Hot bending furnace for colored glazing glass, method for preparing colored glazing toughened hot-bent glass and colored glazing toughened hot-bent glass

A hot bending furnace and glass technology, applied in glass manufacturing equipment, glass forming, glass re-molding, etc., can solve the problems of inability to install hot bending glass, low printing accuracy, poor mold fit, etc., to achieve cooling Long setting treatment time, consistent heat absorption rate, and the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of colored glaze tempered hot-bending glass with a thickness of 8 cm and a radius R corresponding to the bending arc of 60 mm

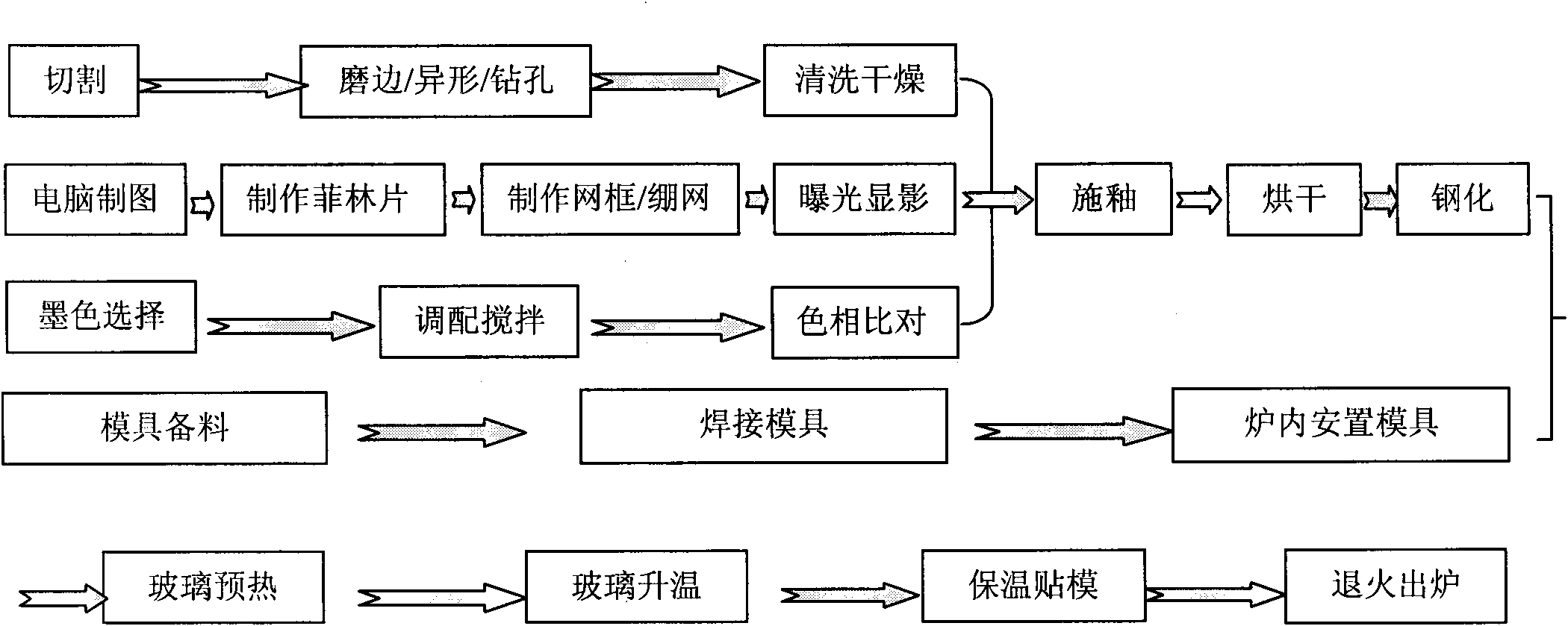

[0068] 1. Production preparation stage

[0069] 1. Make screen version

[0070] A: Carry out CAD drawing according to the graphic specification or sample of the sample to be processed by the user, then print the drawn pattern with sulfuric acid paper, then cut the prepared pattern, and paste it on the transparent film according to the size of the finished product to make a film sheet ;

[0071] B: Cut the silk screen printing mesh according to the processing diagram or the size required by the sample, and fix the edge of the mesh with the frame with a splint, and then put the frame and the printing mesh on the stretching machine (No. 3, Yueqing City, Zhejiang Province) Deli Pneumatic Technology Co., Ltd.) is stretched and flattened, and then the gap between the mesh and the splint of the frame is sealed with a universal ...

