Refrigeration Unit

a refrigeration unit and refrigeration technology, applied in the field of refrigeration equipment, can solve the problems of reducing the refrigeration capability of the refrigeration equipment, reducing the heat exchange capacity of the heat exchanger, and forming frost on the outdoor heat exchanger, so as to reduce the amount of frost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

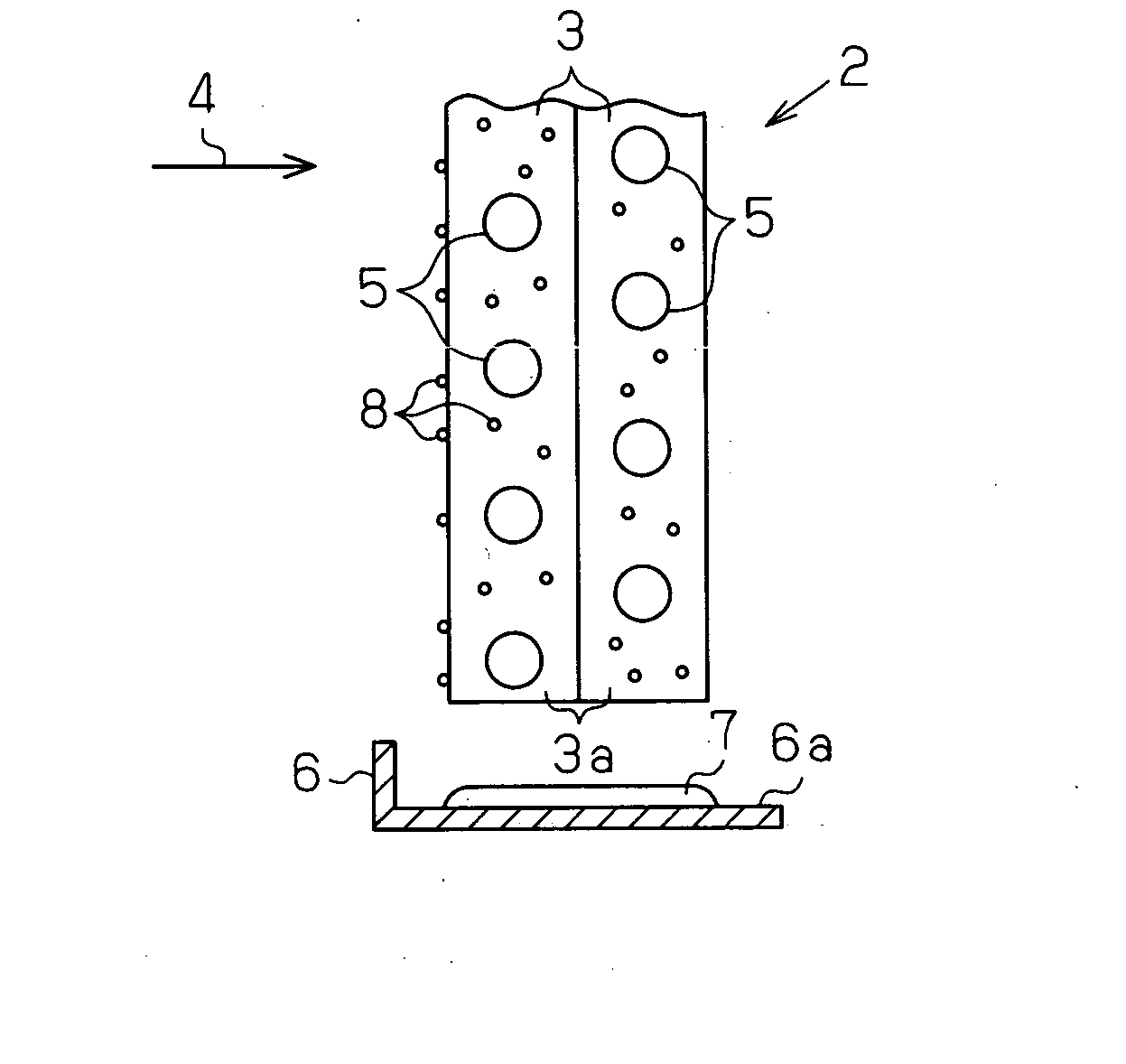

[0033]FIG. 1 is a cross-sectional view showing a portion of an outdoor heat exchanger 2 used in an air conditioner 1 according to a first embodiment of the present invention. FIG. 2 is a circuit diagram showing a refrigerant circuit of the air conditioner 1.

