Package

a technology for packaging and containers, applied in the field of packaging, can solve the problems of limited time-consuming sealing effect and relatively easy split or tear of bags, and achieve the effect of increasing water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

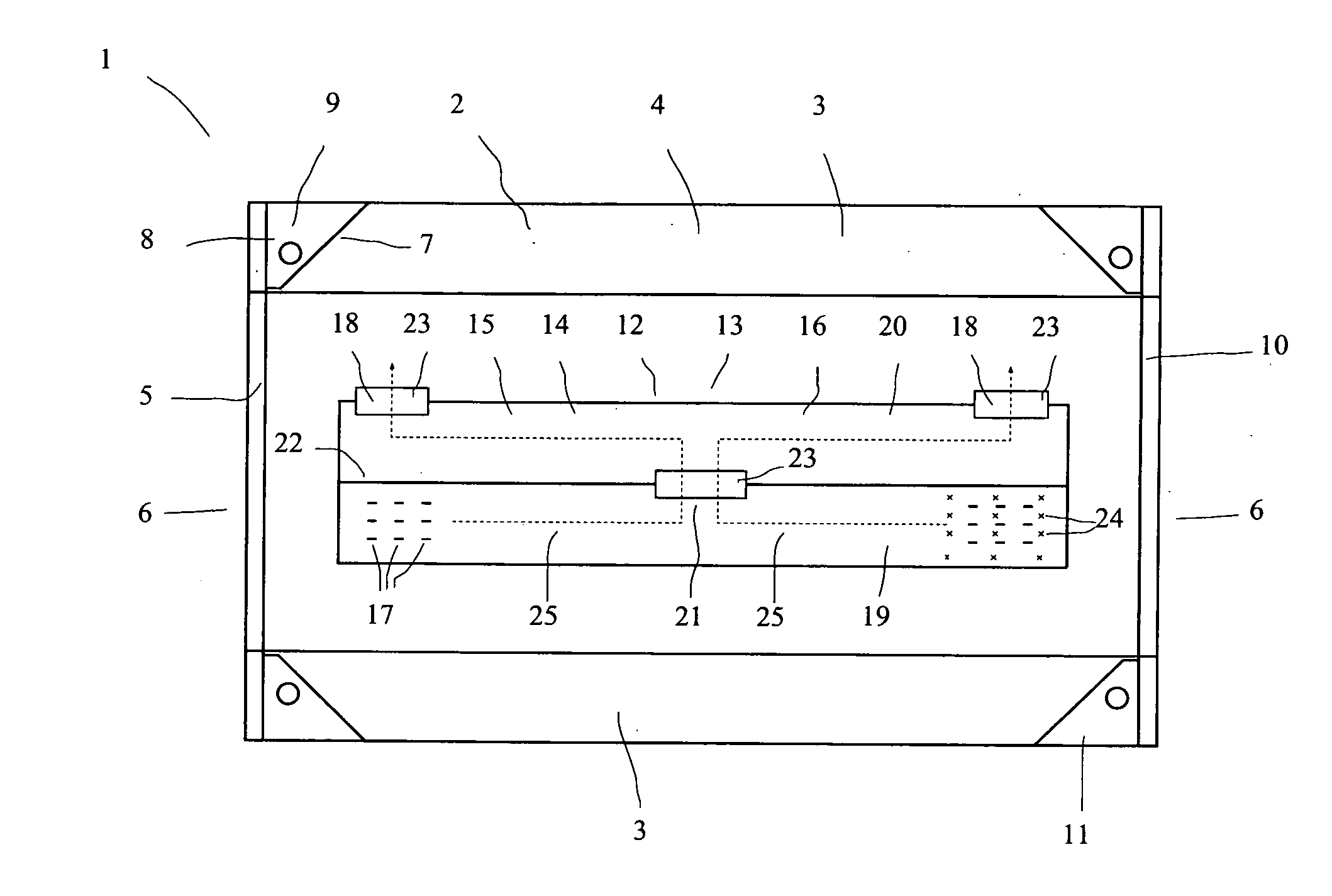

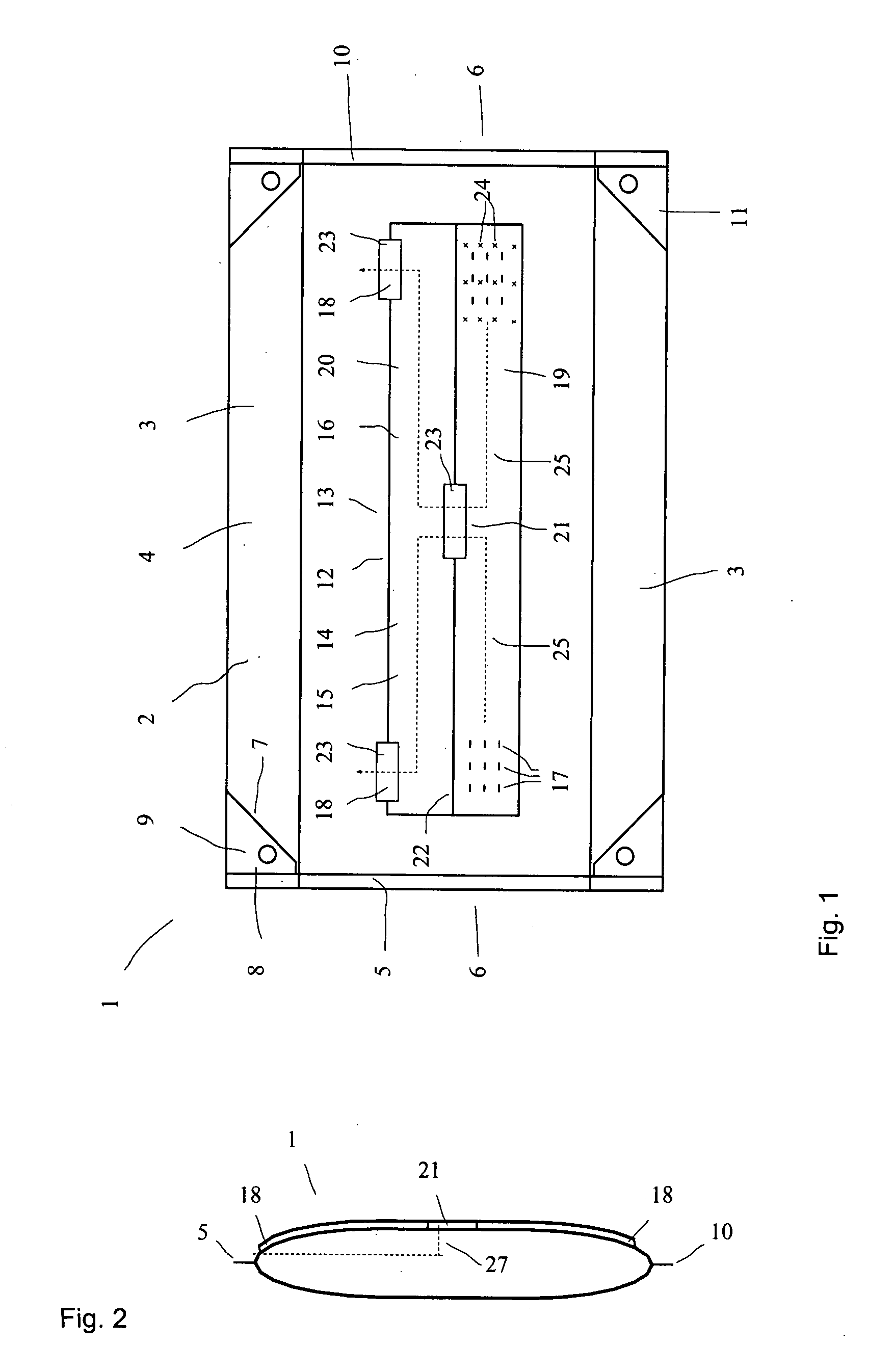

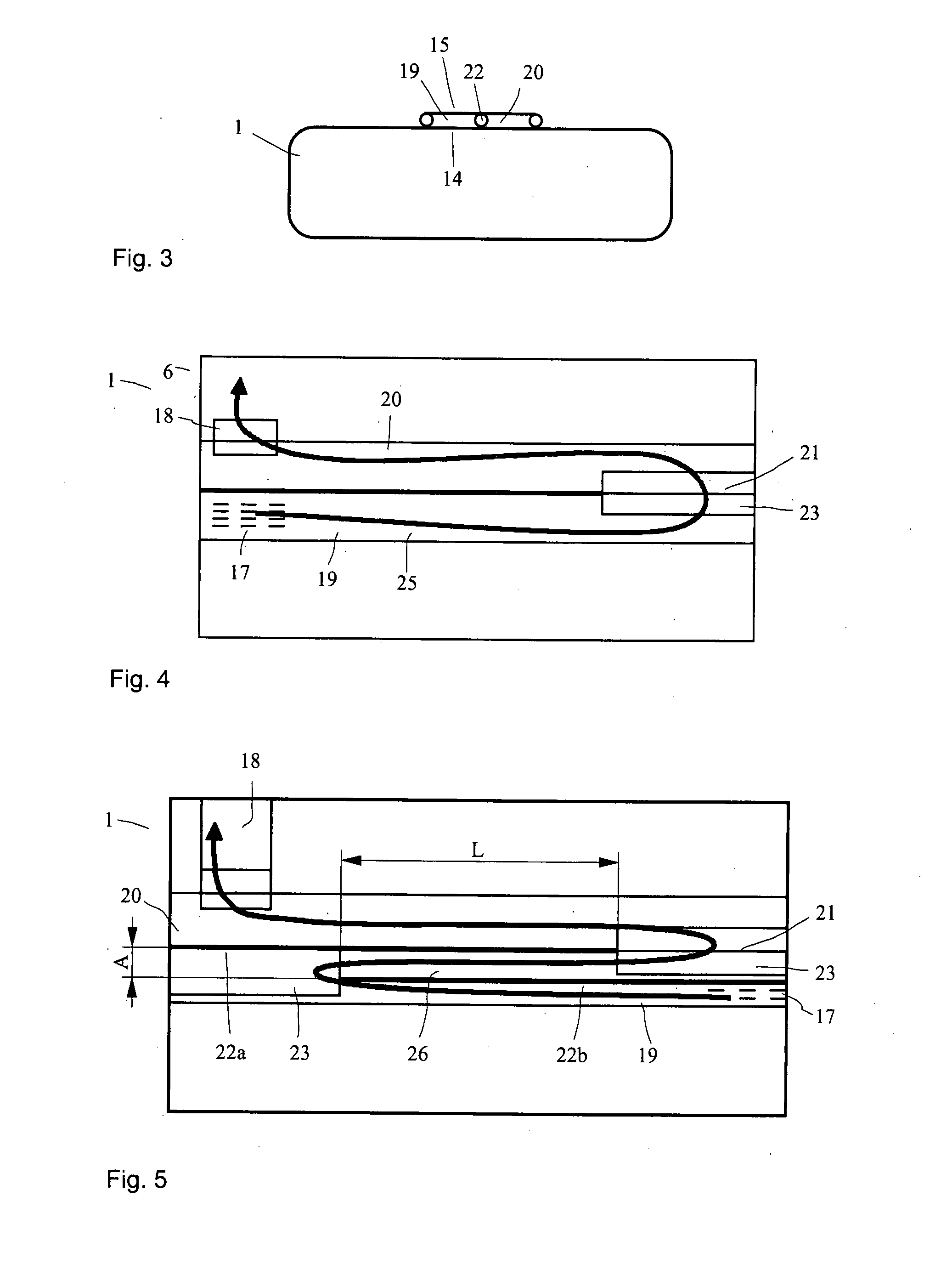

[0042]FIGS. 1 through 3 illustrate a package 1 according to the invention configured as a bag, comprising a package body 2 provided with gussets 3 made of a plastic sheet 4.

[0043] The package 1 serves to take feed material, in particular bulk material. In filling bulk material, air will as a rule enter the package along with the product to be bagged. Furthermore, an air bubble tends to form in the top region as the bag is closed. To allow the air present in the package to escape from the closed package 1, a de-aeration means 