Method for manufacturing synthetic decorative stone with inlays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A method for manufacturing a synthetic decorative stone with inlays in accordance with a preferred embodiment of the present invention includes steps as follows:

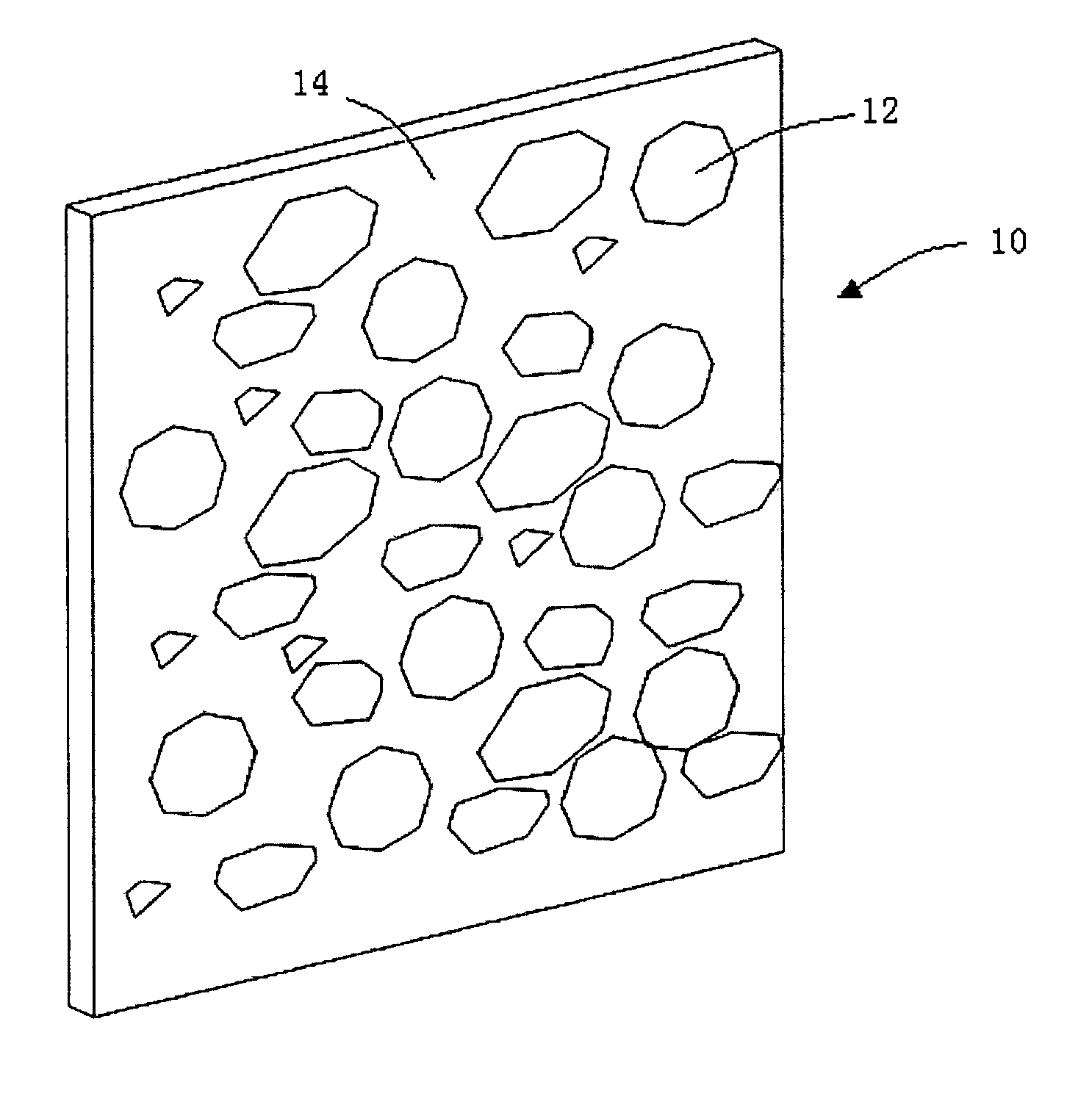

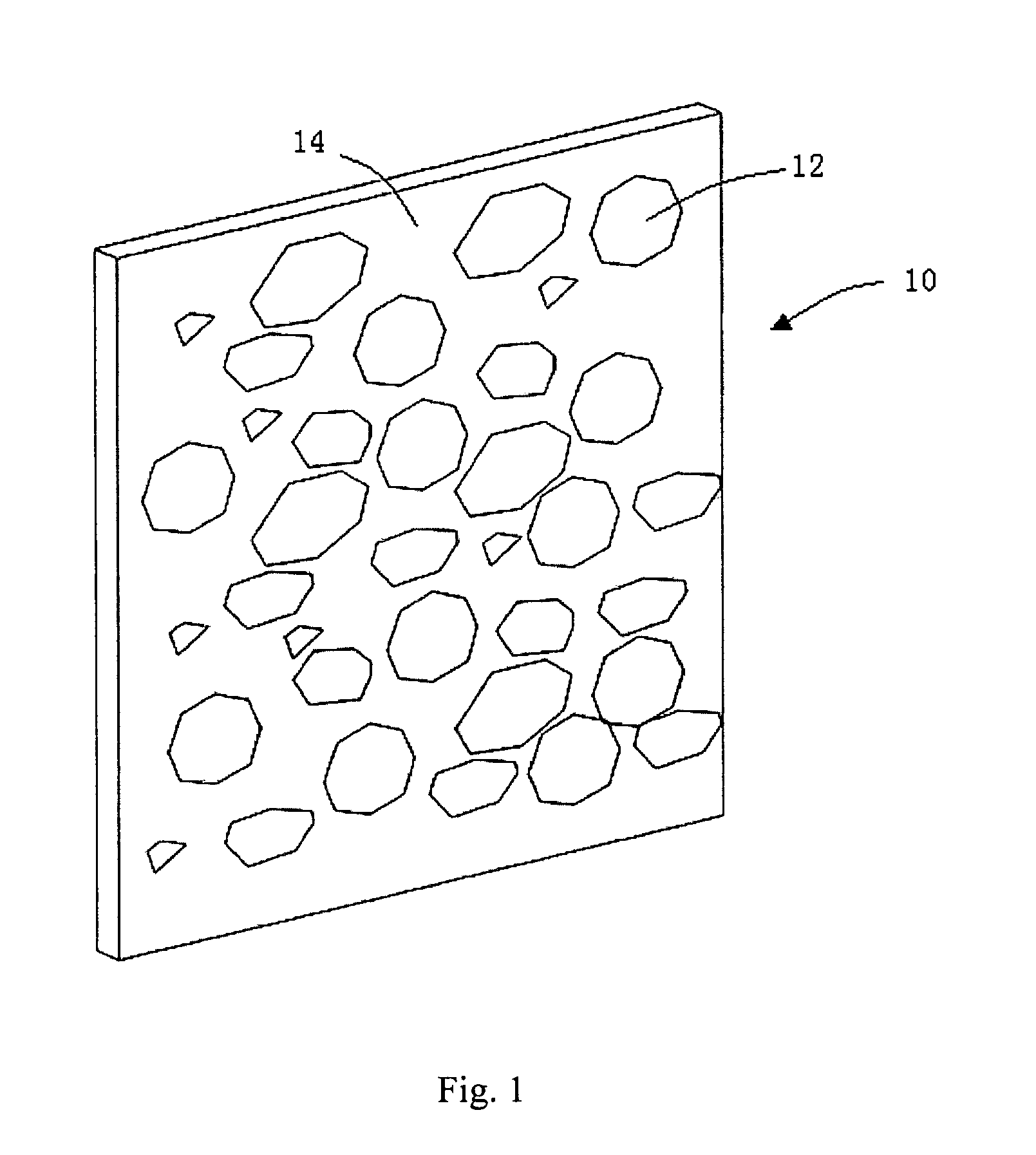

[0013] At the step 1, referring to FIG. 1, on the basis of requirements of different designs, cutting or scrunching a stone or other decorative materials into thin small pieces 12 with different shapes.

[0014] Then turn to the step 2, laying out a plurality of thin small pieces at a bottom of a larger mold (not shown) according to a predetermined pattern.

[0015] At the step 3, mixing various materials which can form a synthetic stone with adhesives and pigments then dumping them into the mold. The various materials include at least on kind of materials among marble power, quartzite power or fragments, granite power or fragments, and alumina powder. The various materials are mixed with adhesives and pigments, such as, resin adhesive, AB adhesive, unsaturated epoxy resins, polyurethane adhesives or other adhesive that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap