Beam construction of air mattress

a technology of air mattress and beam, which is applied in the field of beam construction of air mattresses, can solve the problems of increased production costs, reduced damage to air mattresses, and increased interior air pressure value, and achieve the effect of reducing the pulling force at the seam and ensuring the durability of air mattresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

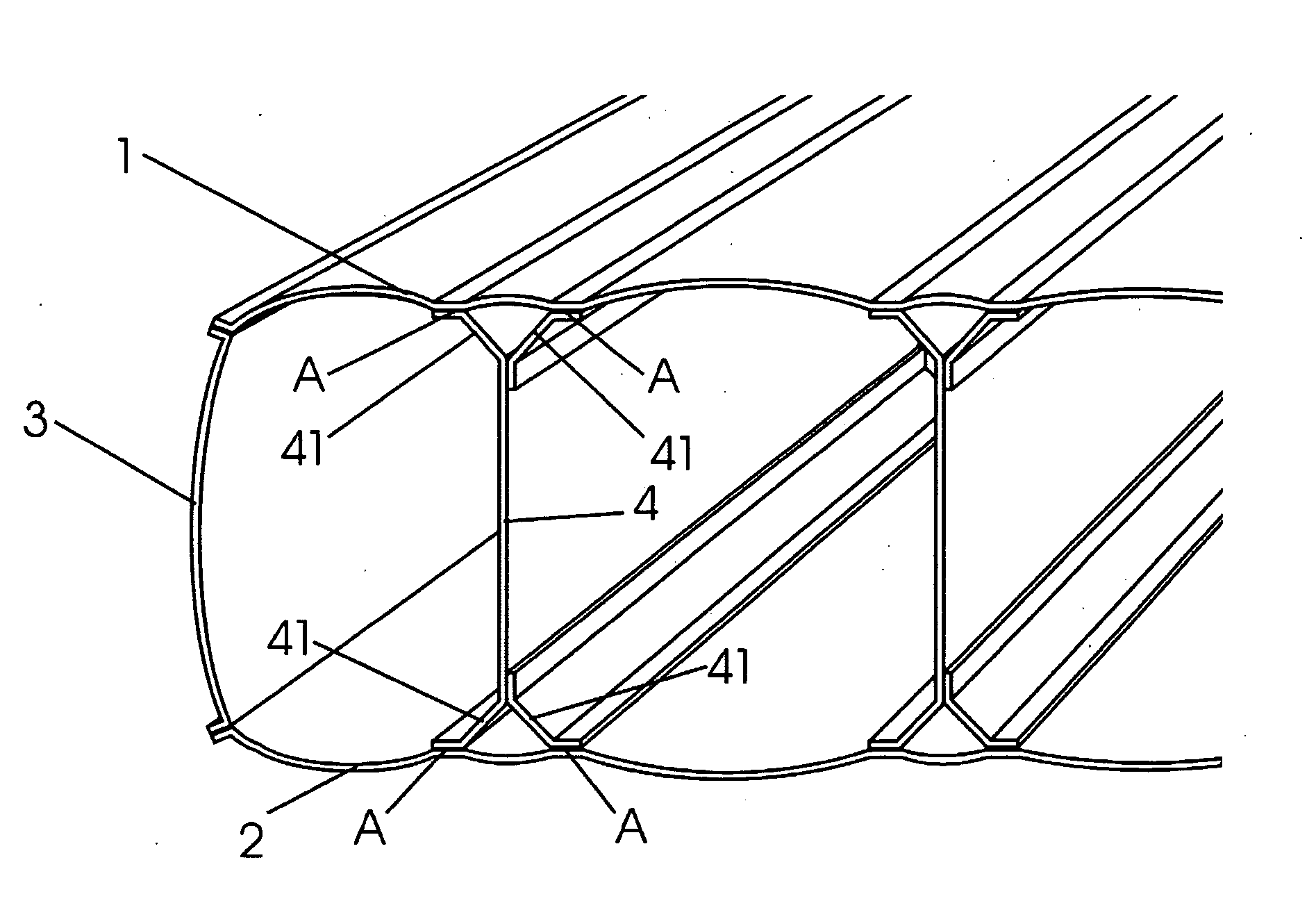

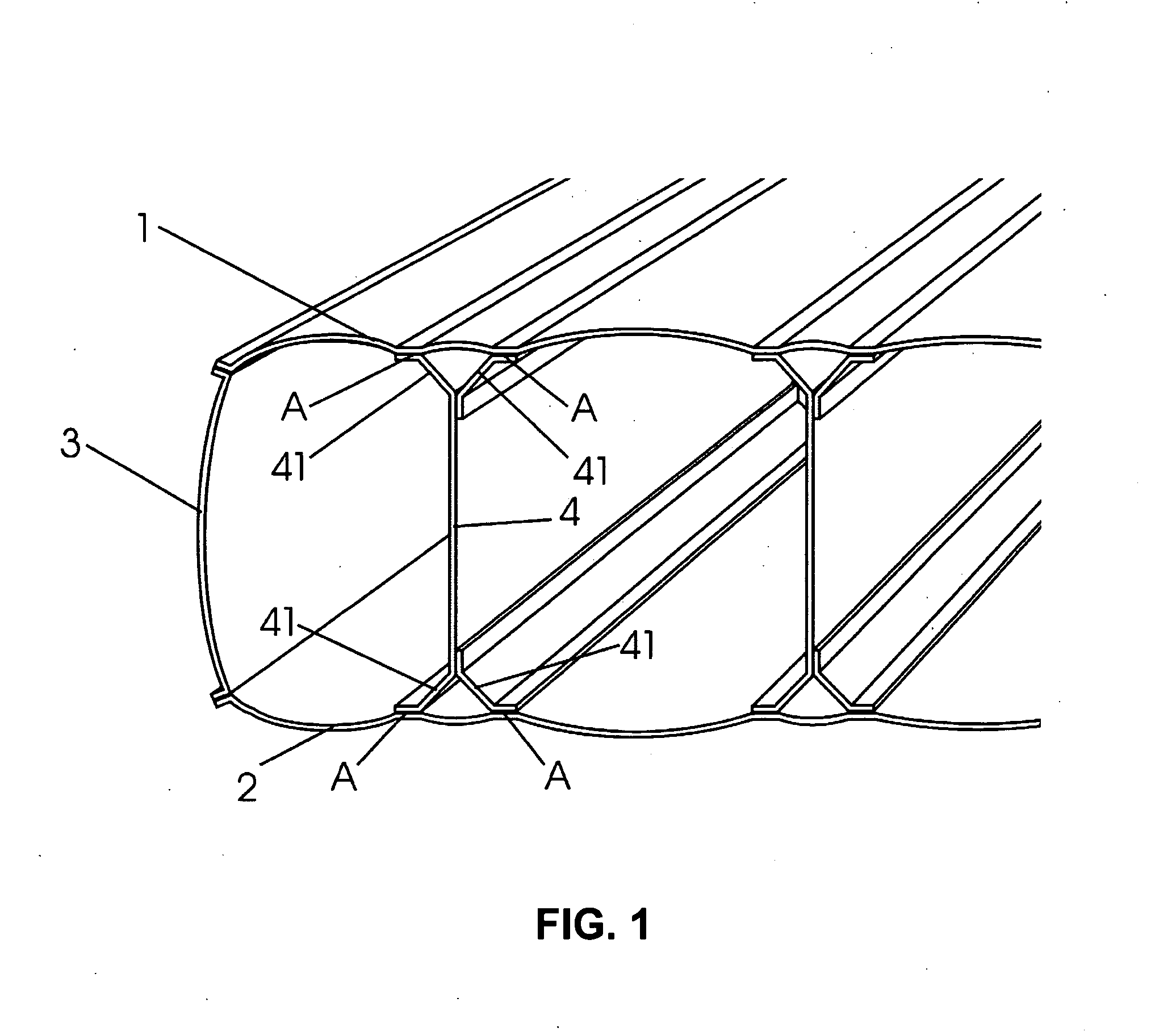

[0011]As shown in FIG. 1, a beam 4 has a substantially “” shape cross-section. The two ends of beam 4 have extending parts 41 that are connected with a top sheet 1 or a bottom sheet 2, respectively, by adoption of high-frequency welding. After inflation, beam 4 of the air mattress exerts pulling forces against the top sheet 1 and the bottom sheet 2 through both ends of the extending parts 41. The pulling forces against the top sheet 1 and the bottom sheet 2 are dispersed. Simultaneously, the extending parts 41 connected with both ends of beam 4 protect the welded joints A. The place where beam 4 connects with the top sheet 1 or the bottom sheet 2 will not easily peel off or be torn away when pulling forces are brought from vertical directions, even when the interior air pressure value in the air mattress is high, or when stronger exterior forces are exerted, which causes a sudden increase of interior air pressure value.

