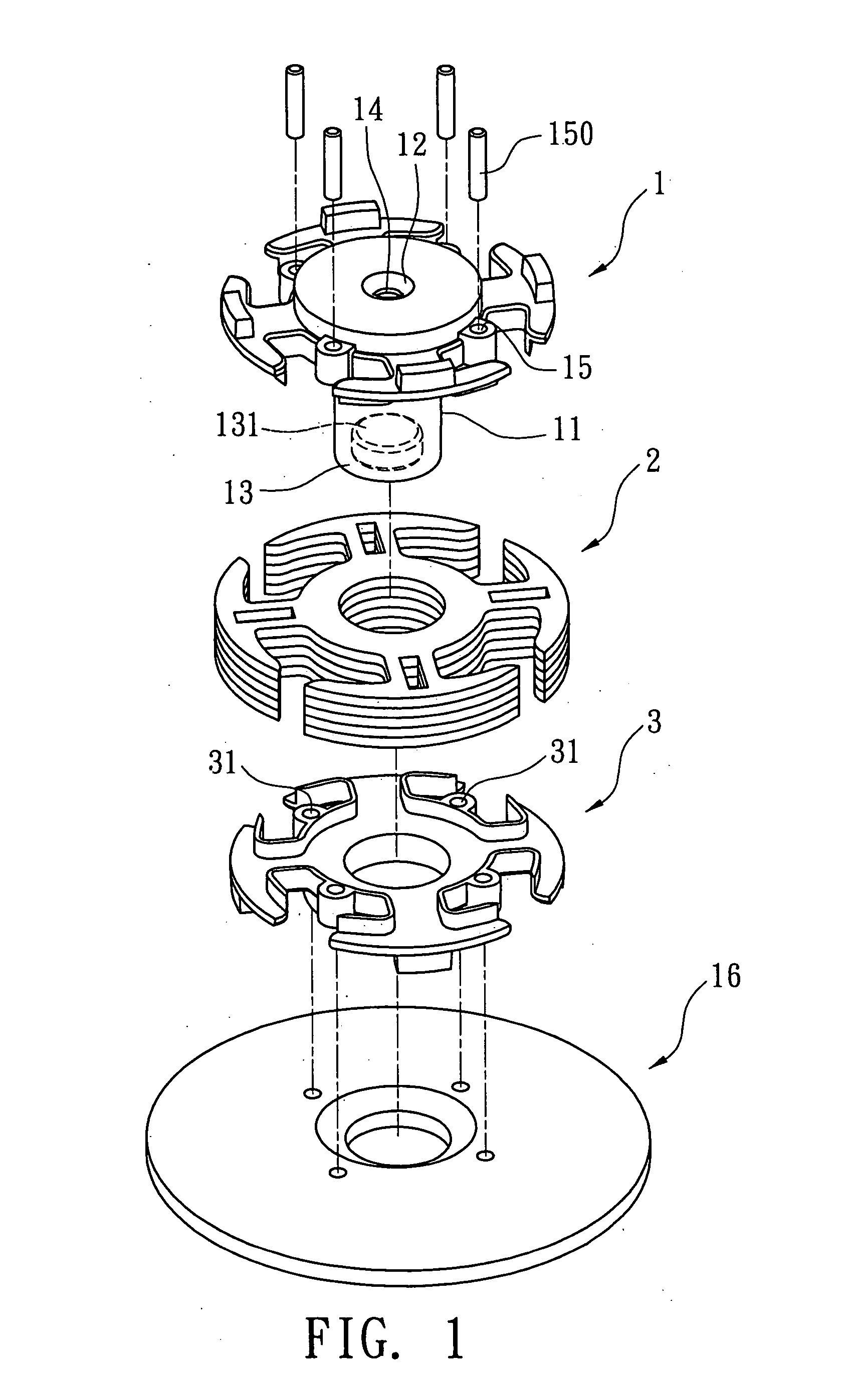

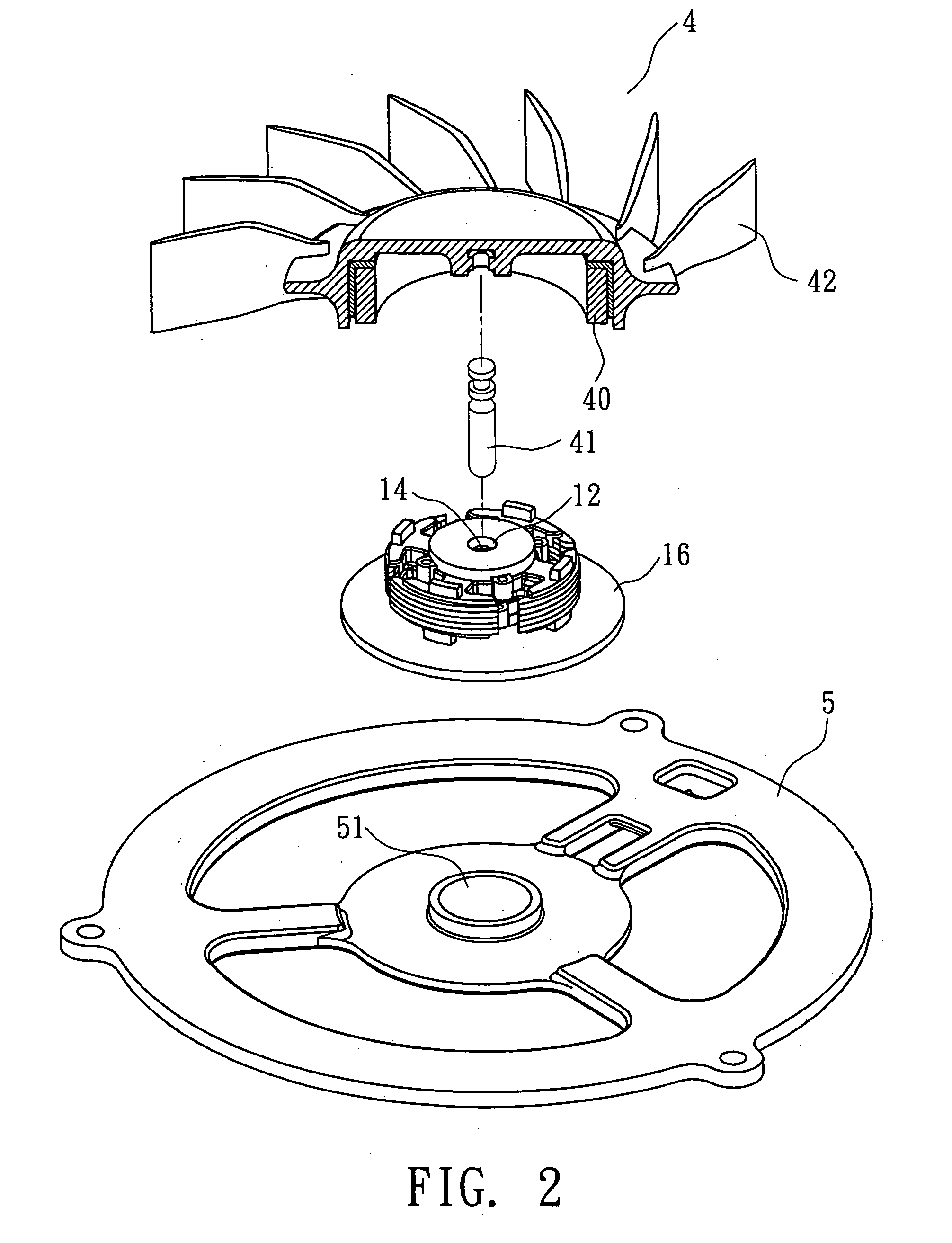

[0013] Please refer to FIGS. 1 to 3. The motor assembly structure of the present invention includes a first bracket 1, a silicon steel plate unit 2, a second bracket 3, a rotor 4 and a base seat 5.

[0014] The first bracket 1 has a hub 11 integrally extending from the first bracket 1 to the second bracket 3. The hub 11 has an opening 12 formed on a top face of the first bracket 1. The hub 11 has a connecting end 10 connected with the first bracket 1 and a close end 13 distal from the opening 12. The hub 11 is formed with a shaft cavity 14 communicating with the opening 12. In this embodiment, a magnet 131 is embedded in the close end 13 for attracting a central shaft 41 of the rotor 4 and keeping the central shaft 41 in a central position.

[0015] The silicon steel plate unit 2 is fitted around the hub 11 of the first bracket 1. In this embodiment, the silicon steel plate unit 2 is composed of multiple silicon steel plates which are piled up.

[0016] The silicon steel plate unit 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com