Gas bags for massaging device

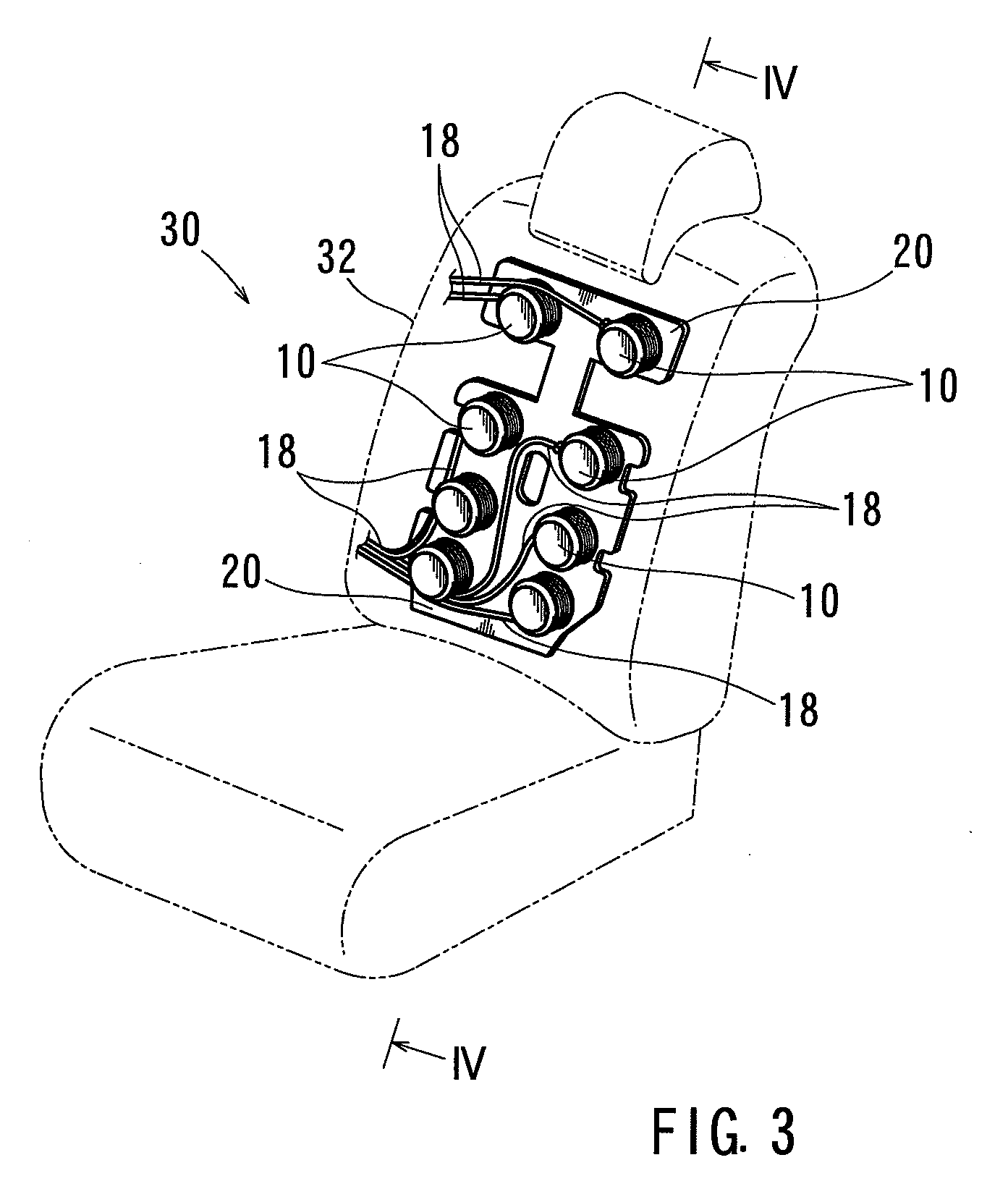

a massaging device and gas bag technology, applied in the field of gas bags for massaging devices, can solve the problem that the gas bag may not be returned to the contracted condition, and achieve the effect of increasing the elastic range, increasing the elongating and contracting distance, and increasing the elastic rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0028]In order to evaluate some properties of the present gas bag, a plurality of different gas bags (Gas Bags A, A′, B, B′, Z and Z′) were prepared.

