Child-resistant packaging for pharmaceutical products

a technology for packaging and pharmaceutical products, applied in the field of packaging, can solve the problems of undetectable limitation of access to the contents, infirm patients, and limited access to the pharmaceutical product by a young child, and achieve the effects of reducing width, increasing separation pressure, and facilitating grasping of the tear-away elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

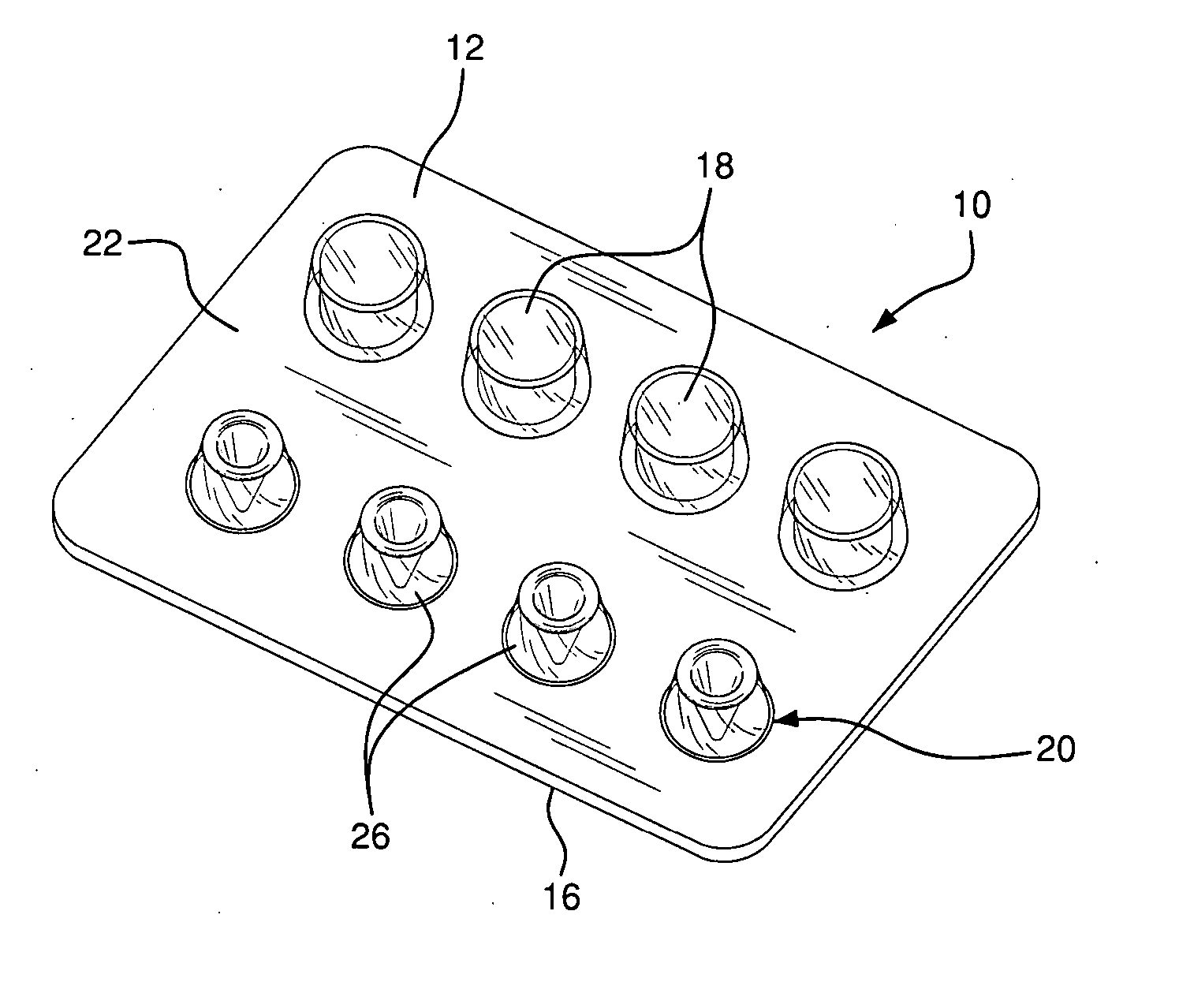

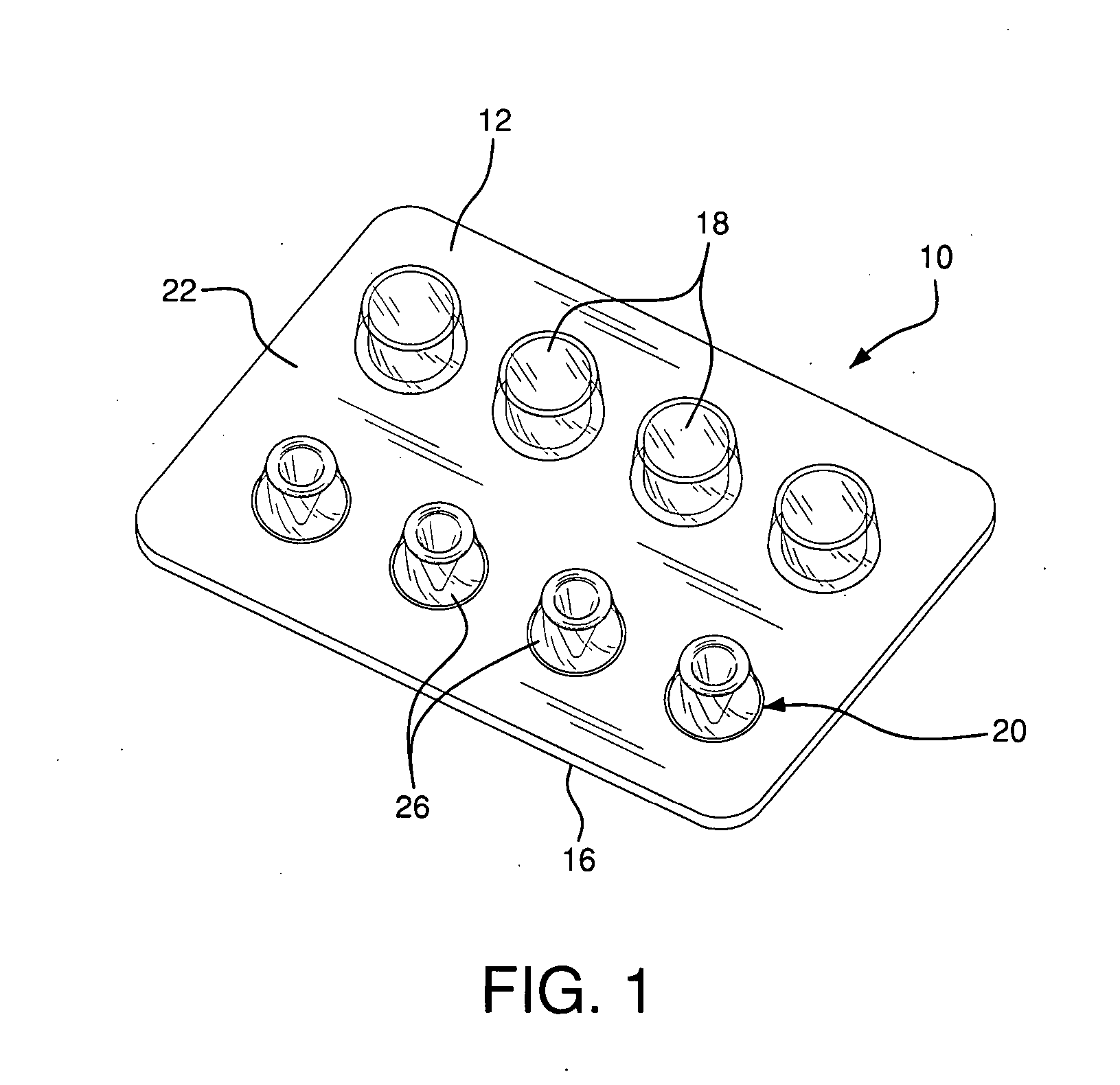

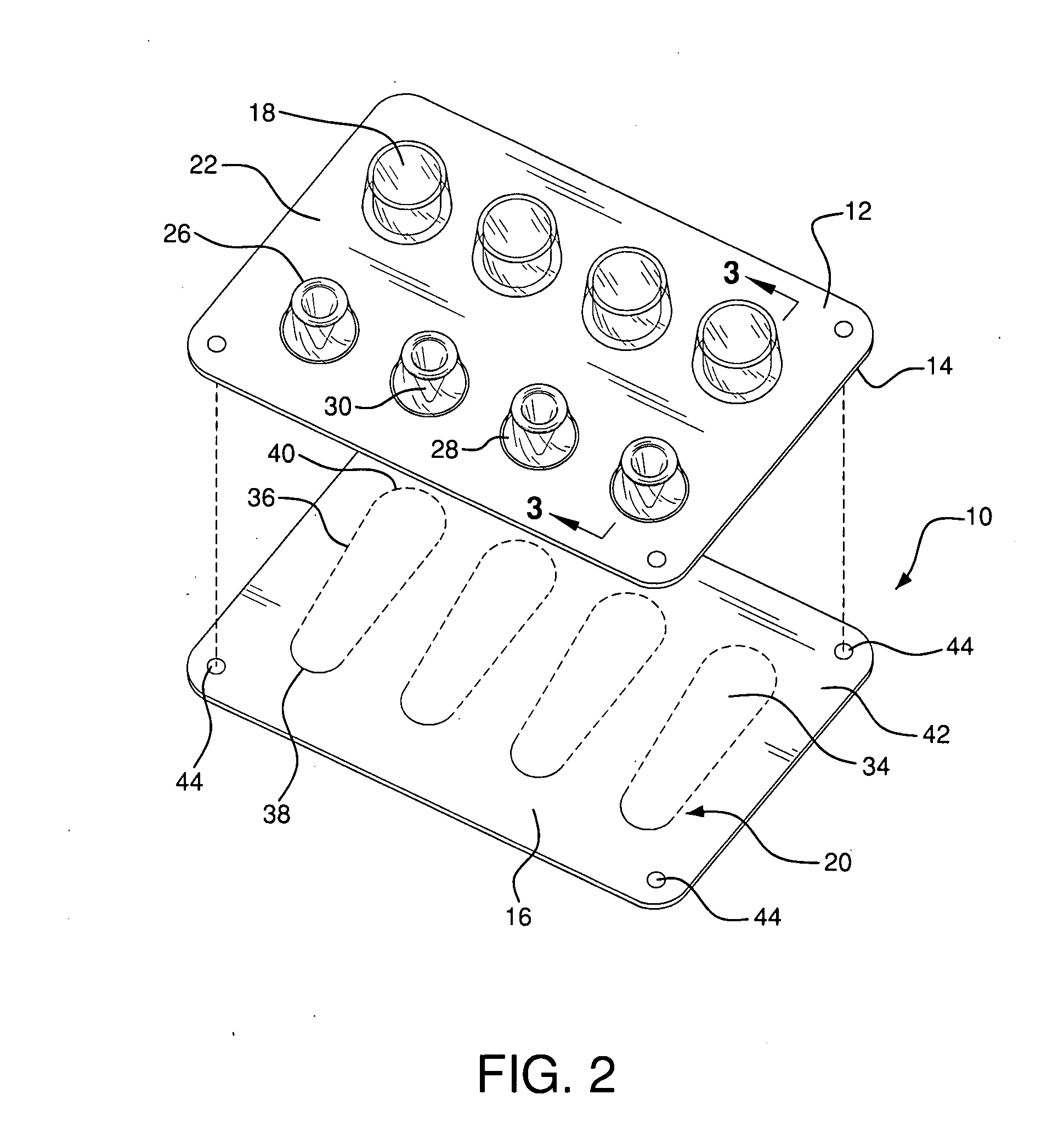

[0020] Referring to the drawings, there is shown in FIGS. 1 through 3 a package 10 for pharmaceutical products such as pills, tablets, capsules, and the like. The pharmaceutical products for use with the package 10 are hereinafter sometimes referred to as “pills” to facilitate description. It should be understood, however, that the invention is not so limited. Referring to FIGS. 1 and 2, the depicted package 10 includes a product casing layer 12, a foil (e.g., aluminum) closure layer 14 and a reinforcing layer 16. The product casing layer 12 includes a plurality of blisters 18 each defining an interior for receipt of a pill. The package 10 includes a plurality of access mechanisms 20 each associated with one of the blisters 18. The access mechanism 20 is adapted to create an opening in the reinforcing layer 16 to provide for dispensing a pill from the blister 18. As described below in greater detail, the access mechanism 20 of the present invention provides a child-resistant feature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| moldable | aaaaa | aaaaa |

| pulling force | aaaaa | aaaaa |

| compressive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com