Patents

Literature

72 results about "Tubular formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

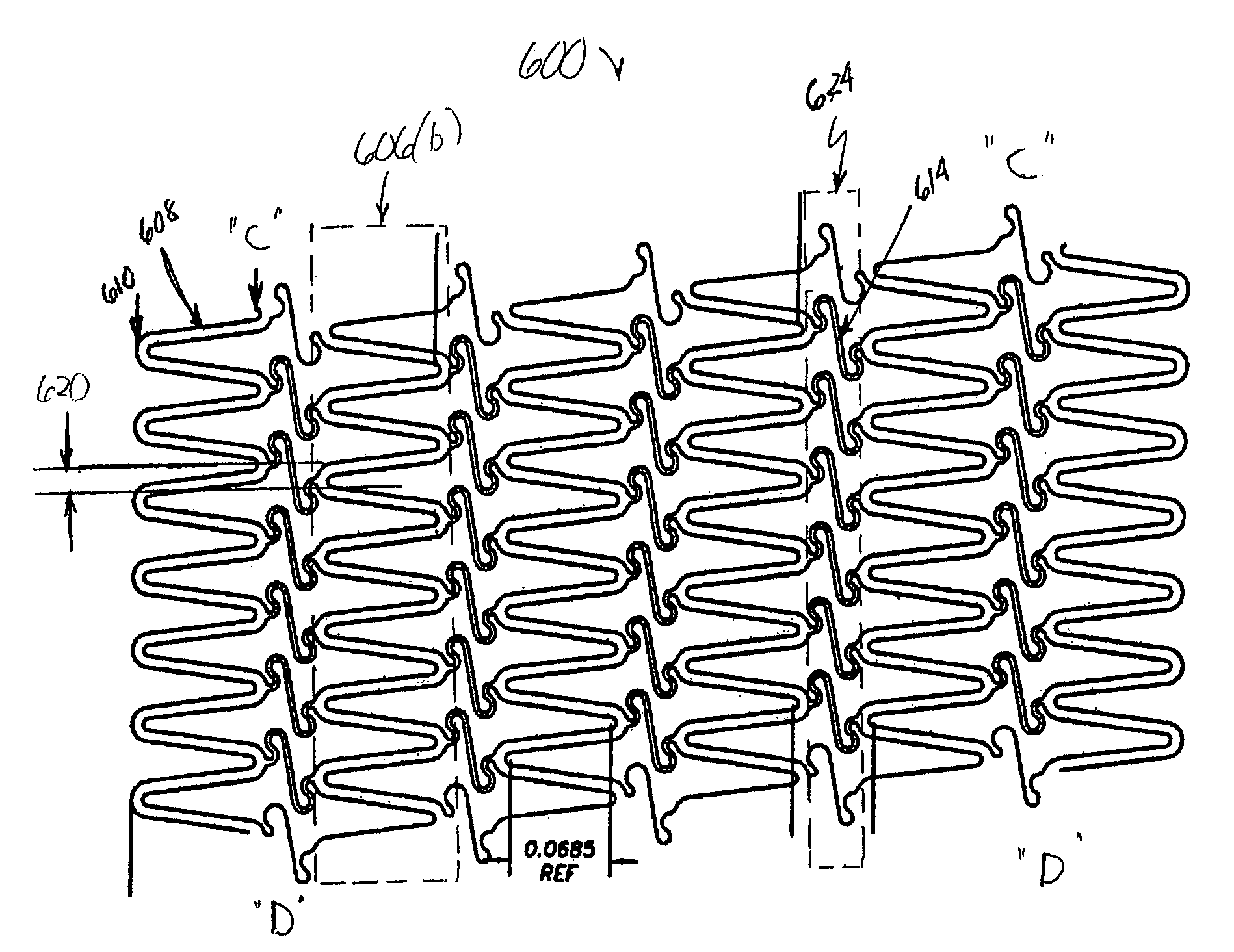

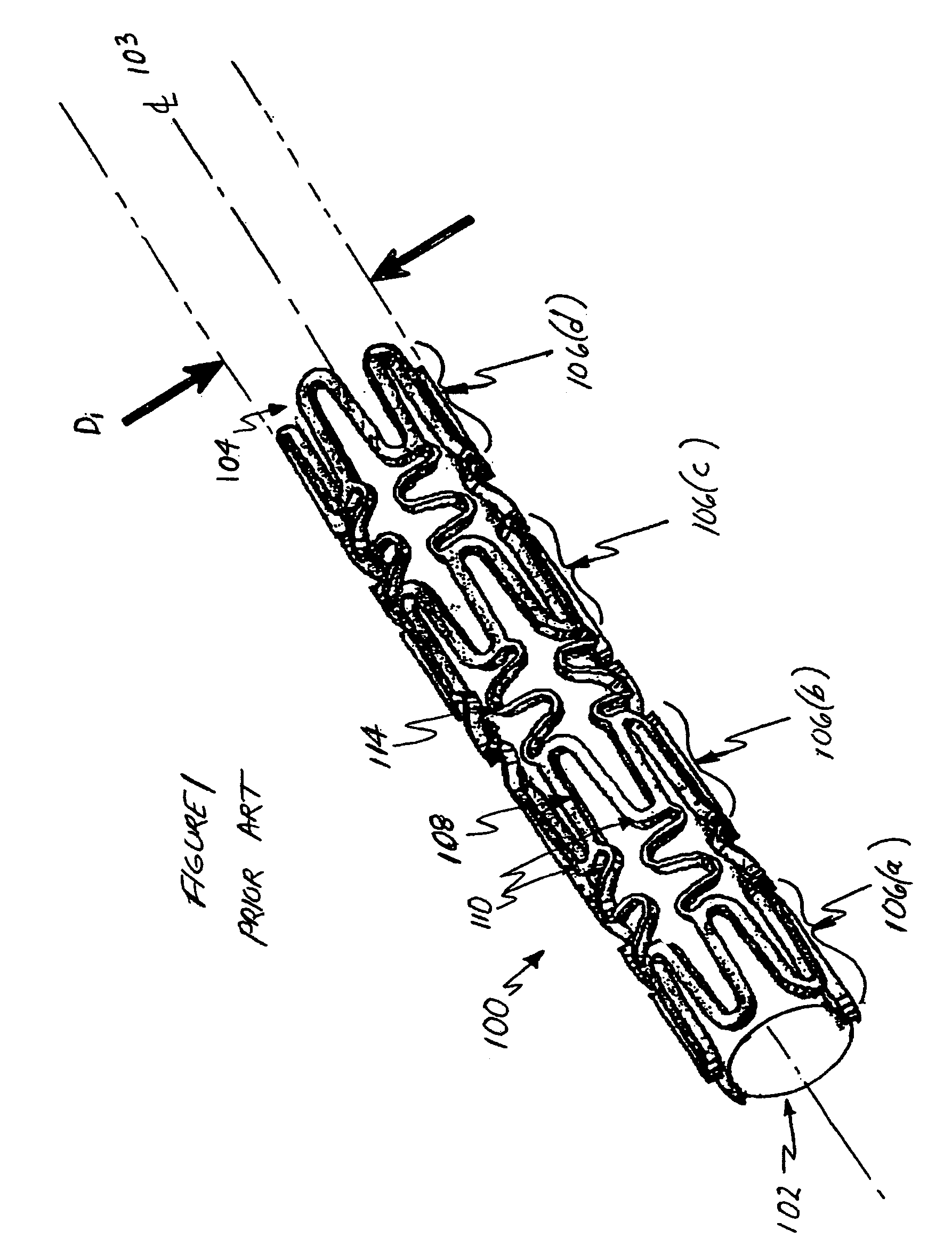

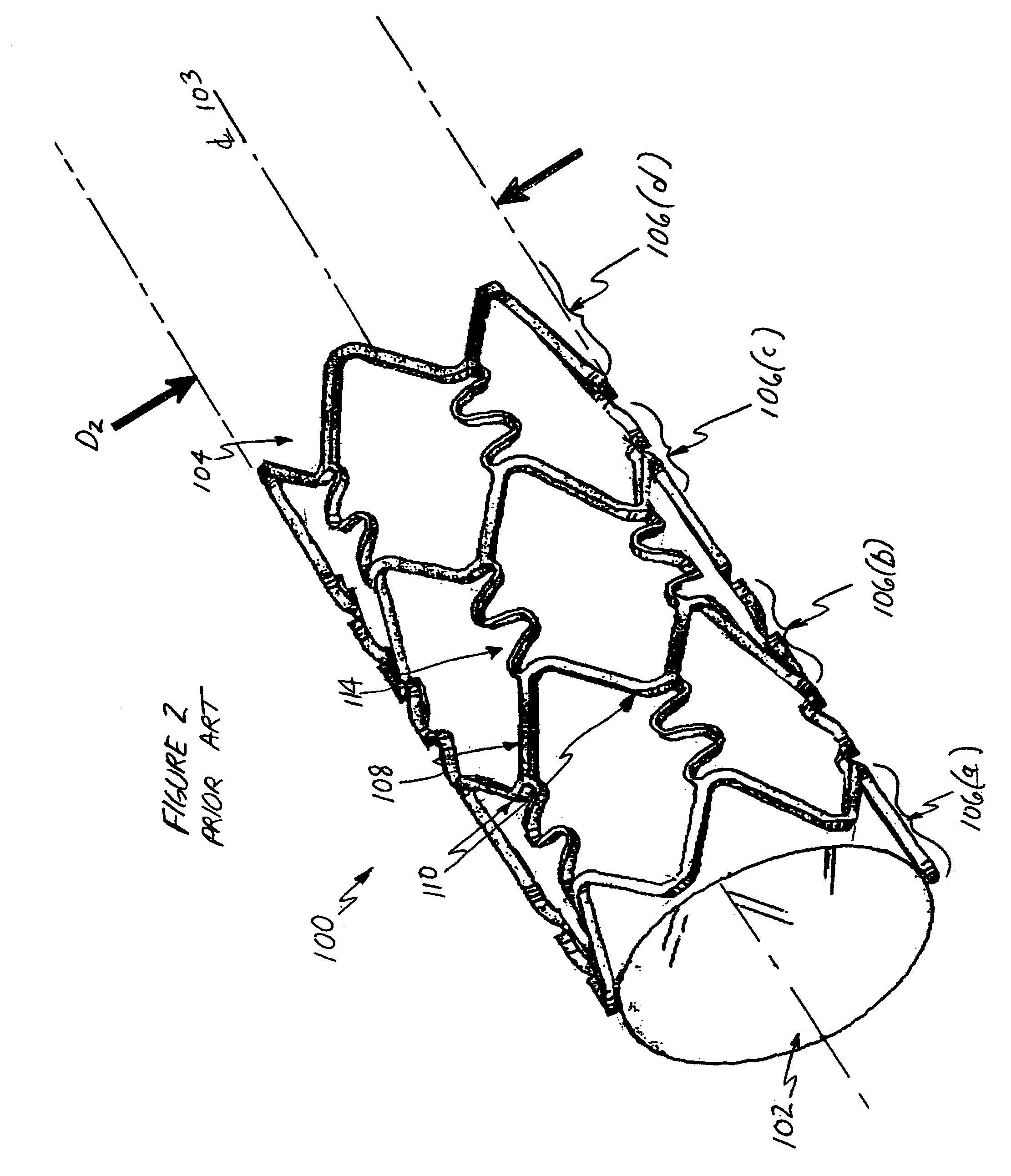

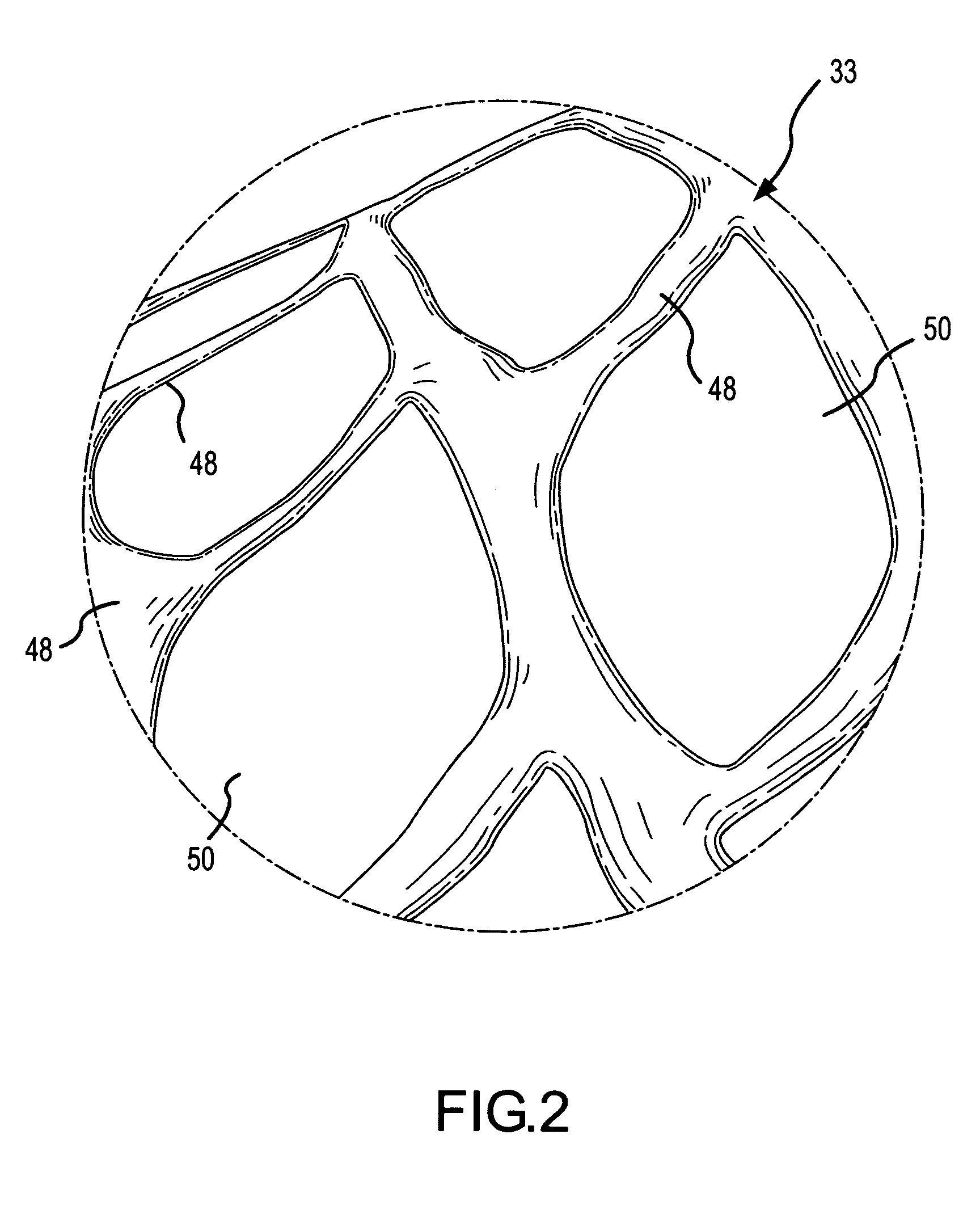

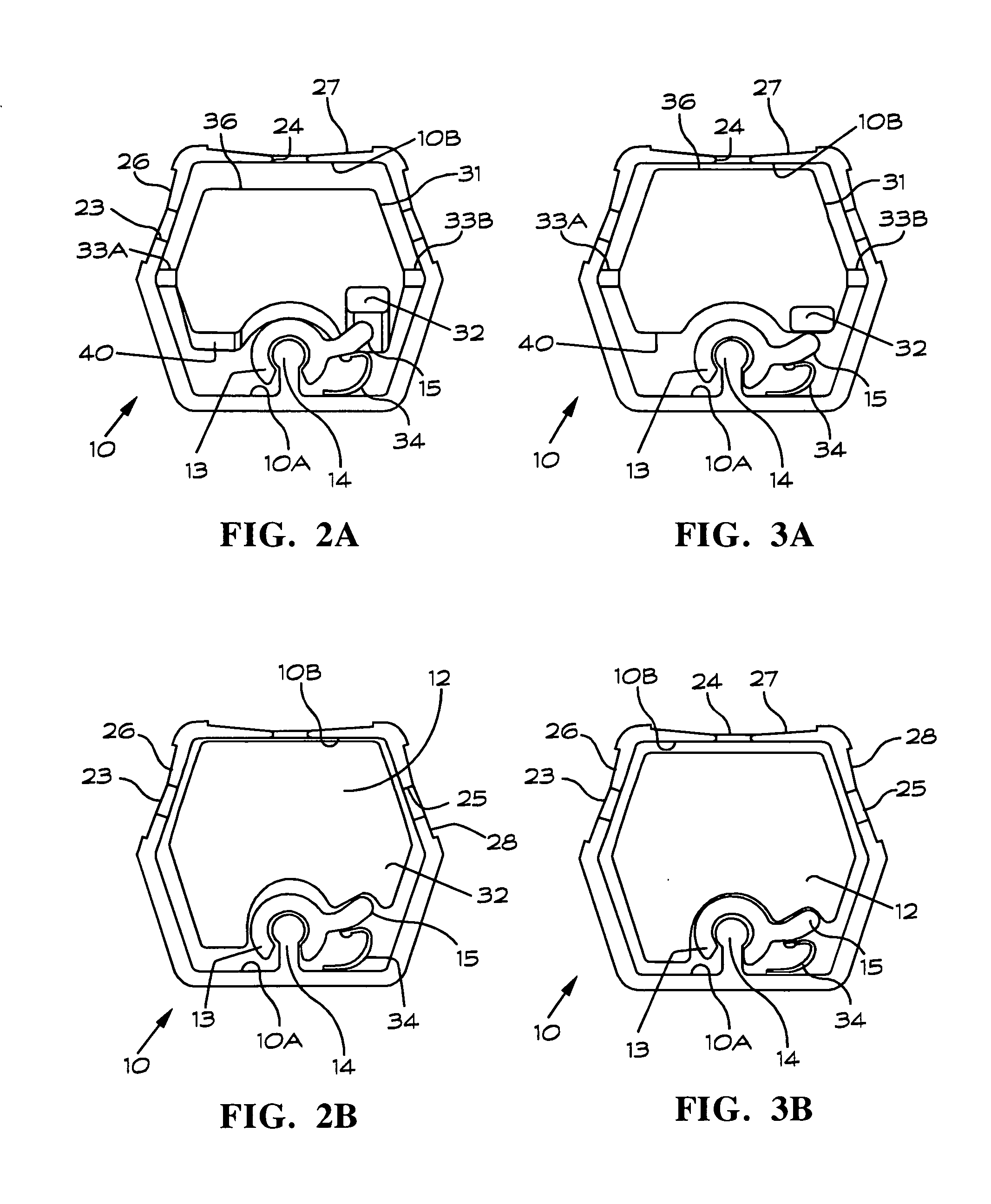

Stent having phased hoop sections

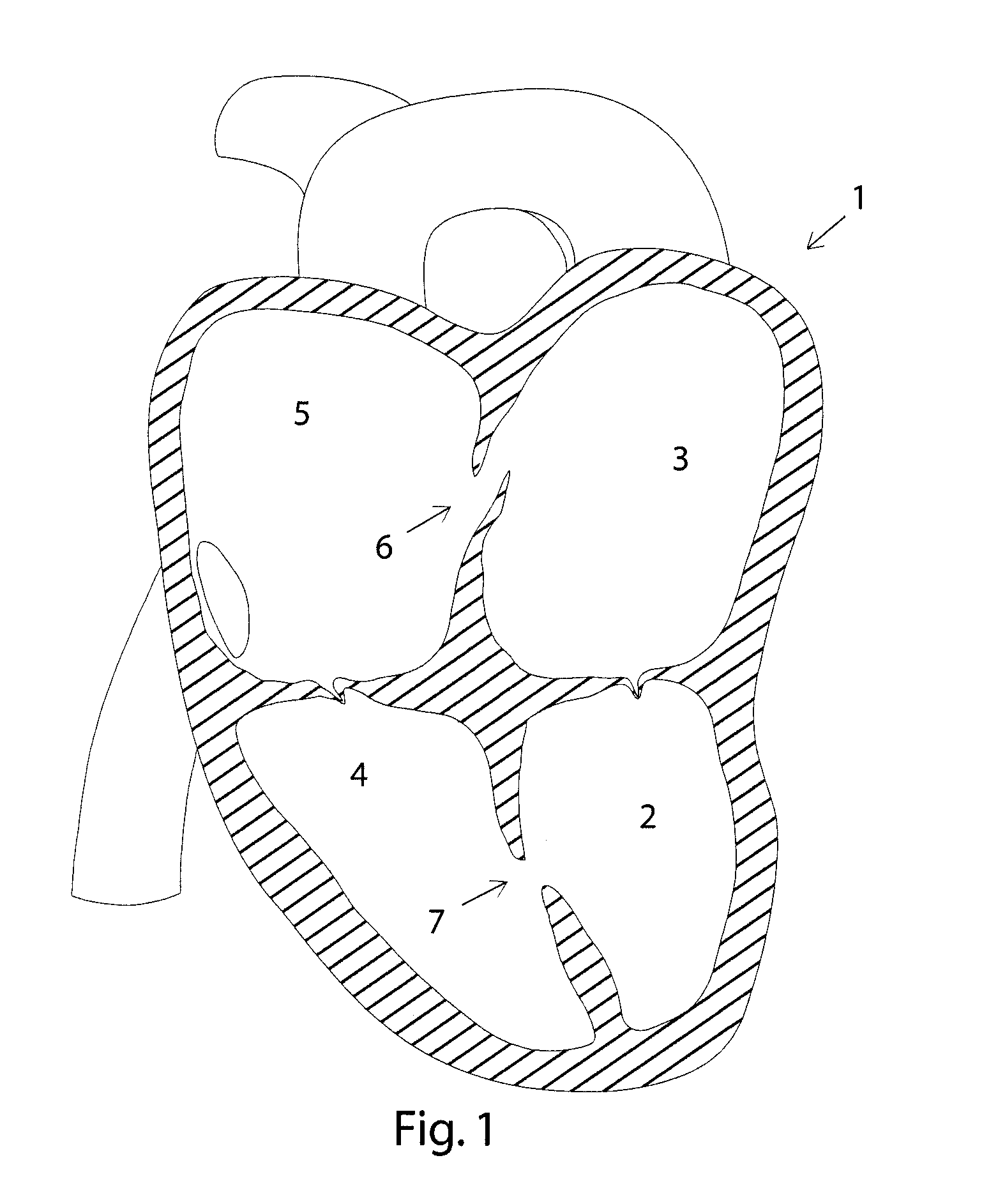

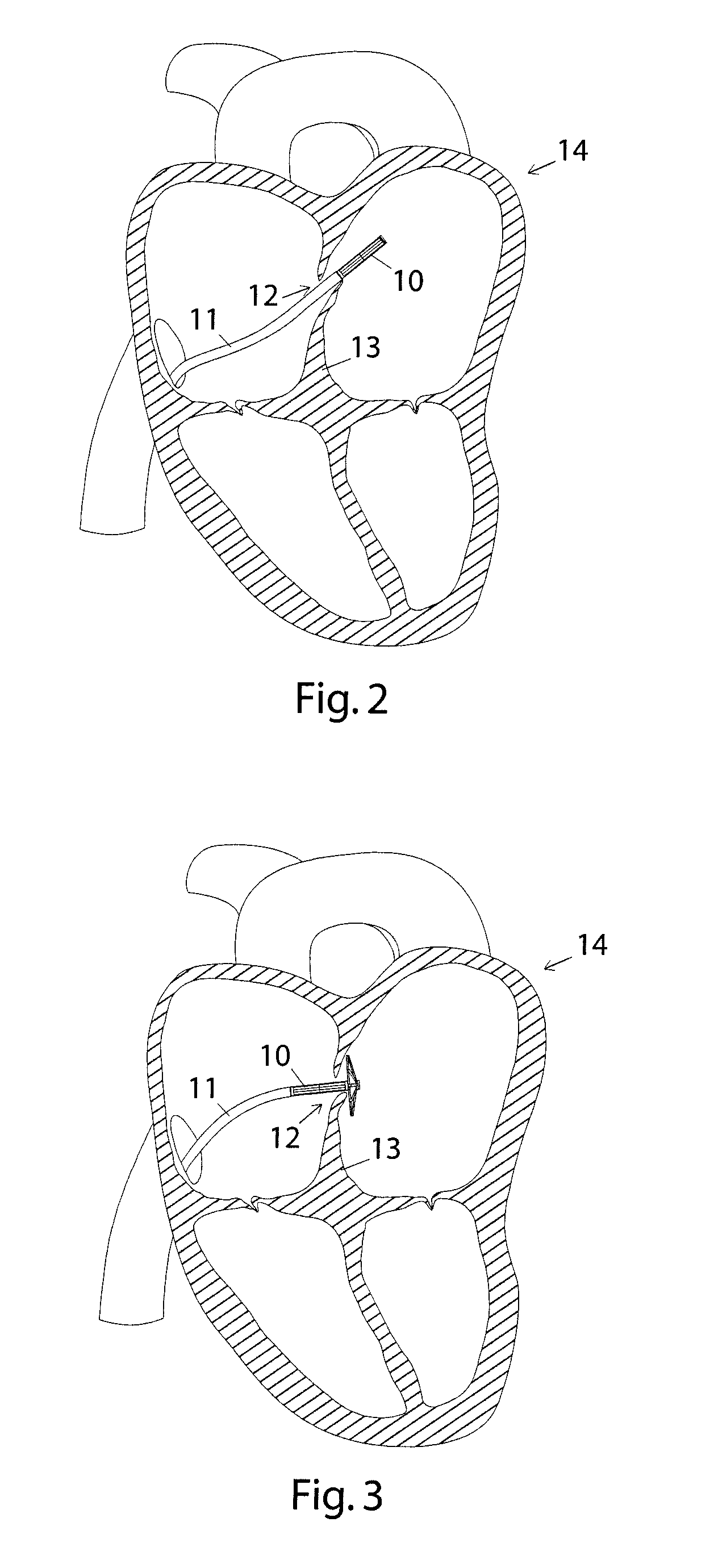

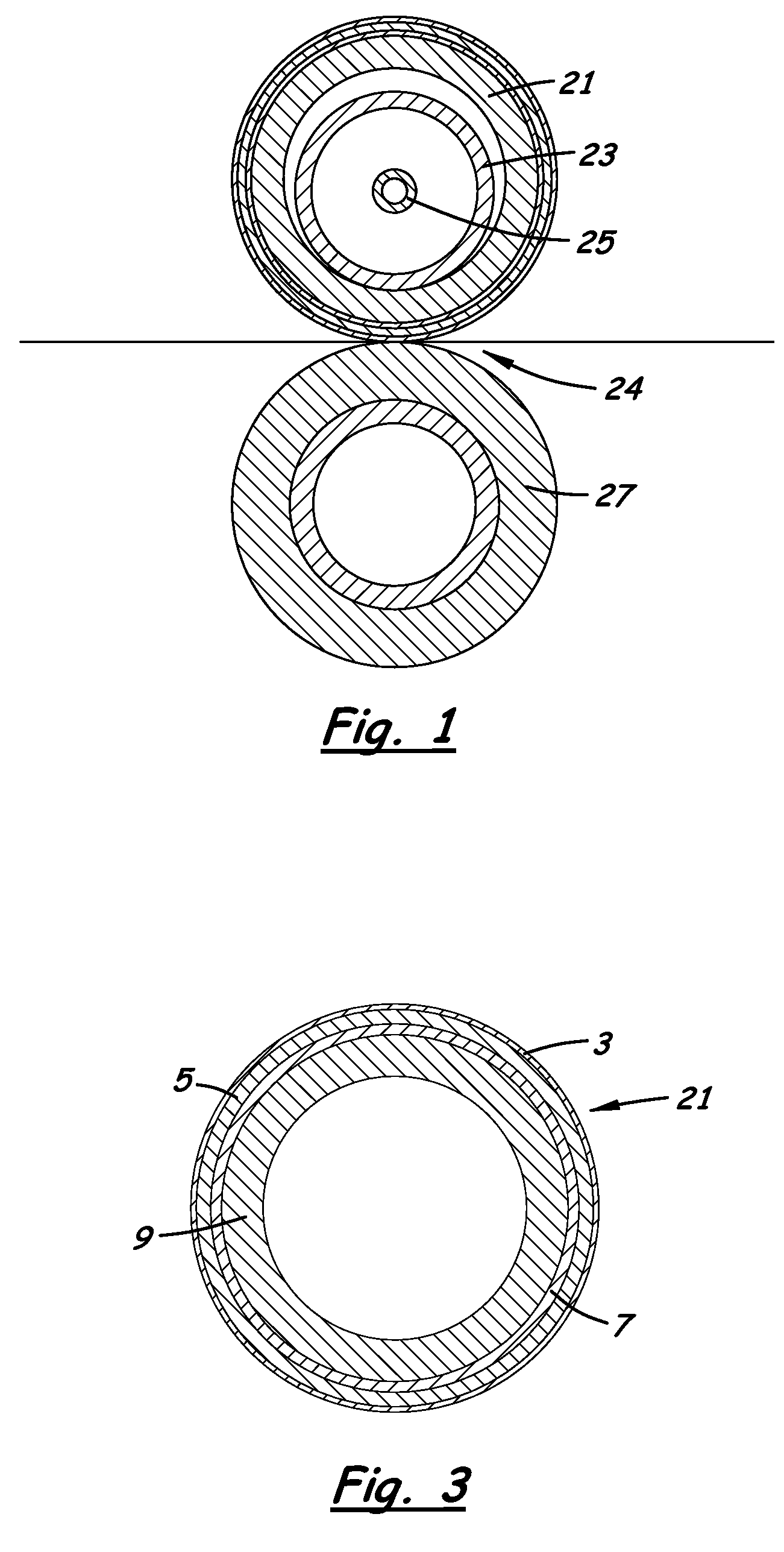

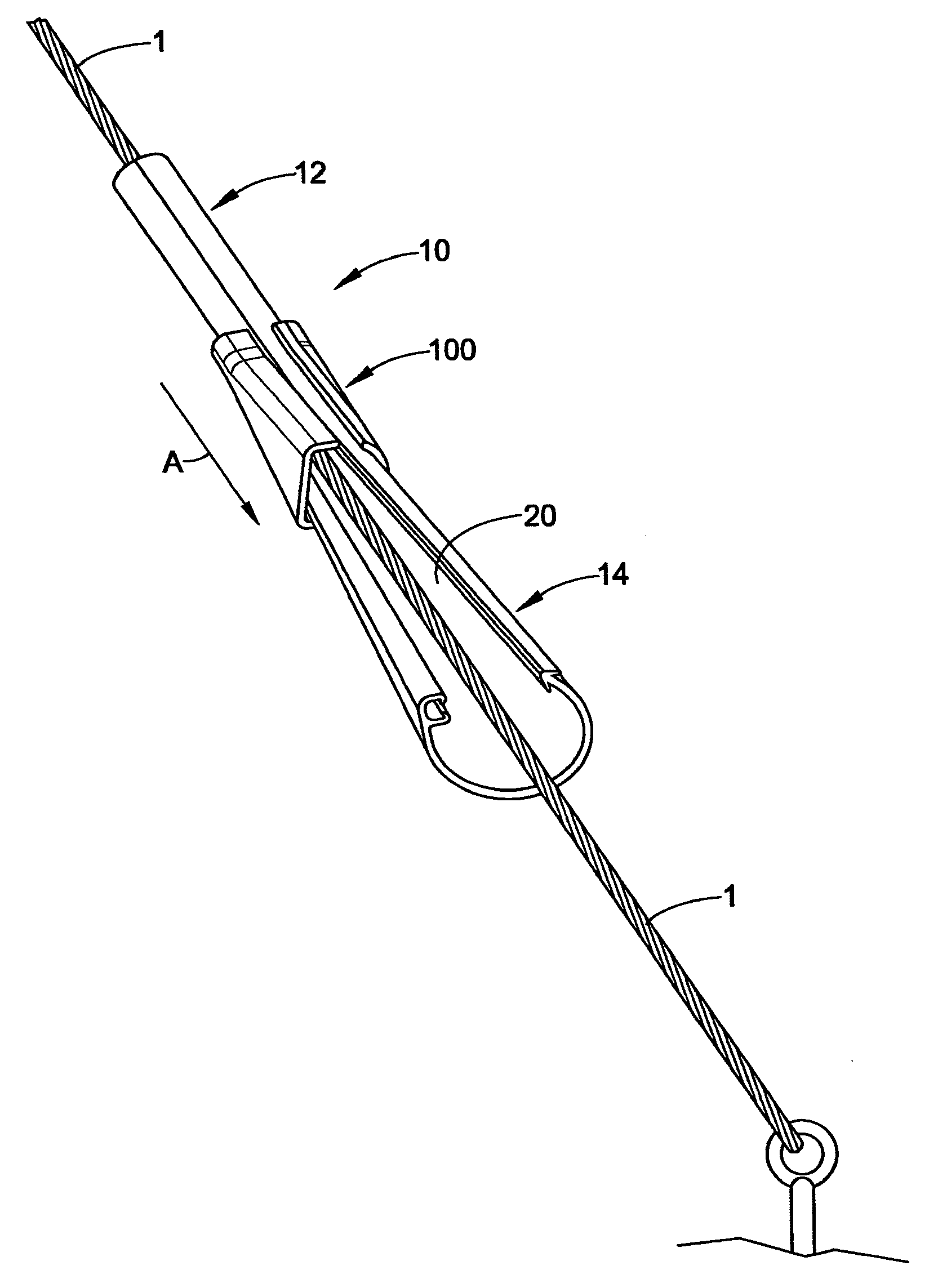

This invention relates generally to an expandable intraluminal medical device for use within a body passageway or duct, and more particularly to a stent having at least a first hoop section and a second hoop section. The first hoop section comprises a tubular configuration of structural elements having proximal and distal open end, and defining a longitudinal axis extending there between. The second hoop section comprises a tubular configuration of structural elements having proximal and distal open end, and extending along the longitudinal axis defined by the first hoop section, but is rotationally offset from the first hoop section about the longitudinal axis.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

