Ski boot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

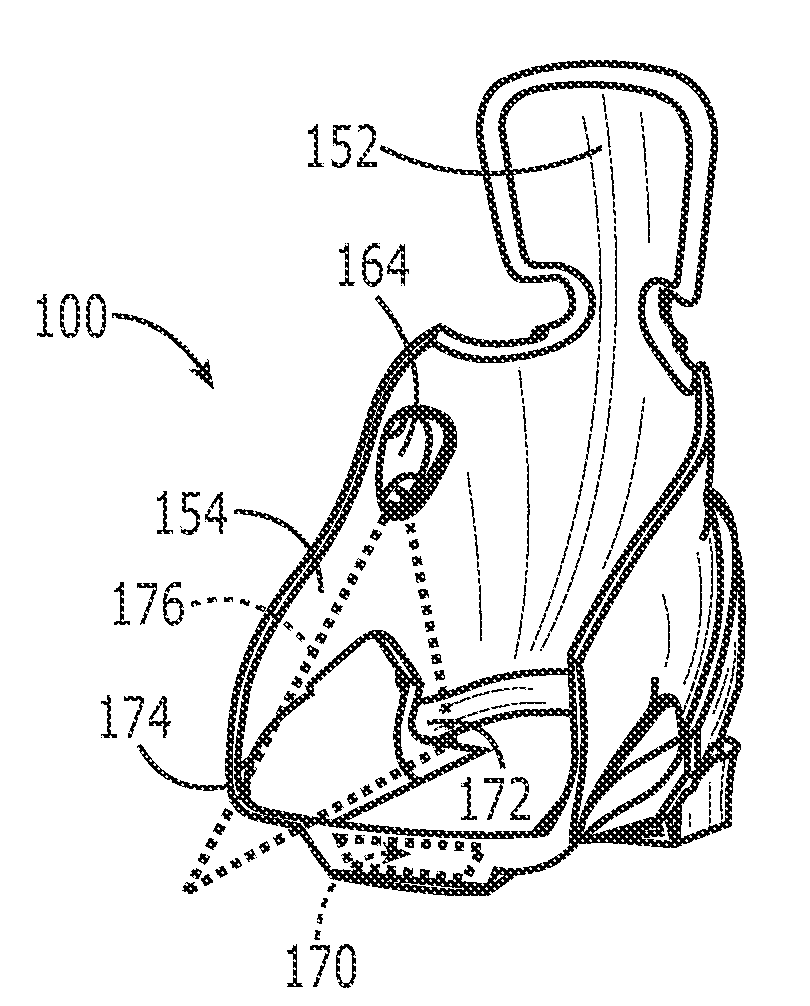

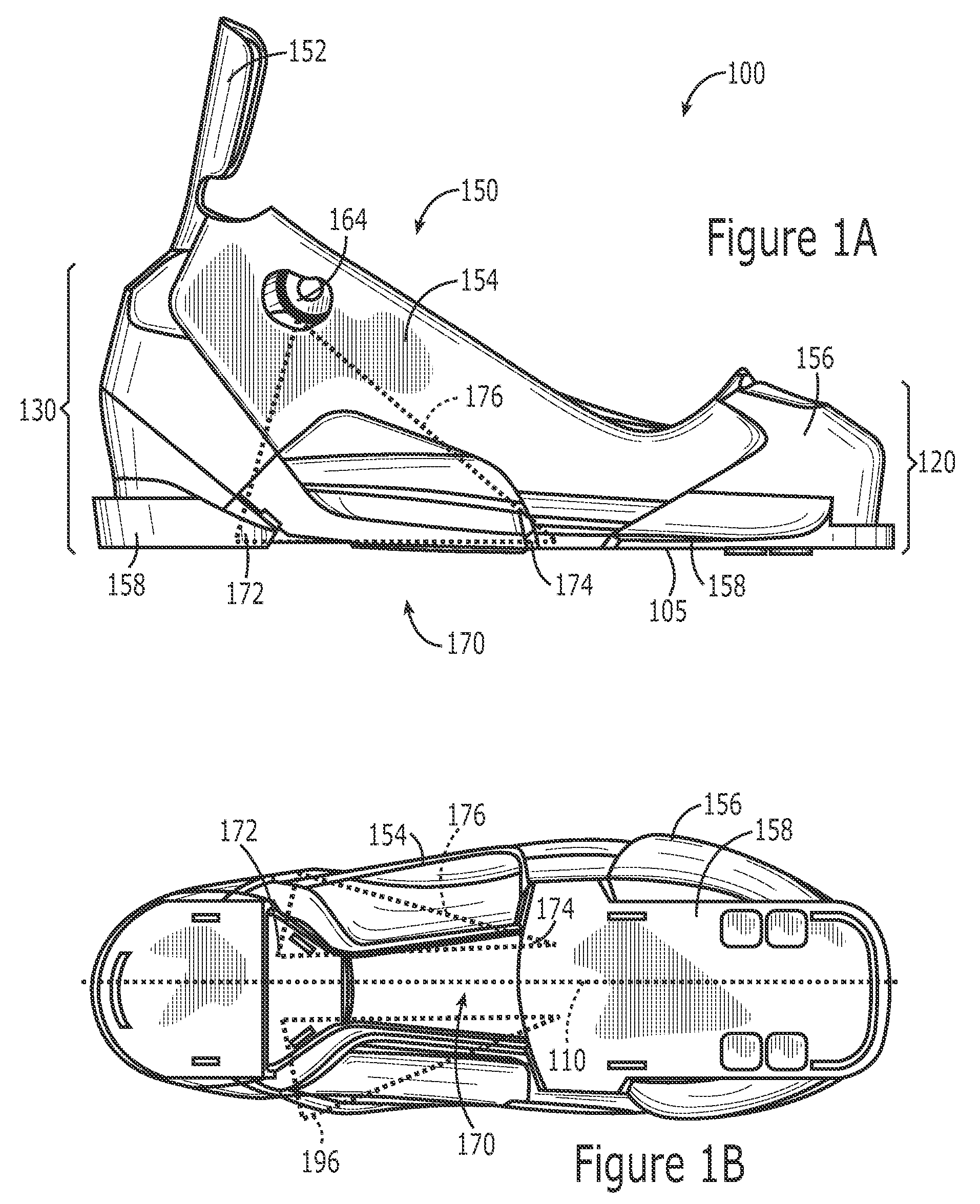

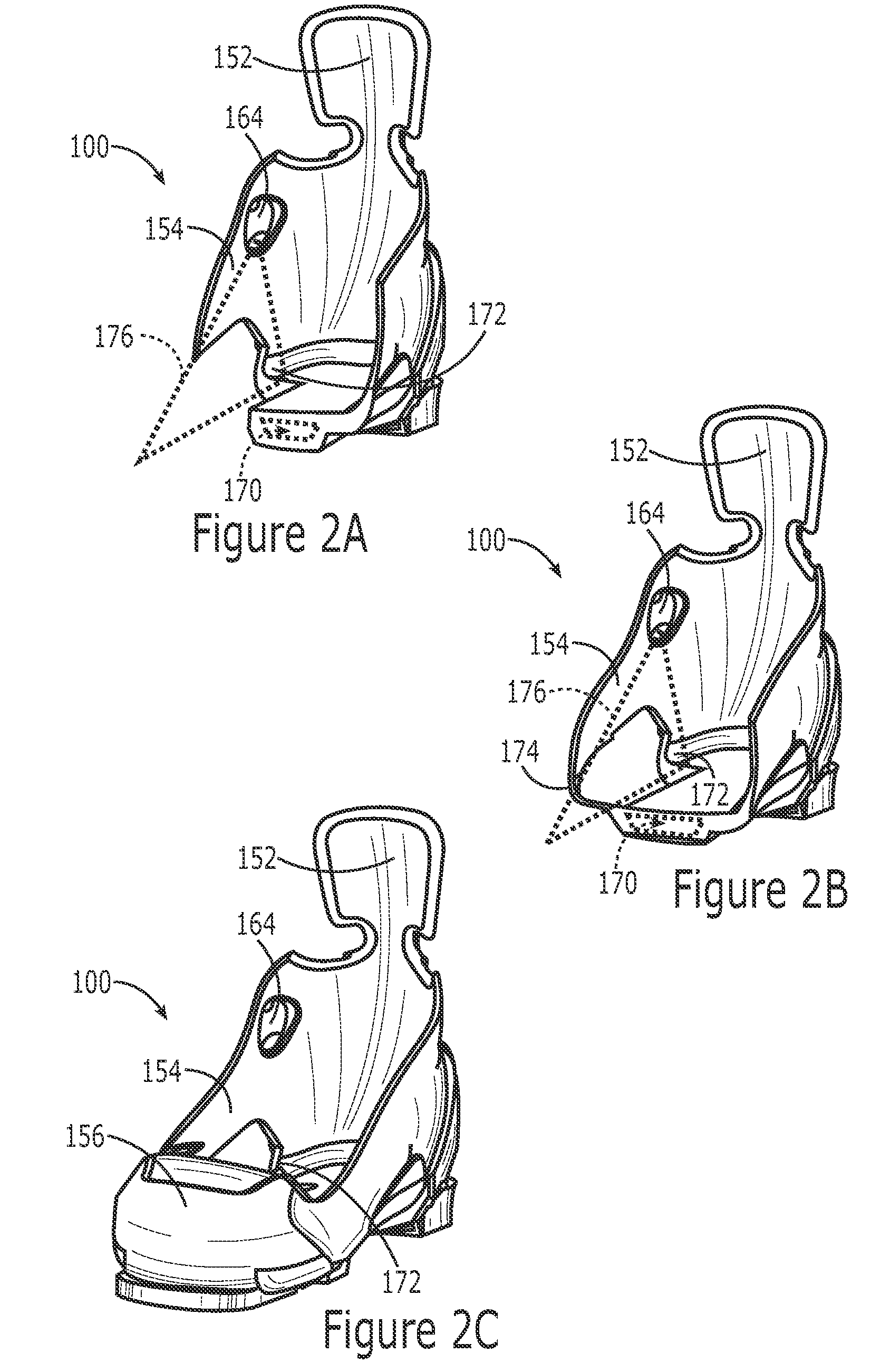

[0018]The present invention relates to a ski boot system with improved torsional support. One embodiment of the present invention is a ski boot system including a shell and an elongated hollow region disposed substantially sagitally within the base or bottom of the shell. The elongated hollow region is rigidly coupled at the proximal and distal ends to a secondary support structure of the shell that extends dorsally on at least one side of the boot, thereby forming a lateral triangular rigid coupling. The lateral triangular rigid coupling increases the torsional support of a user's foot and lower leg disposed within the shell. An optional second lateral triangular coupling may extend dorsally on the opposite side of the ski boot so as to balance medial and lateral torsional support. The elongated hollow region may be formed internally within the base or created by rigidly coupling a rigid member to a lengthwise U-shaped region. A second embodiment of the present invention is a metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com