Double stacked pallet system for rolled sheet goods

a pallet system and double-stacked technology, applied in the field of material handling of rolled sheet goods, to achieve the effect of convenient display, sufficient load bearing strength, and convenient wrapping of the supporting pair of pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

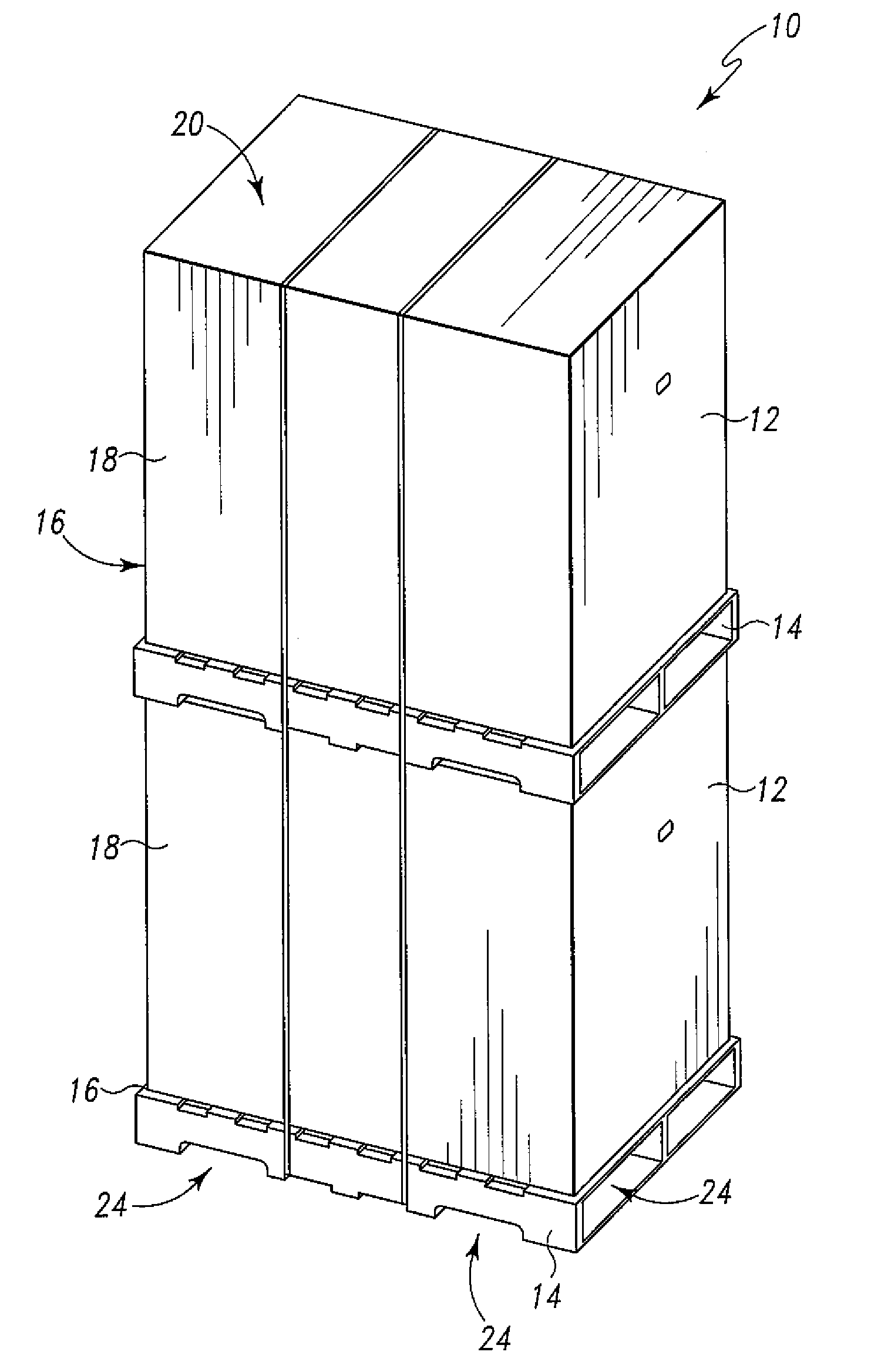

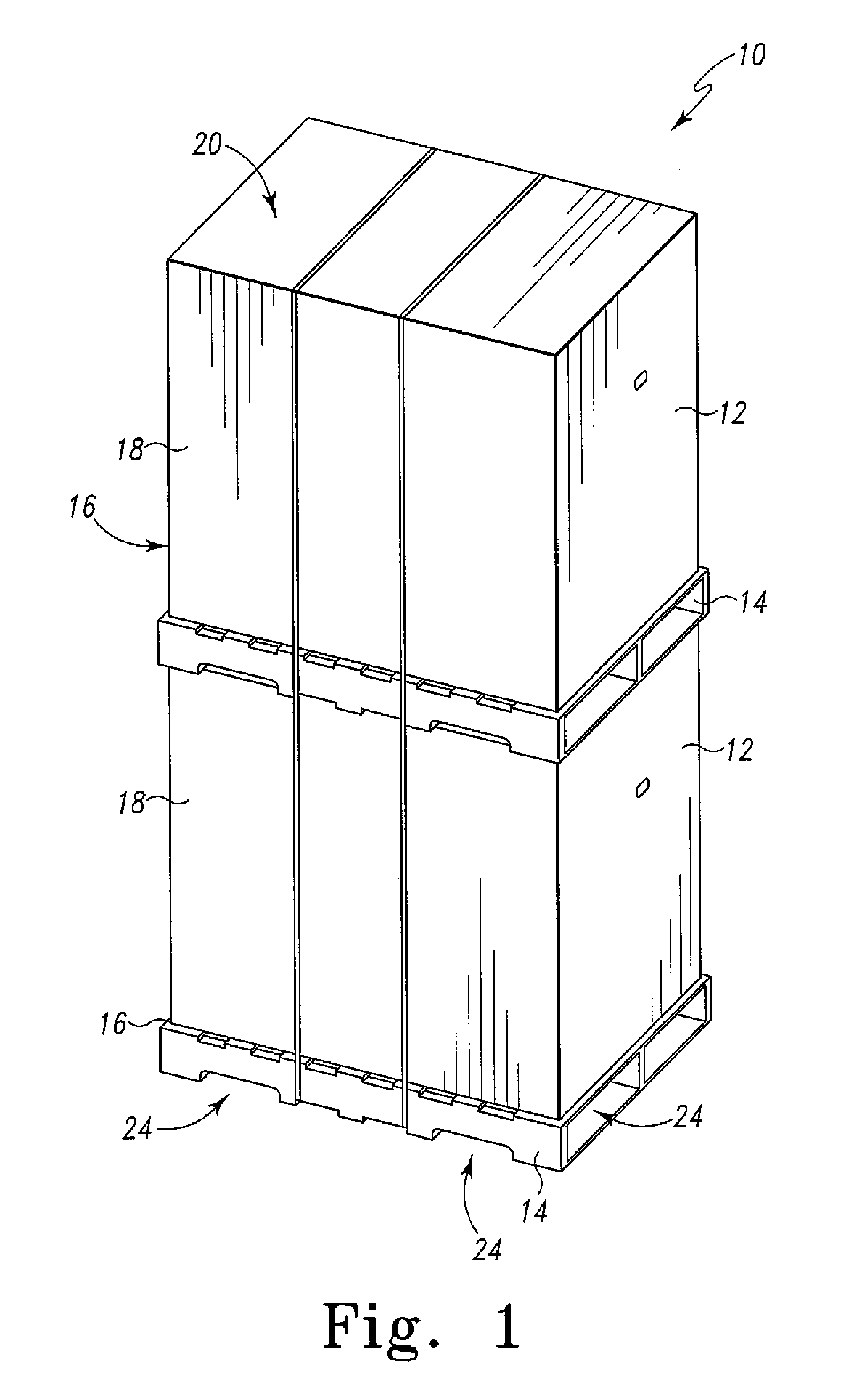

[0021]A system 10 of pallet supported boxes 12 for containing rolled sheet goods is shown in FIG. 1 to include pallets 14 adapted for engagement by a fork lift (not shown). Each box 12 has a bottom 16 supported by the underlying pallet 14. Sidewalls 18 extending upward from the bottom 16 to a top 20. The system 10 allows the boxes 12 and supporting pallets 14 to be vertically stacked at least two units high, and secured in this arrangement by bands 22 or other equivalent structures. The bands 22 can be located at a suitable spacing in a generally laterally central portion of the system 10. The combined vertically stacked units can be handled by insertion of a standard set of forks of a fork lift in openings 24 in either the lower pallet or the upper pallet 14. The ability to vertically stack the units is accomplished by arranging for proper supporting structure within the boxes 12.