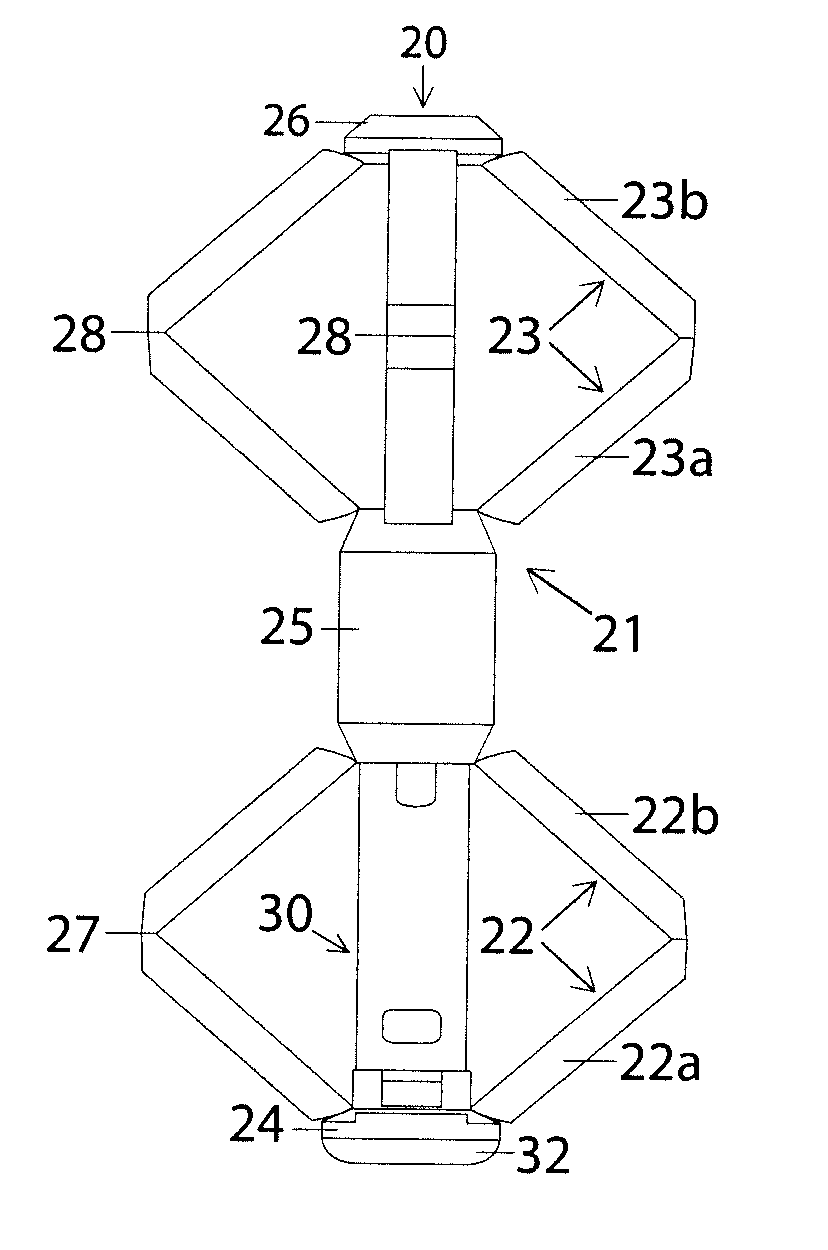

Closure device

InactiveUS20090030450A1Reliable and versatileEasy to adaptSurgical veterinaryWound clampsEngineeringTubular formation

Owner:RADI MEDICAL SYST

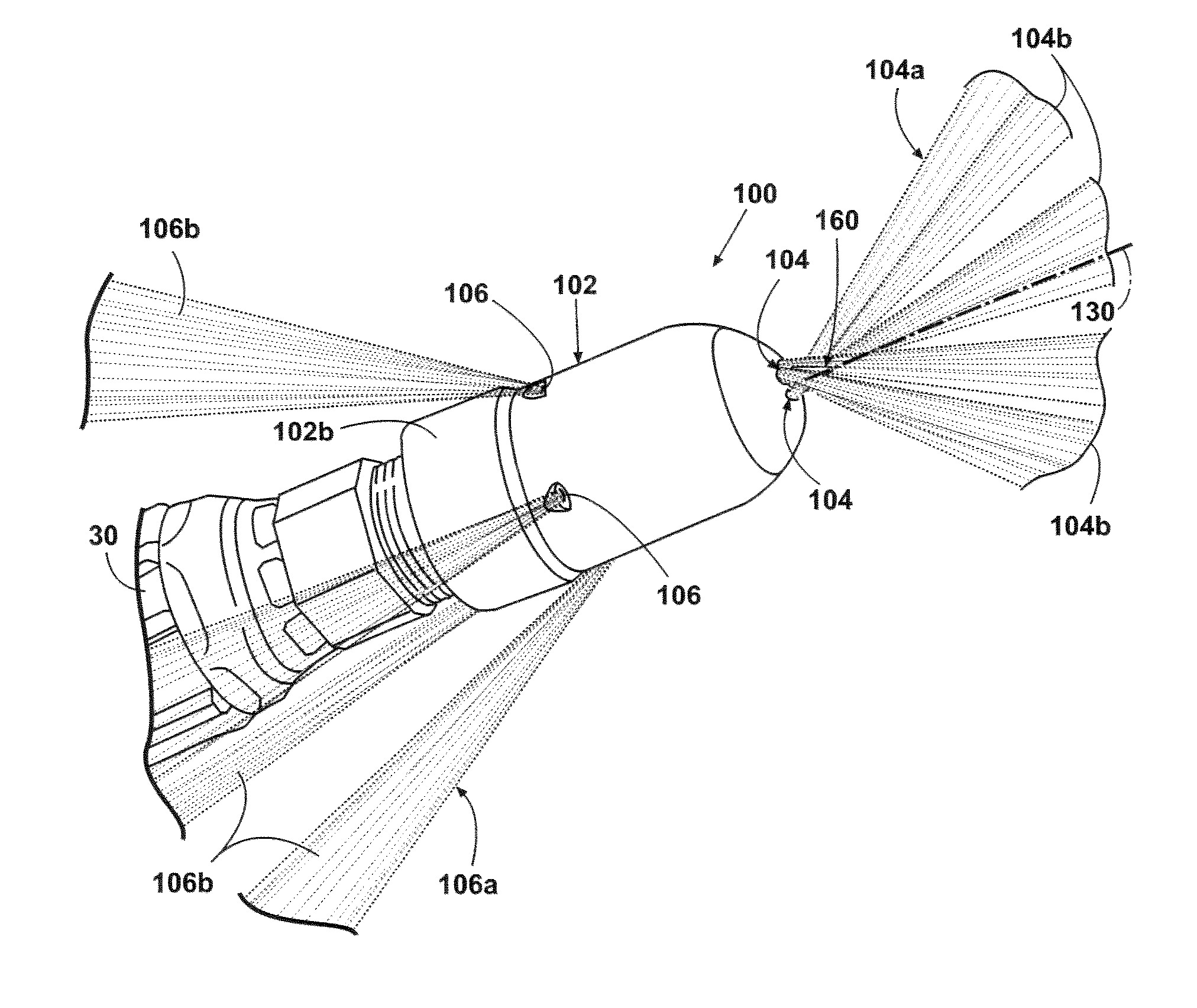

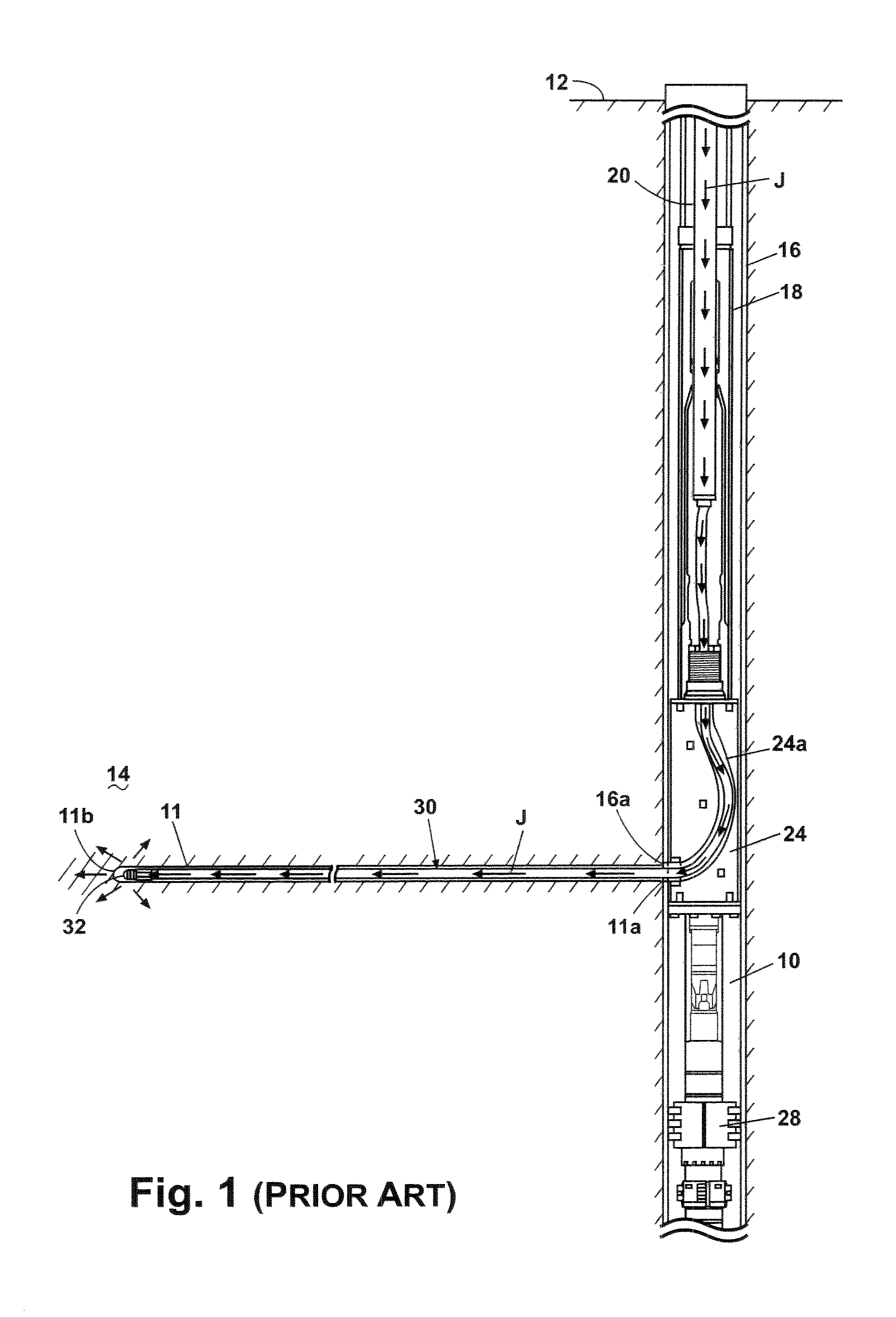

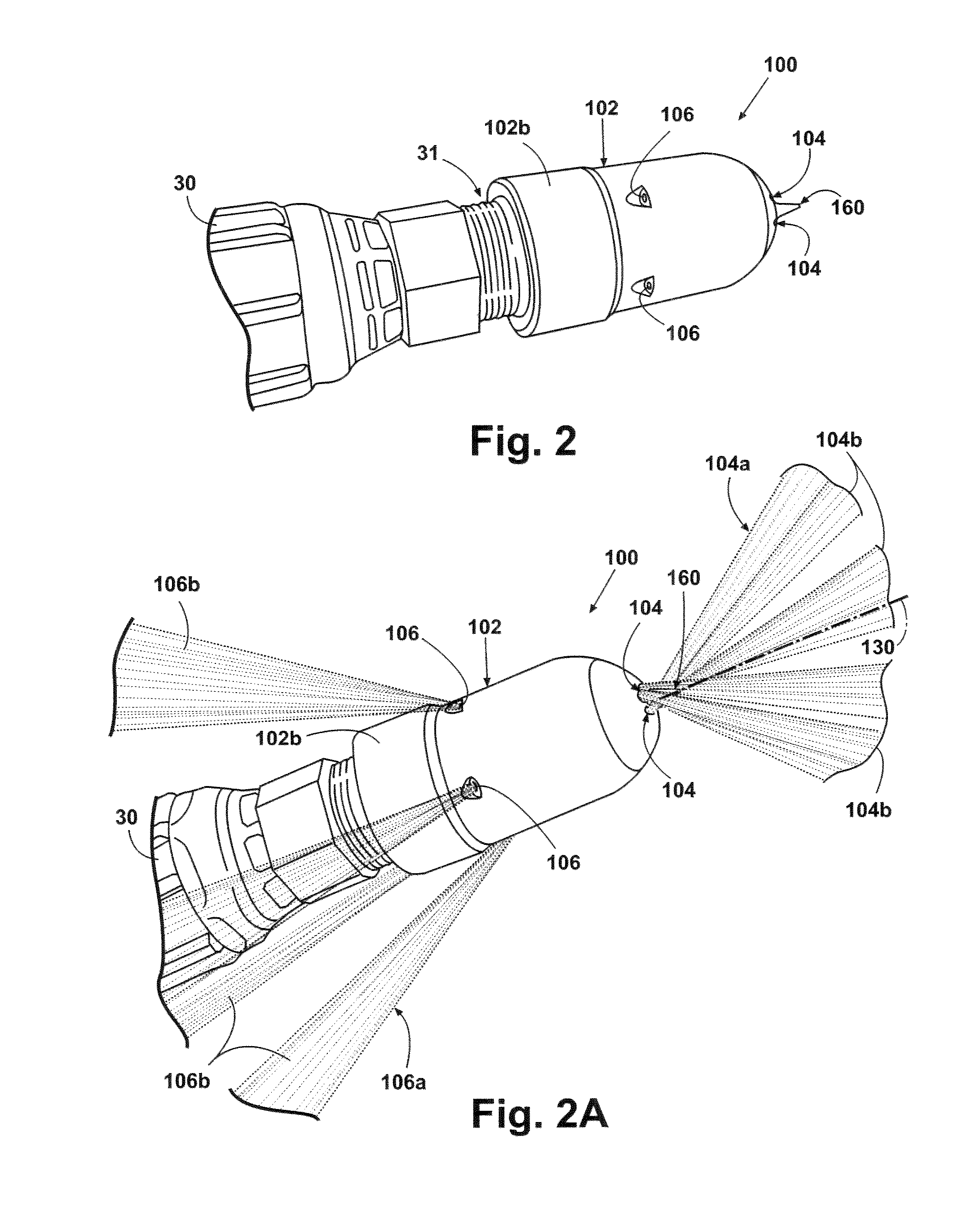

Method and apparatus for forming a borehole

A jetting nozzle for forming boreholes or for cleaning out other tubular formations has a vibration-inducing mechanism that maximizing penetration rates and expands the diameter of the boreholes. The vibration-inducing mechanism can be an internal turbine responsive to the flow of pressurized jetting fluid through the nozzle. The nozzle has forward openings defining a voraxial spray pattern for the forward-directed jetting portion of the fluid exiting the nozzle. The nozzle can also have a pointed end that is adapted to penetrate the formation. The vibration also reduces friction between the fluid supply hose and the borehole being jetted through the formation by the nozzle. A system for forming boreholes with the jetting nozzle and a method of forming boreholes is also disclosed.

