Device and method for the transferring of grain from a grain bin

a technology for grain bins and devices, applied in agriculture tools and machines, building types, construction, etc., can solve the problems of more difficult, necessary to minimize and achieve the effect of reducing the risk of deformation of the bin wall and minimizing the loading on the bin wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

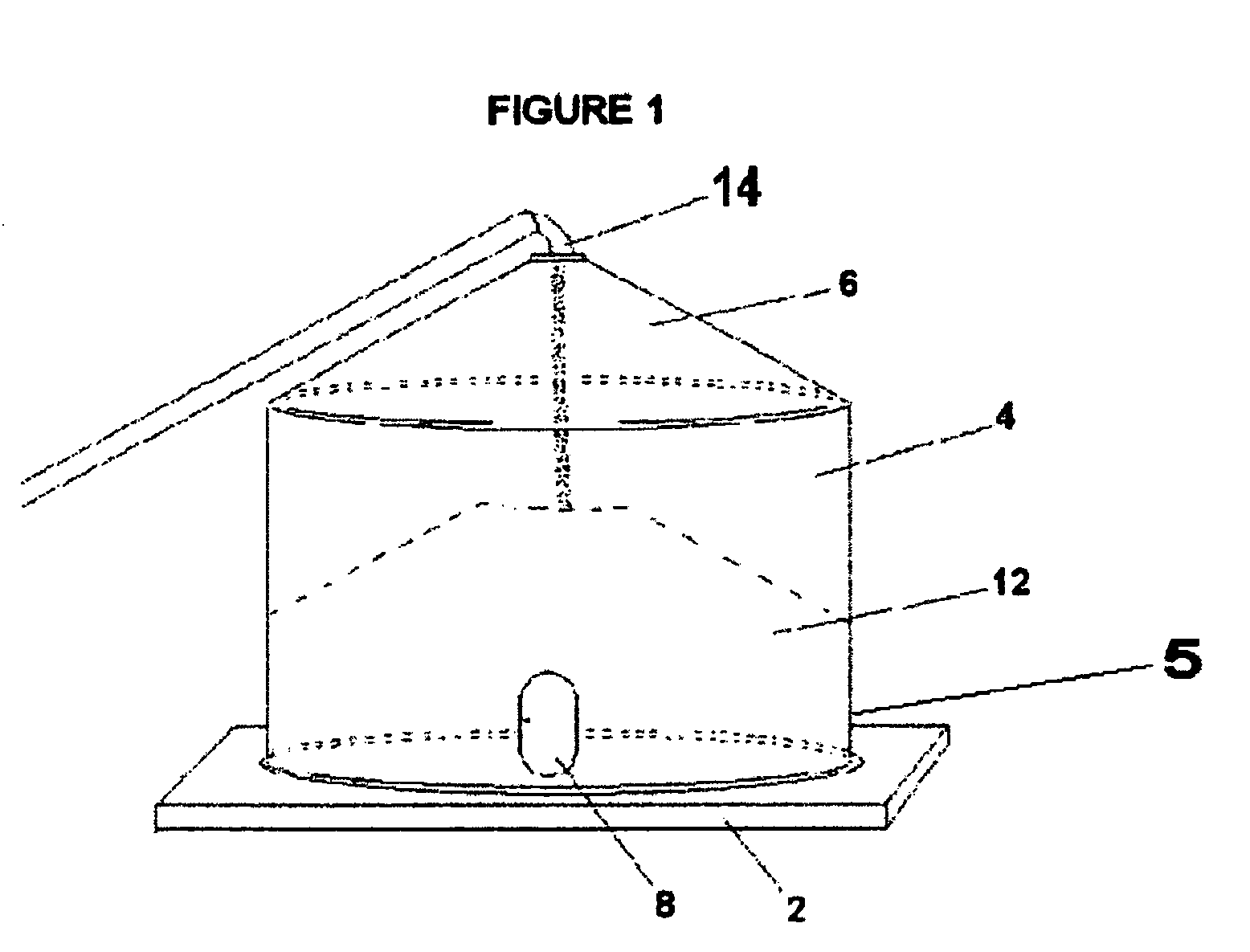

[0028] Referring to FIG. 1, positioned upon a concrete pad 2, is a typical grain bin 4, it being understood that grain bins may be positioned upon other suitable pads or materials known to a person skilled in the art. The vertical walls 5 and conical roof 6 of the typical grain bin 4 are generally made of corrugated stainless steel or other suitable material, known to a person skilled in the alt. An access door 8 provides access for personnel and equipment into the interior of the grain bin 4 and an access port 10 at the top of the grain bin 4 permits grain to be transferred from a conveyor system 14 into the interior of the grain bin 4 for storage, which typically forms a pile 12 generally centered within the grain bin 4.