Embodiment 2

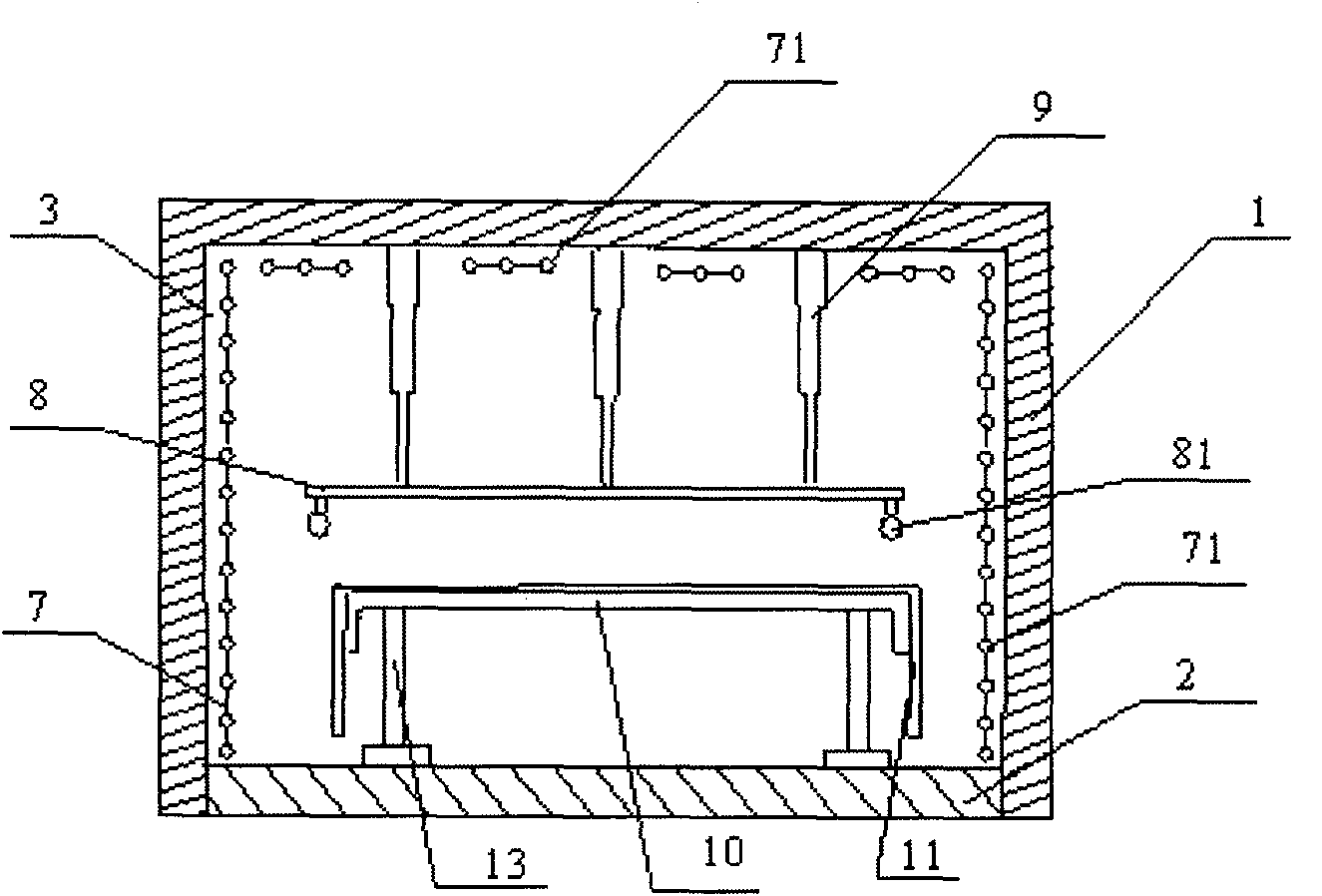

[0117] Example 2 Preparation of colored glaze tempered hot-bending glass with a thickness of 15 cm and a radius R corresponding to the bending arc of 90 mm

[0118] Except that the radius R corresponding to the radian of the mold bending arc produced is 90mm, and the thickness of the glass is 15cm; during the hot bending process, the heating rate of the preheating treatment step is 5.63°C / min; the heating rate of the heating treatment step is 4.38°C / min. min; the distance between the moving heating furnace wire 8 and the bending arc in the heat preservation and molding processing step is 1.5cm; the cooling rate in the first stage of the cooling and shaping processing step is 4.5°C / min, and the cooling rate in the second stage is 2.5°C / min , the cooling rate in the third stage was 1.0°C / min, and the rest were the same as in Example 1, and the colored glaze tempered hot bending glass was prepared.

[0119] According to the national building materials industry promotion standard ...

Embodiment 3

[0120] Example 3 Preparation of colored glaze tempered hot-bending glass with a thickness of 12 cm and a radius R corresponding to the bending arc of 45 mm

[0121] Except that the radius R corresponding to the curved arc of the mold is 45mm, the thickness of the glass is 12cm; during the hot bending process, the heating rate of the preheating treatment step is 7.03°C / min; the heating rate of the heating treatment step is 5.38°C / min; The distance between the moving heating furnace wire 8 and the bending arc in the thermal insulation and molding processing step is 2.0cm; the cooling rate in the first stage of the cooling and shaping processing step is 6.0°C / min, and the cooling rate in the second stage is 2.5°C / min. The cooling rate of the third stage is 1.0°C / min, except that the cooling rate of the fourth stage is 0.53°C / min, all the other are the same as in Example 1, and the colored glaze tempered hot-bending glass (such as Figure 6 shown).

[0122] According to the natio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com