Owner:FUTURE TECH LTD

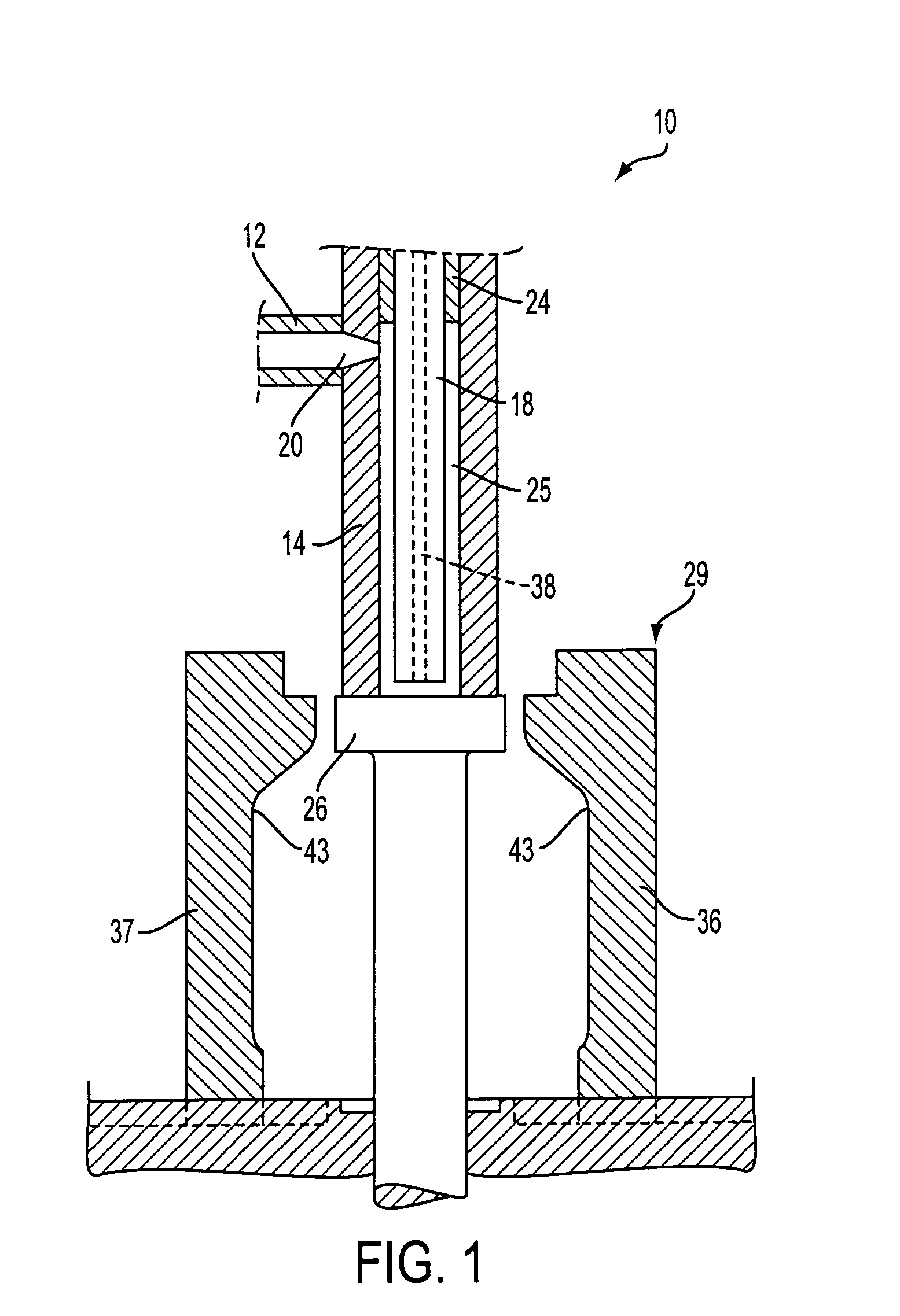

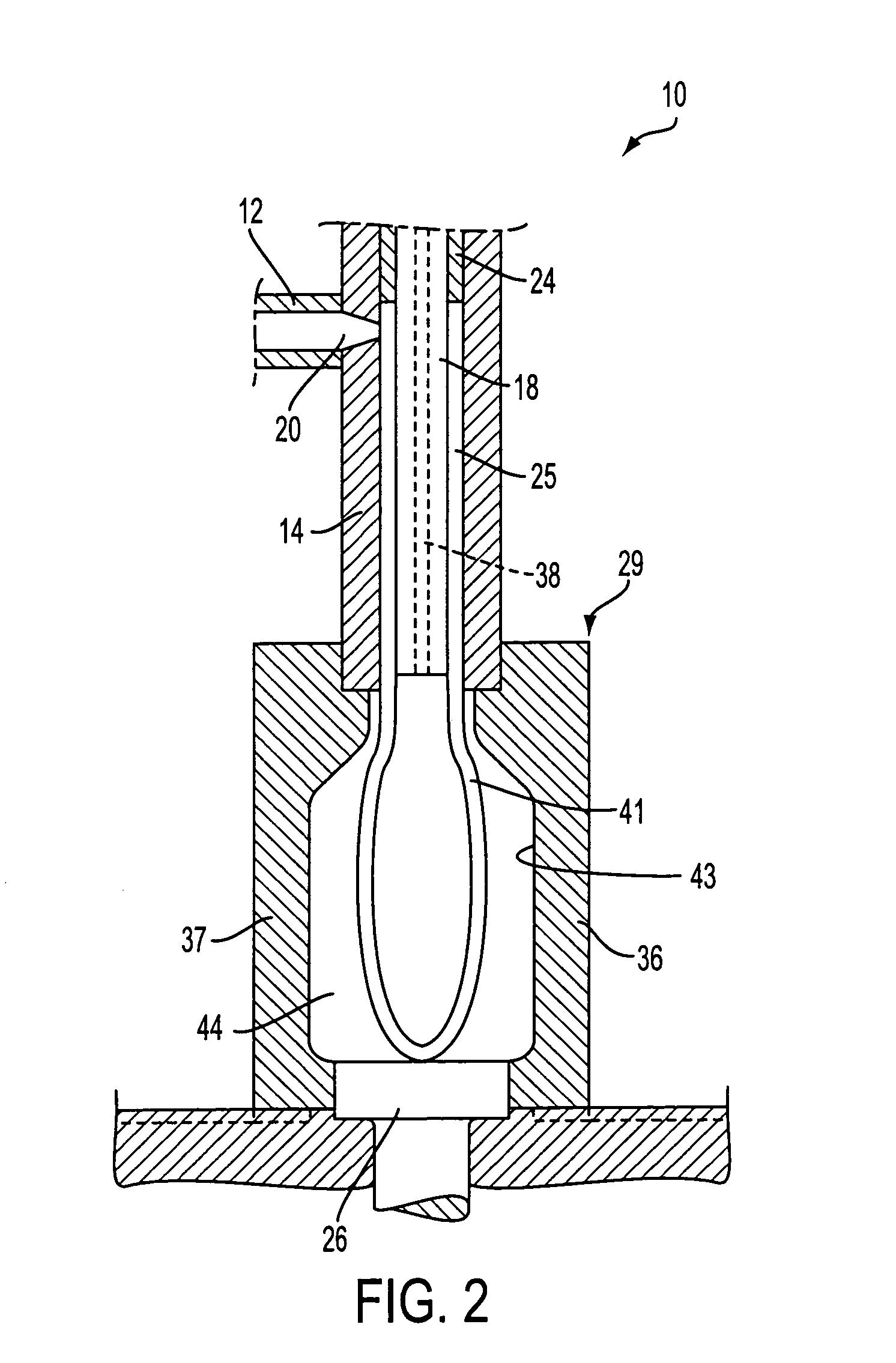

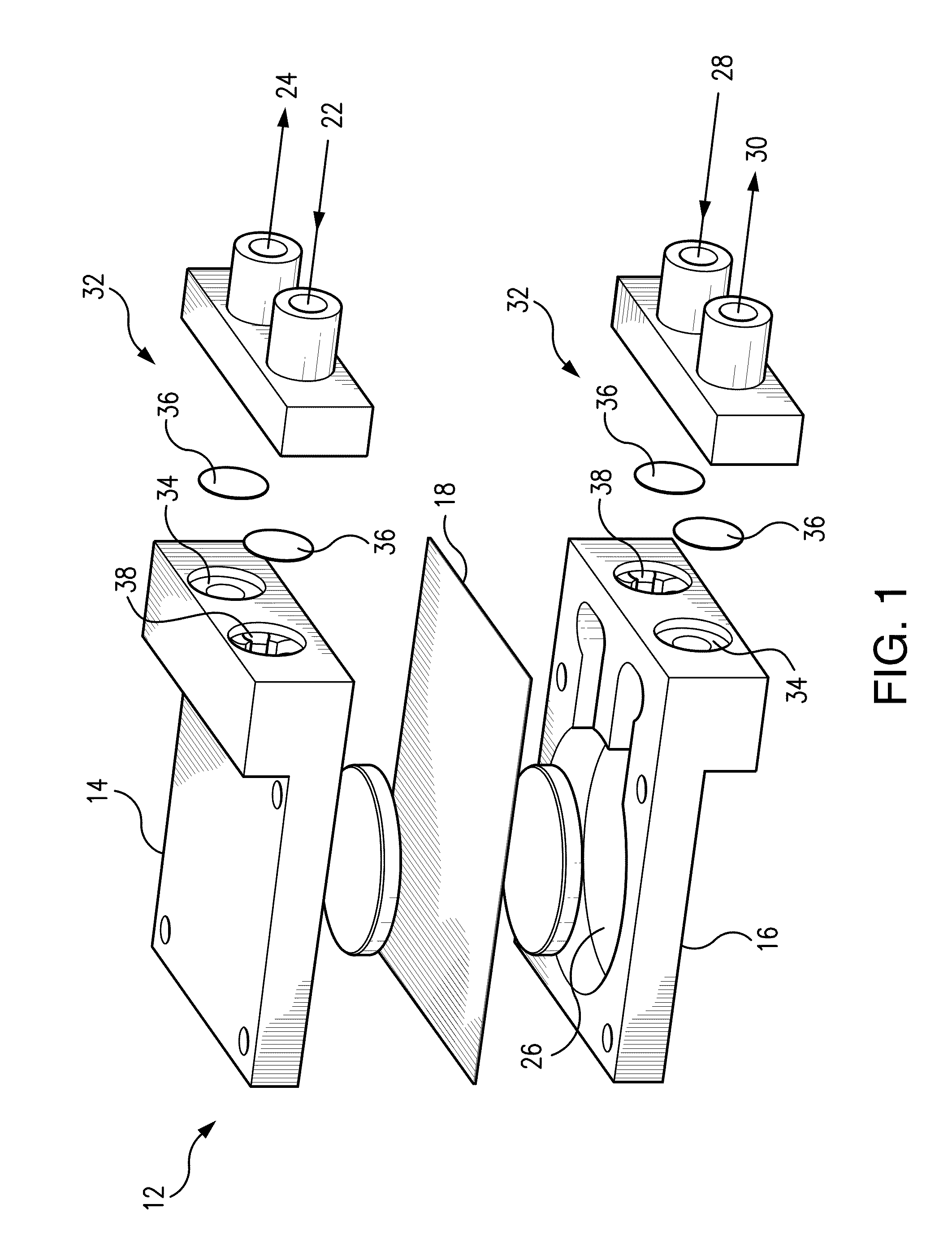

Method and apparatus for blow molding large reinforced plastic parts

A method for molding large parts, comprises the steps of providing a reinforced plastic melt comprising at least one thermoplastic material and reinforcement particles dispersed within the at least one thermoplastic material, the reinforcement particles comprising less than 15% of a total volume of the plastic melt, at least 50% of the reinforcement particles having a thickness of less than about 20 nanomenters, and at least 99% of the reinforcement particles having a thickness of less than about 30 nanometers; communicating a tubular formation of the plastic melt to a mold assembly having a mold cavity defined by mold surfaces, the mold surfaces corresponding to a configuration of the part to be molded; applying pressurized gas to an interior of the tubular formation to expand the tubular formation into conformity with the mold surfaces; and solidifying the plastic melt to form the part; and removing the part from the mold assembly.