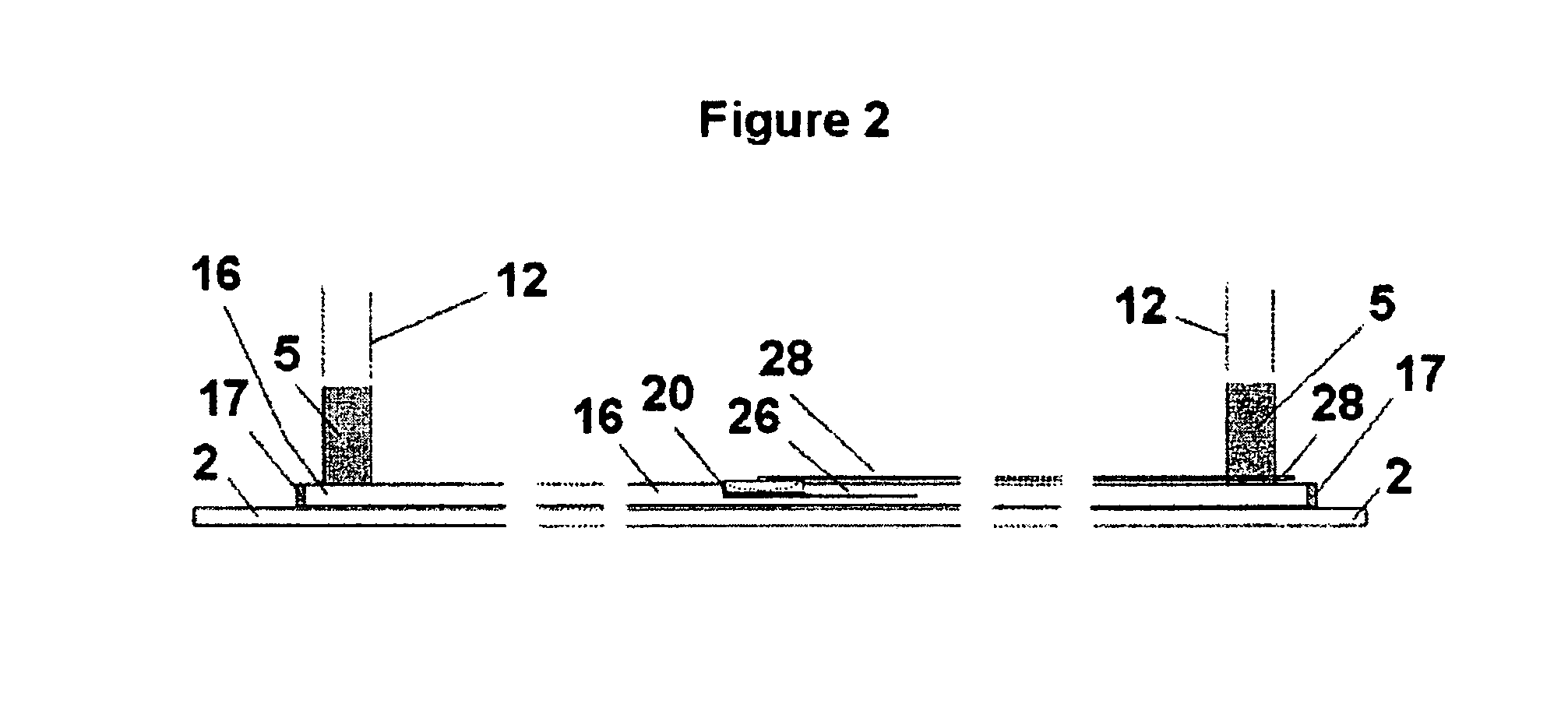

[0029] Referring to FIG. 2, a metal tube 16 extends across the concrete pad 2 (or other floor material for the bin, hereinafter referred to as the “concrete pad”), and is securely anchored thereto by means of anchors, straps, bolts or other devices known to a pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com