Gas Bags A and A′:

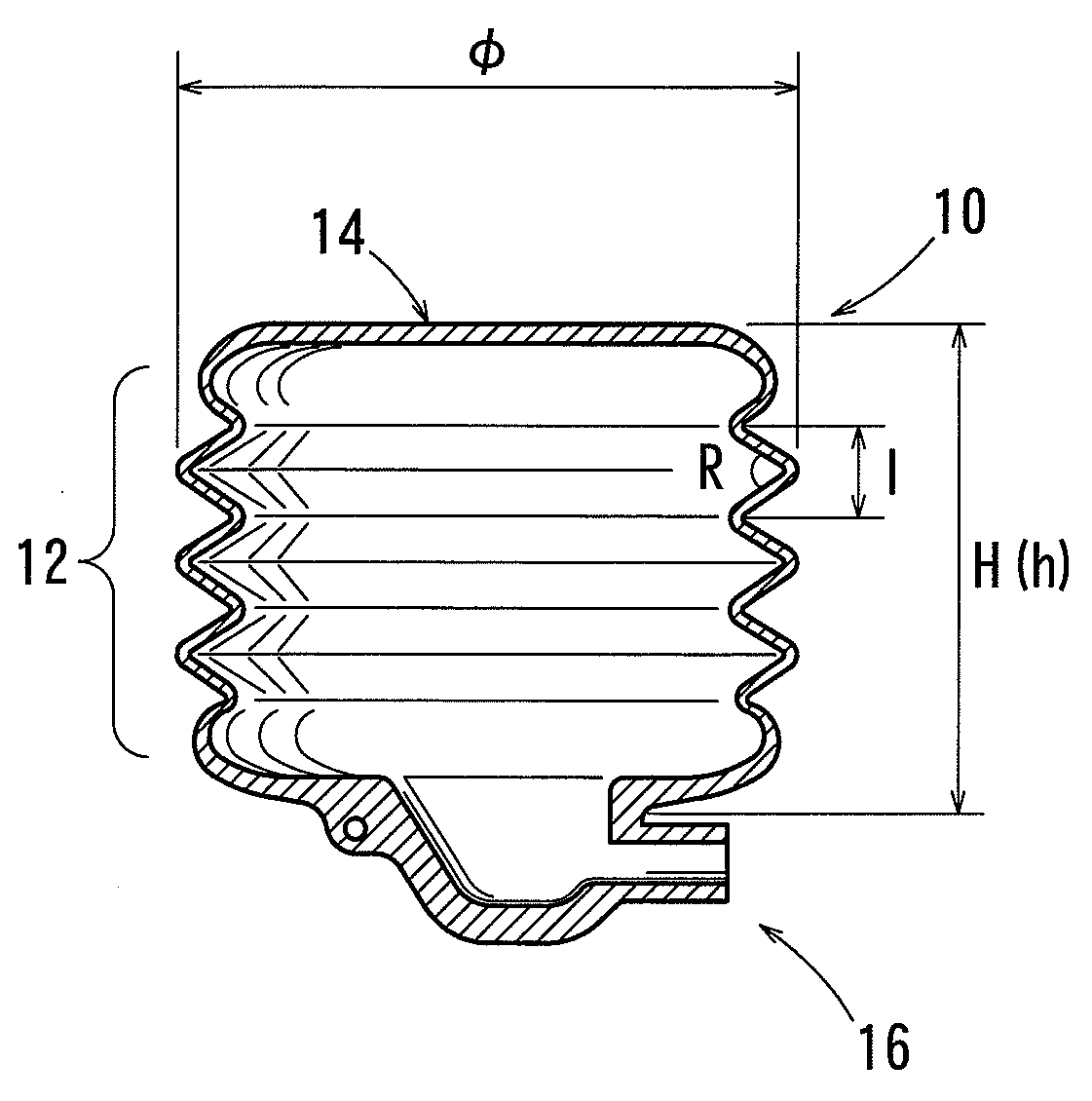

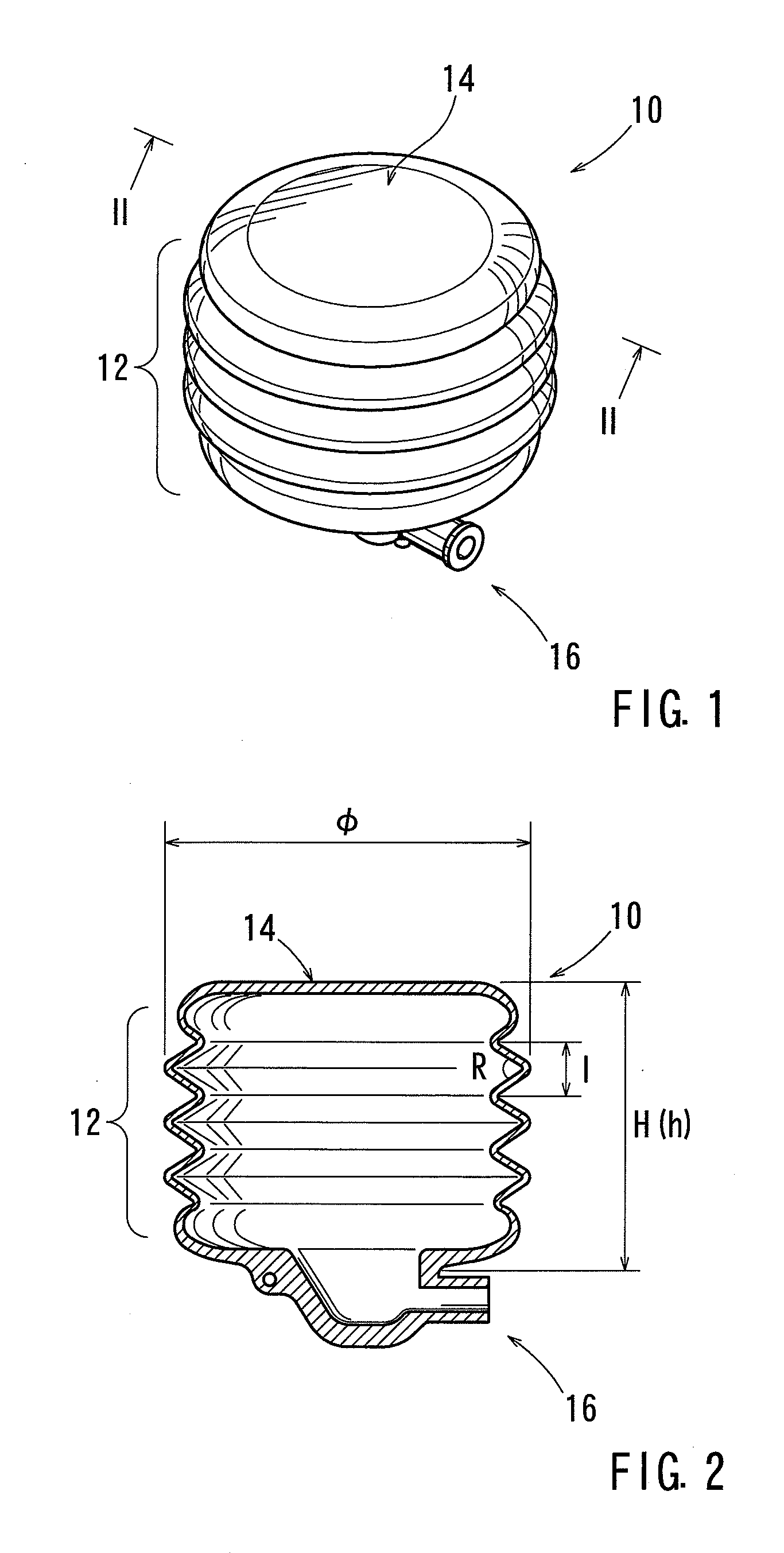

[0029]A thermoplastic polyester elastomer (TPEE) (“PELPRENE” (registered trademark) manufactured by TOYOBO CO., LTD.) was molded by blow molding, thereby forming an intermediate gas bag (an untreated gas bag), which will be referred to as Gas Bag A′. Gas Bag A′ thus formed had a length (a natural length) h of 44.3 mm. Thereafter, Gas Bag A′ thus formed was annealed at 165±8° C. while the bellows-shaped portion thereof is compressed so as to have a length of 22 mm shorter than the natural length h (44.3 mm) thereof. Thereafter, heated Gas Bag A′ was slowly cooled, thereby producing a final gas bag (a treated gas bag), which will be referred to as Gas Bag A. Gas Bag A thus produced had a length (a compressed natural length) H of 22 mm. Dimensions of Gas Bags A′ and A are shown in Table 1. Further, references φ, I, R and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com