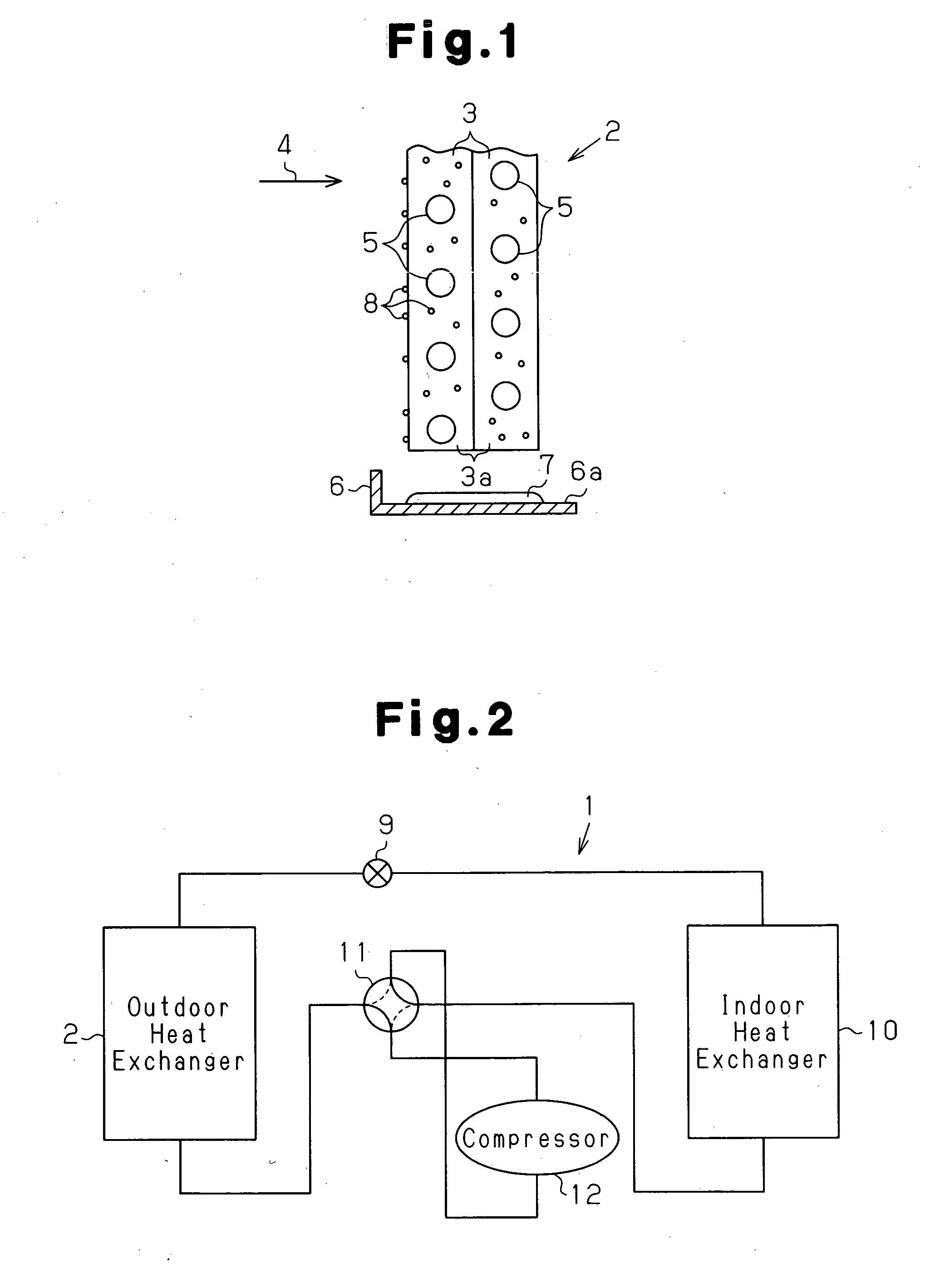

[0034] In the air conditioner 1, the outdoor heat exchanger 2, an expansion valve 9, an indoor heat exchanger 10, a four-way switch valve 11, and a compressor 12 are connected by a refrigerant pipe to form a refrigerant circuit as shown in FIG. 2. During a cooling operation of the air conditioner 1, the four-way switch valve 11 is set as indicated by solid lines in FIG. 2. In this state, a refrigerant serving as a heating medium discharged from the compressor 12 circulates in the order of the four-way switch valve 11, the outdoor heat exchanger 2, the expansion valve 9, the indoor heat exchanger 10, and the four-way switch valve 11, and is sucked into the compressor 12. As a result of circulation of the refrigerant, the outdoor ...

