Gas generant compositions

a technology of compositions and gas, applied in the direction of pressure gas generation, explosives, weapons, etc., can solve the problem of filtration requirements of inflators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

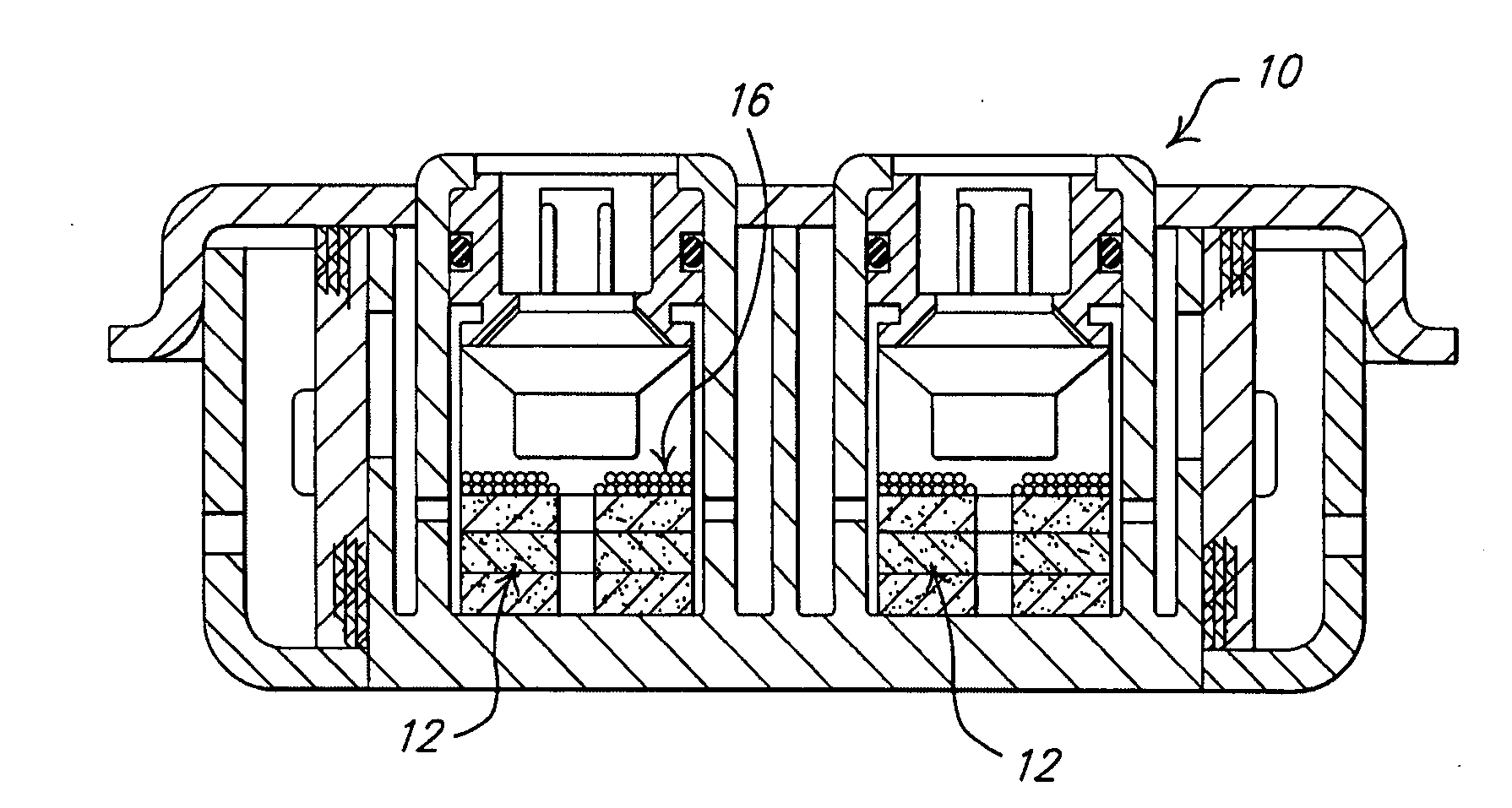

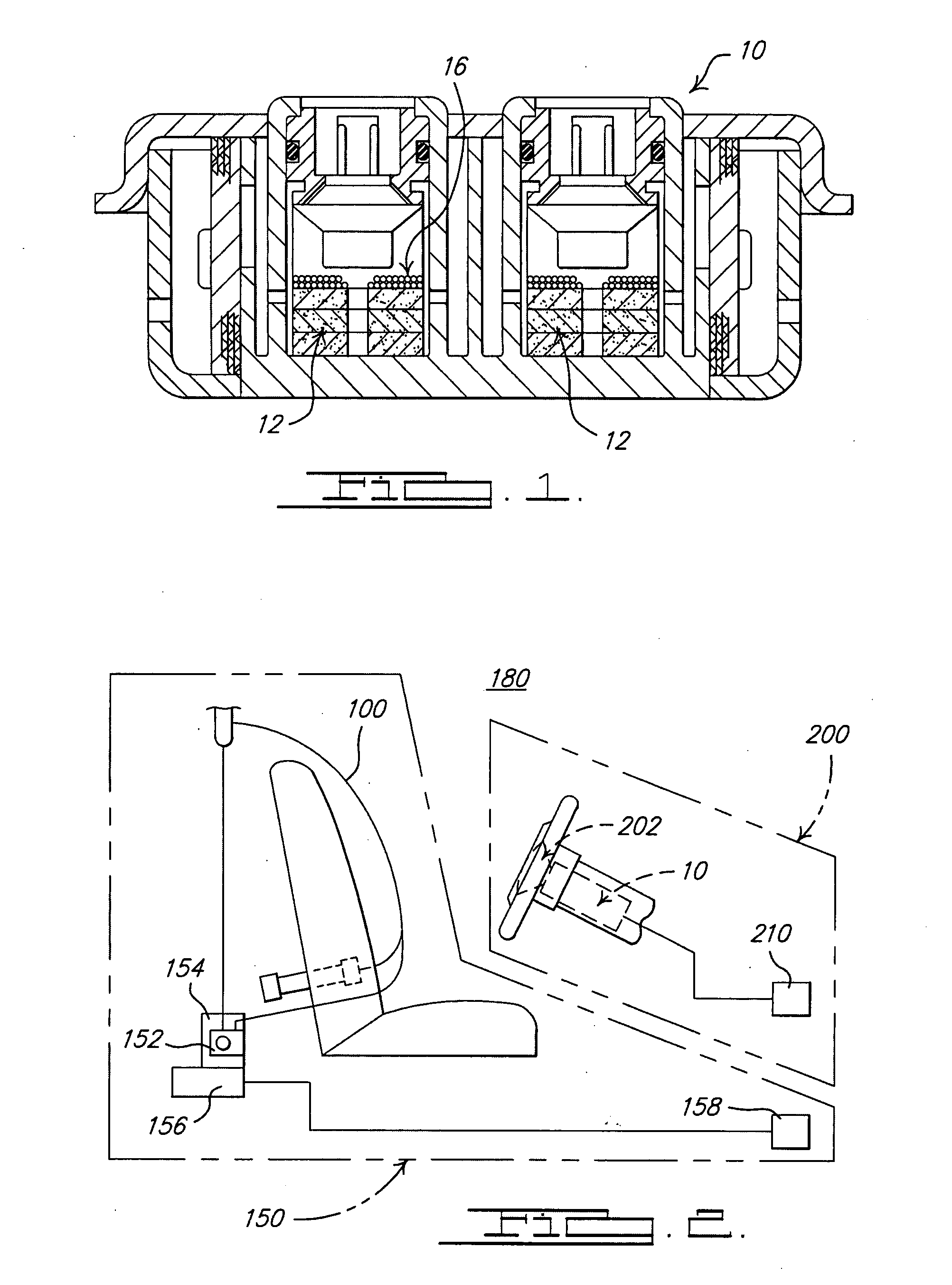

Image

Examples

example 1

[0018]A composition was formed by homogeneously mixing dry copper 5-aminotetrazole at 30 weight percent and dry phase stabilized ammonium nitrate at about 70 weight percent of the total composition. The resultant gas yield was about 88.5% of the total combustion products. The % weight loss when heat aged at 107 C for about 400 hours measured about 0.30 to 0.50 weight percent of the total composition.

example 4

[0021]A composition was formed in accordance with the present invention, and in the same manner as given in Example 1. Burn rate tests were performed by employing samples weighing about 2.6 grams, having about 0.45 inches in height, and having about 0.5 inches in diameter. Each respective sample was ignited under the pressures indicated, and the burn rate was thereby measured. The burn rate was about 0.48 inches per second (ips) at 1000 psig; about 0.65 ips at 1500 psig; about 0.72 ips at about 2000 psig; about 0.88 ips at 2500 psig; about 0.82 ips at 3000 psig; about 1.19 at about 4000 psig; about 1.18 at about 4500 psig; and about 1.28 at about 5500 psig.

example 6

[0023]A composition was formed in accordance with the present invention, and in the same manner as given in Example 1. Differential scanning calorimetry (DSC) evaluations indicated an exotherm at 258.89 C, prior to heat aging as per USCAR requirements. After heat aging at 107 C for about 400 hours, DSC evaluations indicated an exotherm at 266.19 C, thereby exemplifying the thermal stability of the present compositions, before and after heat aging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com