12 is provided on the flat surface of the package 1. In the de-aeration area 13, an inner sheet layer 14 that is adjacent to the product present in the interior volume of the package 1 overlaps with an outer sheet layer 15 that is adjacent to the environment.

[0044] Between the two sheet layers 14 and 15 there is positioned a de-aeration channel 16 connecting a plurality of inner de-aeration openings 17 with one or two outer de-aeration openings 18, thus providi...

fourth embodiment

[0065]FIG. 6 illustrates a package according to the invention in a general and simplistic sectional side view. In this embodiment the package body 2, the outer sheet layer 15 and the inner sheet layer 14 are formed integrally. The first and second chambers 19, 20 are positioned adjacent to one another. The chambers extend one above the other at least in part and, depending on the configuration they may be not at all adjacent. A separate interlayer 28 between the outer sheet layer 15 and the inner sheet layer 14 separates the two chambers 19 and 20 from one another. The individual chambers are subdivided by means of seams 29 at the sheet.

fifth embodiment

[0066] In a package according to the invention illustrated in FIG. 7 at least part of the first and second chambers are also positioned one above the other. The interlayer 28 is also formed integrally of the sheet such that the package body 2, the outer sheet layer 15 and the inner sheet layer 14 and the interlayer 28 consist of one piece of sheet. In manufacturing, the individual sheet layers 14, 15, and 28 are created by folding over and stacking the sheet and using suitable intermediate or bonded seams 29. The intermediate or bonded seams 29 separate and seal the chambers 19 and 20 from the side faces, except in those points where a separating layer 23 is provided (see FIG. 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com