Method of thinning a wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

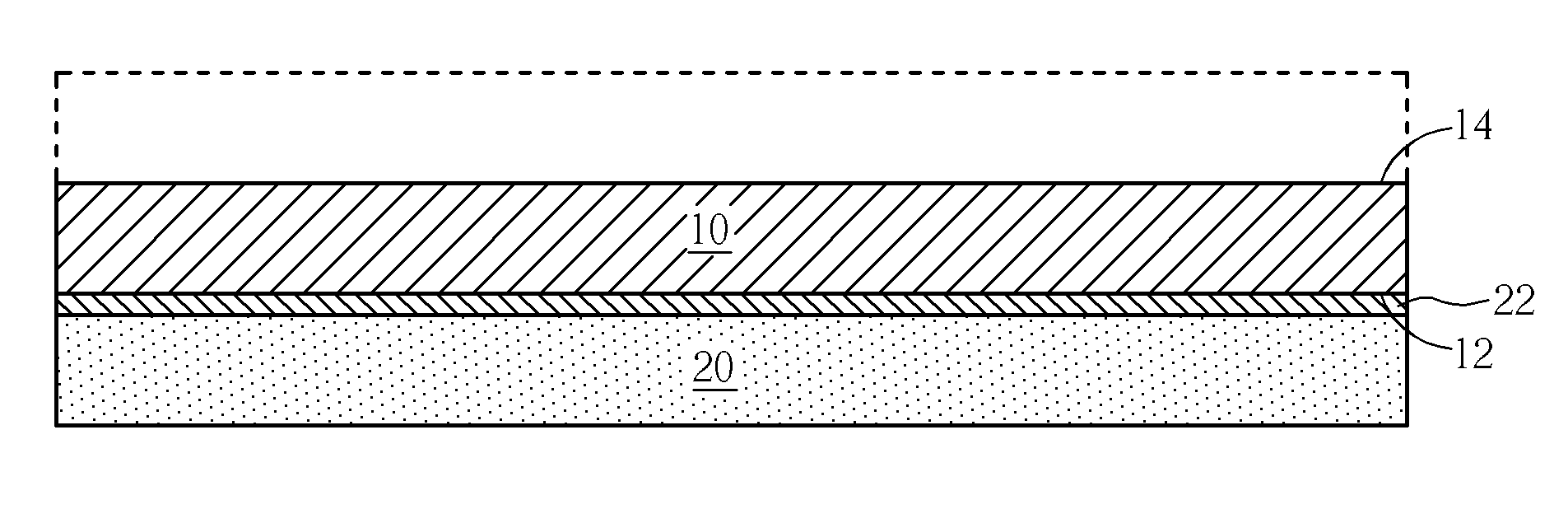

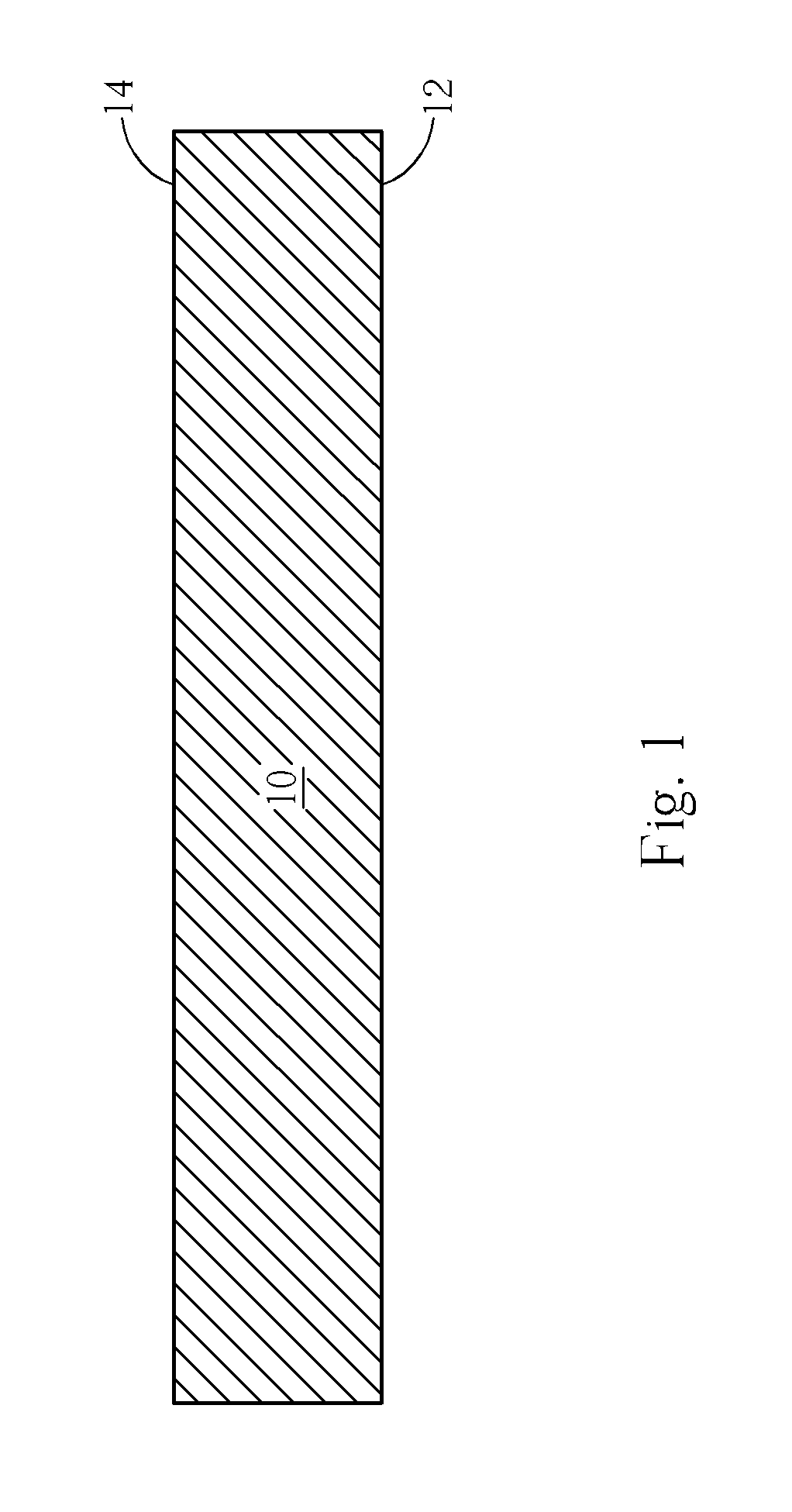

[0009]Please refer to FIGS. 1 to 10. FIGS. 1 to 10 are schematic diagrams illustrating a method of thinning a wafer according to a preferred embodiment of the present invention. As shown in FIG. 1, a wafer 10 is first provided, the wafer including a front surface 12 and a back surface 14. In this preferred embodiment, the wafer 10 is a wafer that already includes the needed semiconductor components or micro-electromechanical components (not shown in the figure) in