Golf club head having complex striking plate structure

a golf club head and striking plate technology, applied in the field of golf club head striking plate structure, can solve the problems of loss of the structural strength of the central portion of the striking plate, design limitations of such a striking plate, and increase the manufacture cost, and achieve the effect of enhancing the striking stability of the golf club head and high degree of elastic deformation of the striking pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

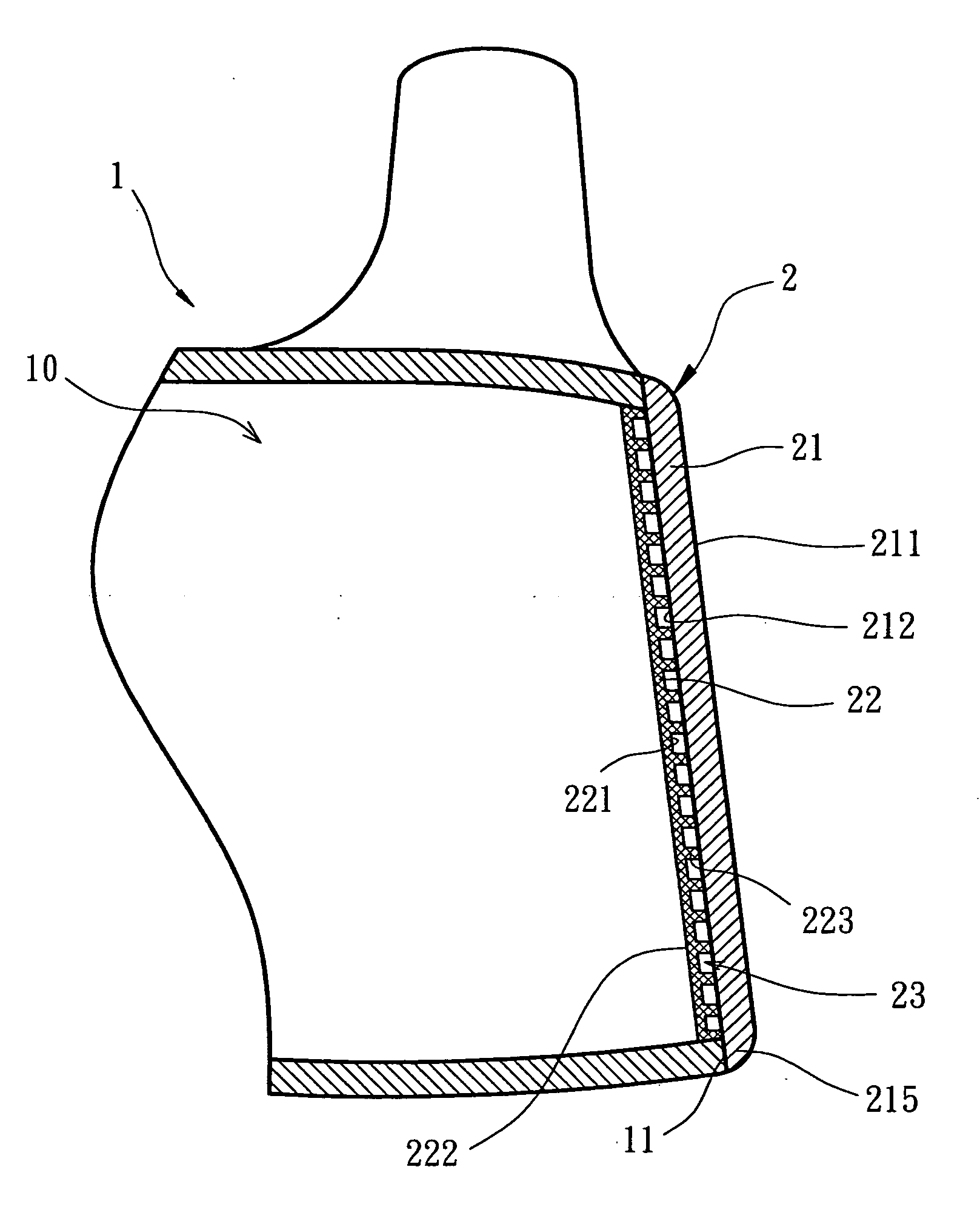

