Single-piece cooling blocks for casting and molding

a single-piece cooling block and casting technology, applied in casting apparatus, melt-holding vessels, manufacturing tools, etc., can solve the problems of multiple manufacturing steps, failure potential of joints between pieces, and the need for additional time and money to complete conventional cooling blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

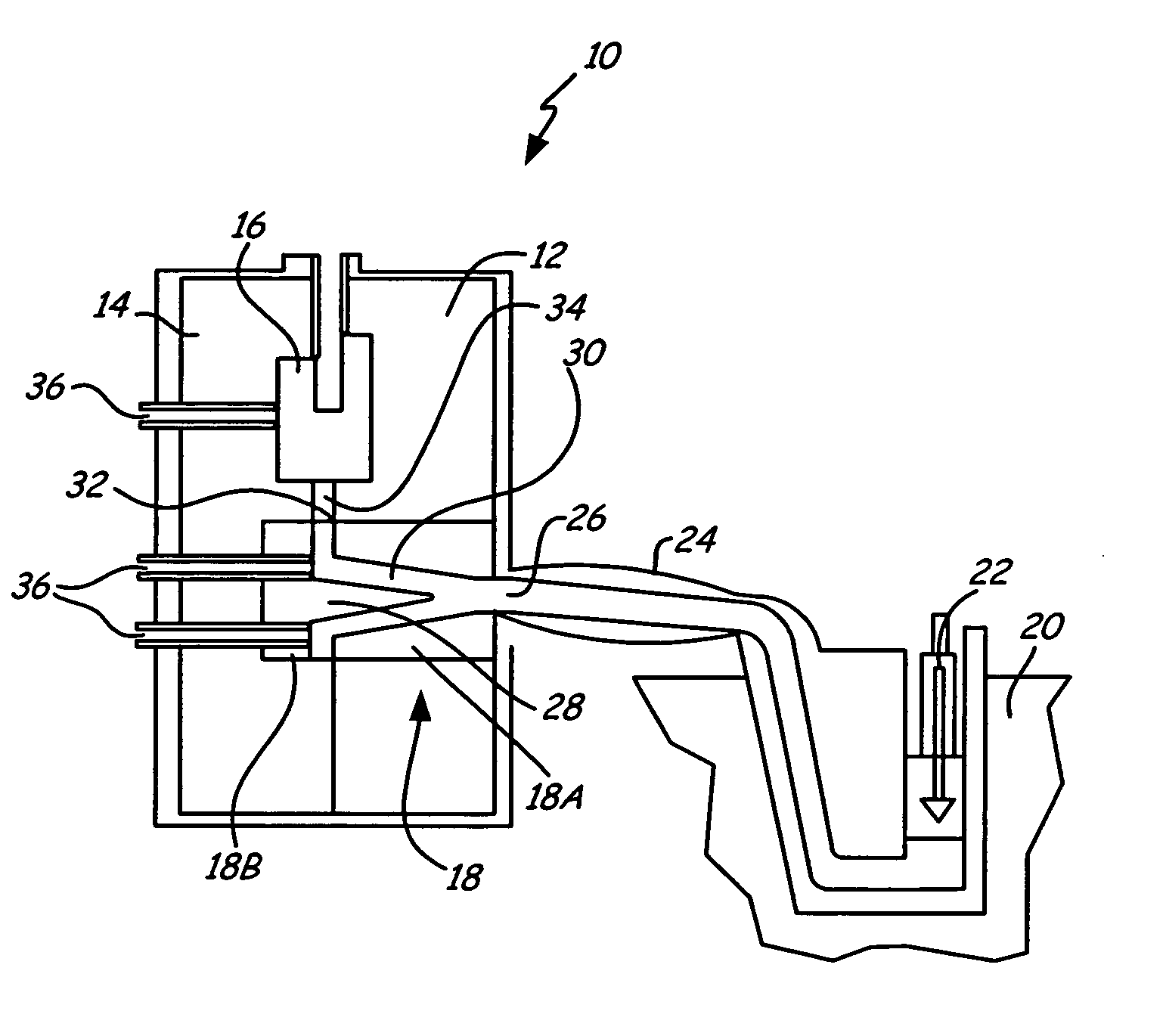

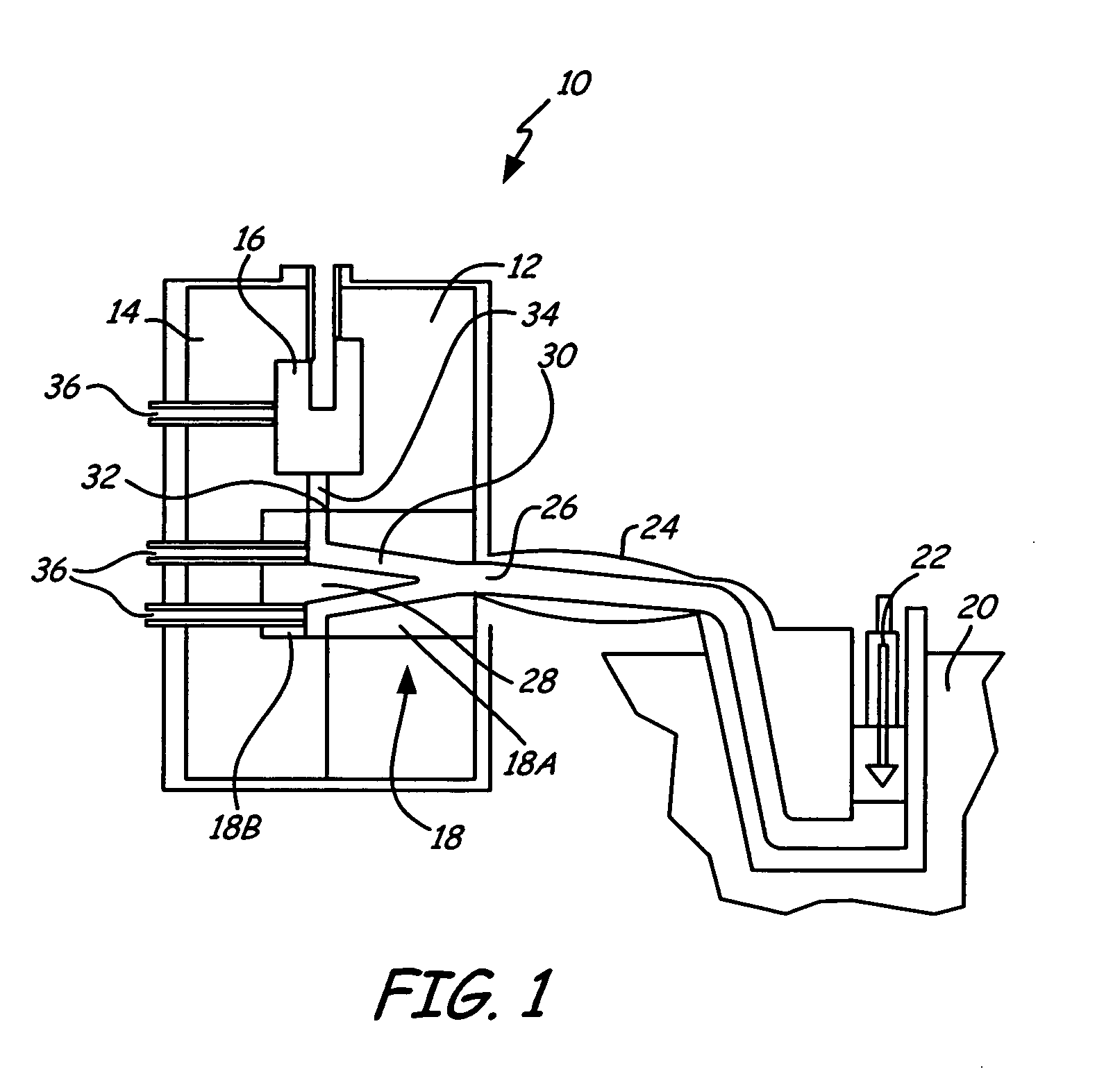

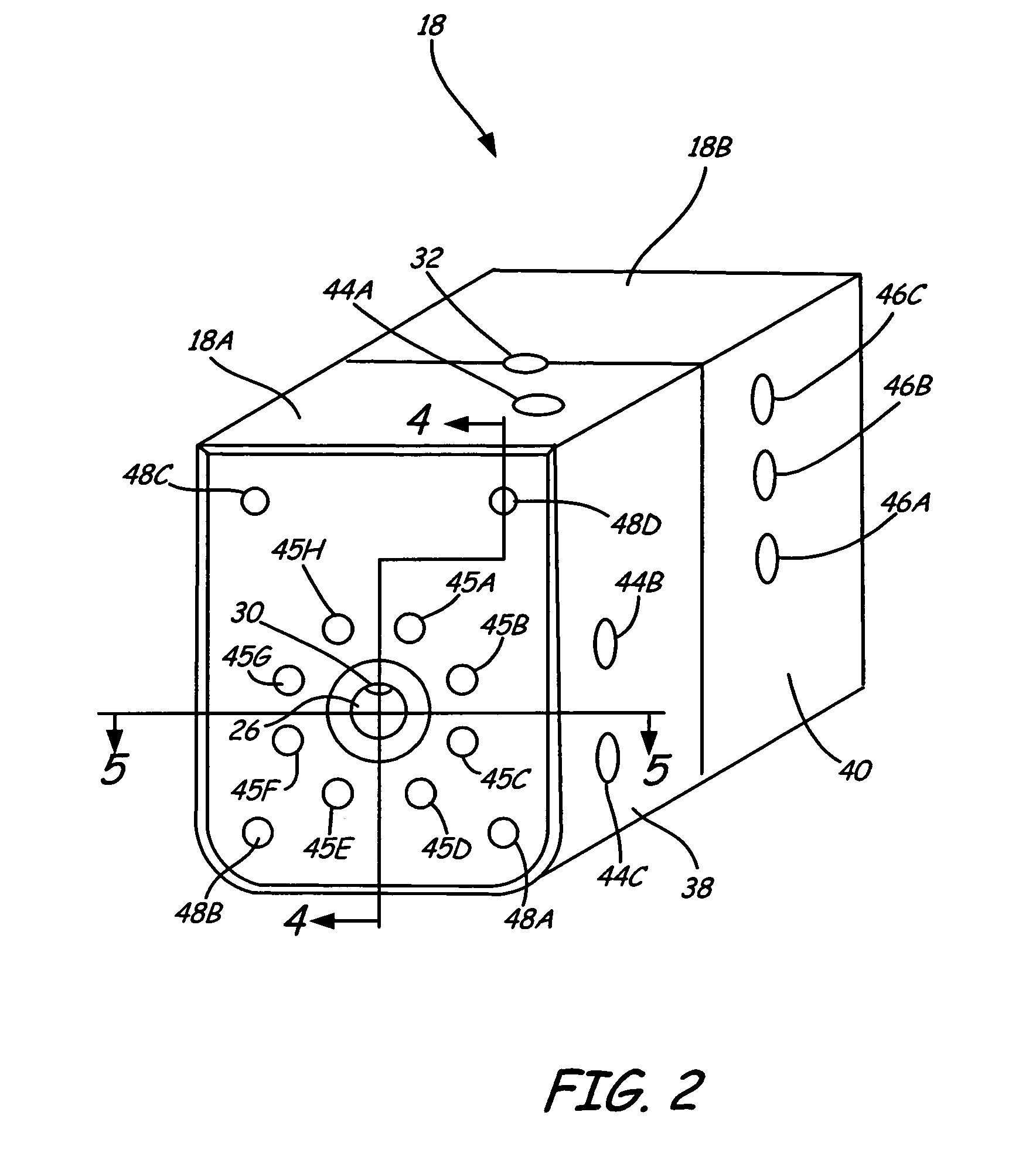

[0014]FIG. 1 shows a sectional view of die casting system 10 in which the present invention is used. The invention is typically used in zinc or magnesium hot chamber die casting operations, and the invention is hereinafter described in reference to die casting. In other embodiments, however, the present invention can also be used in cold chamber die casting operations, or injection molding applications. Die casting system 10 includes stationary die half 12 and moving die half 14. Stationary die half 12 and moving die half 14 together comprise mold cavity 16, which has the shape of an object that can be molded with die casting system 10. Die casting system 10 also includes cooling blocks 18A and 18B (collectively referred to as cooling block 18 when assembled), which are used to control the flow of molten metal into die cavity 16. Molten metal from crucible 20 is injected with piston 22 into die casting system 10 through nozzle 24 and sprue 26 of cooling block 18A. As molten metal en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com