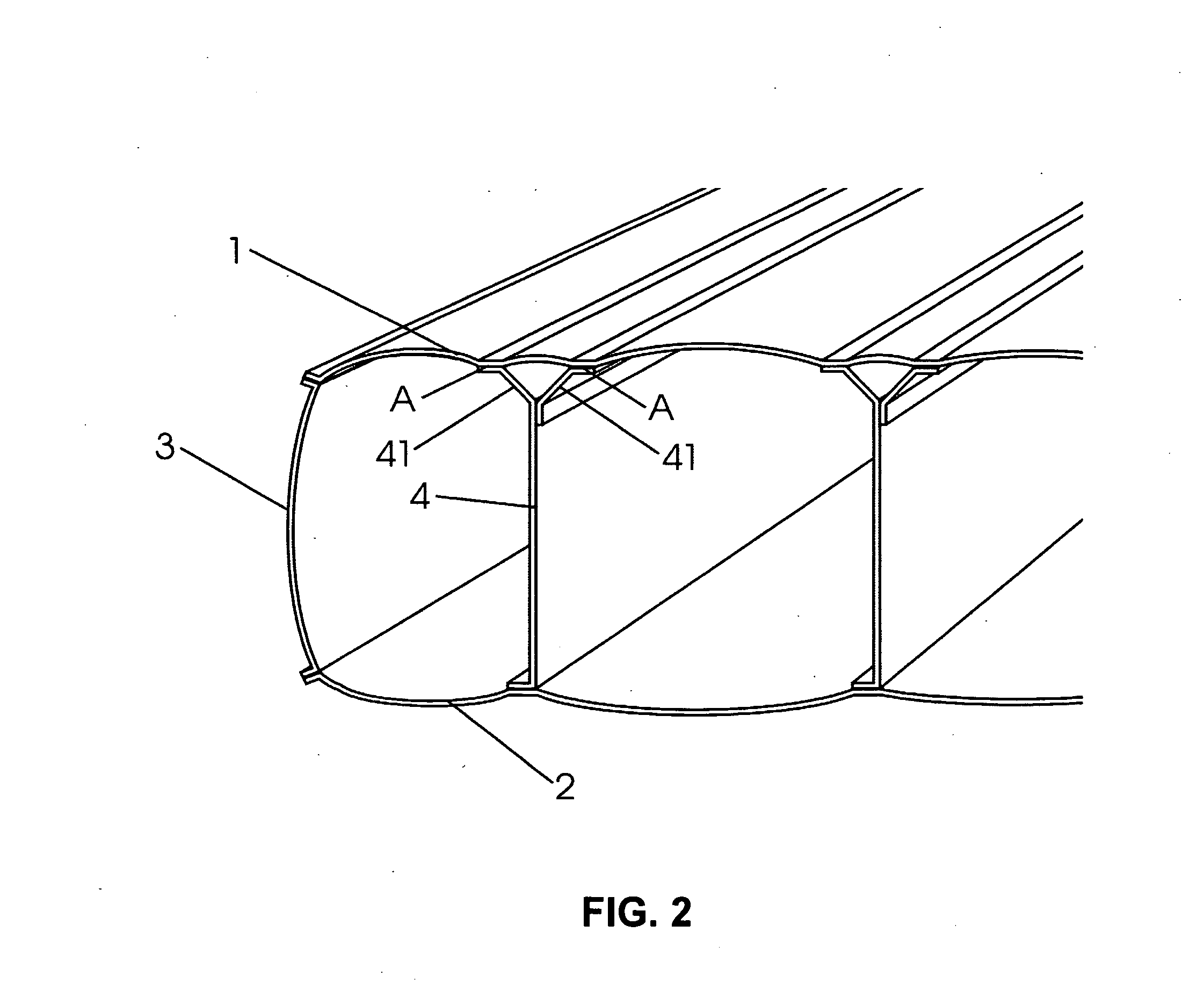

[0012]The embodiment shown in FIG. 2 is similar to the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com