Owner:MAGNA INT OF AMERICA

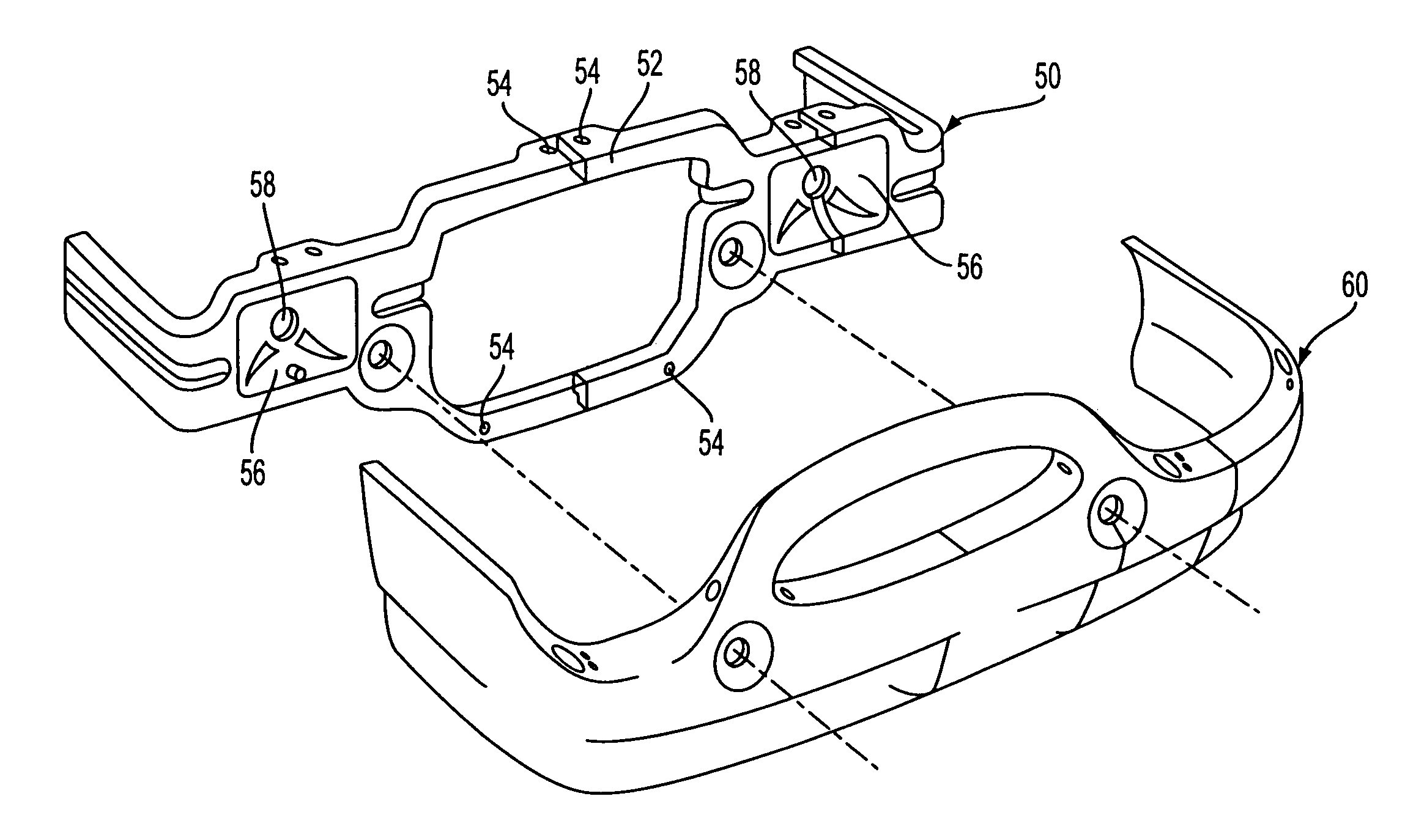

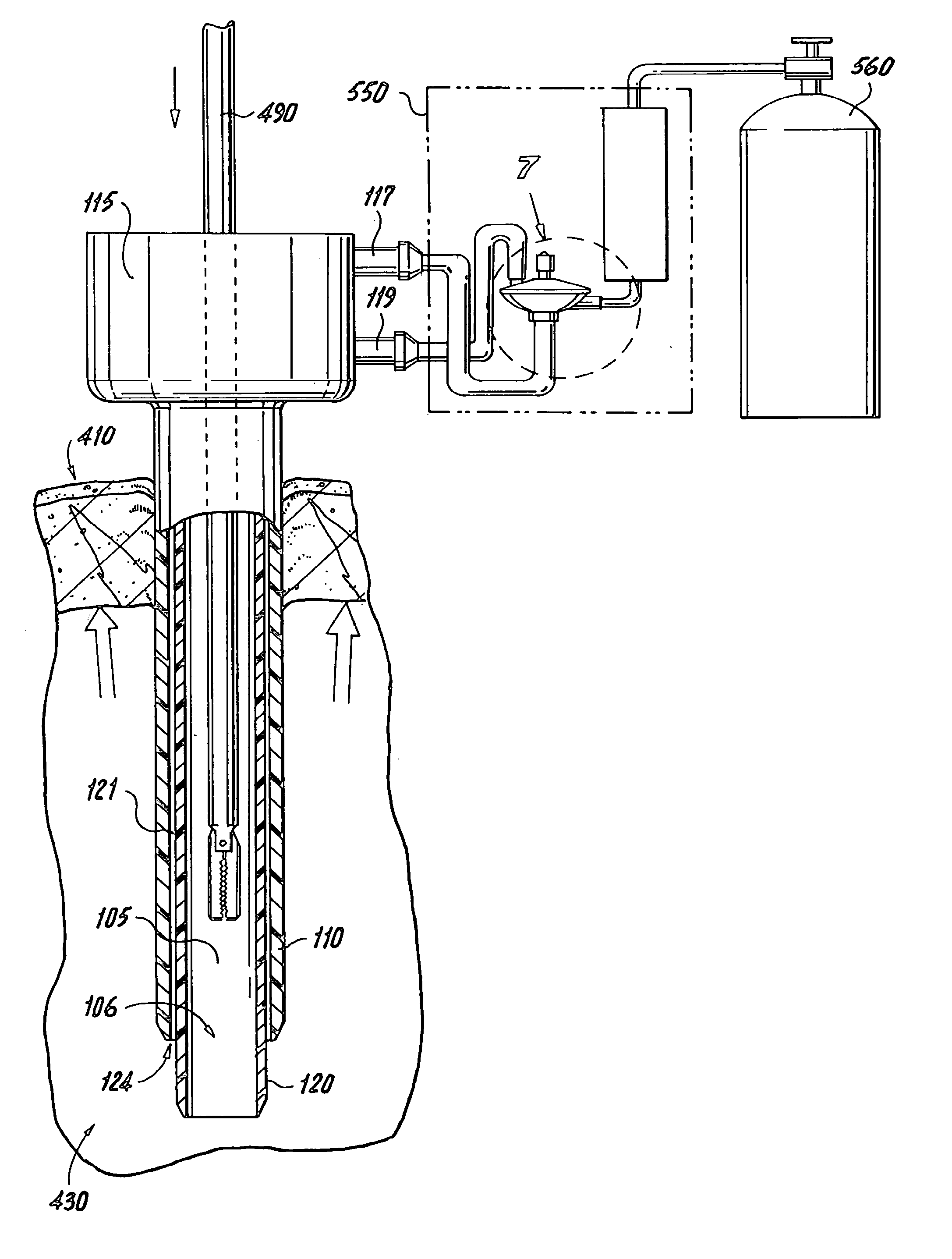

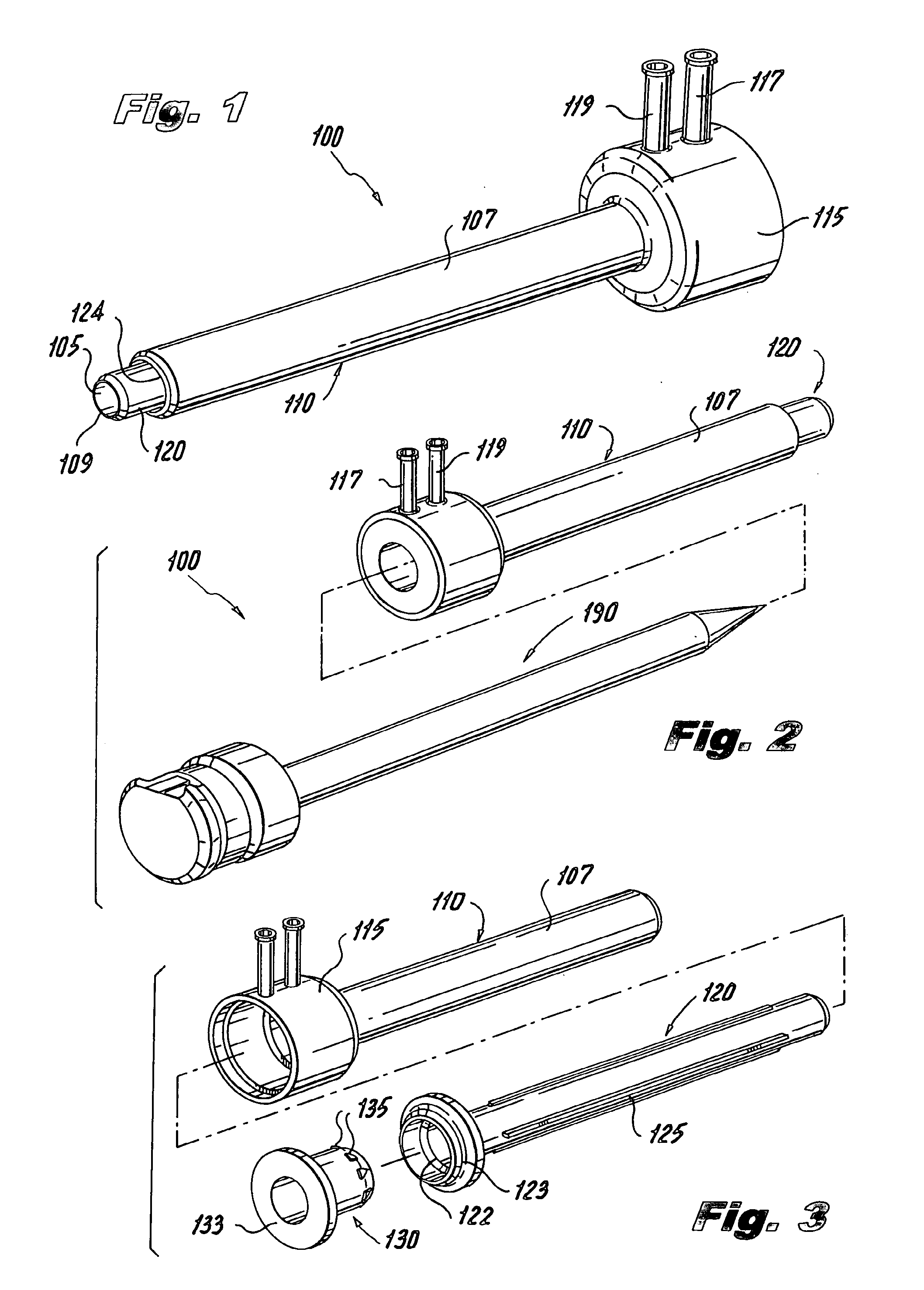

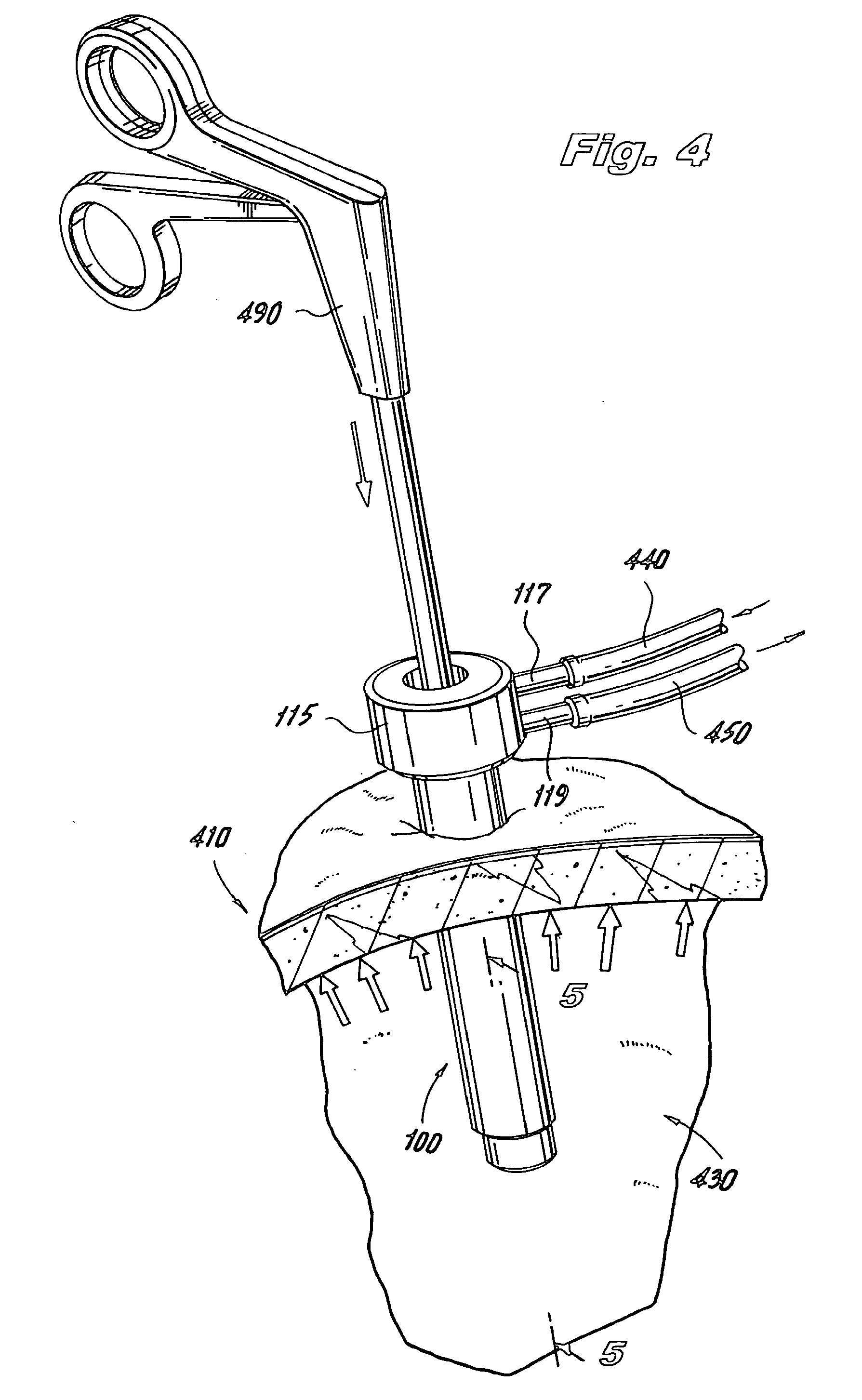

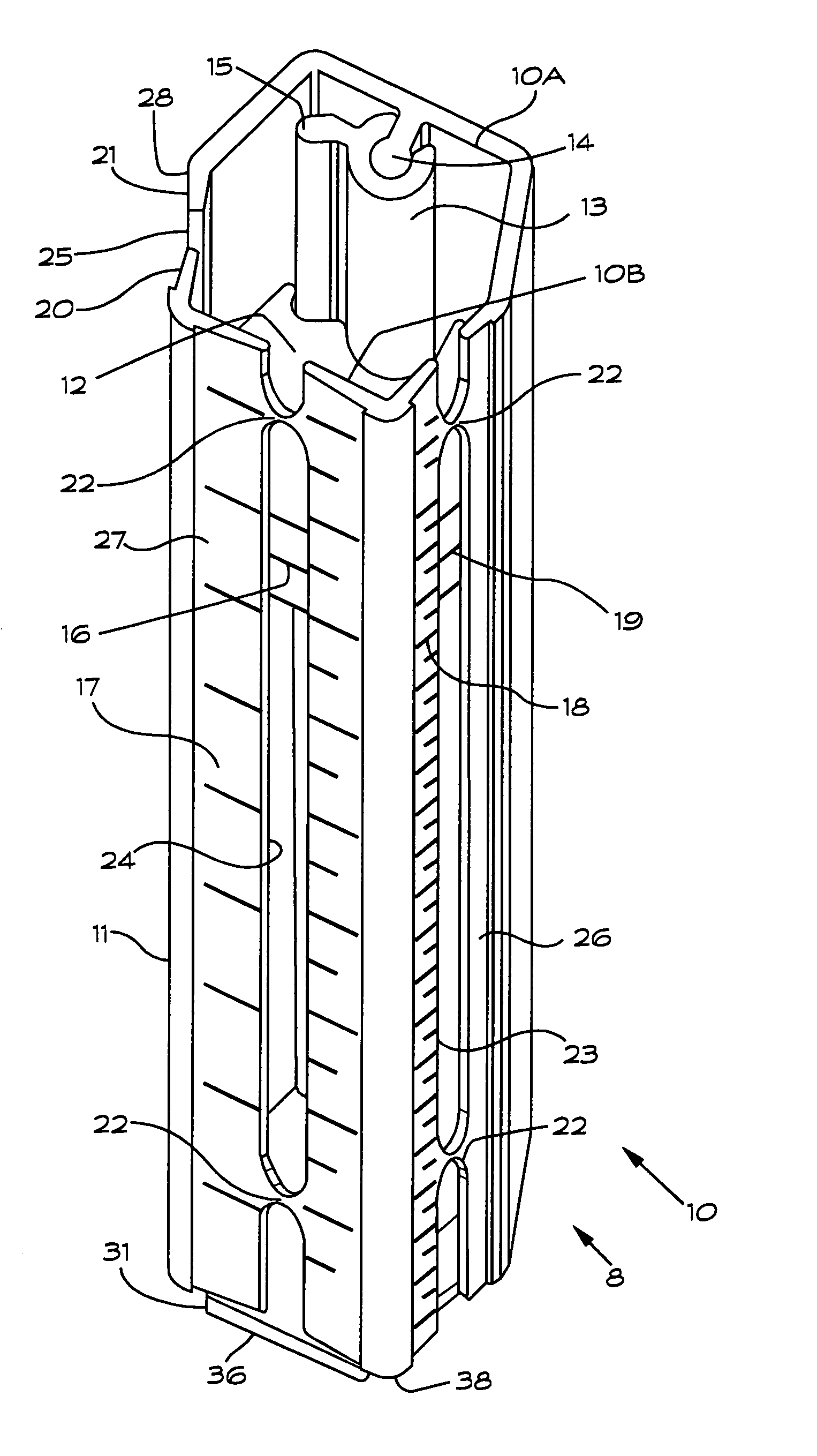

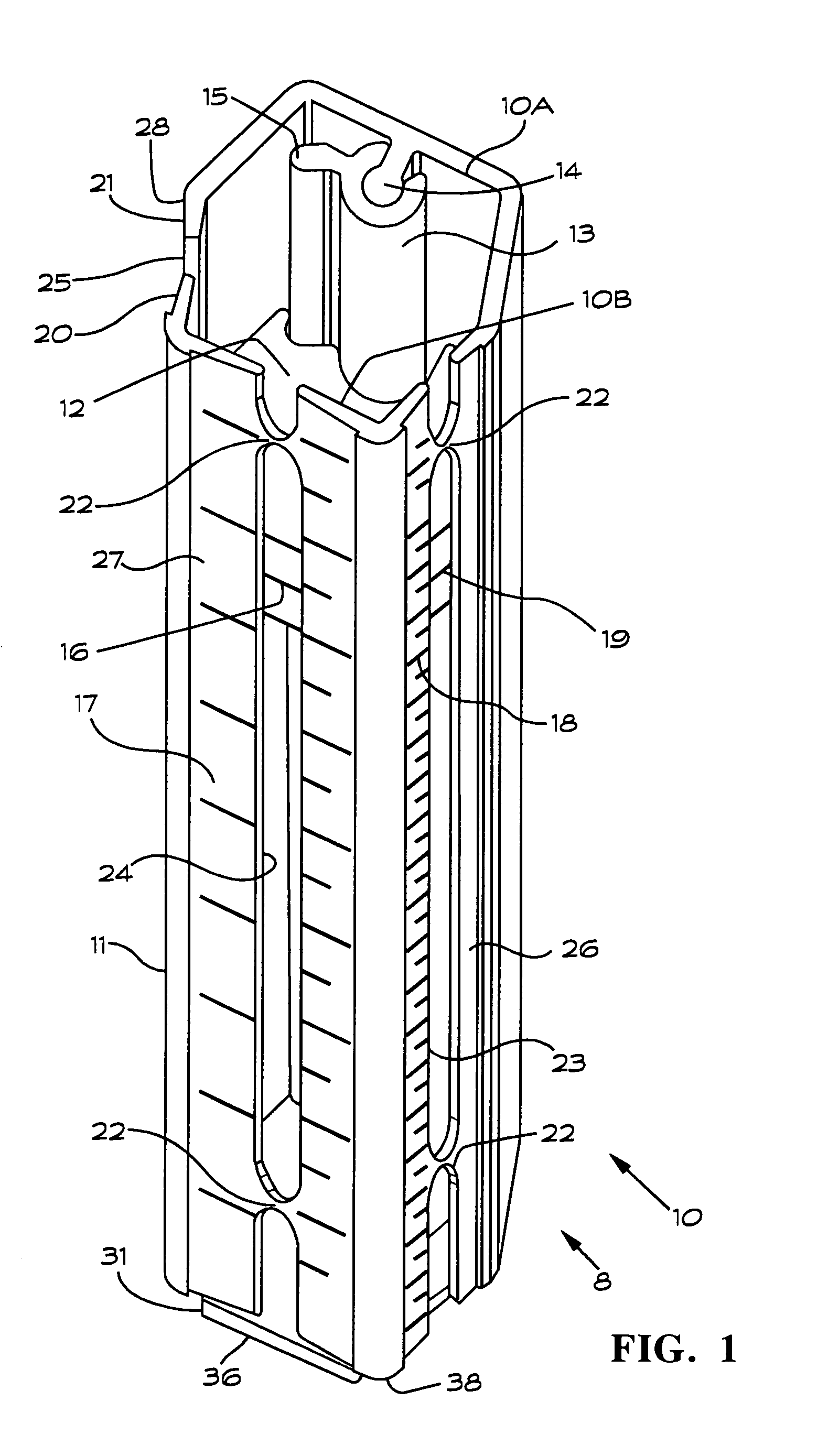

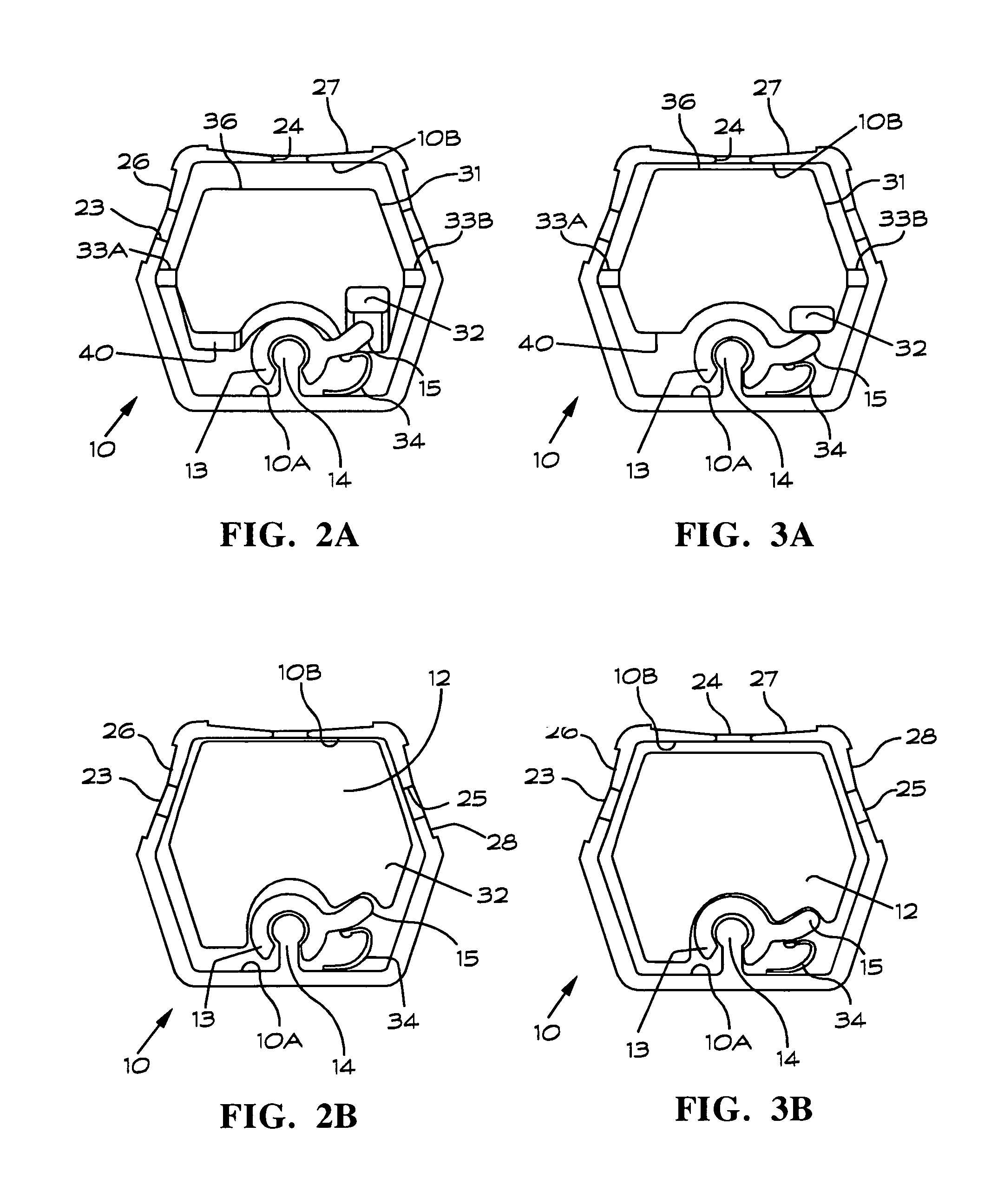

Trocar assembly with pneumatic sealing

A trocar for use in a minimally invasive surgical procedure includes an elongated body, nozzle means and means for delivering a pressurized flow of fluid to the nozzle means. The elongated body has a generally tubular configuration with coaxially arranged inner and outer walls and longitudinally opposed proximal and distal end portions, with the inner wall defining a lumen to accommodate passage of an instrument therethrough. The nozzle means is operatively associated with the inner wall of the body for directing pressurized fluid into the lumen to develop a pressure differential in an area within a region extending from a location adjacent a distal end portion of the lumen to a location adjacent a proximal end portion of the lumen, to form a fluid seal around an instrument passing therethrough.

Owner:SURGIQUEST

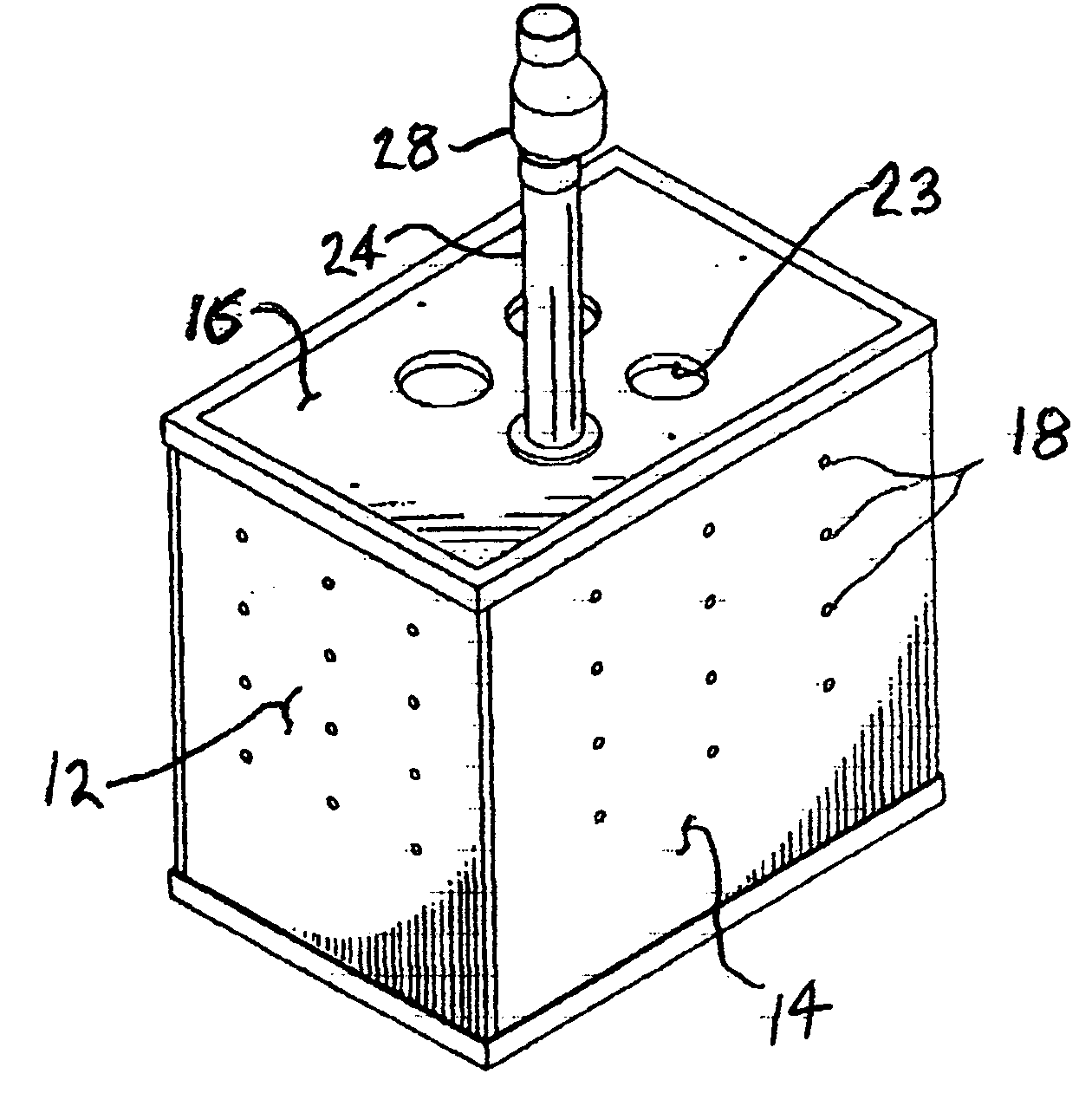

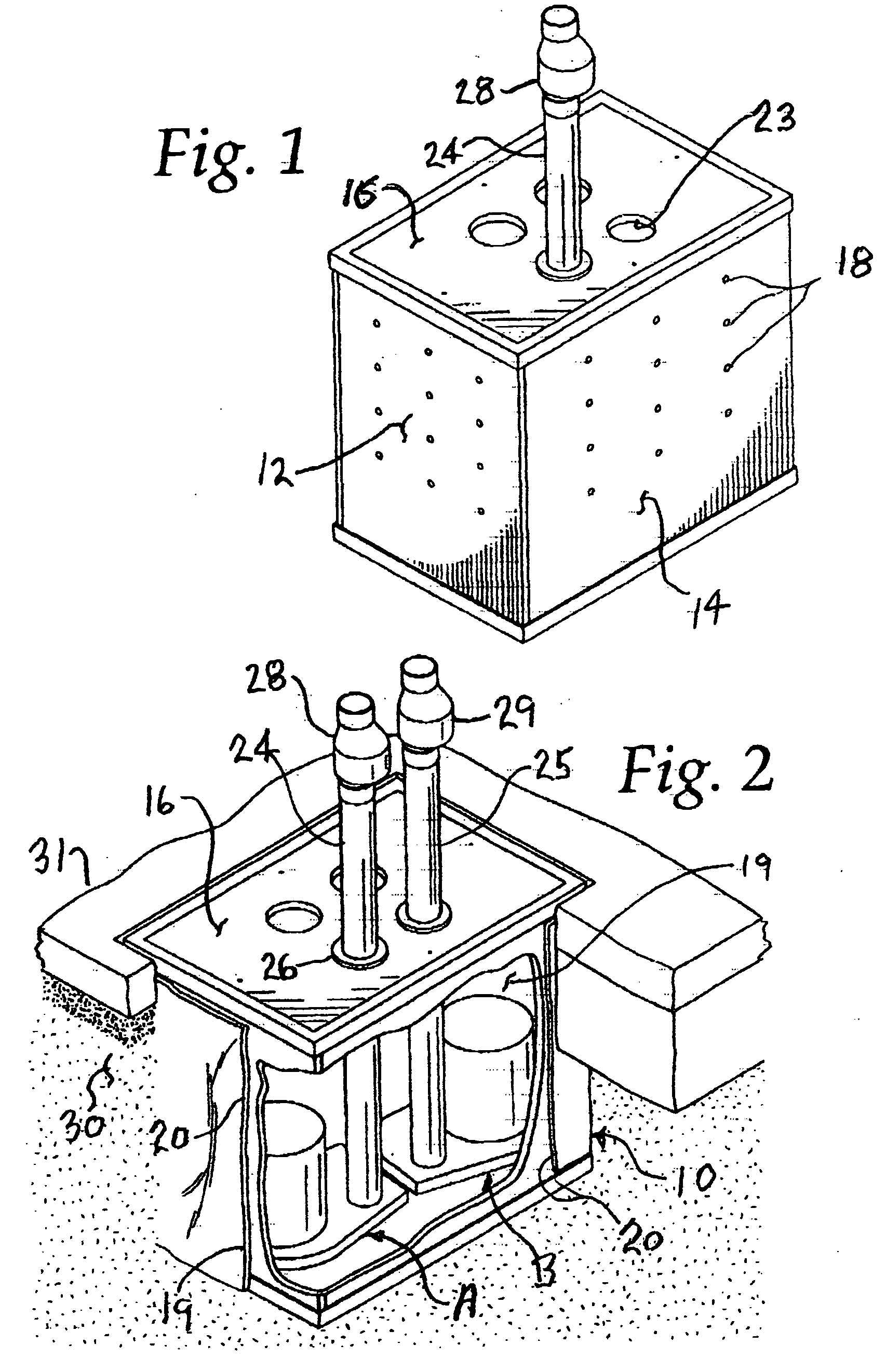

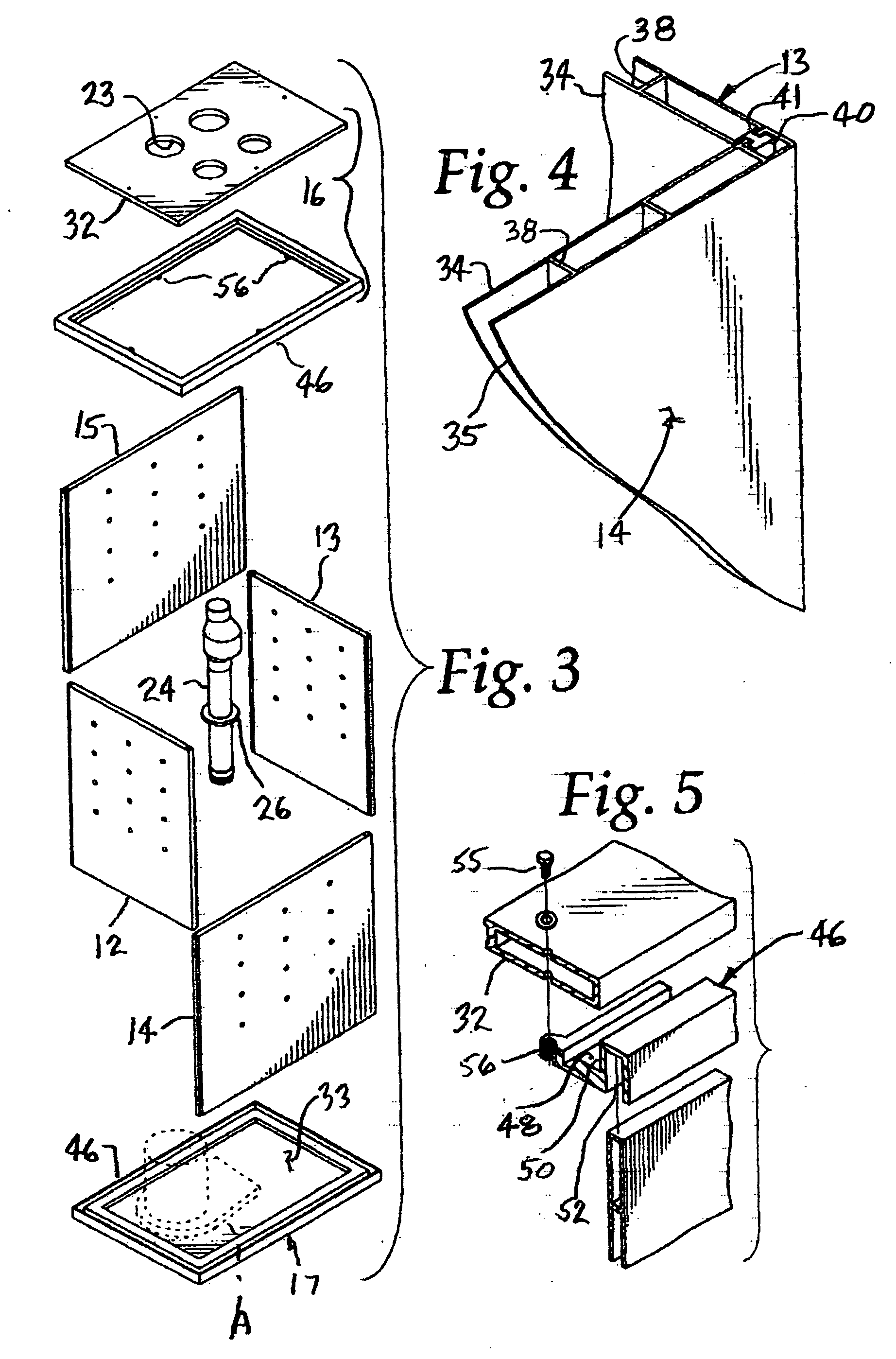

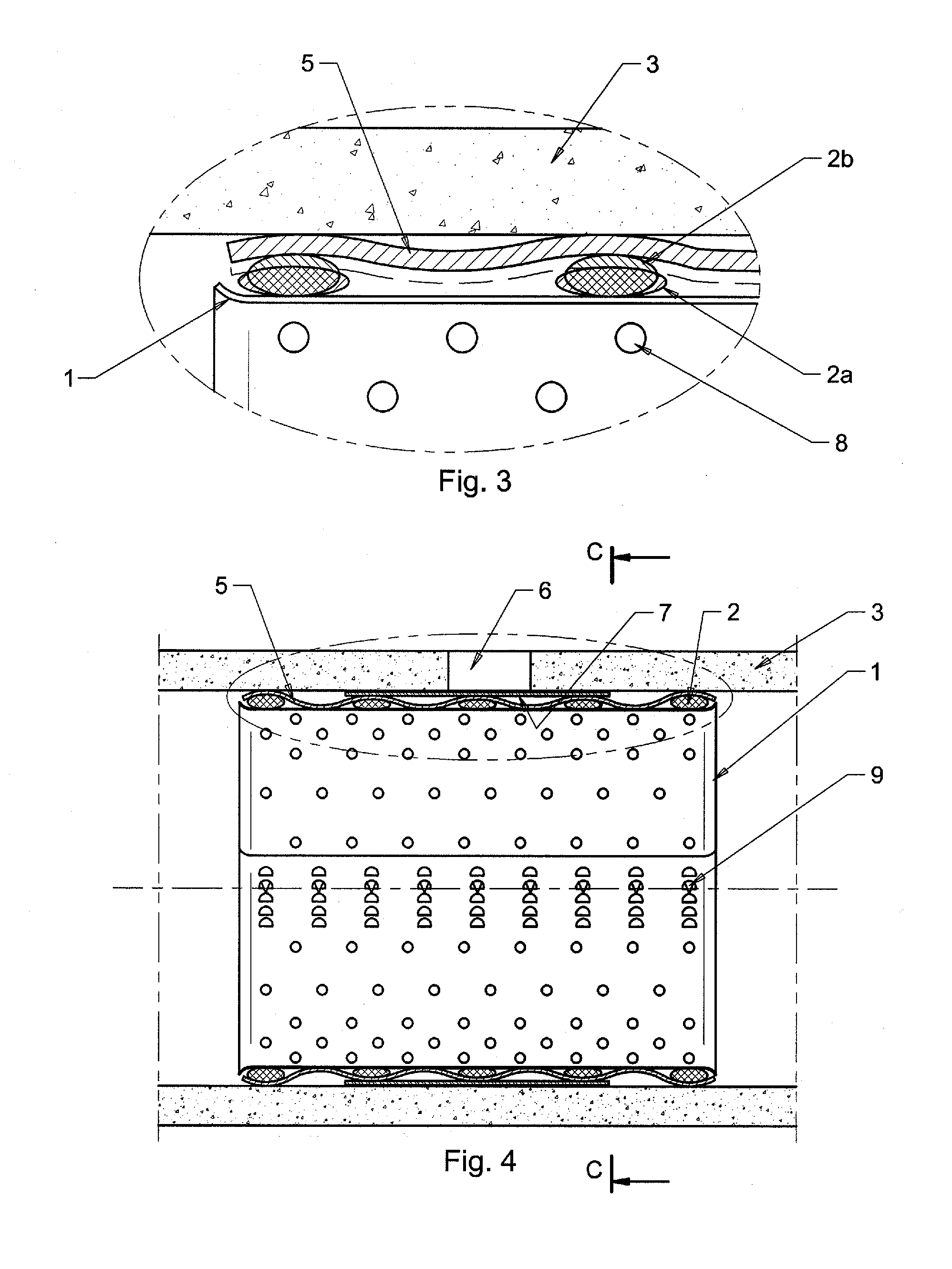

Modular sump pump pit assembly

InactiveUS20090183785A1Easy to carryIncreased durabilitySewerage structuresPositive displacement pump componentsSewageEngineering

The disclosed sump pump pit is modular, being formed from substantial planar lightweight top, bottom and side walls that when disassembled can be carried compactly stacked on one another to an intended sump hole, and can then be assembled and secured together as the rigid pit defining an enclosure sized to hold at least one sump pump (preferably two sump pumps side-by-side). Cooperating tongue and groove configurations on the side wall edges interlock these components in a tubular configuration, and the end edges of the side walls can be fitted into and secured in channels in the top and bottom walls, making the pit rigid. The pit walls are perforated for communicating the sump hole with the pit enclosure. Piping extended through the top wall allows water to be pumped from the sump hole via the pit pump(s).

Owner:COLE LOUIS F +1

Apparatus and method for internal repair of conduits

InactiveUS20100263759A1Avoid creatingReduce external loadUnderground chambersPipe elementsLocking mechanismWater well

An apparatus and method for internal repair of pipes and conduits, such as sewer pipes, pressurized water mains, water wells, and natural gas lines. The conduit repair apparatus includes a sleeve with locking mechanism to lock the sleeve in a tubular configuration. The sleeve is made of metallic or rigid plastic sheet having perforations. Some of the perforations are shaped like elongated slots and strips. A number of resilient O-rings are applied over the outer surface of the sleeve. A resilient membrane is applied over the O-rings. In one embodiment, a reinforcement band is used, and an additional layer of O-rings are included between the membrane and the reinforcement band.

