Roll Roofing

a technology of roofing and roll roofing, applied in the field of roofing, can solve the problems of reducing the speed of production lines, reducing the availability of raw materials, and reducing the use of adhesives, so as to achieve the effect of reducing the number of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

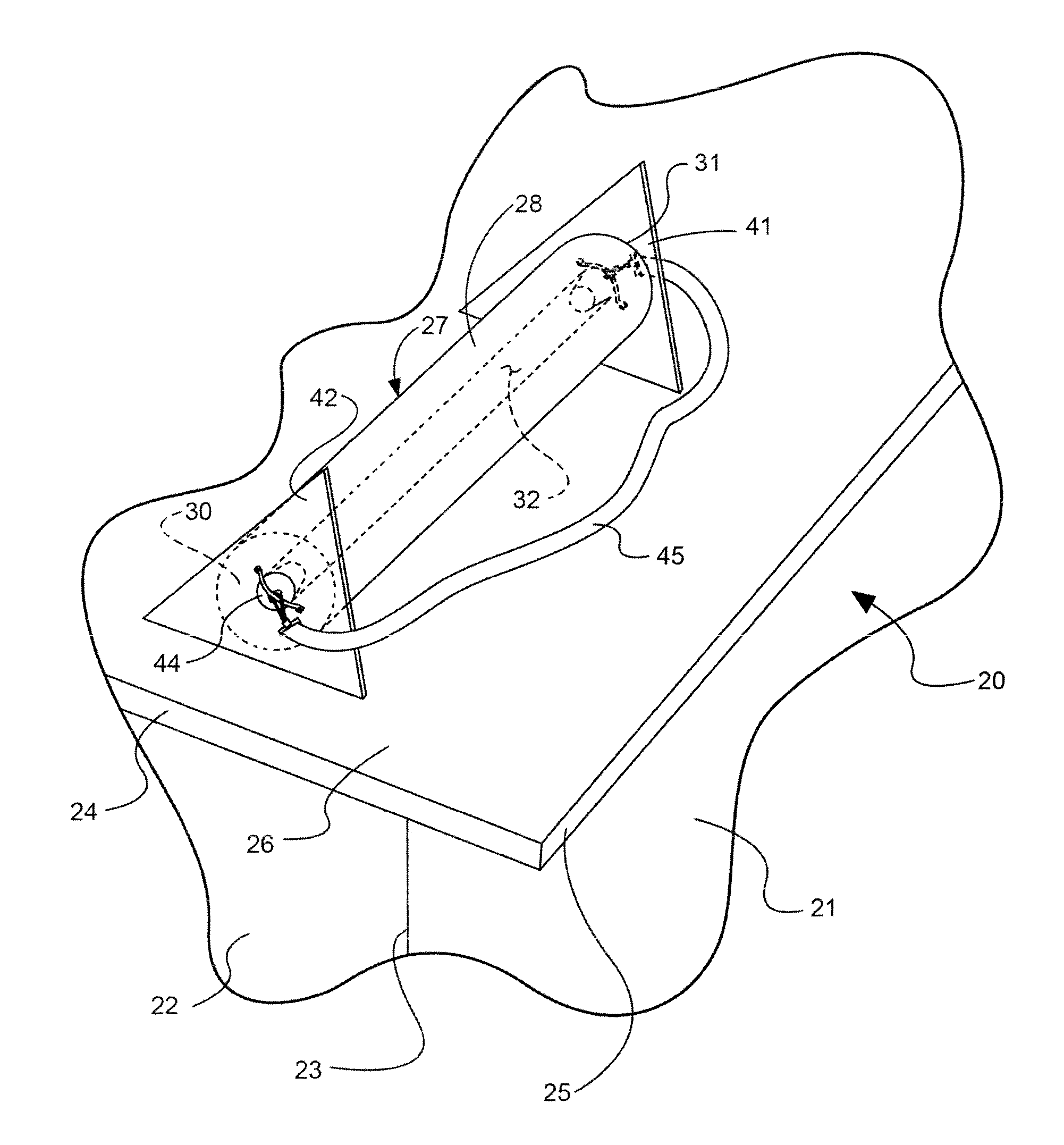

[0029]Referring now to the drawings in detail, reference is first made to FIG. 1, wherein there is fragmentally illustrated a building generally designated by the numeral 20, having adjacent walls 21 and 22, that meet at a corner 23, and wherein a roof 24, of the sloped or pitched type is illustrated, having an overhang 25, and with the upper surface 26 of the roof being sloped, as shown.

