Platform-Type Shelf and Assembling Method thereof

a platform-type shelf and platform-type technology, applied in the field of platform-type shelves, can solve the problems of inability to generate stable connecting force between the longitudinal lattice beam and the transverse lattice beam, need adhesive to increase the connecting force, and easily distorted or loose, so as to achieve the effect of enhancing the connecting force and supporting for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Reference will now be made to the figures to describe the present invention in detail.

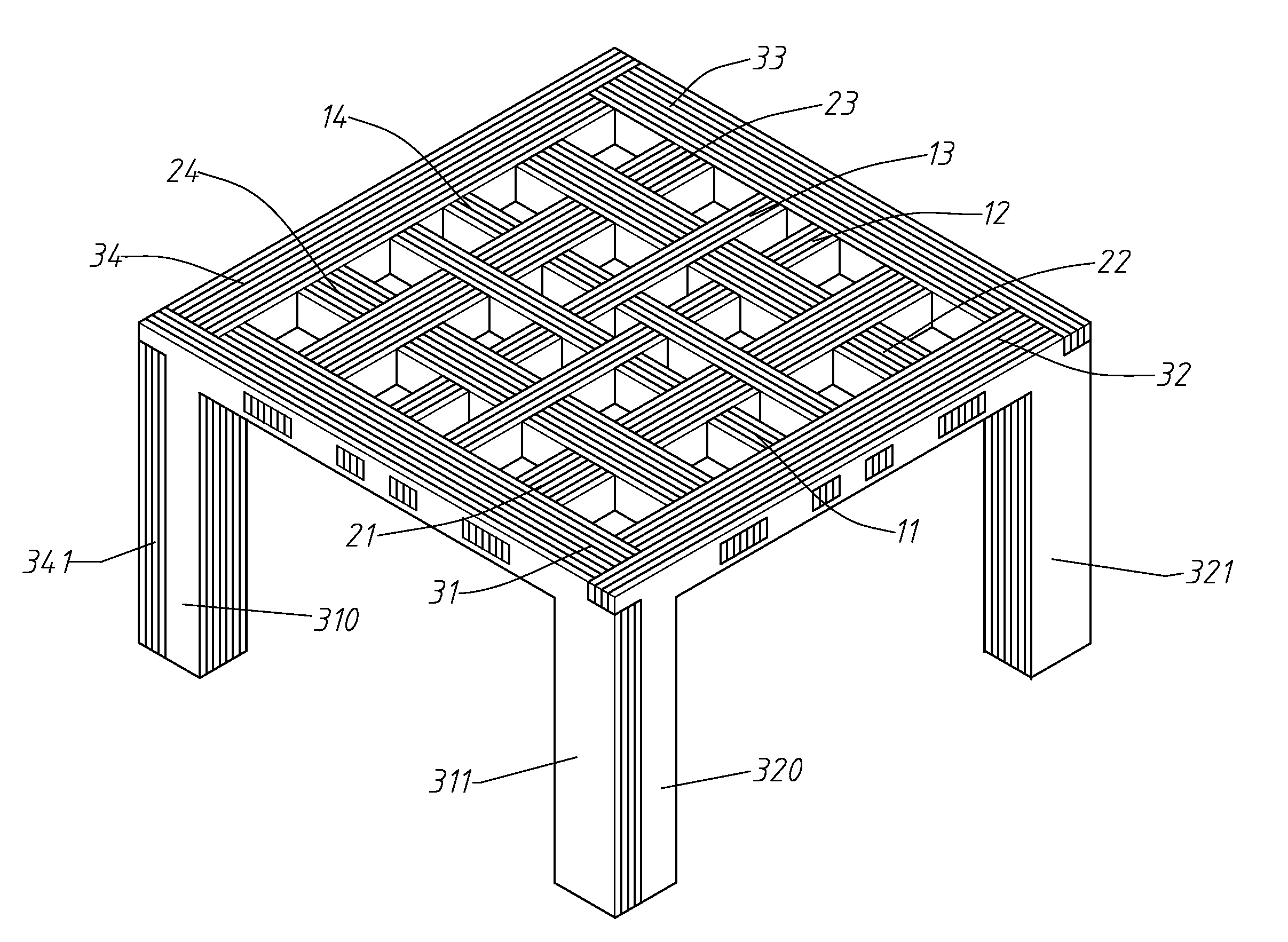

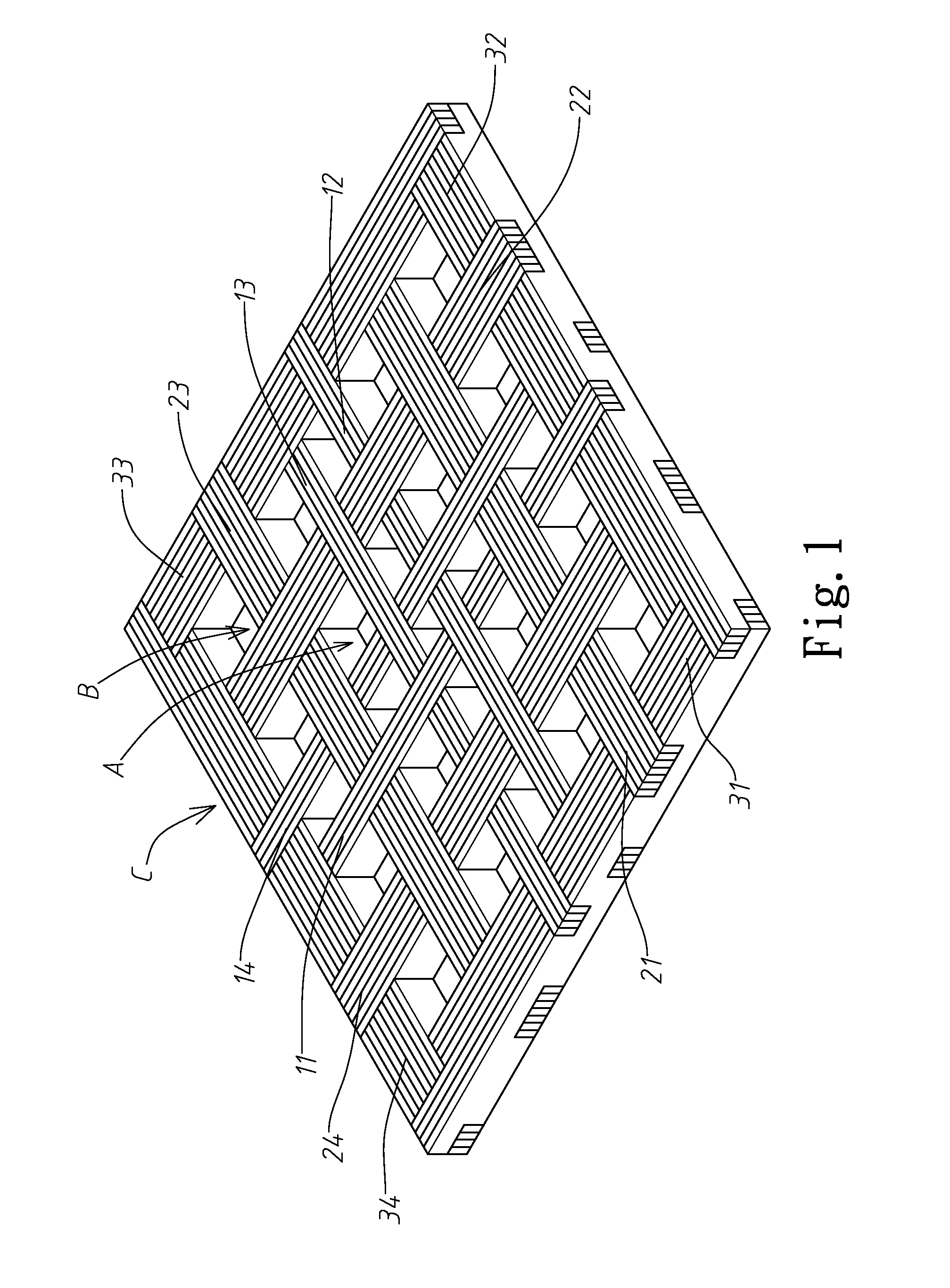

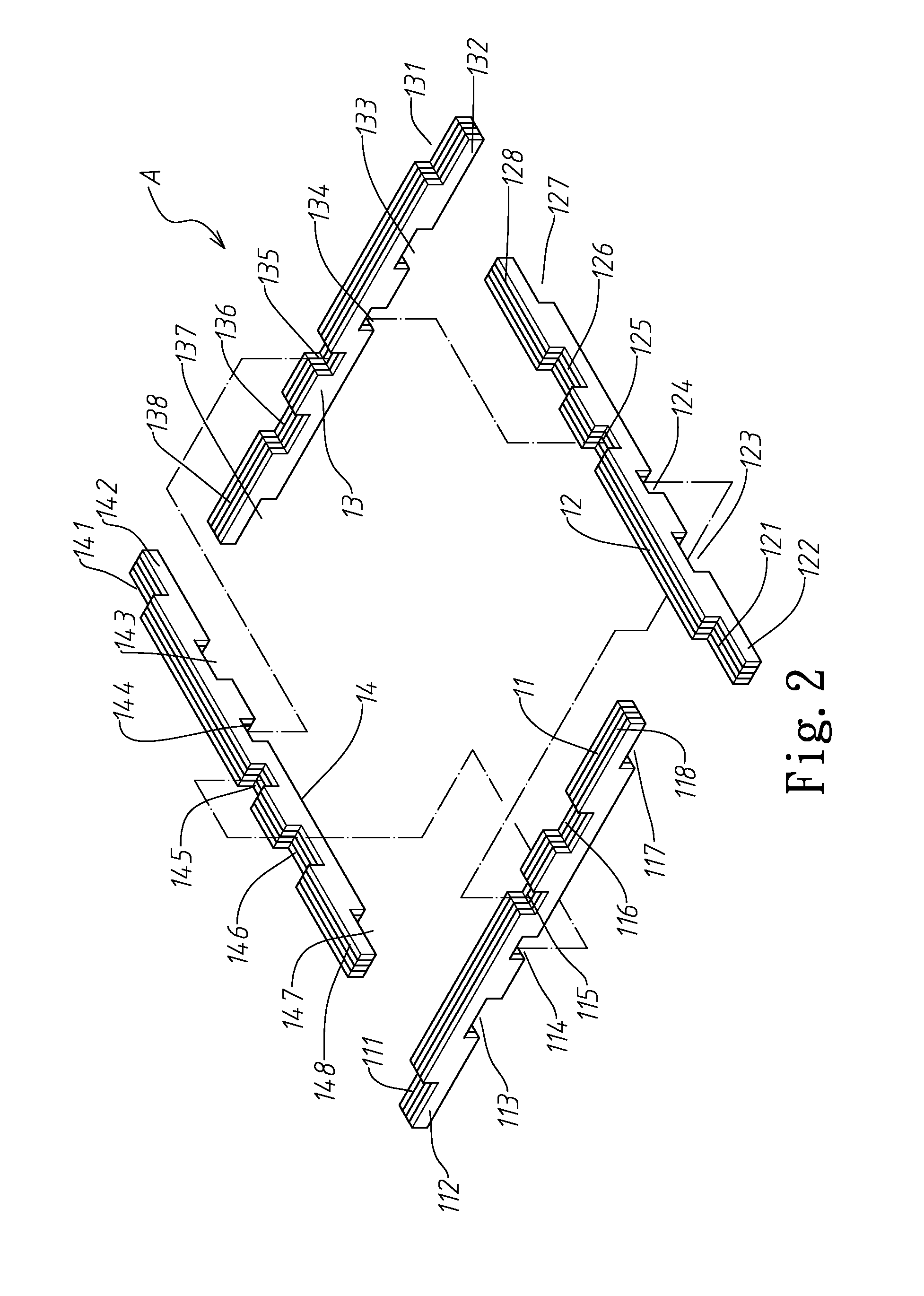

[0043]Referring to FIGS. 1 to 4, a platform-type shelf in accordance with a first embodiment of the present invention is shown. The platform-type shelf includes a central lattice beam group A, a locking lattice beam group B, and a frame beam group C. The central lattice beam group A includes two lengthways lattice beams 11 and 13, and two transverse lattice beams 12 and 14, which together form a central basic structure via a weaving technique. The central basic structure is a small pane as shown in FIG. 2. Also referring to the central lattice beam group A shown in FIG. 2, the lattice beams 11, 13, 12 and 14 define downward first engaging grooves 114, 134, 124 and 144 and upward first engaging groove 115, 135, 125 and 145, respectively. The terms “downward” and “upward” mean positional relationships between the grooves and the lattice beams (e.g., the term “downward” mean that the first engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com