Owner:LINK PIPE

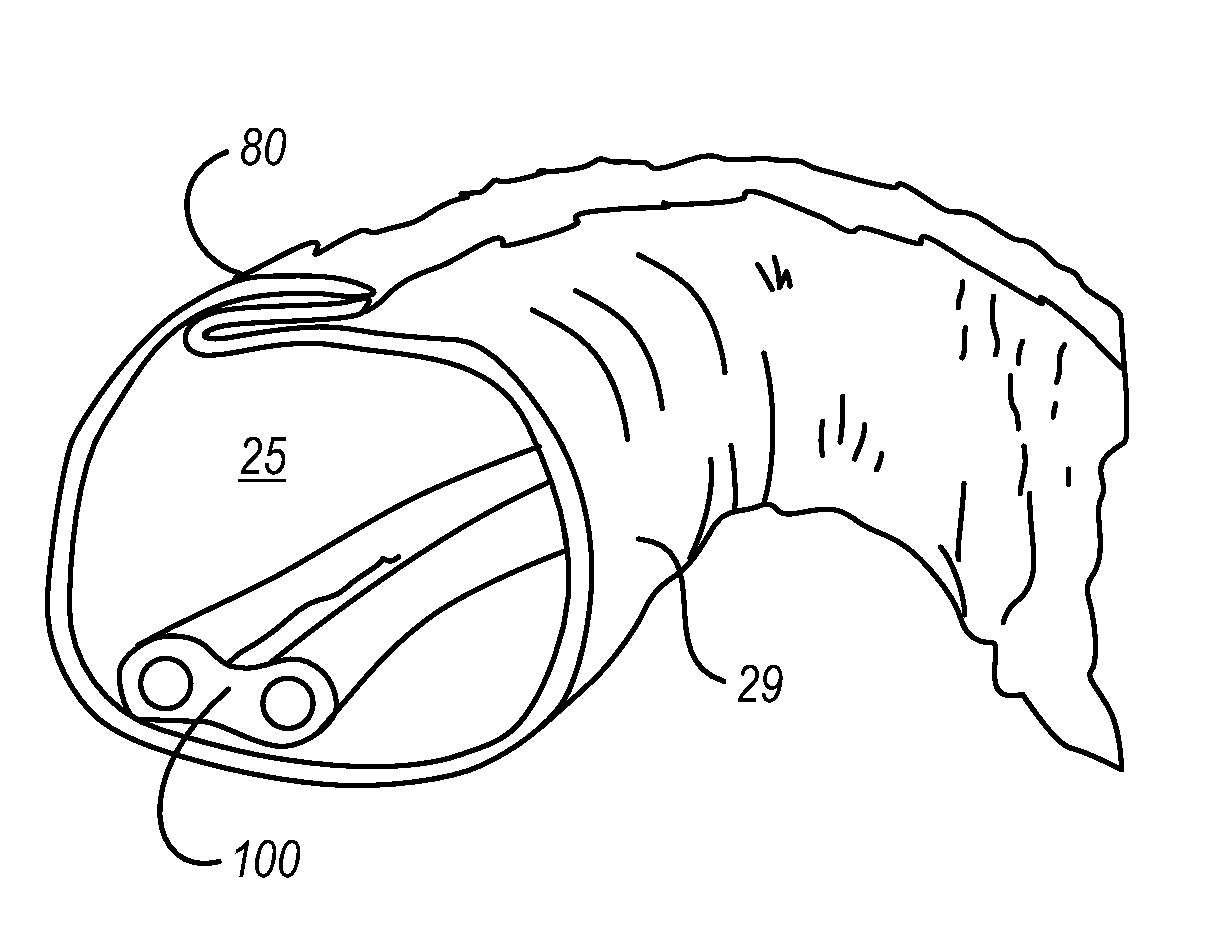

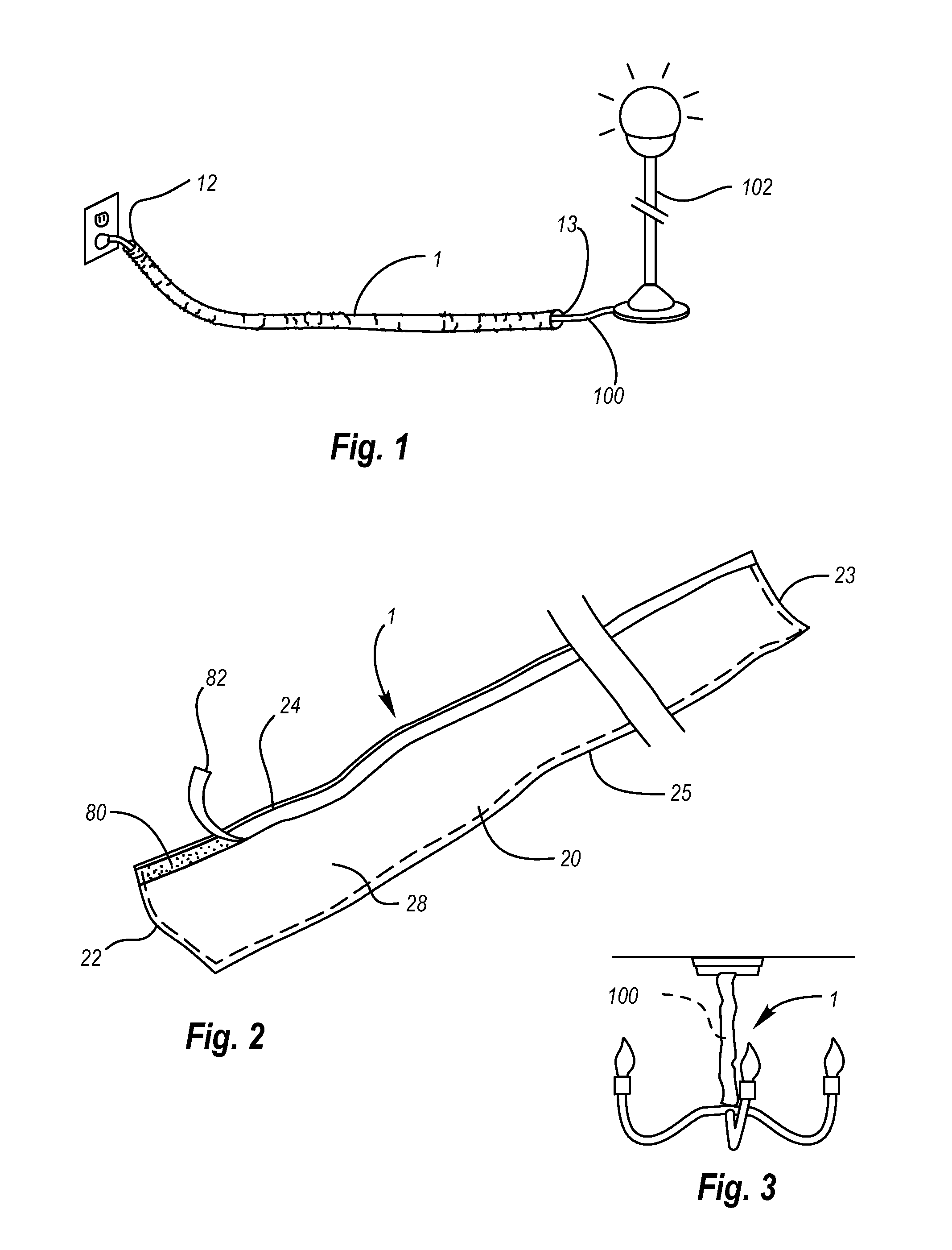

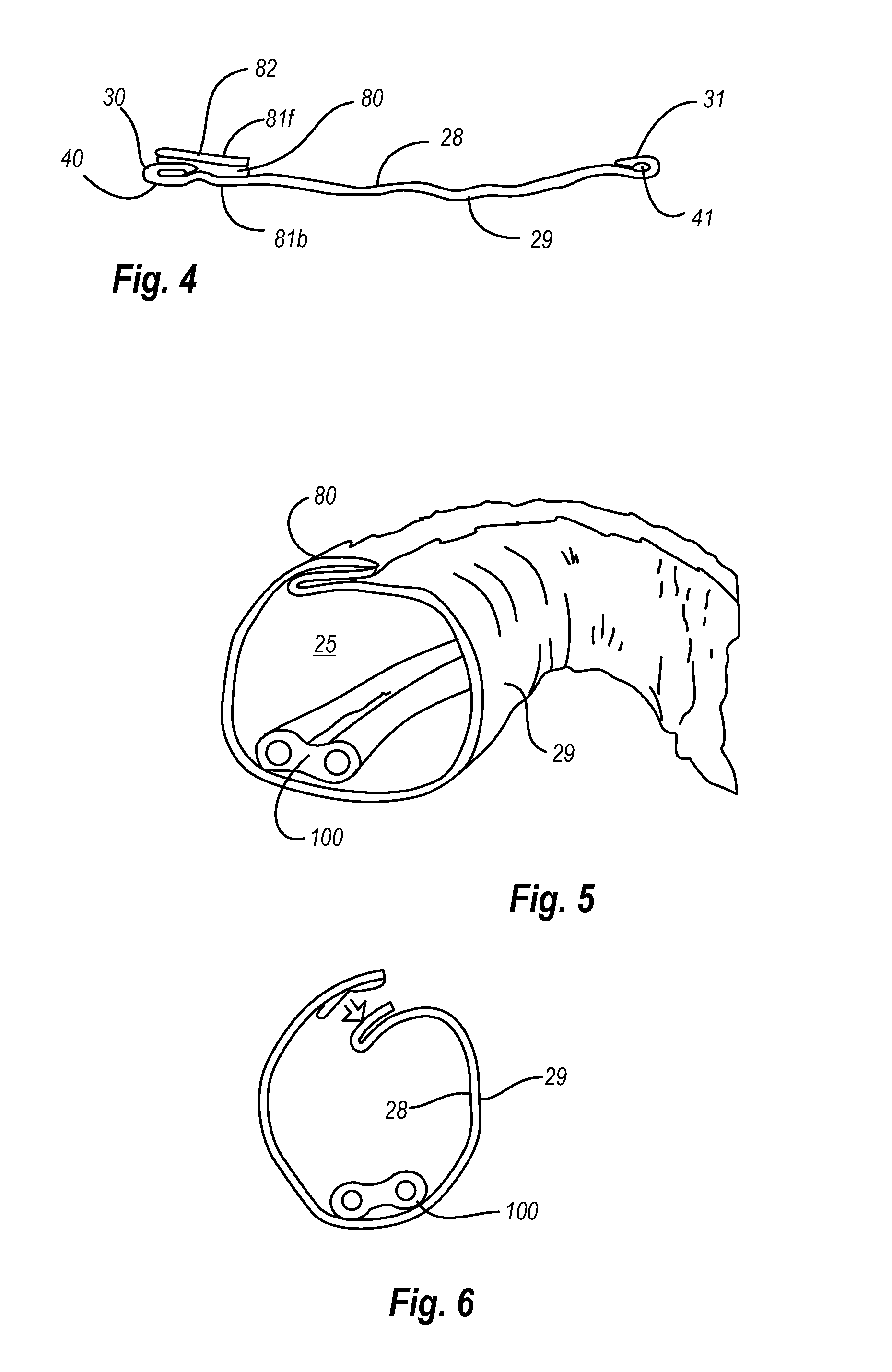

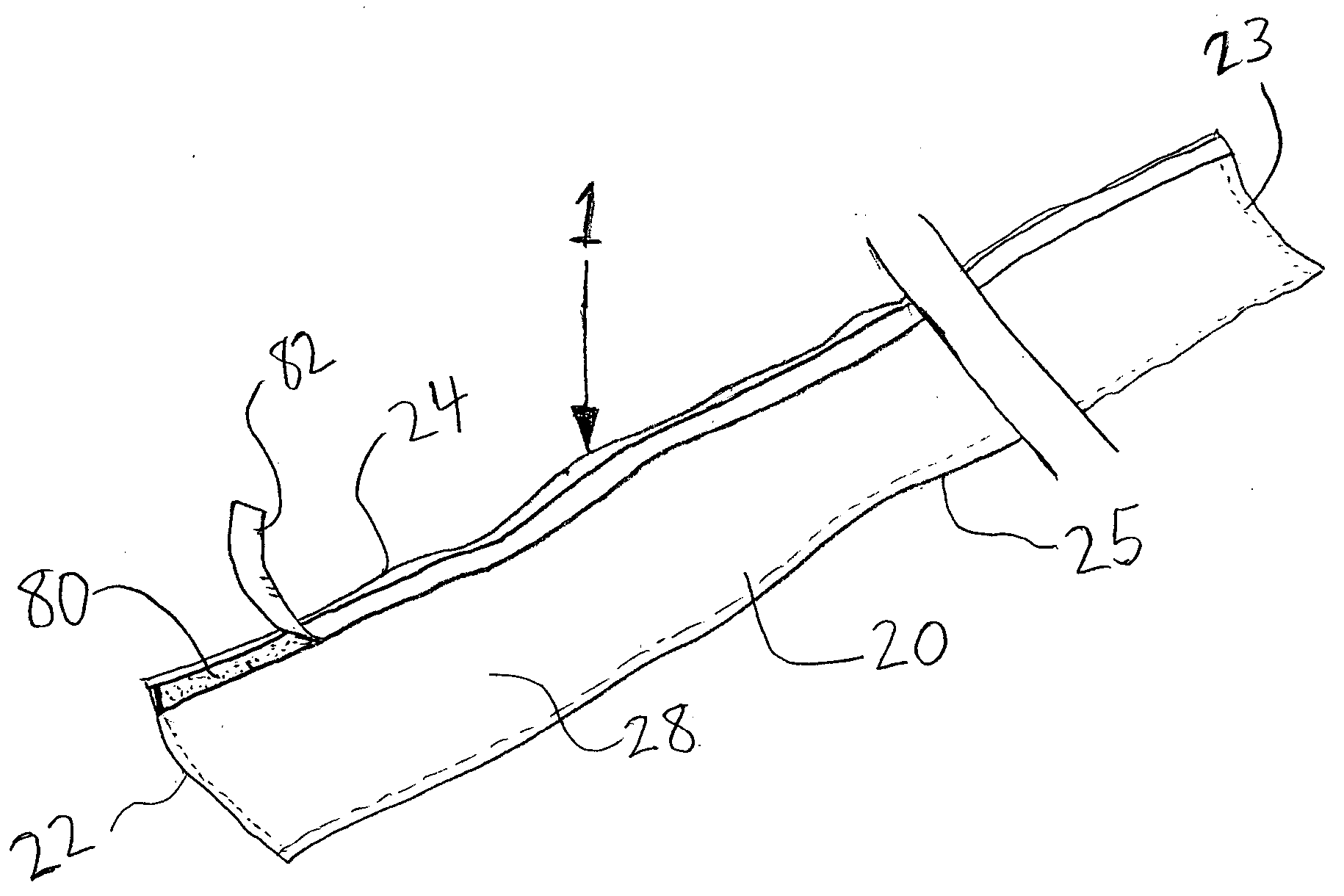

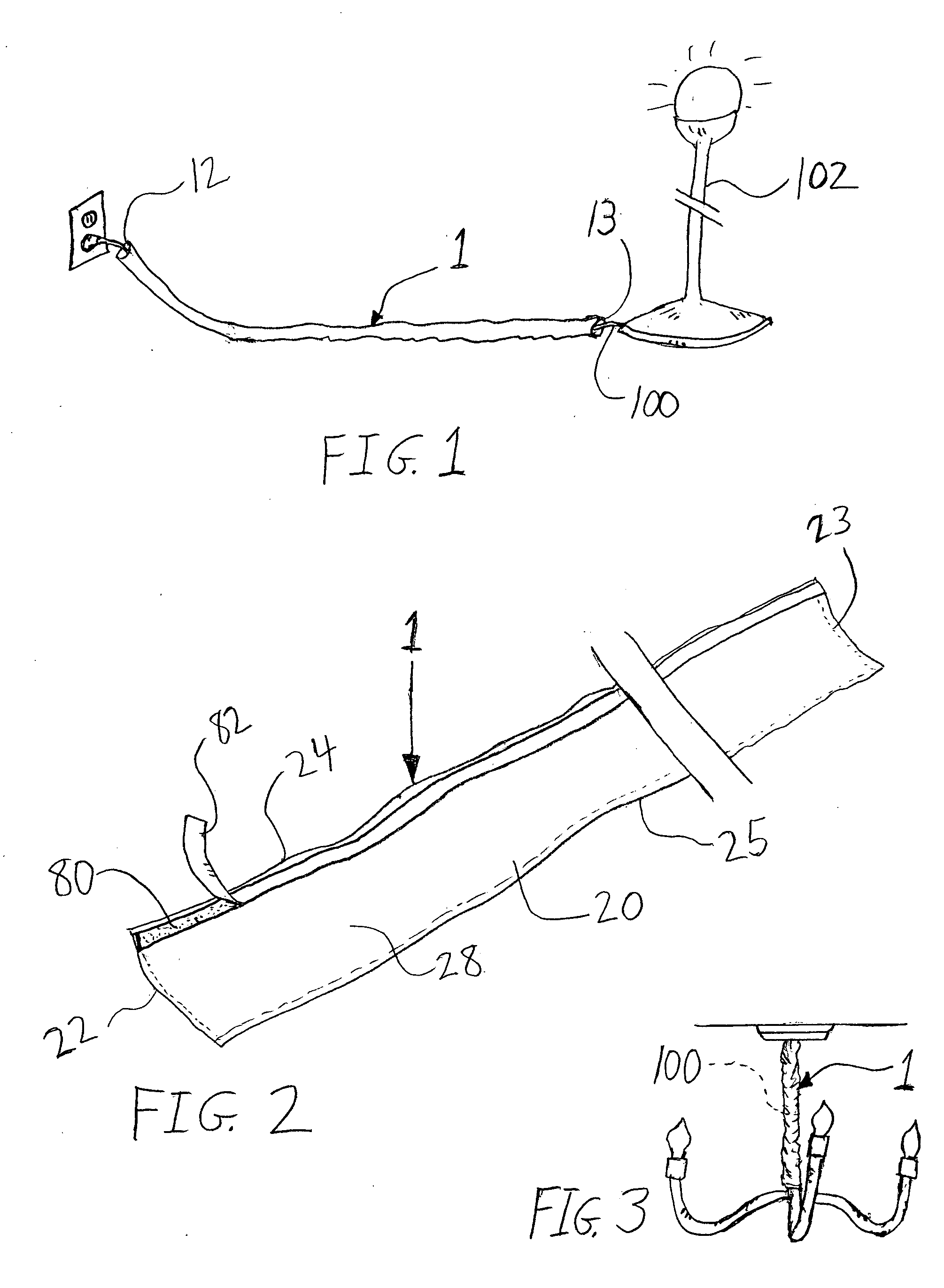

Adhesive cord cover

InactiveUS7438964B2Efficient use ofEasy and less-expensive to manufactureFlexible coversDecorative coversEngineeringTubular formation

An adhesive cord cover for enveloping a cord, such as an electrical cord or chandelier chain. The adhesive cord cover is formed from a lengthwise strip of fabric. A pressure sensitive adhesive is attached to the fabric strip, preferably along a first lengthwise edge. The pressure sensitive adhesive is positioned and configured to allow a fastening side of the pressure sensitive adhesive to be selectively adhered to the lengthwise strip of fabric to thereby form a tubular configuration for enveloping a cord. The pressure sensitive adhesive is preferably an adhesive transfer tape. The transfer tape preferably has a removable liner on the fastening side. The removable liner assists in preserving the adhesive properties of the pressure sensitive adhesive prior to use. The pressure sensitive adhesive transfer tape is preferably a continuous strip that extends substantially along the entire length of the piece of fabric.