second embodiment

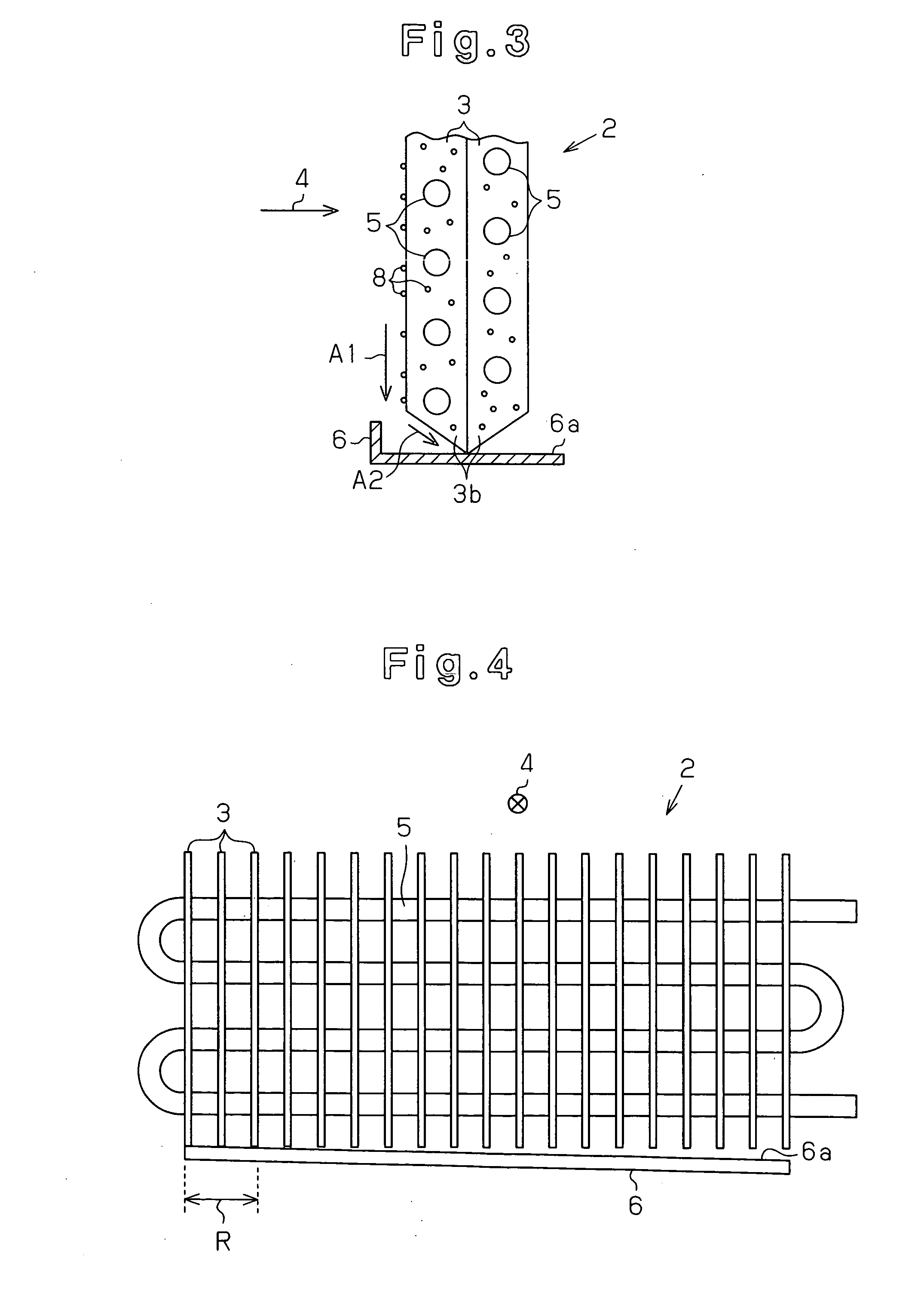

[0044] A second embodiment of the present invention will now be described with reference to FIGS. 3 to 5. The structure of the second embodiment is the same as the structure of the first embodiment except in the shape of the outdoor heat exchanger 2 and the positional relationship between the outdoor heat exchanger 2 and the drain pan 6. The components of the second embodiment common to the first embodiment will not be described in detail.

[0045]FIG. 3 is a cross-sectional view showing a portion of an outdoor heat exchanger 2 according to the second embodiment of the present invention. FIG. 4 is a rear view showing the outdoor heat exchanger 2 as viewed from a downstream side in an air circulation direction 4.

[0046] As shown in FIG. 4, the outdoor heat exchanger 2 of the second embodiment is arranged in a manner such that its lower end partially comes into contact with an upper surface 6a of a drain pan 6. Thus, the lower end of the outdoor heat exchanger 2 is supported by the drai...

third embodiment

[0056] A third embodiment of the present invention will now be described with reference to FIG. 6. The structure of the third embodiment is the same as the structure of the second embodiment except in the shape of the outdoor heat exchanger 2. The components of the third embodiment common to the second embodiment will not be described in detail.

[0057]FIG. 6 is a rear view showing a portion of an outdoor heat exchanger 2 according to the third embodiment of the present invention as viewed from a downstream side in an air circulation direction 4.

[0058] In the third embodiment, projections are formed on lower ends of some plate fins 3L in such a manner that the projections extend more downward than lower ends of other plate fins 3S. More specifically, two types of plate fins 3L and 3S that differ in vertical length are used (reference numeral 3 refers generically to the two different plate fins), and each of the plate fins 3L with the long vertical length is arranged at every predete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com