Modular Metal Wall Framing System

a metal wall and modular technology, applied in the direction of walls, constructions, building components, etc., can solve the problems of slow adoption of innovative methodologies or technologies in the construction industry, and achieve the effect of reducing the number of unskilled labor and being convenient to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

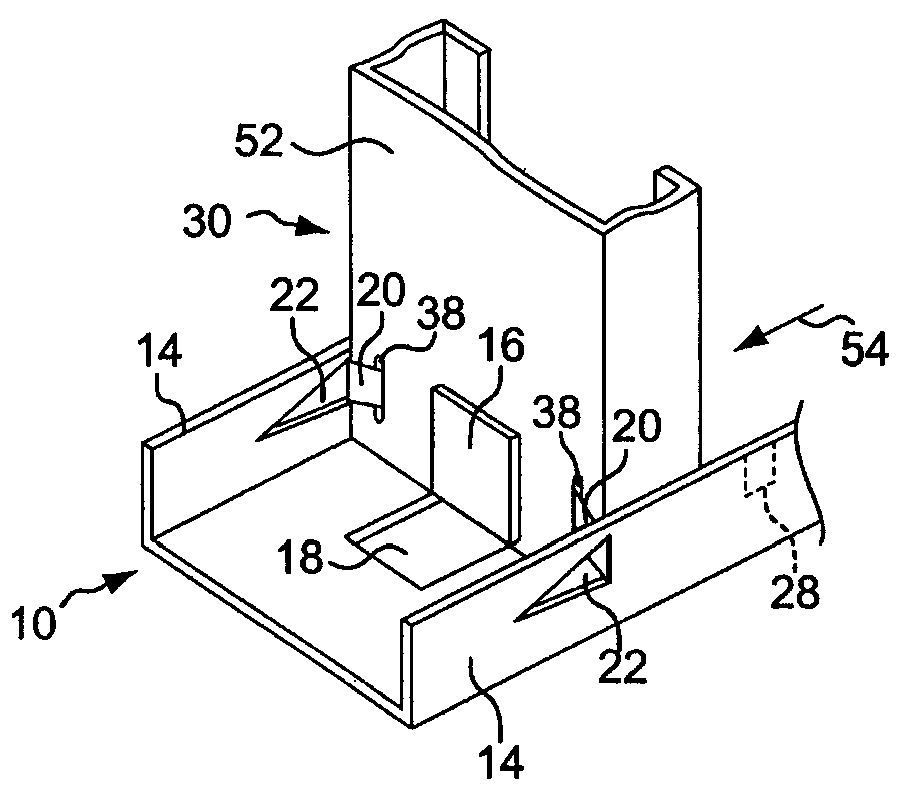

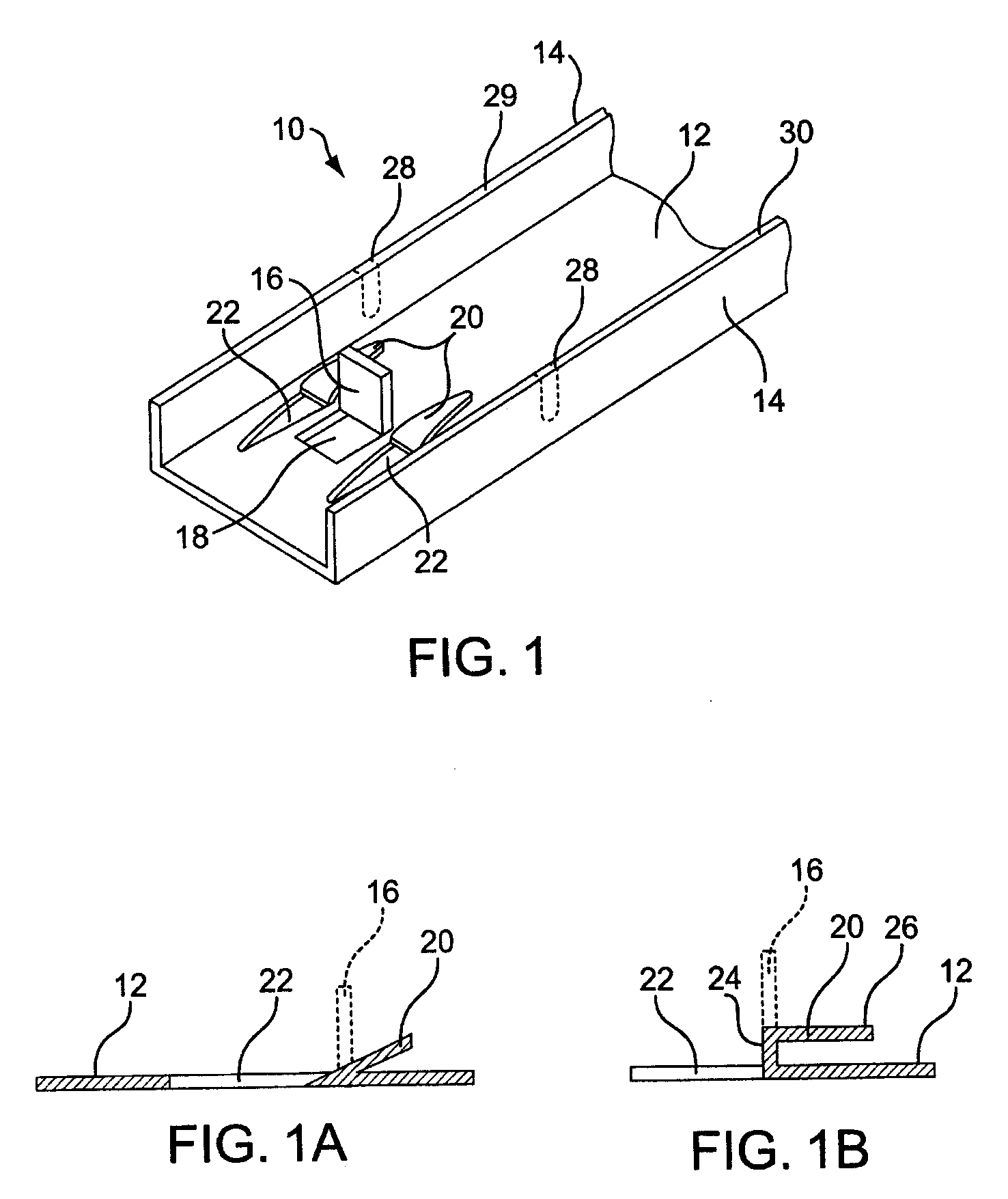

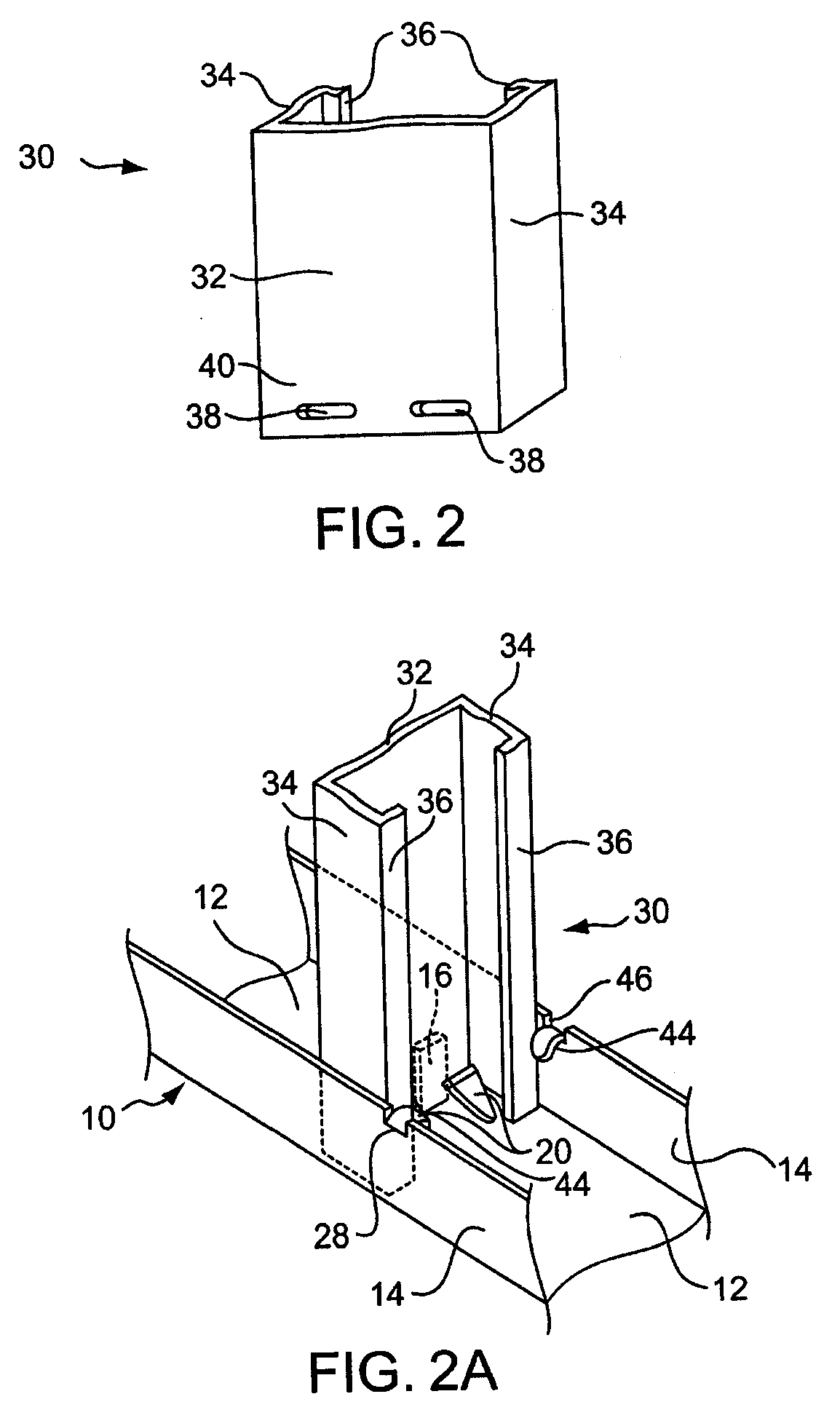

[0126]The present invention will now be described in conjunction with the drawings, beginning with FIG. 1, which shows a channel member 10 constructed in accordance with the invention. The channel member 10 is adapted to be installed in a known manner on a lower support surface such as a floor. An identical second or upper channel member 10 is typically installed in a known manner on an overhead support surface such as a ceiling. The upper and lower channel members are aligned parallel with one another and typically aligned within a common vertical plane.

[0127]The channel member 10 includes a flat, longitudinally-extending central floor 12 and a pair of upstanding parallel side walls 14 that are bent upwardly at right angles from each side of the floor 12. The channel member 10 is formed of a sheet metal material such as steel. A stud locator or stop member in the form of a tab 16 is struck or punched upwardly from the channel floor 12, leaving behind an open aperture 18 in the floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com