Owner:CLARK KIM MARIE

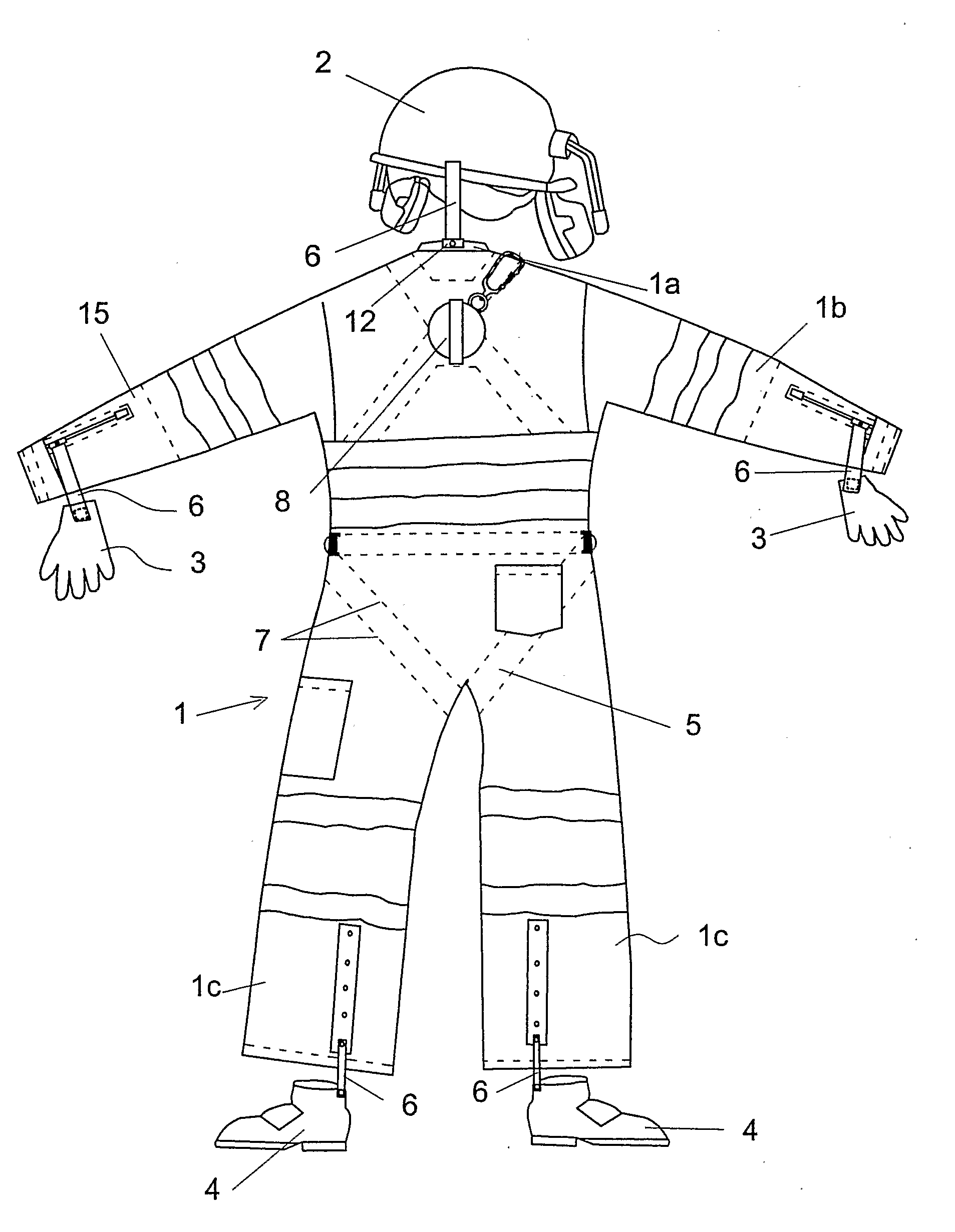

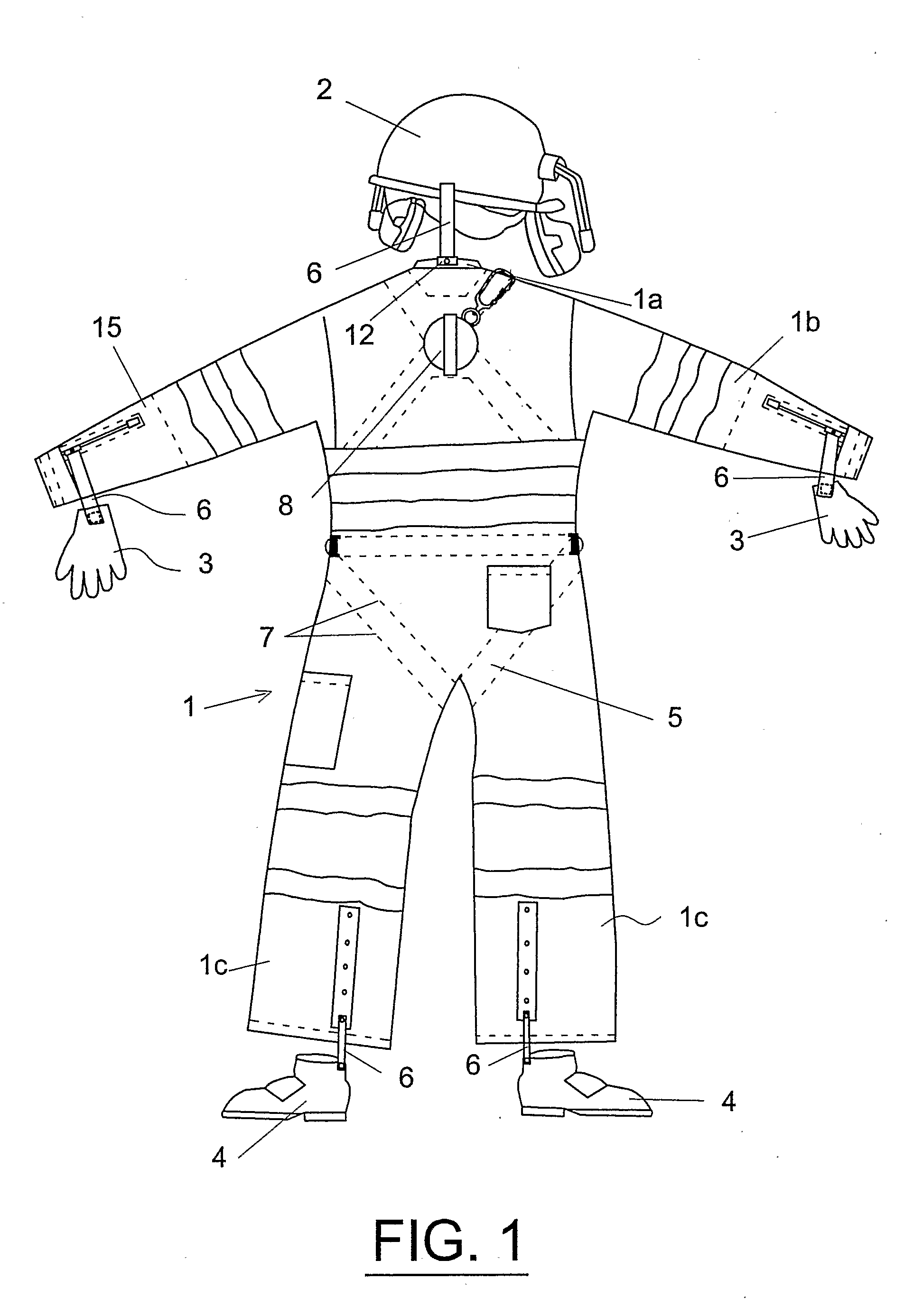

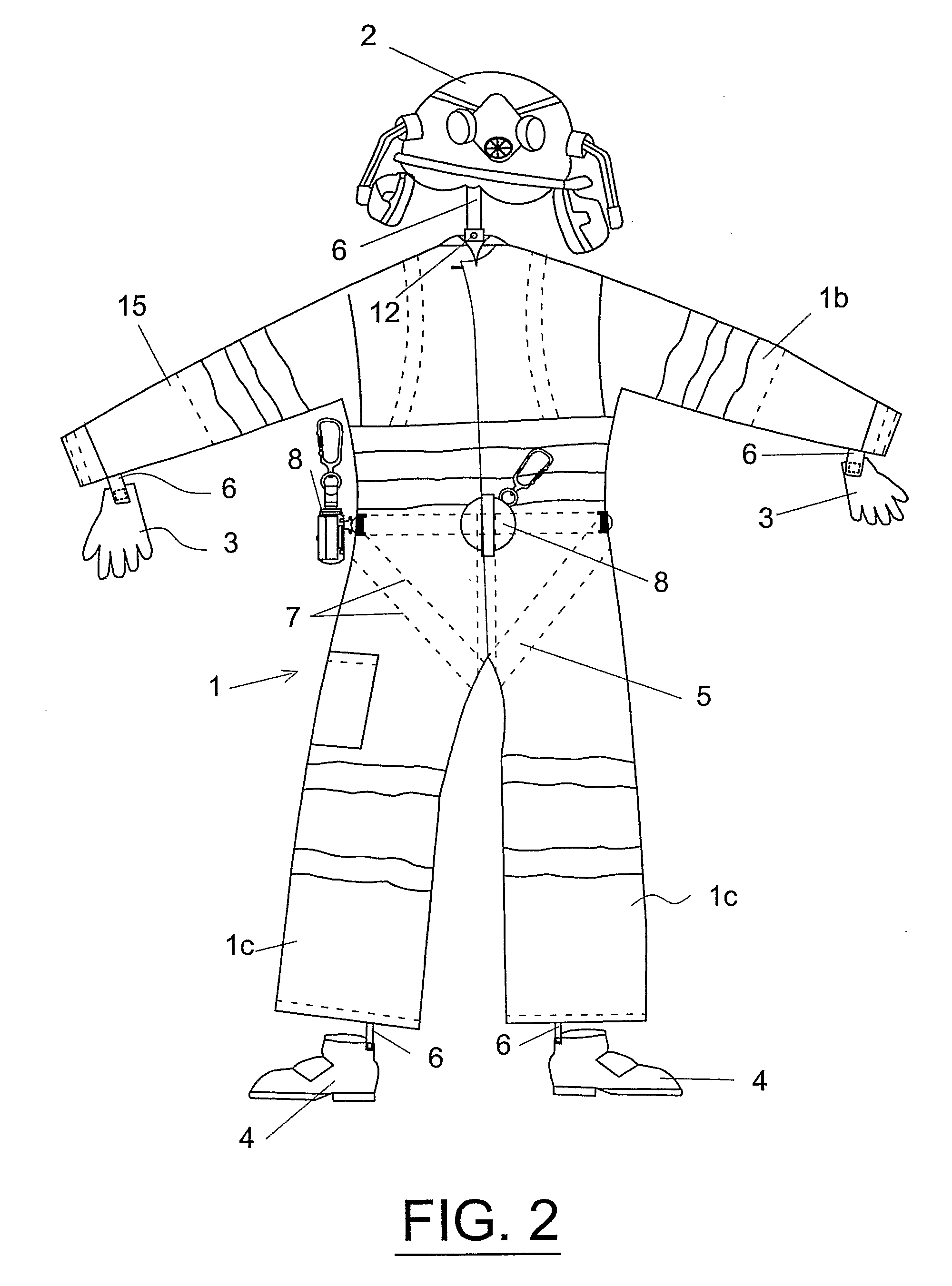

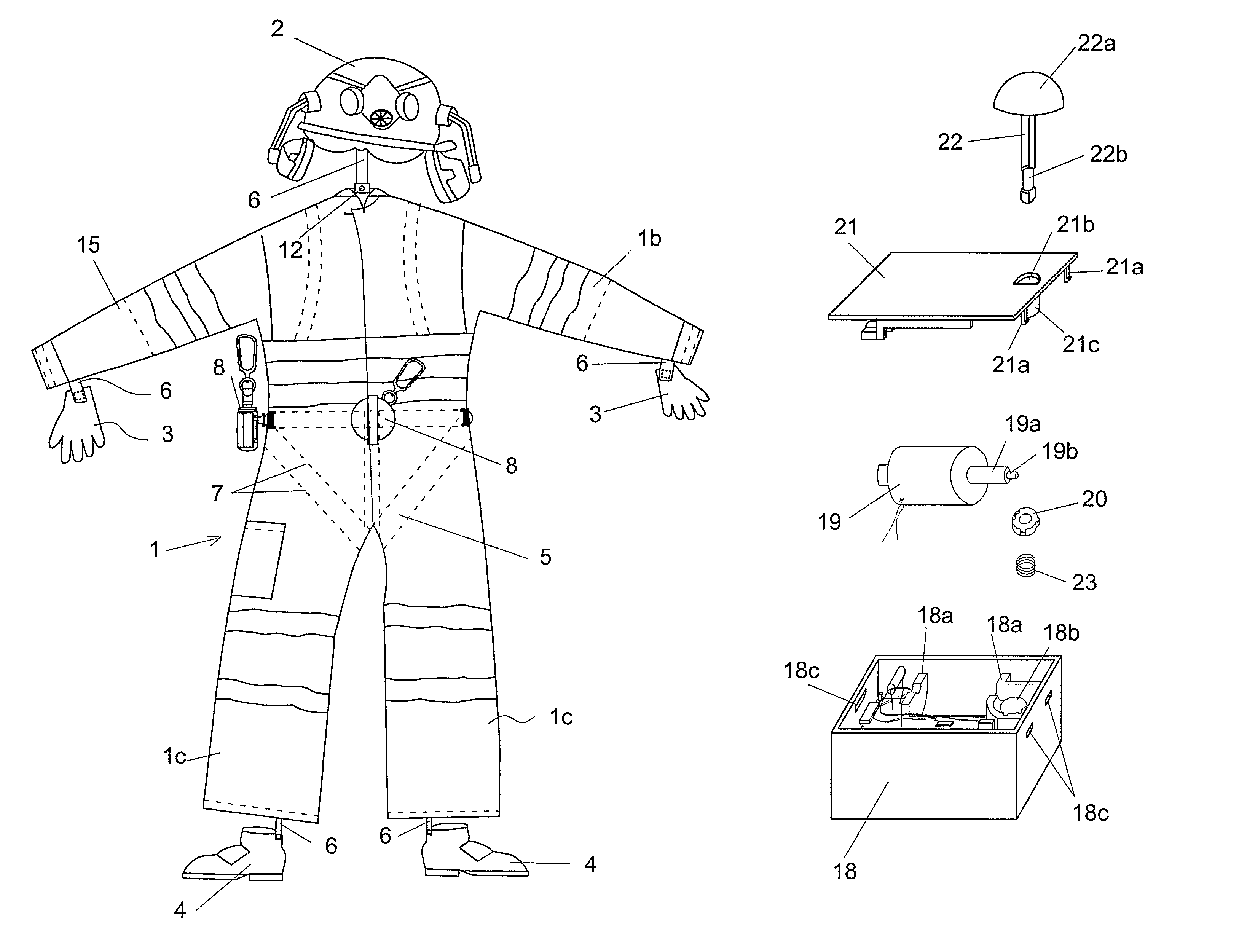

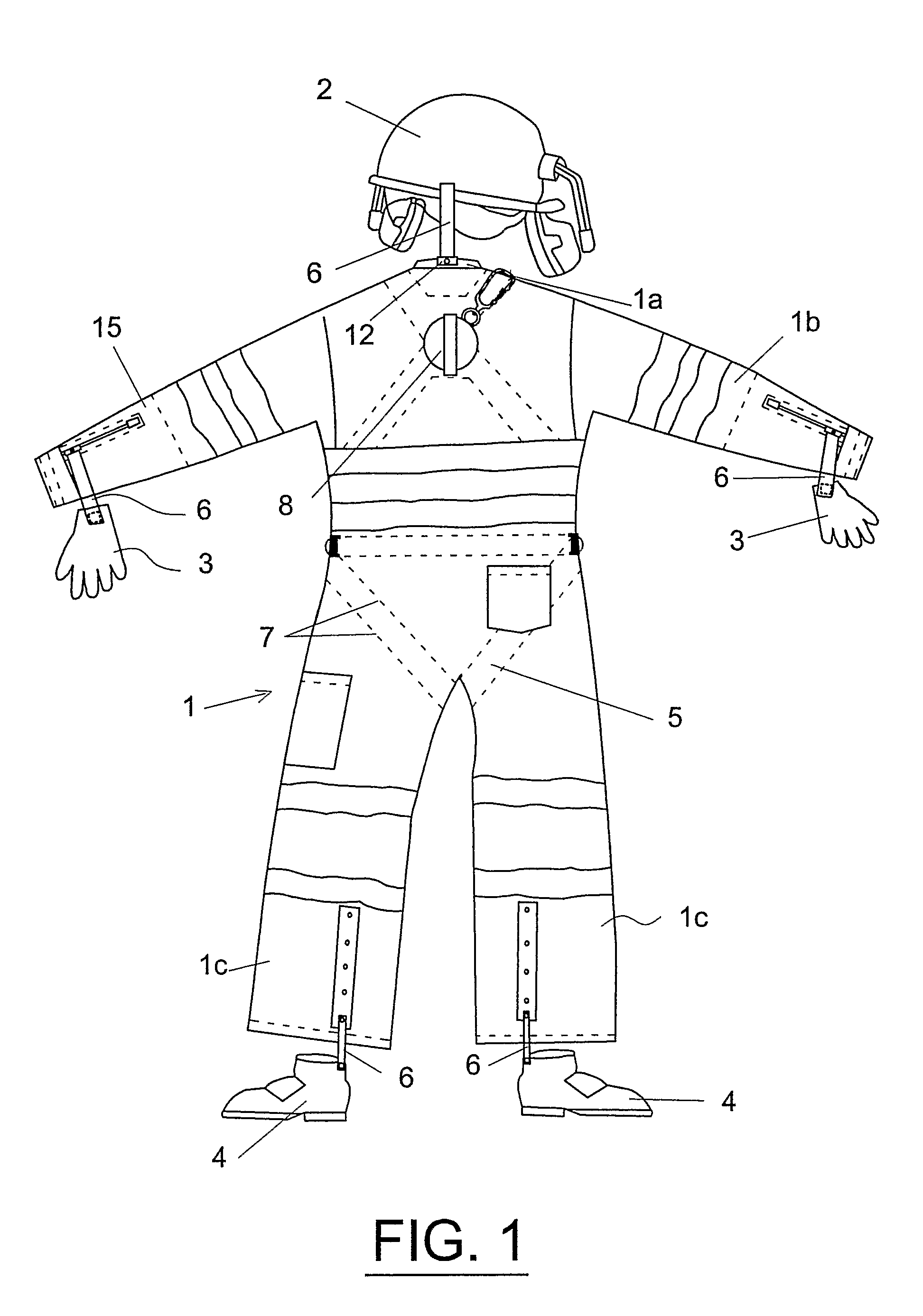

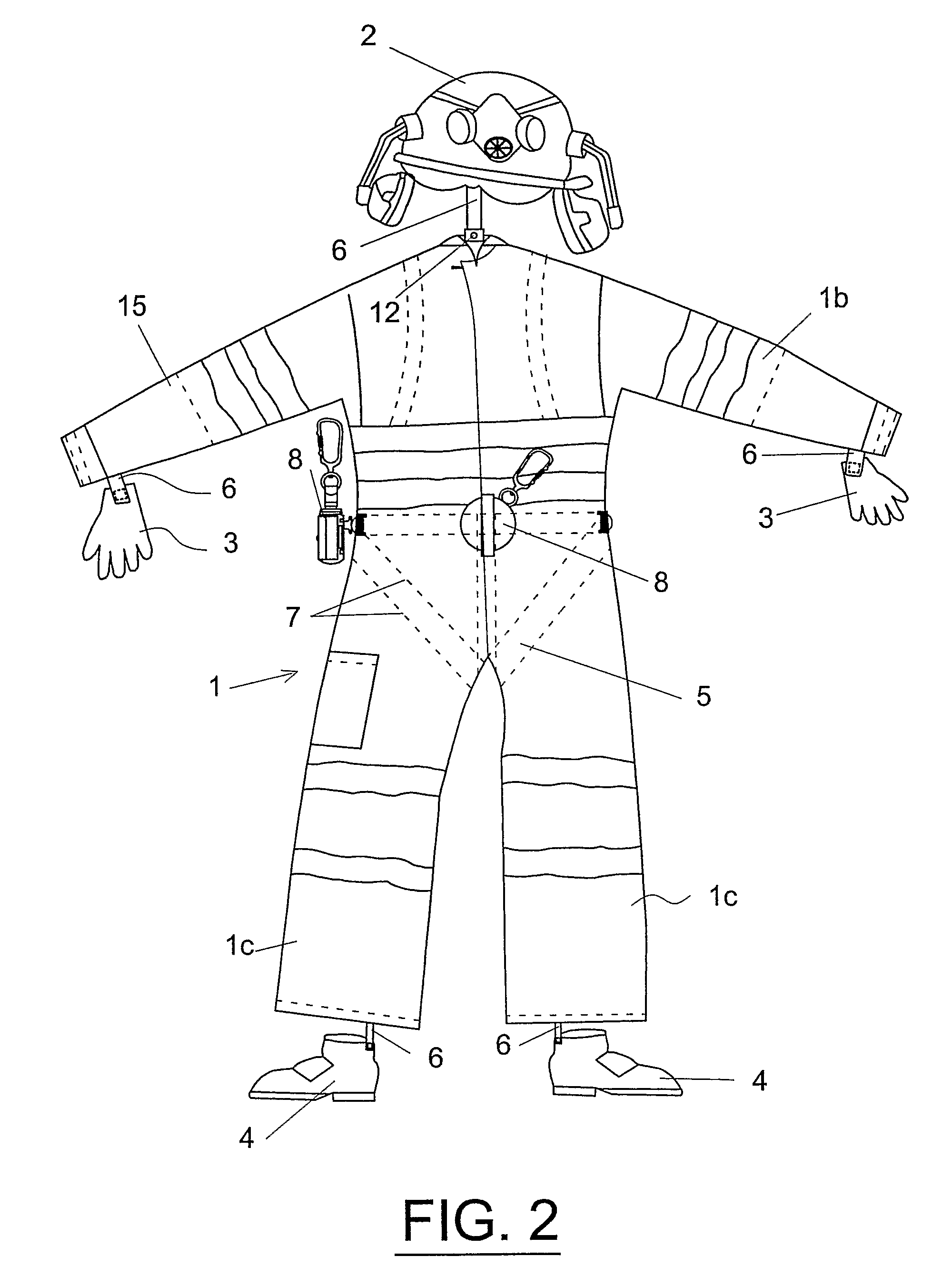

Integral Protection for a Job Garment, with Freely Incorporated Retention Elements, and Digital Activation of Bolt Retainer

InactiveUS20090064400A1Improve functionalityImprove operating conditionsSnap fastenersChemical protectionEngineeringBiological activation

The invention relates to an integral protective work clothing item comprising releasable integrated retaining elements and a digitally-activated retaining fastener. The inventive clothing item includes a harness and a retractable mechanism for securing a user to a standard lifeline. The item also comprises additional protective elements, such as a helmet, gloves and shoes which are connected thereto by means of respective elastic bands. Each of said bands is equipped with a hole for a fastener device that can only be released using a device designed for said purpose. The digitally-activated fastener comprises an electromagnet, a mobile discoidal part and a spring element. The cover of the fastener casing is provided with a hole and a tubular formation in which a pin or rod can be inserted and guided. In the operative position, the core of the electromagnet retains the rod in place and prevents the removal thereof, such that the casing and the rod are connected to one another and can only be released using the separate releasing device.

