Constant lead edge paper inverter system

a paper inverter and lead edge technology, applied in the direction of electrographic process equipment, instruments, thin material processing, etc., can solve the problems of increasing the risk of duplex image misalignment and placement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] As will be evident by the ensuing detailed description, the present invention provides a printing apparatus and method of providing duplex imaging with single lead edge registration.

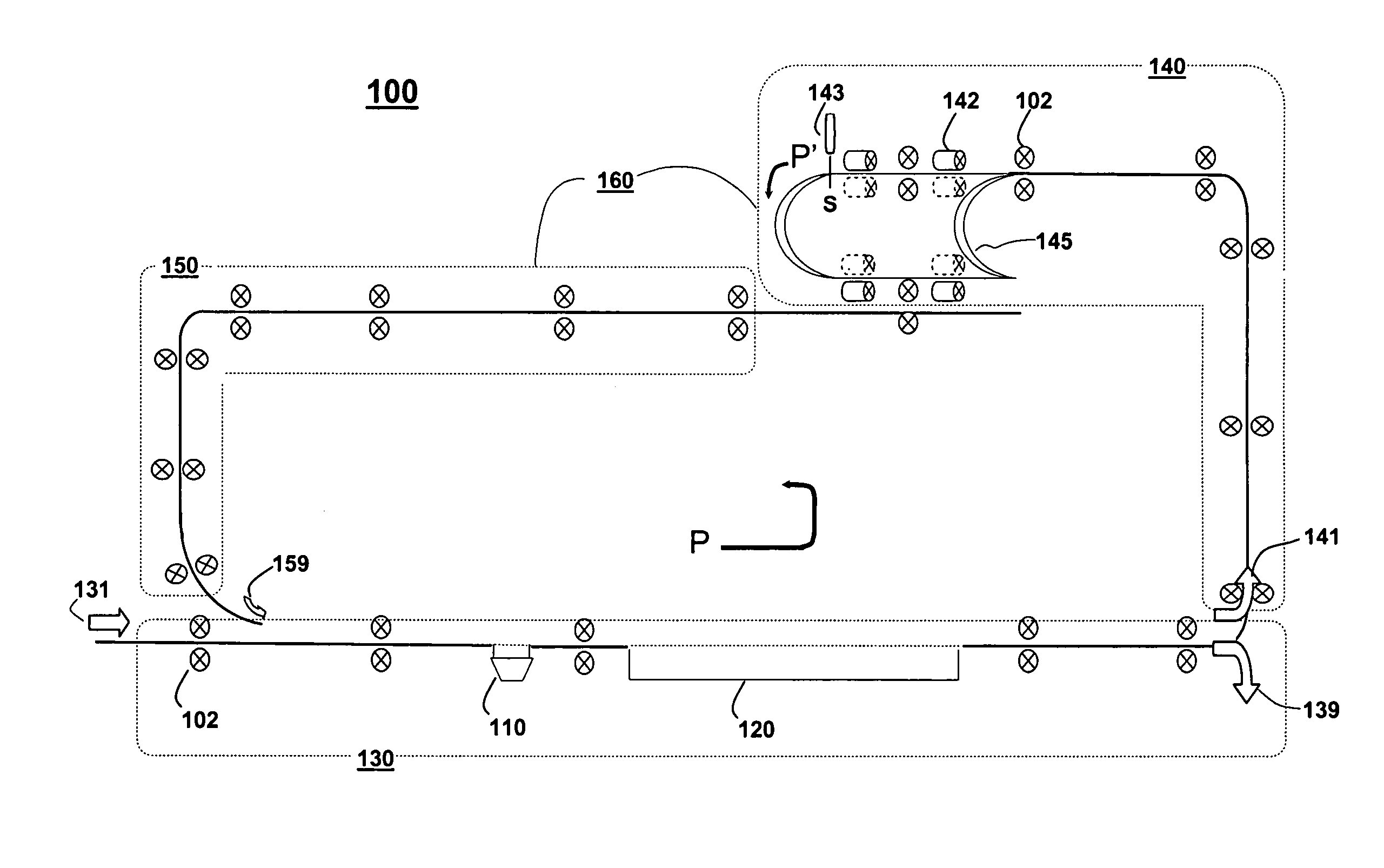

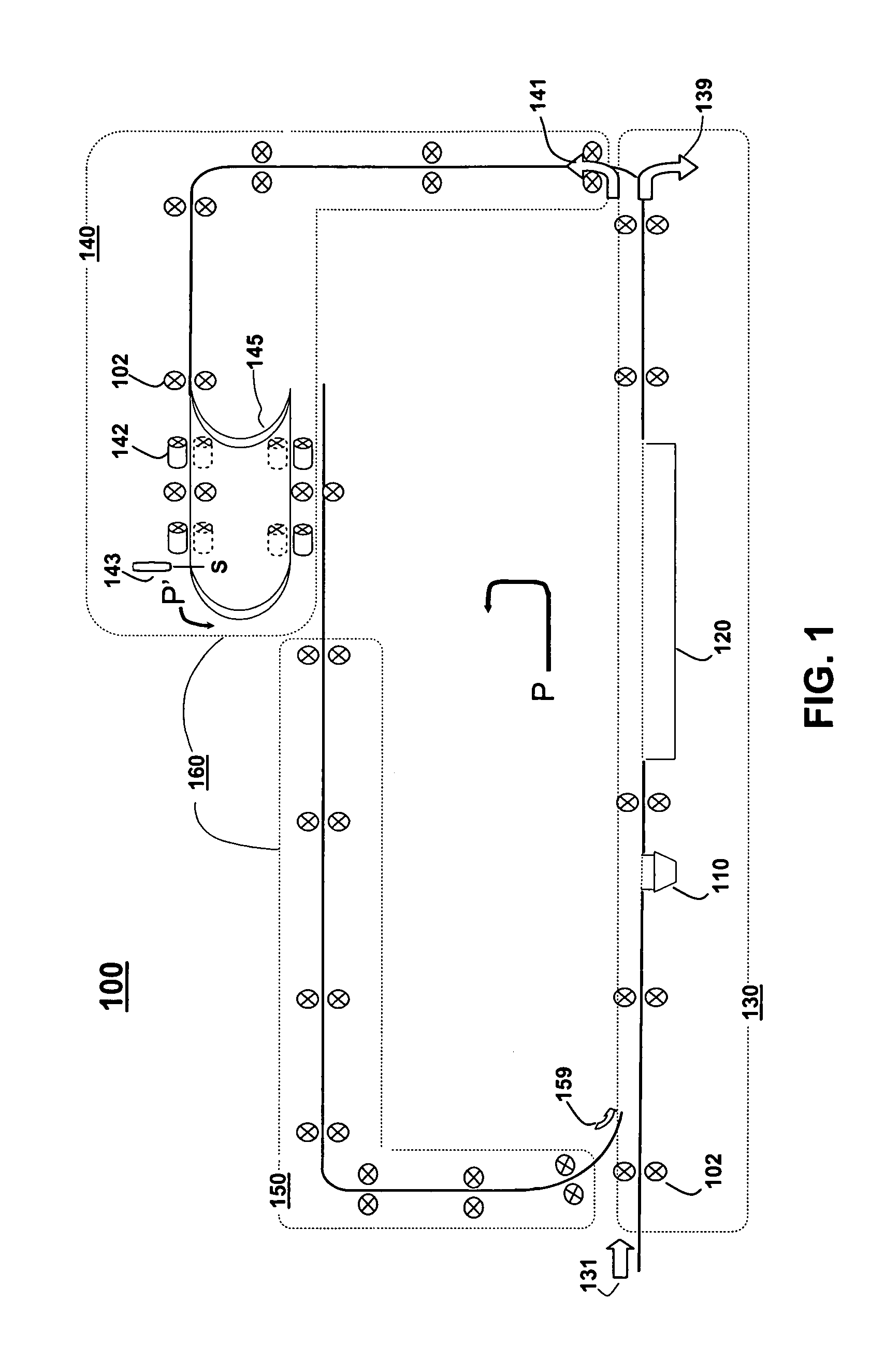

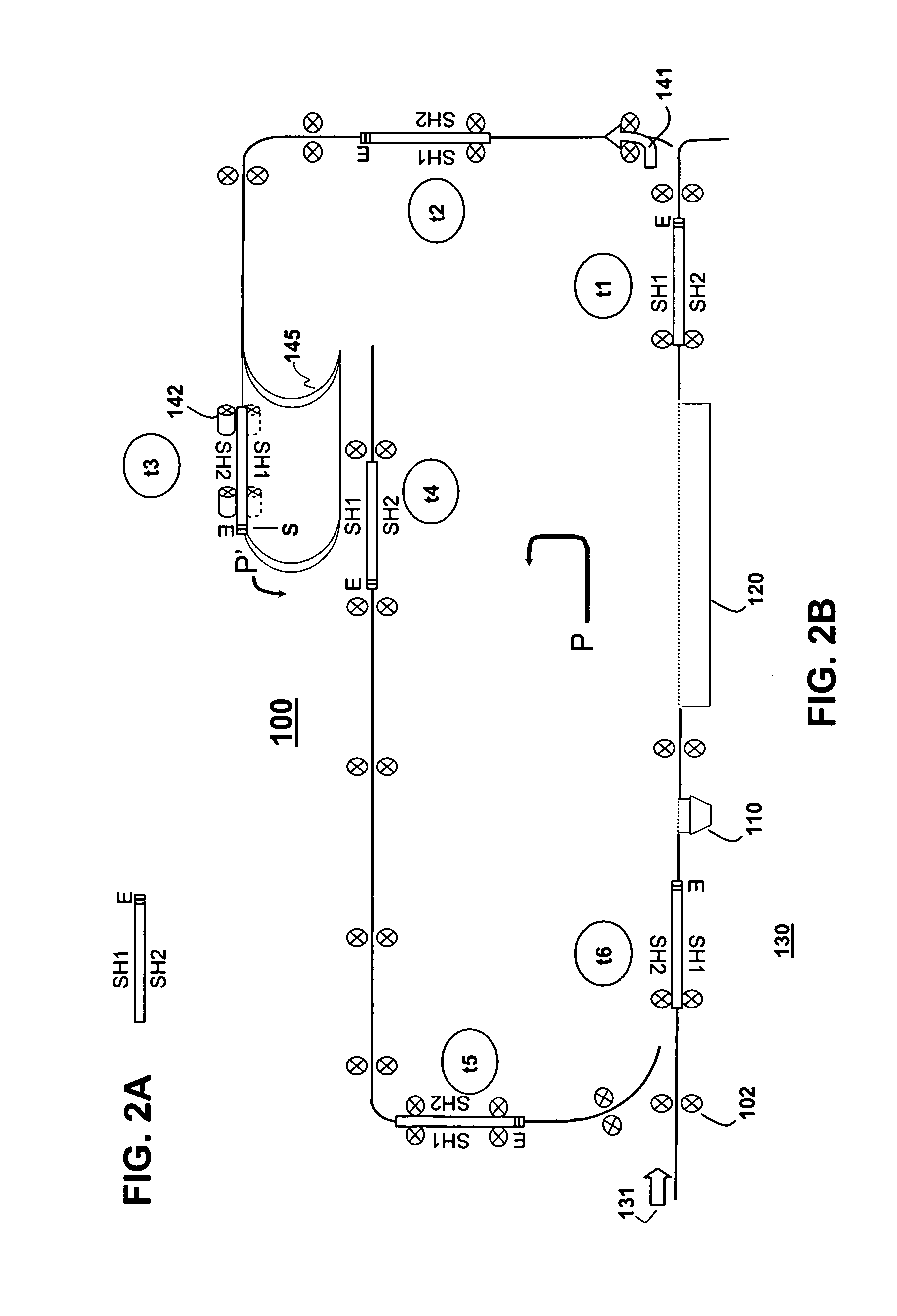

[0016]FIG. 1 schematically depicts the principle elements of the image processing station of a duplex capable printing apparatus 100, in accordance with an embodiment of the present invention. Such an apparatus is intended to cover printers, copiers, facsimiles, or other multifunction machines that are capable of duplex imaging. As illustrated in FIG. 1, printing apparatus 100 comprises a side edge position detector 110, a marking device 120, a simplex transport path 130, and a constant lead edge paper inverter system 160. In turn, constant lead edge inverter system 160 comprises an upper duplex transport path 140 and a lower duplex transport path 150. The orientation of FIG. 1 is depicted so that the image processing direction, that is, the general direction in which a sheet of paper is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com