Flexible interlocking wall system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

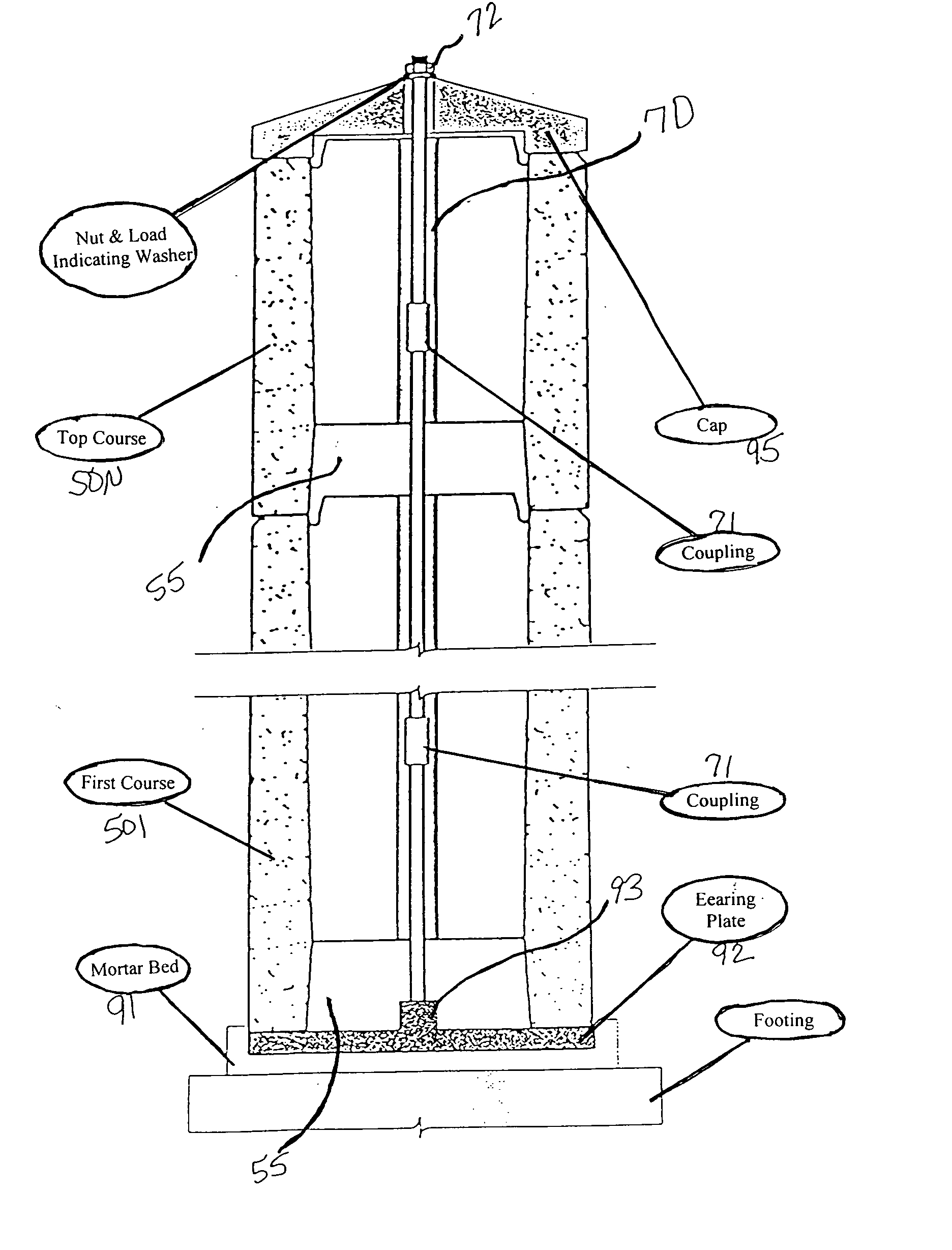

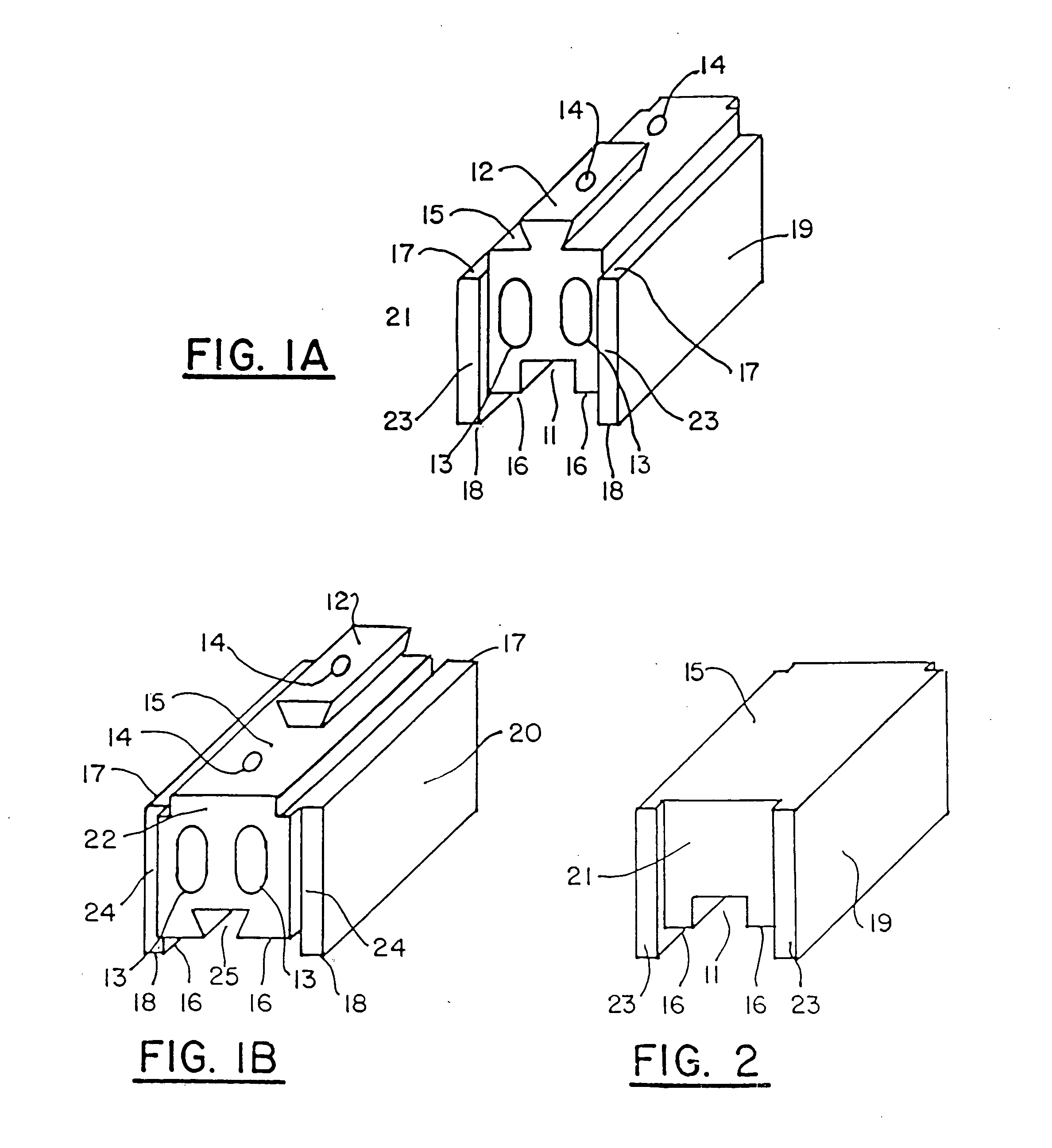

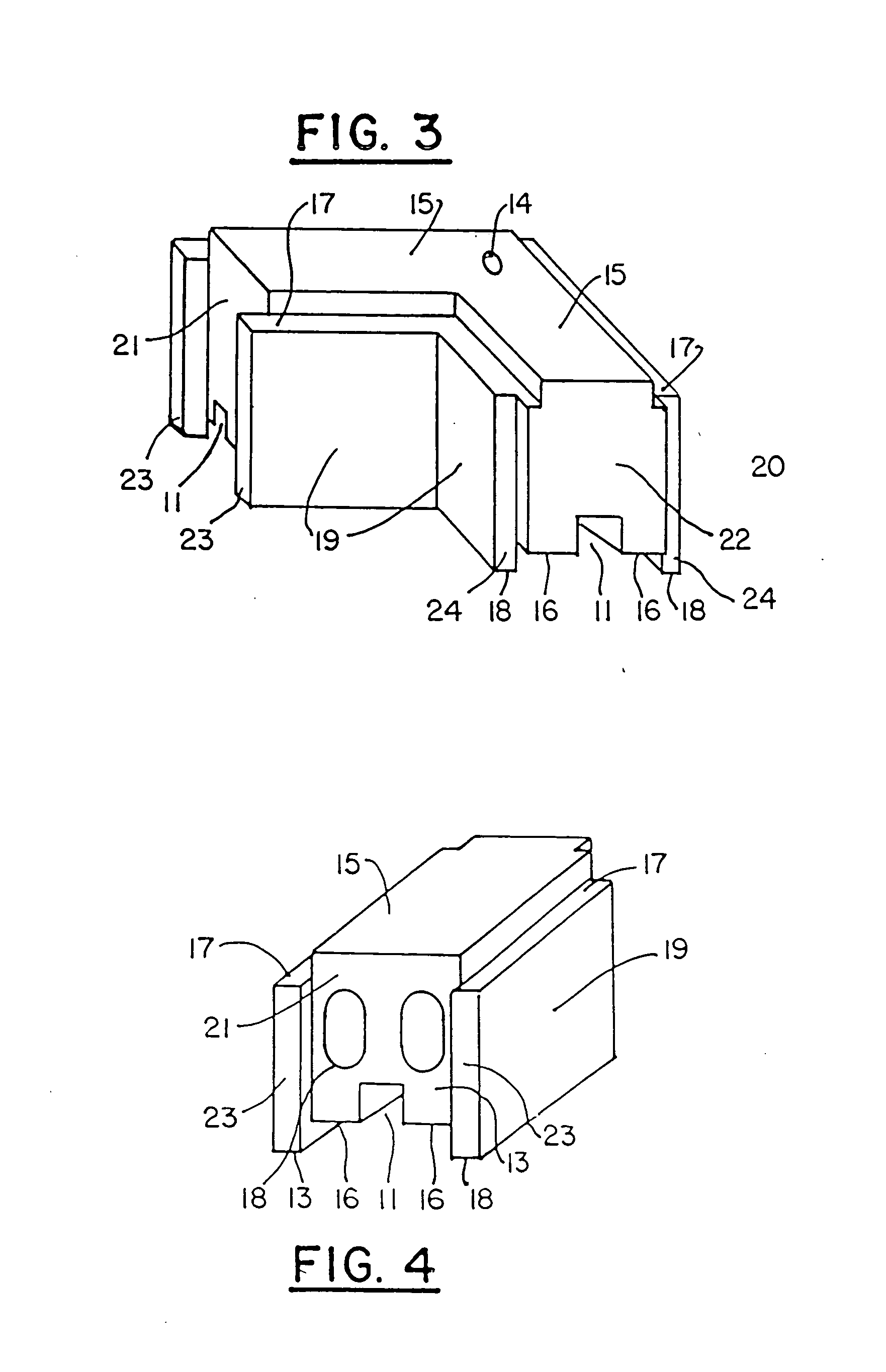

[0107] FIGS. 1(a) and 1(b) depict two perspective views of the main block constituting the present invention. The drawing designation numerals included in FIGS. 1(a) and 1(b) remain the same for all of FIGS. 1(a)-10. For the sake of clarity and efficient consideration of all of the drawings, the legend of the drawing designation numerals is provided below:

11.square receiving slot12.dovetail13.through holes14.stabilizing holes15.upper plane16.lower plane17.upper shoulder18.lower shoulder19.interior sides20.exterior sides21.front plane22.rear plane23.front shoulder24.rear shoulder25.dovetail receiving slot26.corner block27.cynderbrick (main block)28.short block29.footer30.foundation

[0108] The wall system of the present invention is essentially composed of three basic components. These include: a main block, a corner block, and short block. The main block, shown in FIGS. 1(a) (front view) and 1(b) (rear view), is the fundamental component upon which the entire wall system is based. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com