Owner:OLIEQUIP

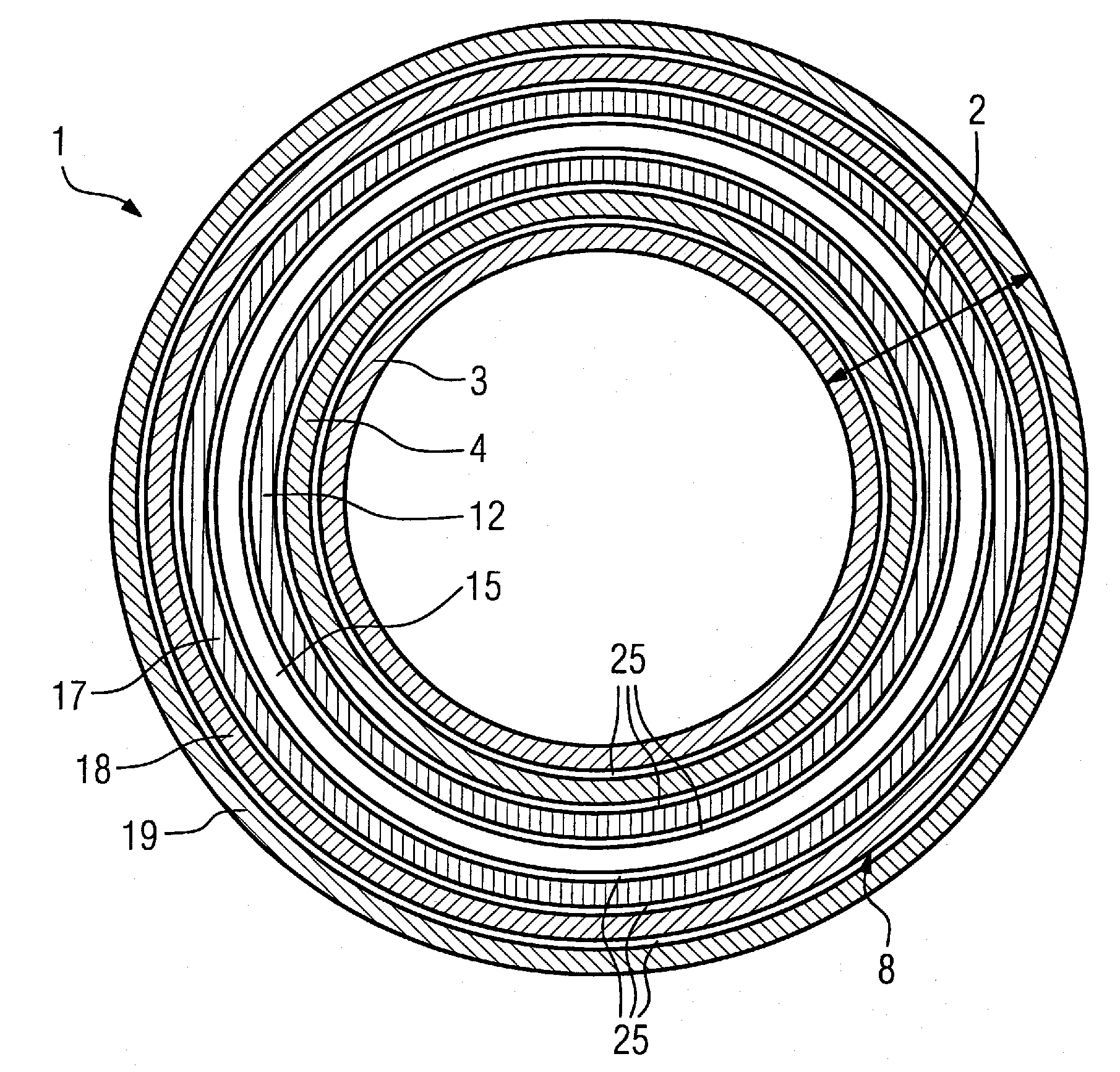

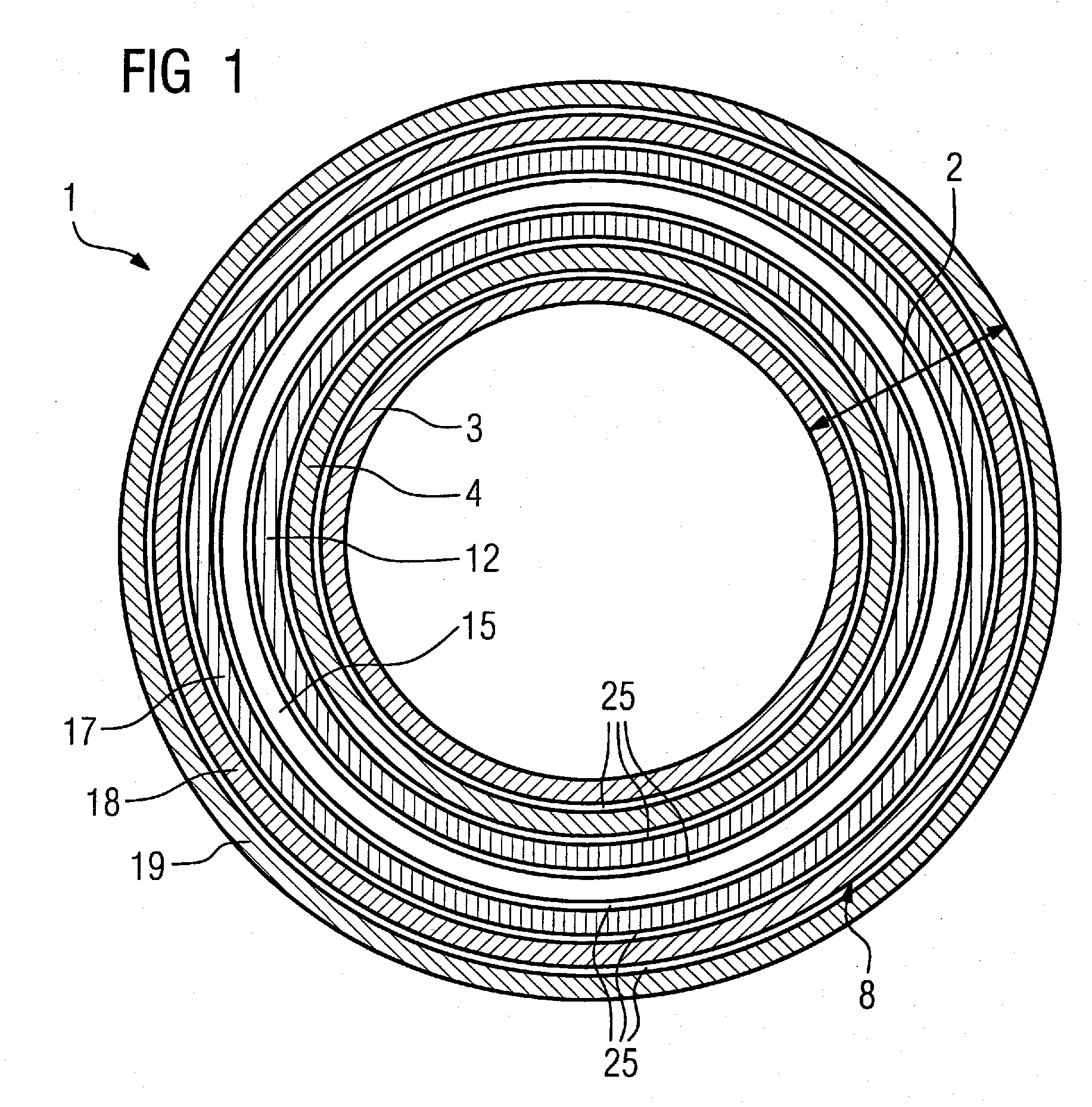

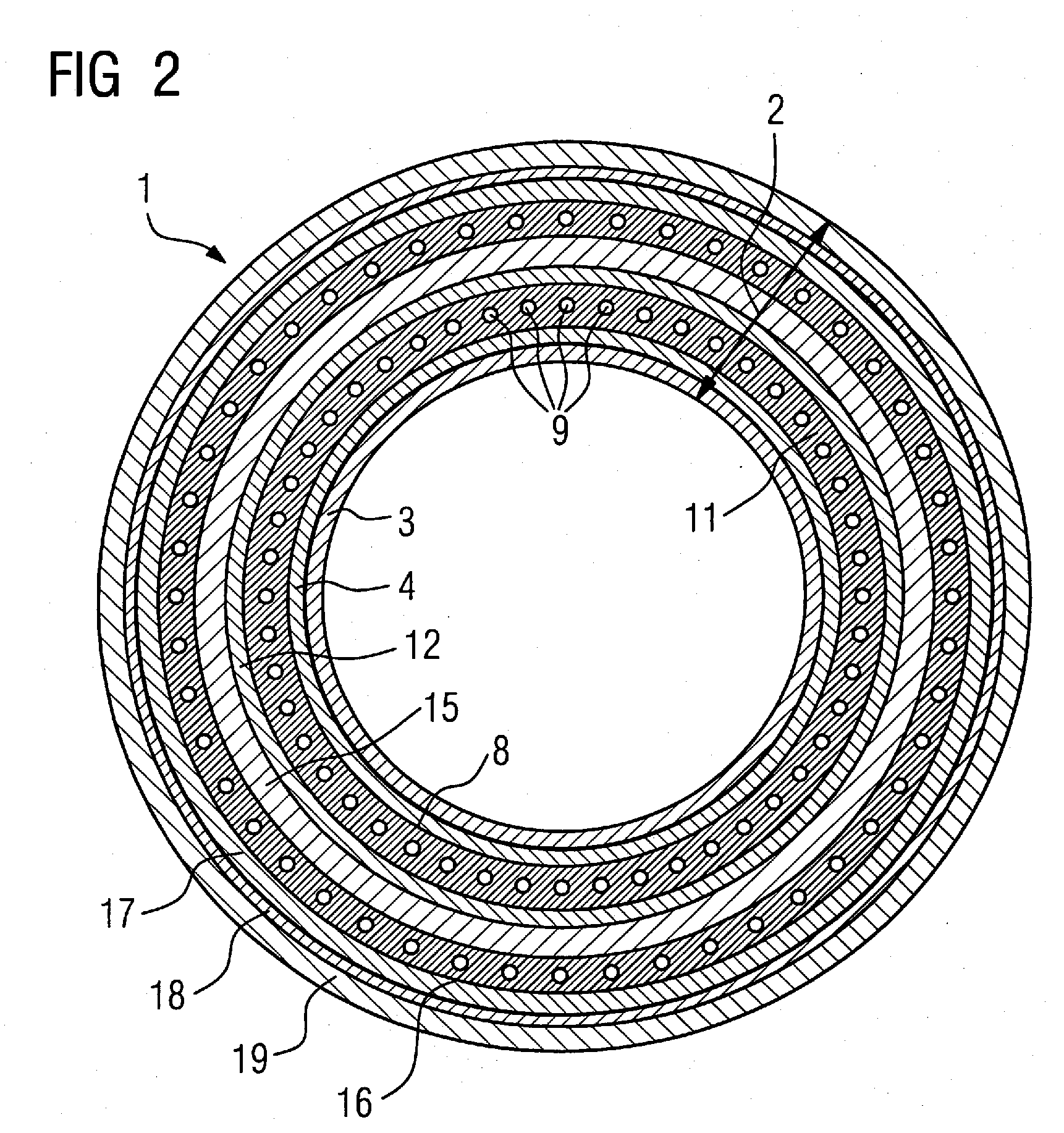

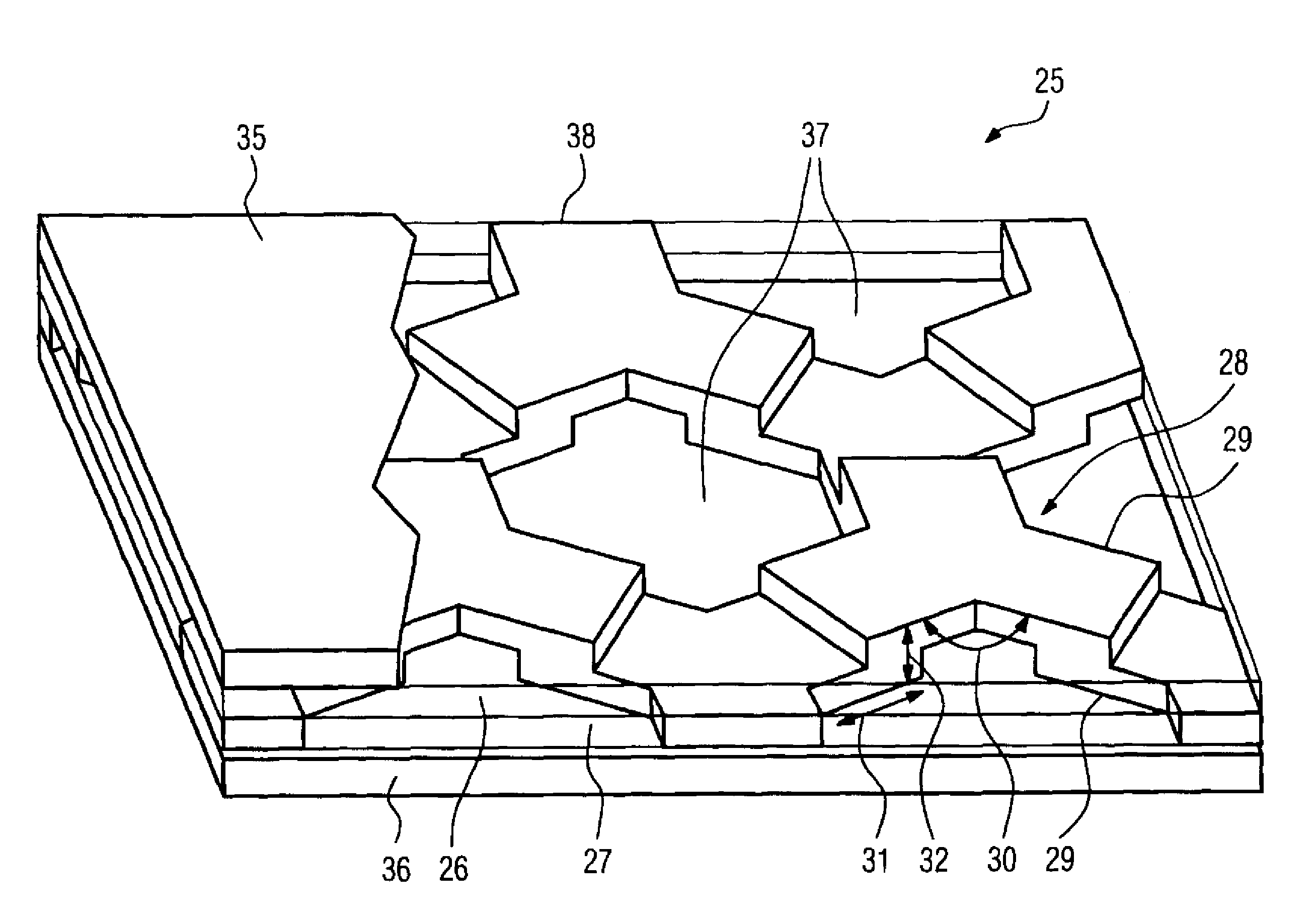

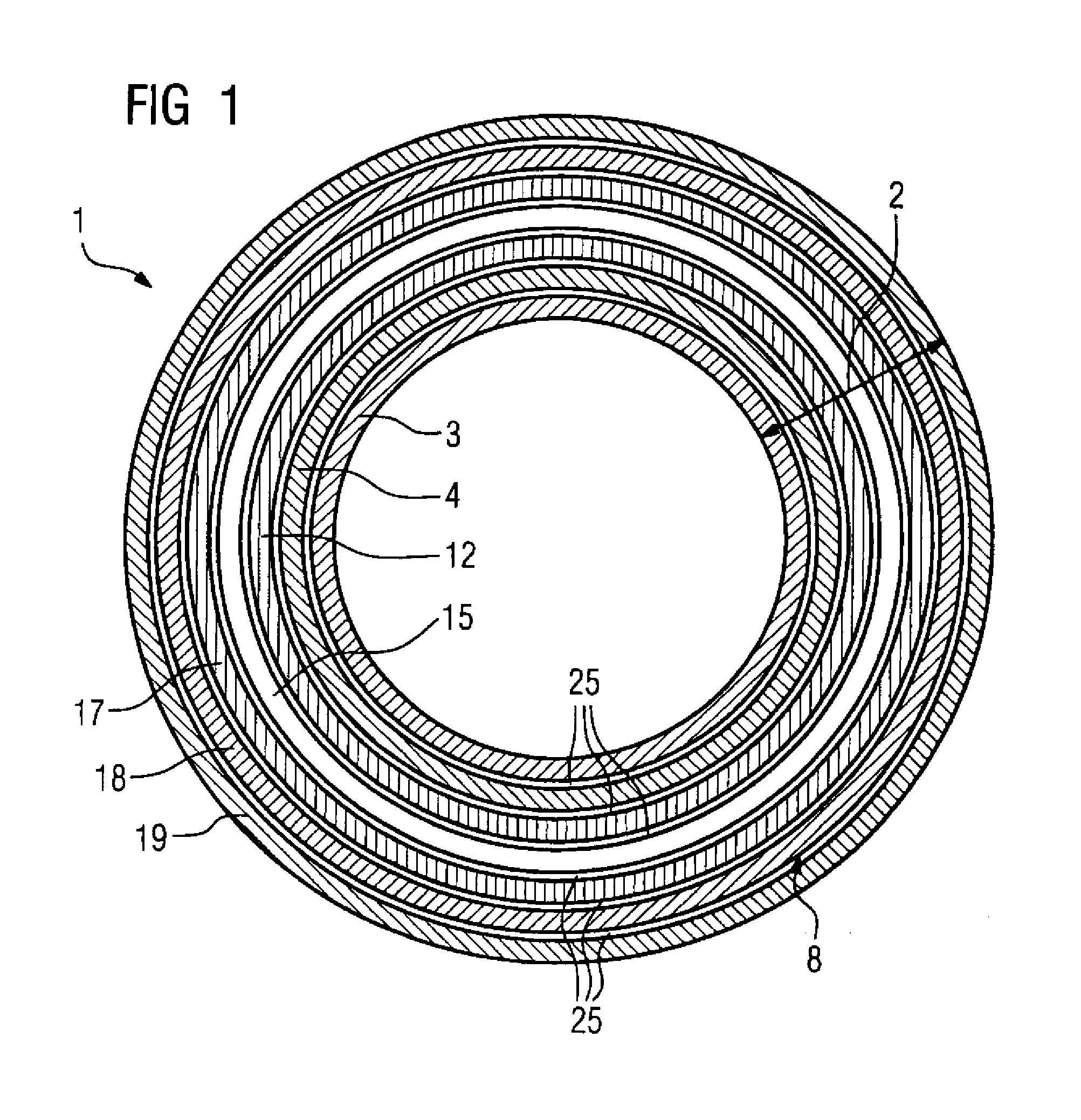

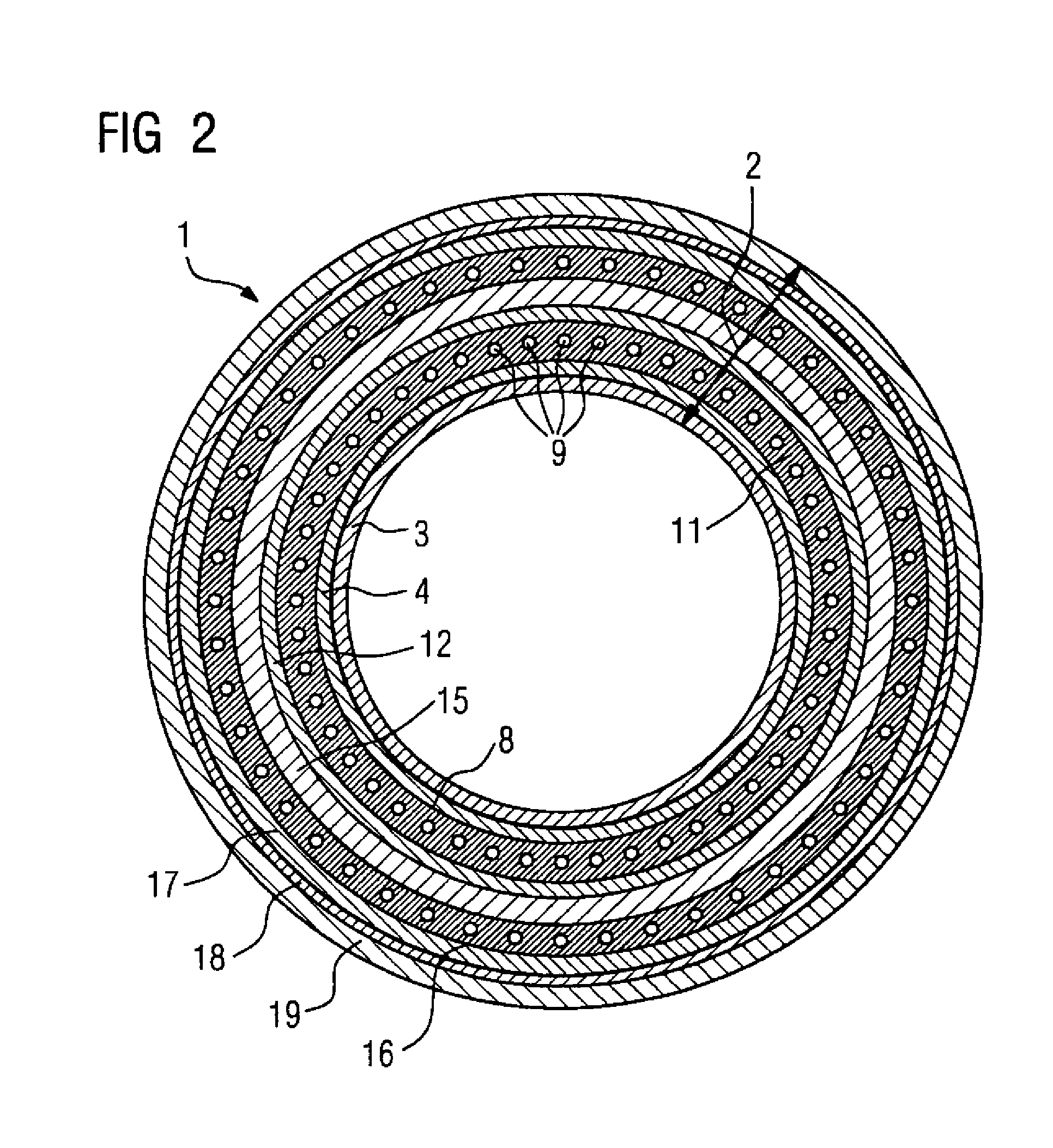

Gradient coil system and mr imaging system embodying same

ActiveUS20080030194A1Manufactured as easily and economicallyImprove cooling effectTransformers/inductances coolingElectric/magnetic detectionPlate heat exchangerResonance

A gradient coil system for a magnetic resonance tomography apparatus has a layer structure including a gradient coil layer and a cooling layer. The cooling layer is fashioned as a plate heat exchanger, composed of plates, for cooling the gradient coil layer. In this way, a highly efficient cooling of the gradient coil layer is achieved with a lower structural height compared to conventional tubular configurations.

Owner:SIEMENS HEALTHCARE GMBH

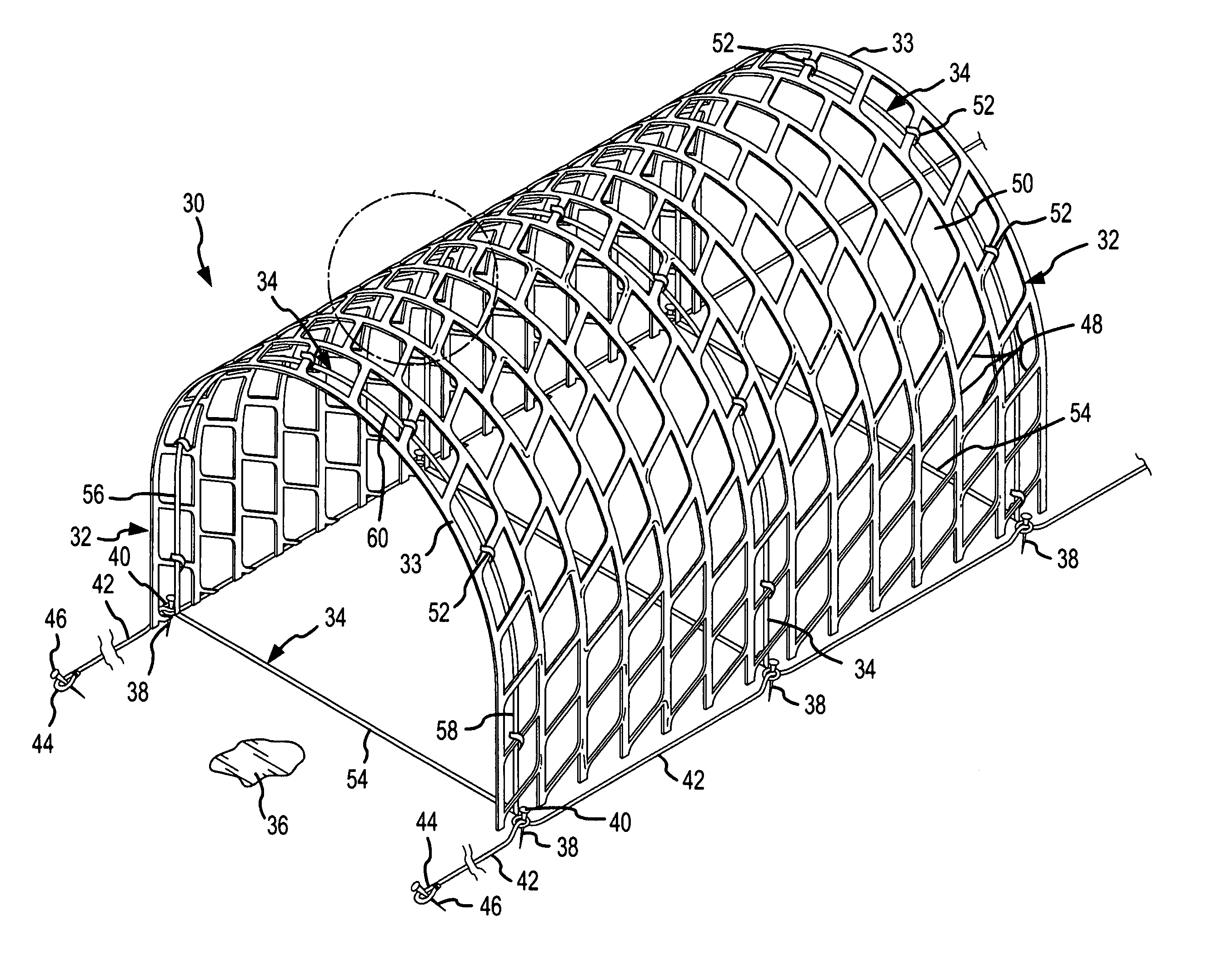

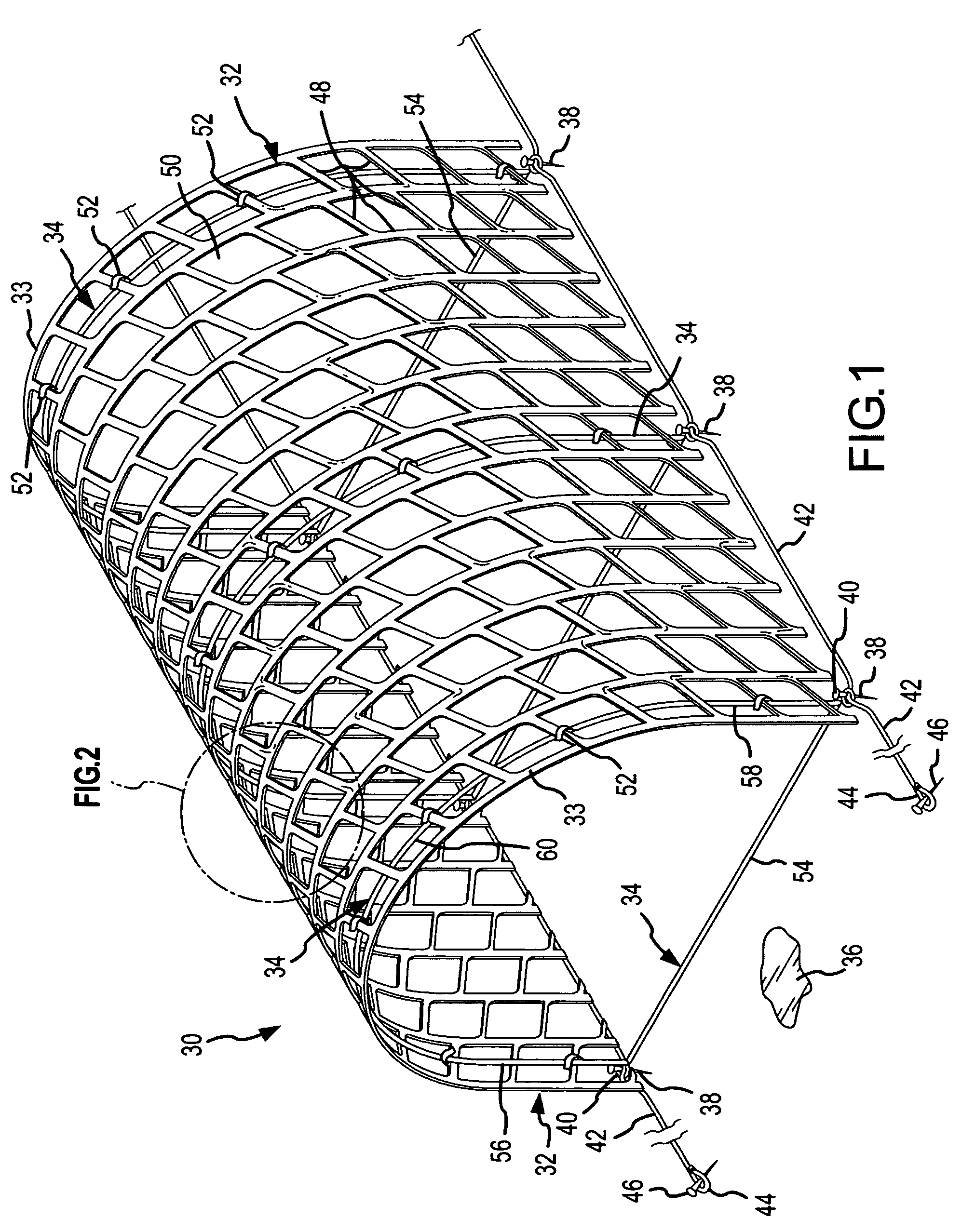

Porous tubular device and method for controlling windblown particle stabilization deposition and retention

InactiveUS6986624B1Easy to disassembleEasy to deployProtective constructionExcavationsAerodynamic dragDevice form