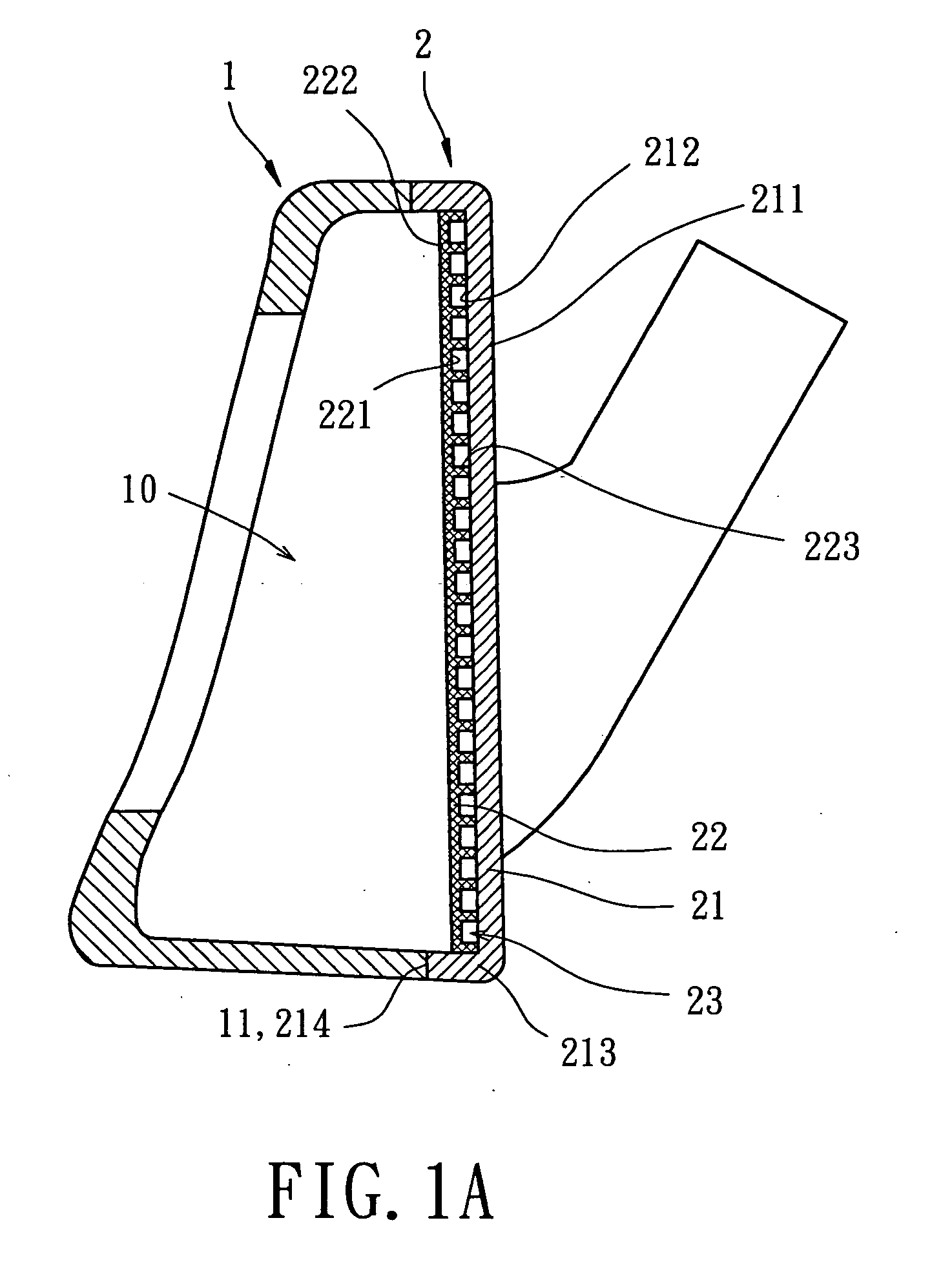

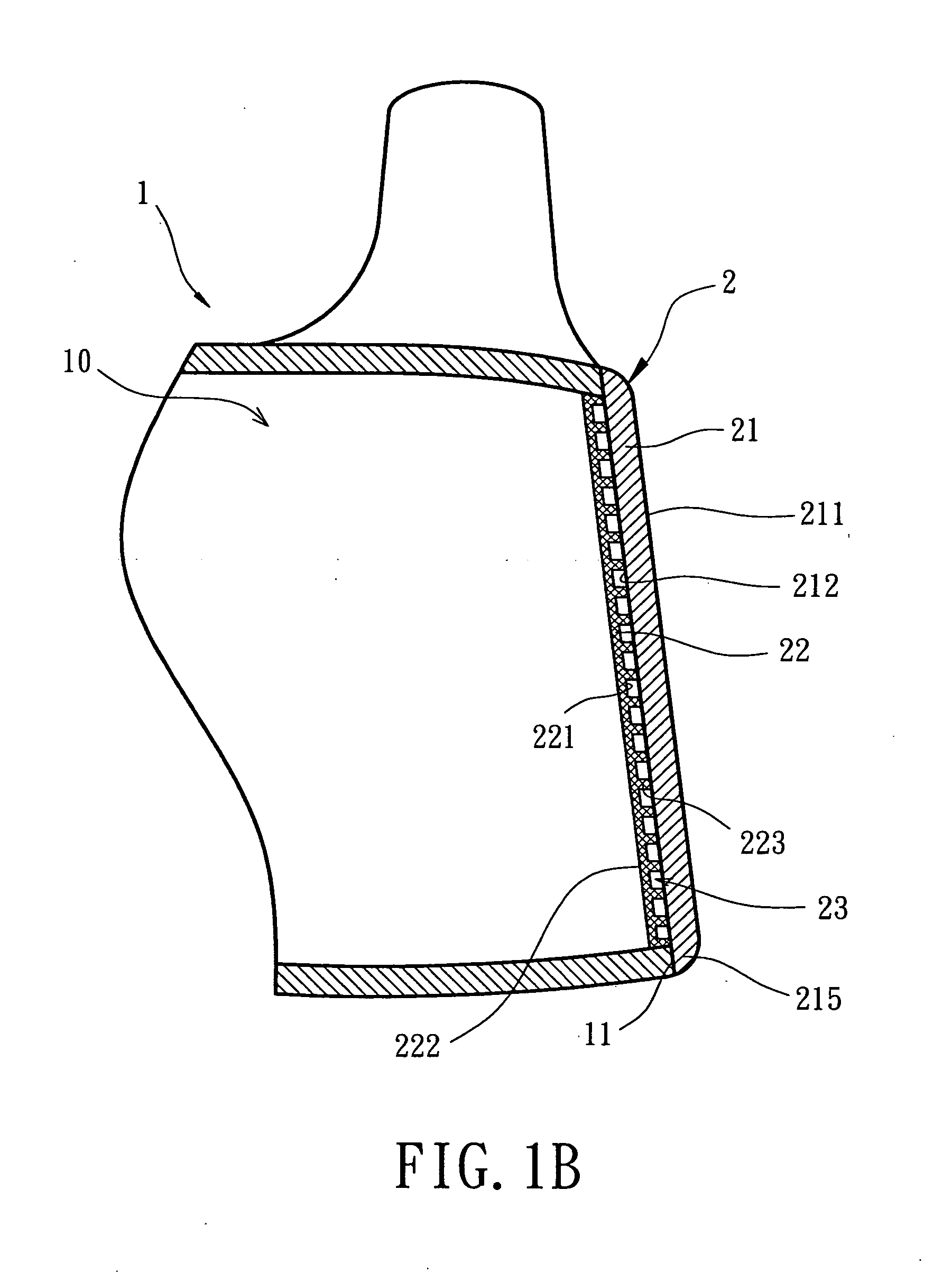

[0048]Referring initially to FIGS. 1A and 1B, views of two golf club heads each having a complex striking plate structure in accordance with a first embodiment of the present invention are shown. Preferably, the golf club head utilized in practicing the embodiment of the present invention can be selected from iron-type club head, a wood-type club head or a putter-type club head. By way of example, the golf club head utilized in practicing this illustrated embodiment of the present invention is selected from an iron-type club head or a wood-type club head.

[0049]With continued reference to FIGS. 1A and 1B, the golf club head in accordance with the first embodiment of the present invention includes a golf club head body designated numeral 1 and a complex striking plate designated numeral 2. The golf club head body 1 has an opening 10 and a connecting end portion 11 at its front side. The connecting end portion 11 of the golf club head body 1 delimits a periphery of the opening 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com