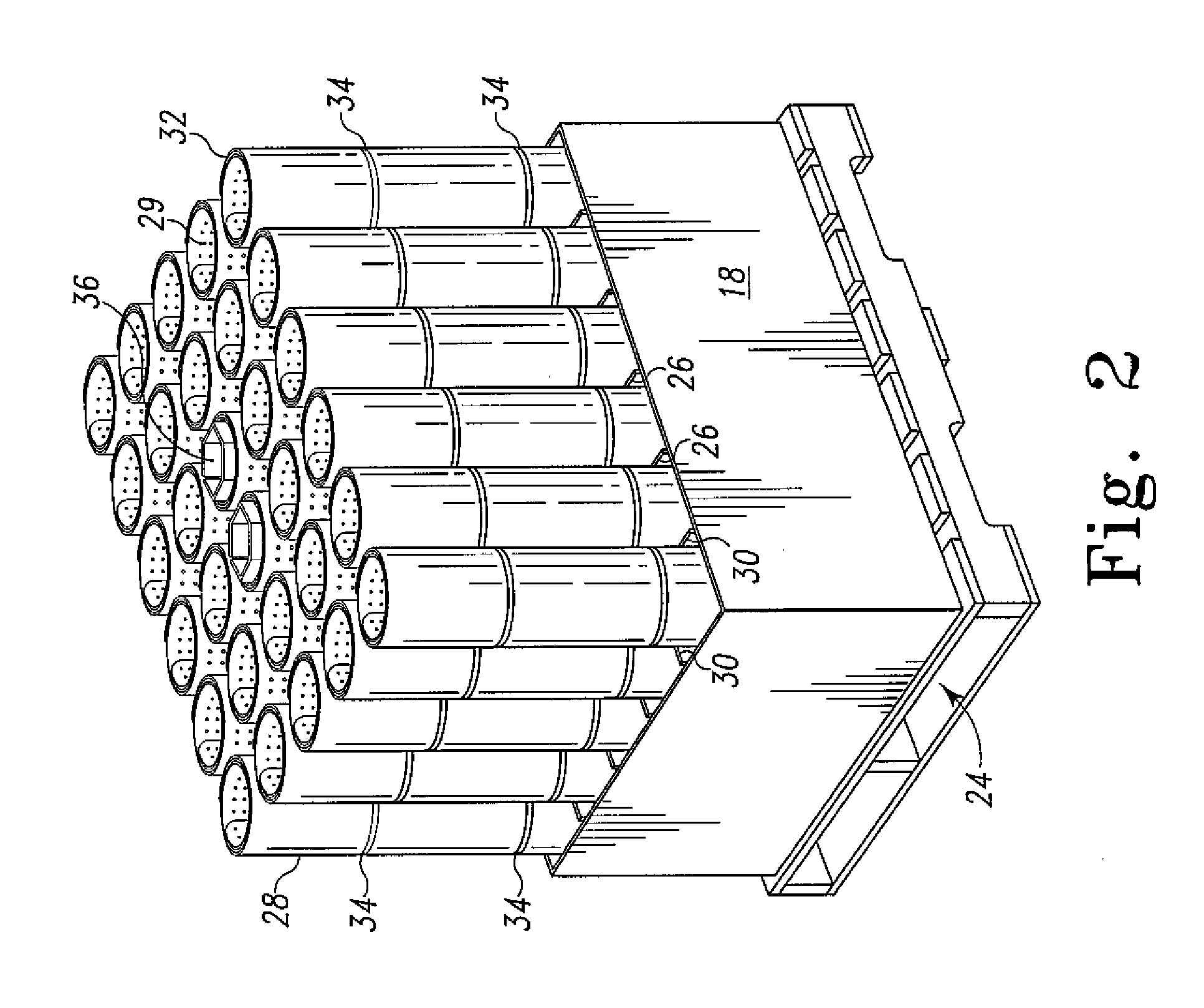

[0022]The interior of a box 12 usable in a system 10 is shown in FIG. 2. The box can include a network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com