[0030]A roll roofing material generally designated 27 is shown disposed on the roof. The roll roofing material 27 includes a wound cylindrical roll 28 which, between its ends 30, 31 may, for example, be 36 inches in length, and which may, in an unrolled (not shown) condition be anywhere from 36 feet to 144 feet or more, in length. The roll roofing material 27 will generally have a cylindrical hollow core 32, which may be comprised of a hollow cardboard, plastic or the like sleeves about which the roll roofing material is wound.

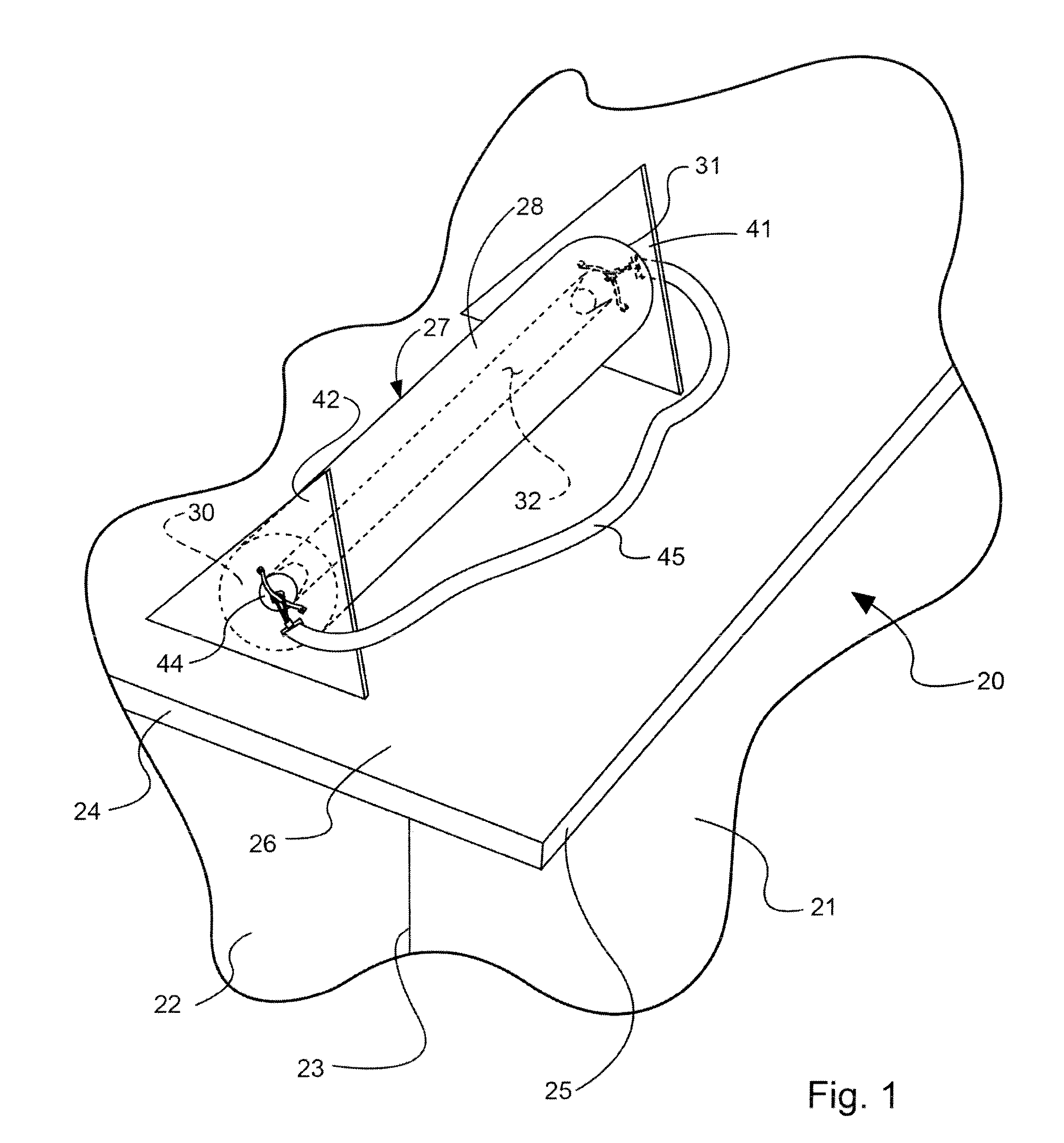

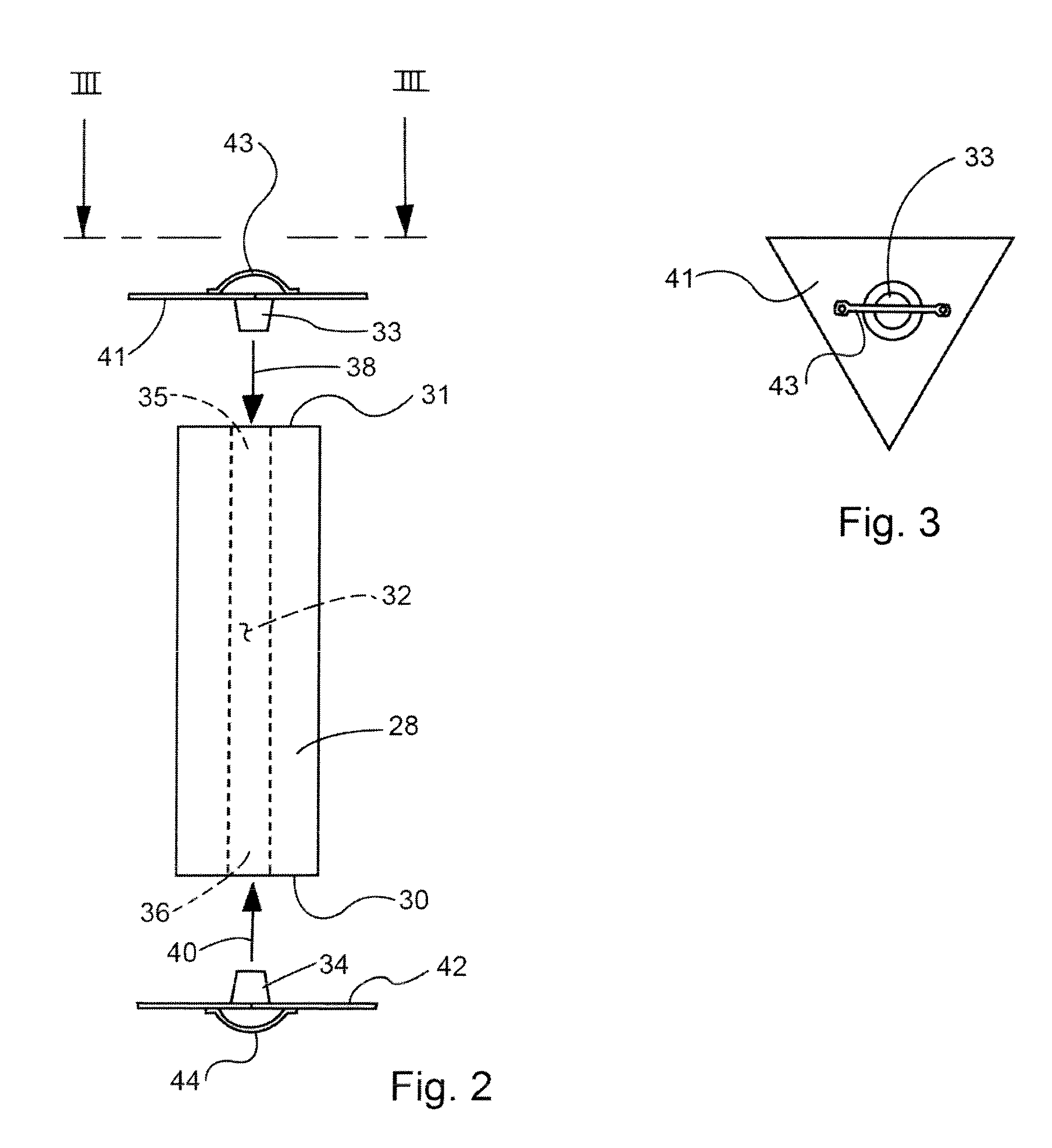

[0031]With specific reference to FIGS. 2 and 3, the roll roofing material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com