its front surface 12, and also requires thinning. However, the method of the present invention is not limited by this preferred embodiment, and can be applied to any wafer thinning process in semiconductor processes or in micro-electromechanical processes.

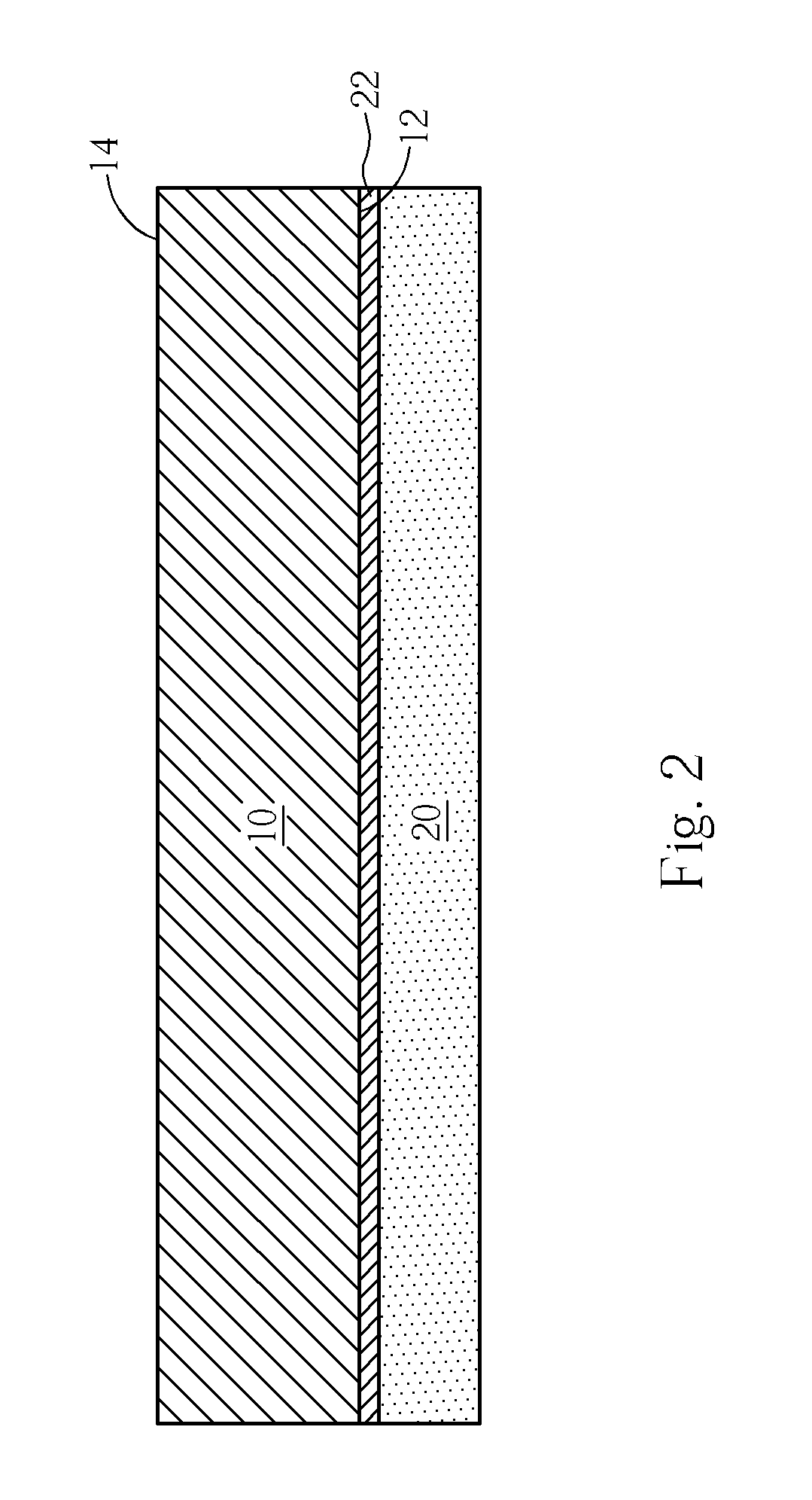

[0010]As shown in FIG. 2, a carrier wafer 20, such as a semiconductor wafer, a glass wafer, a plastic wafer, or a silicon wafer, is subsequently provided, and the front surface 12 of the wafer 10 is bonded to a surface of the carrier wafer 20 with a bonding layer 22. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com