Owner:TABLER RONALD D

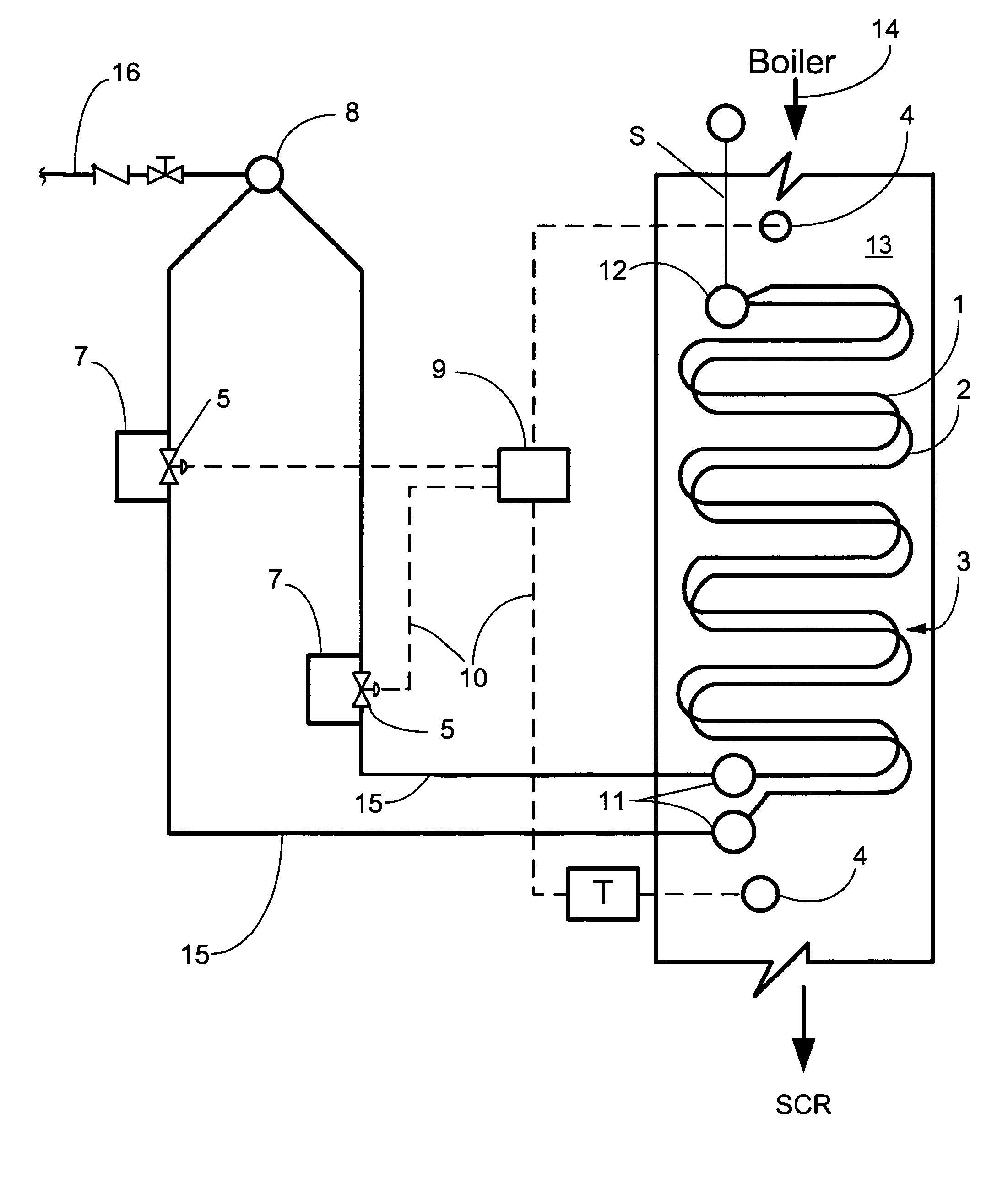

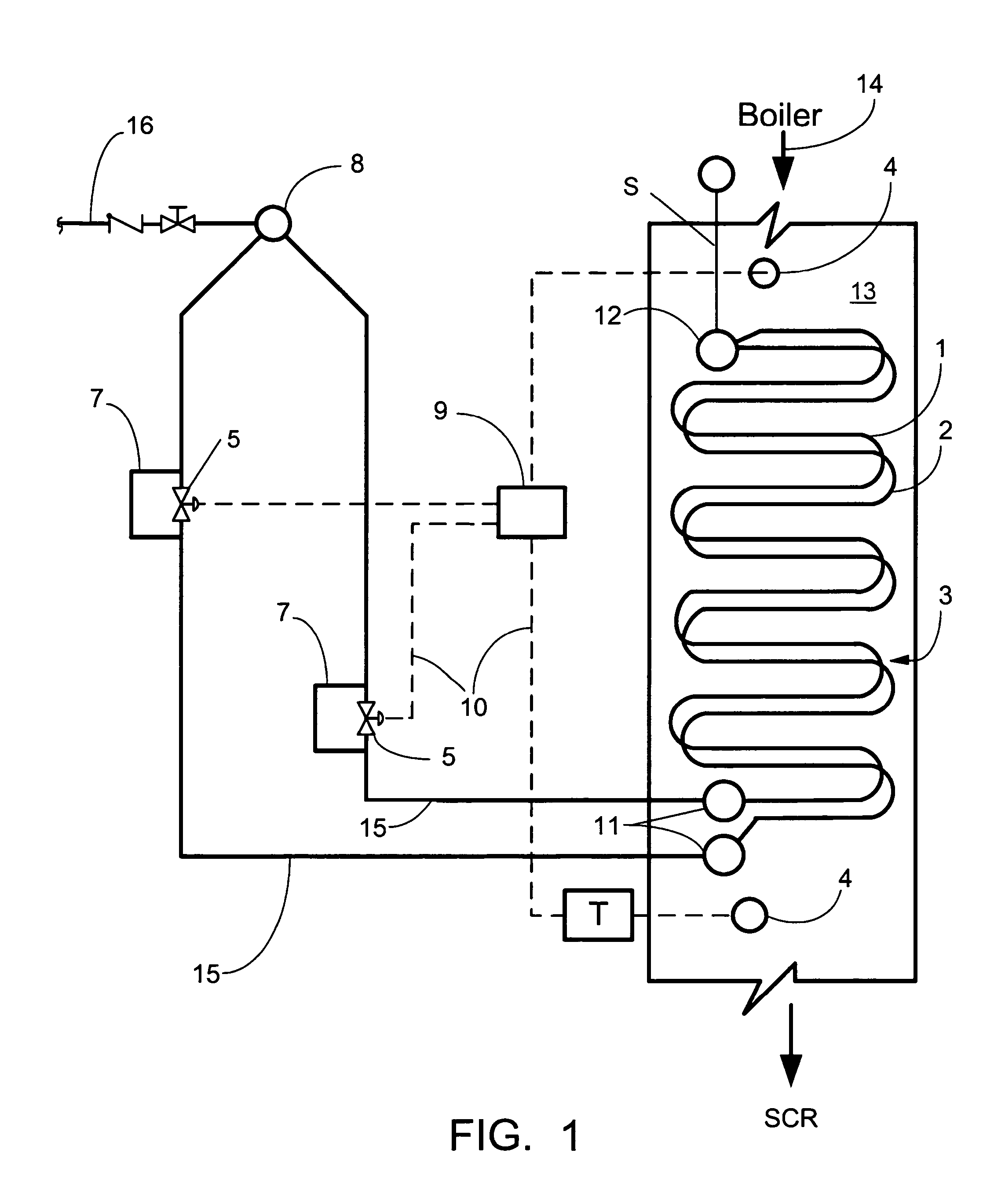

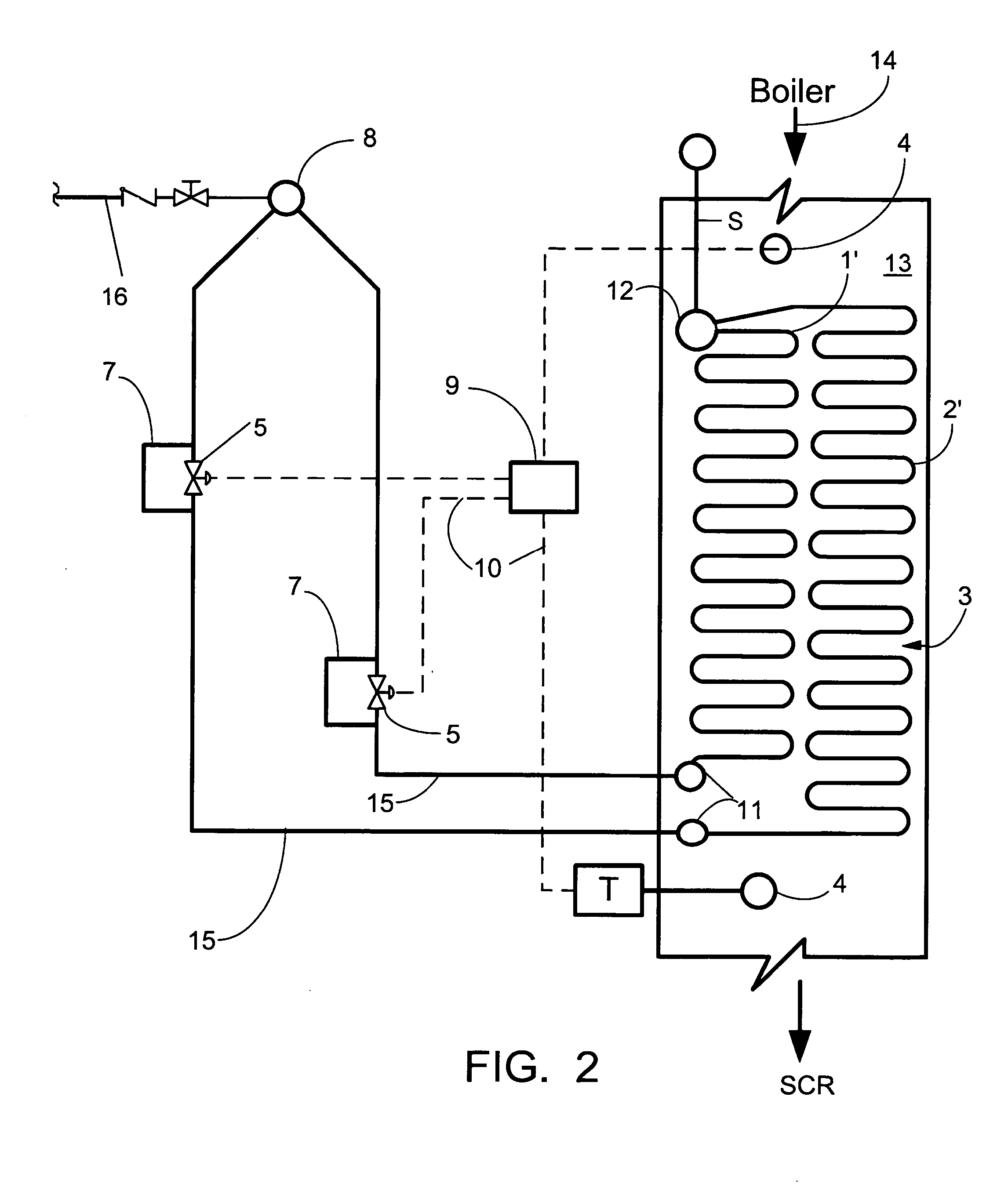

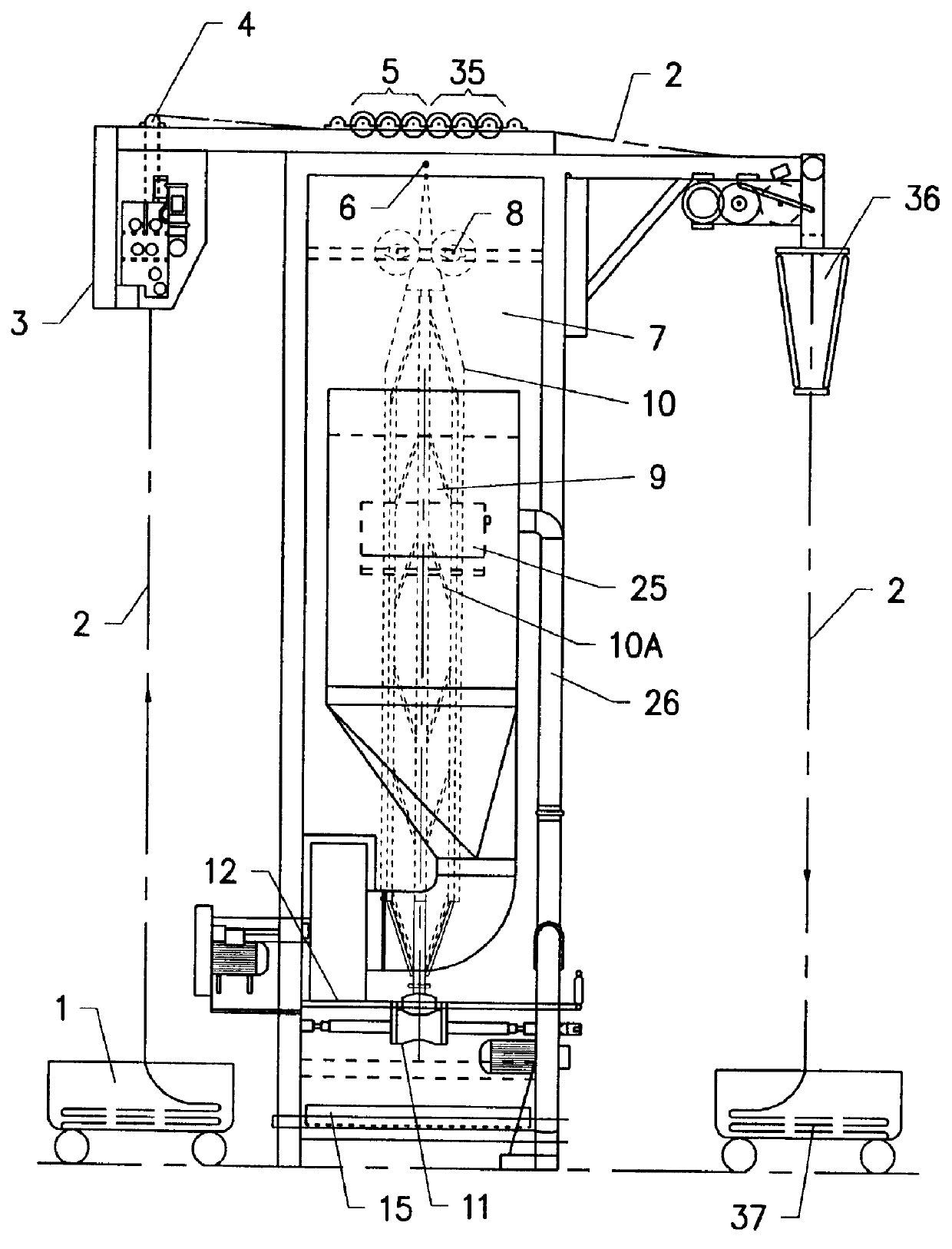

Multiple pass economizer and method for SCR temperature control

InactiveUS20070261646A1Raise the outlet temperatureReduce water flowWater circulationFuel injection apparatusTemperature controlFlue gas

A gas temperature control system for maintaining a desired economizer outlet gas temperature across a range of boiler loads comprises a plurality of tubular configurations having surfaces that are in contact with the flue gas. Each tubular configuration, preferably, comprises a plurality of serpentine or stringer tubes arranged horizontally or vertically back and forth within the economizer, and each tubular configuration having a separate feedwater inlet. Heat transfer from the flue gas is accomplished by controlling the feedwater flow rates through the tubular configurations. In a temperature control system having two tubular configurations, the overall heat transfer capacity of the economizer may be reduced to maintain the desired economizer outlet gas temperature during low boiler loads by reducing feedwater flow through one tubular configuration and by overflowing the other tubular configuration, such that total flow of feedwater through the economizer is maintained substantially constant.

Owner:THE BABCOCK & WILCOX CO

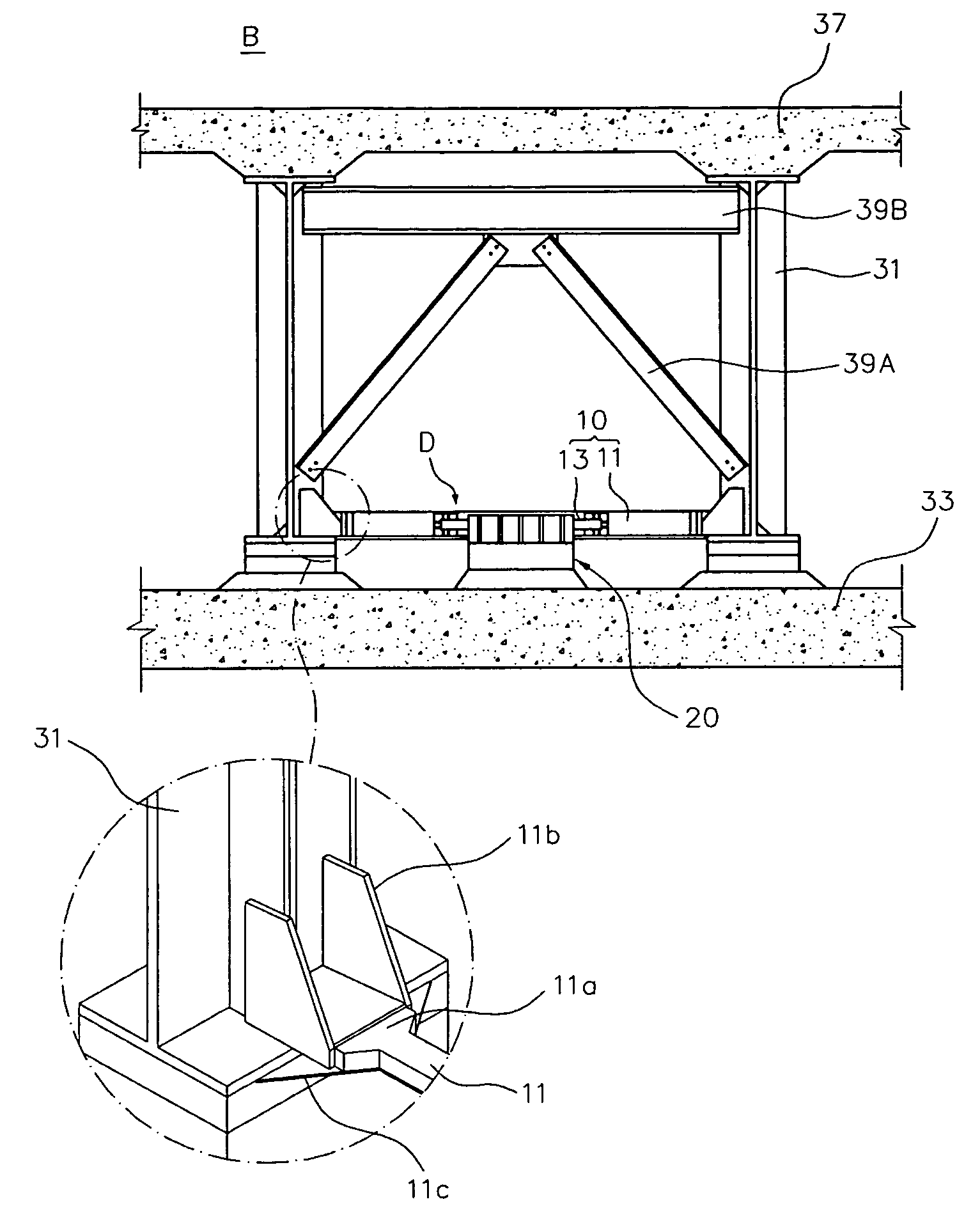

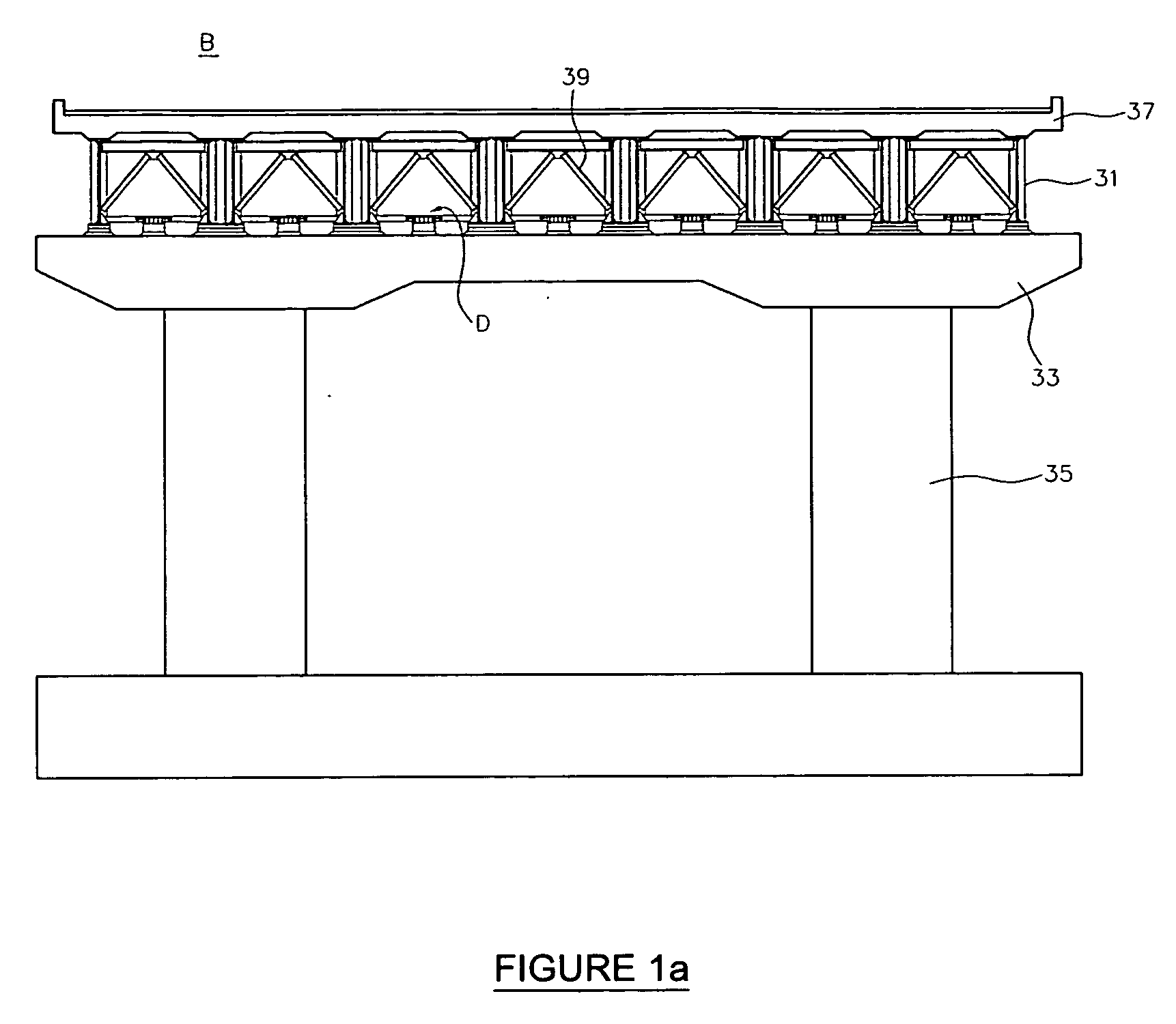

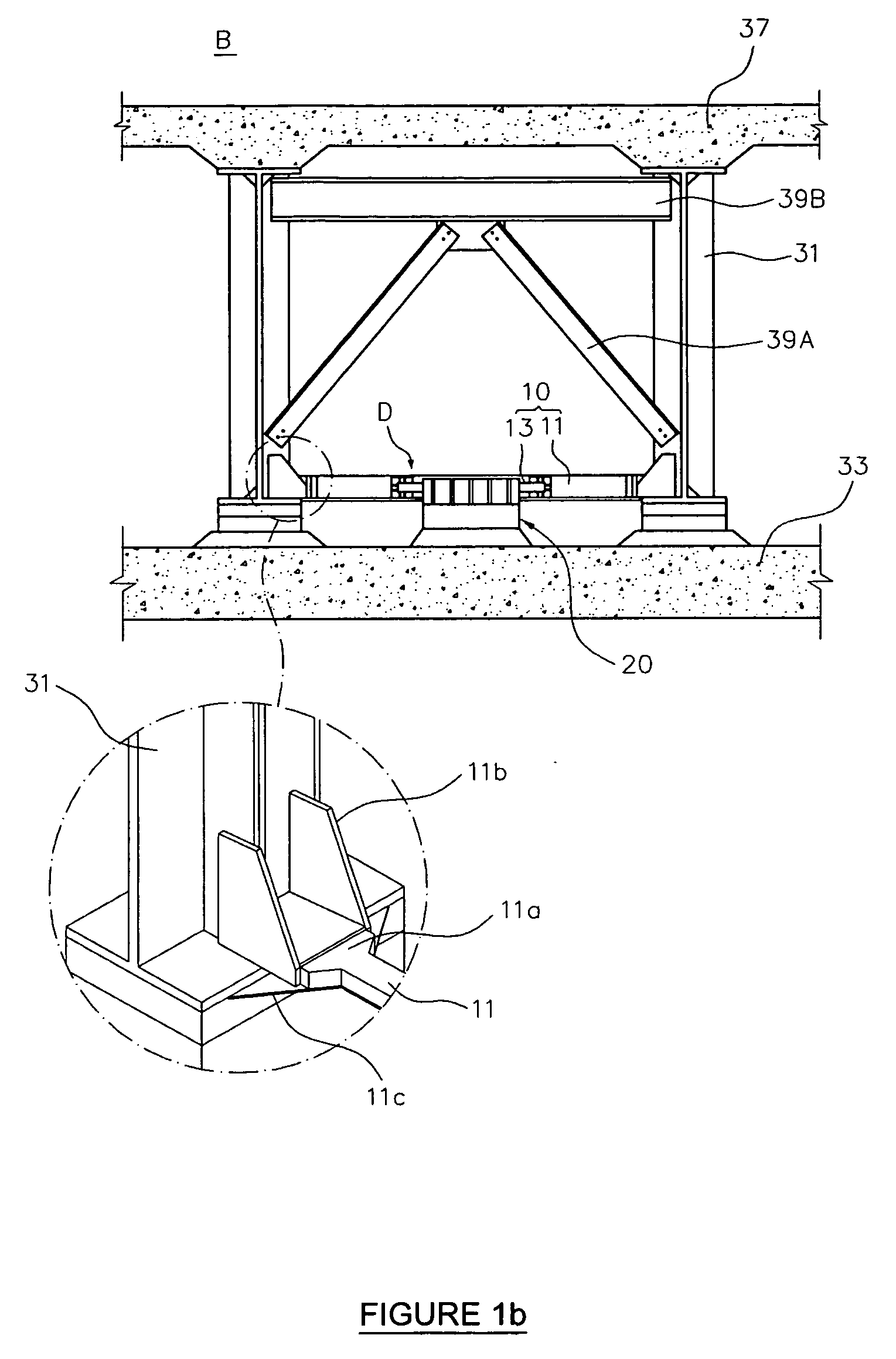

Girder bridge protection device usin sacrifice means

InactiveUS20070000078A1Improving structural behaviorEfficiently dissipatedBridge structural detailsProtective buildings/sheltersEngineeringAbutment

An girder bridge protection device comprises sacrifice means including girders which are installed on an upper surface of a bridge seat of an abutment or pier to support a bridge floor, a symmetrical main support member which connects two girders and has a pipe-shaped configuration, and an auxiliary support member which projects from one surface of a center portion of the main support member in a direction perpendicular to an axial direction of the main support member; and restraining means secured to the bridge seat of the abutment or pier and including an accommodating section which accommodates the auxiliary support member such that the auxiliary support member is separated from the accommodating section in a forward and rearward direction and in a leftward and rightward direction, thereby controlling the behavior of the auxiliary support member.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Combined protective garment and safety harness with detachable protective devices

The invention relates to an integral protective work clothing item comprising releasable integrated retaining elements and a digitally-activated retaining fastener. The inventive clothing item includes a harness and a retractable mechanism for securing a user to a standard lifeline. The item also comprises additional protective elements, such as a helmet, gloves and shoes which are connected thereto by means of respective elastic bands. Each of said bands is equipped with a hole for a fastener device that can only be released using a device designed for said purpose. The digitally-activated fastener comprises an electromagnet, a mobile discoidal part and a spring element. The cover of the fastener casing is provided with a hole and a tubular formation in which a pin or rod can be inserted and guided. In the operative position, the core of the electromagnet retains the rod in place and prevents the removal thereof, such that the casing and the rod are connected to one another and can only be released using the separate releasing device.

Owner:OLIEQUIP

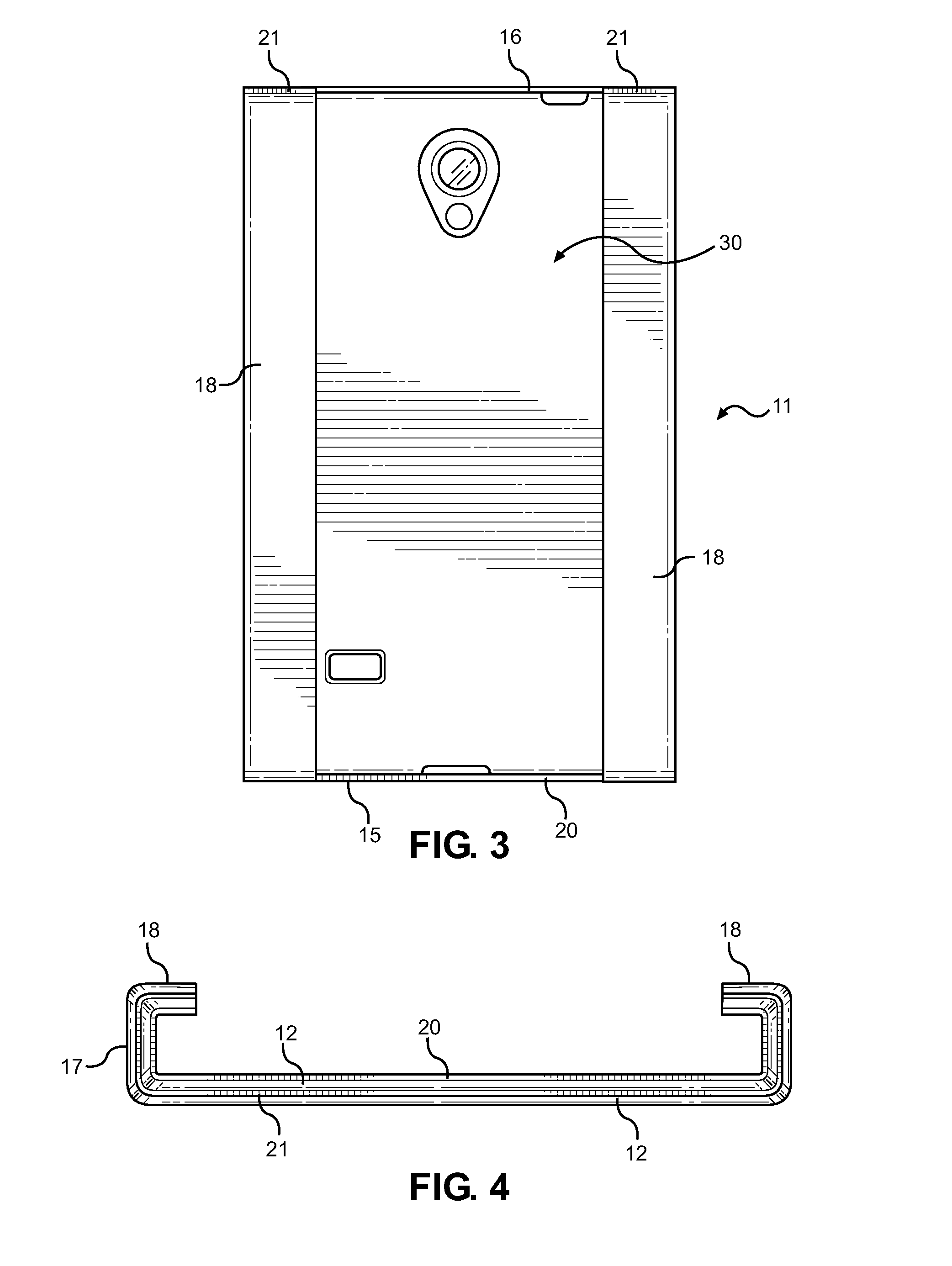

Electronic Device Cover

ActiveUS20150162948A1Avoid damageReadily and easily appliedTransmissionTelephone set constructionsEngineeringTubular formation

An electronic device cover is provided having an elongated first surface, a first and second sidewall surface, and a first and second inward lip member forming a sleeve-like configuration to accept a handheld electronic device therein. The first end of the cover comprises an inwardly flaring surface adapted to prevent an electronic device from sliding therethrough. The second end of the cover comprises an outwardly flaring surface adapted to facilitate insertion of an electronic device therethrough. The device is adapted to be sized such that the first surface and sidewall surfaces are coextensive with a rectangular smartphone or tablet device. The inward lip members extend partially over the outer surface of the electronic device to retain the same within the cover interior volume. Overall, the cover dissipates impact energy and improves acoustics of the electronic device when secured thereto.

Owner:RESTIVO KEITH RICHARD

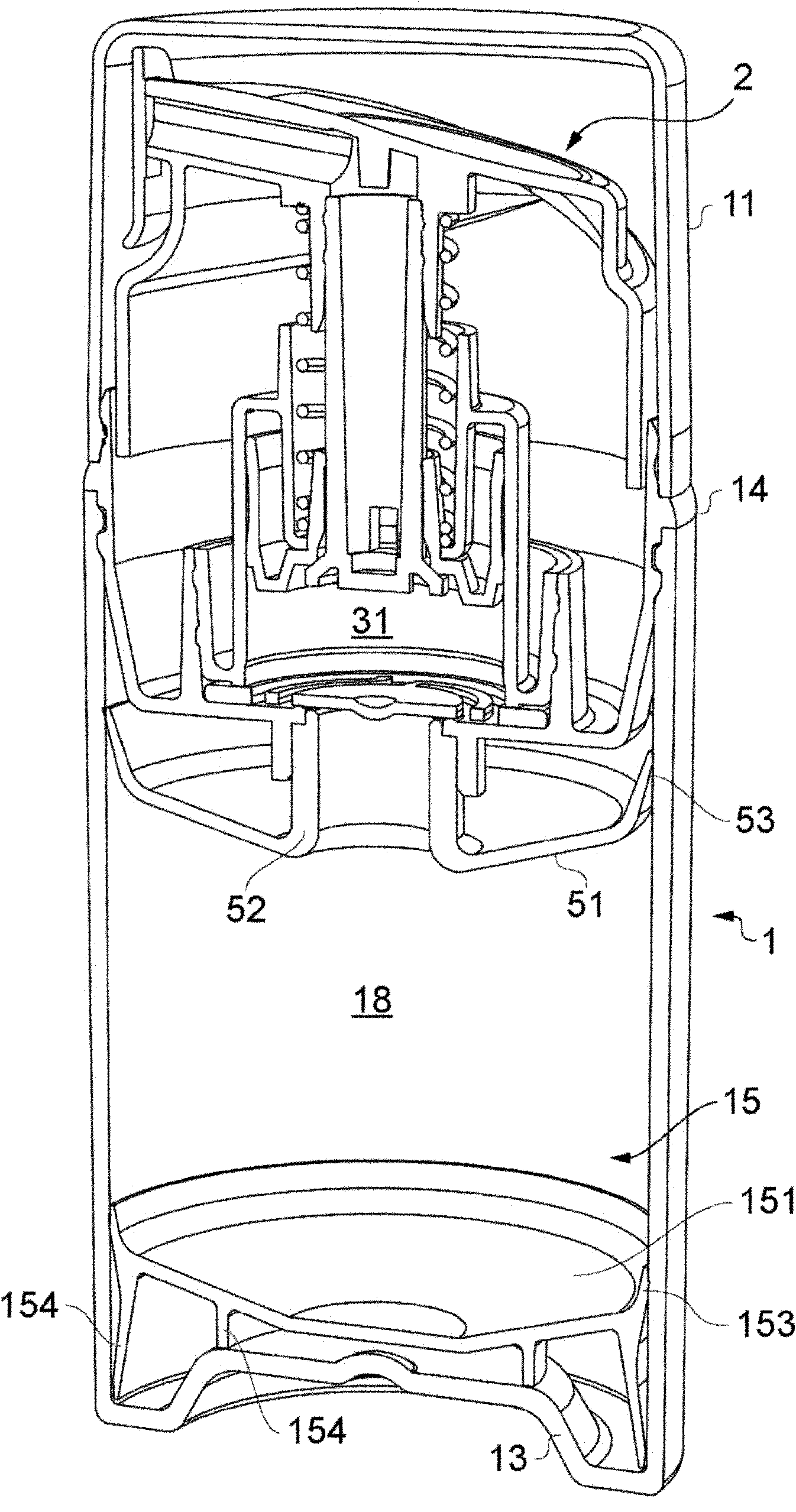

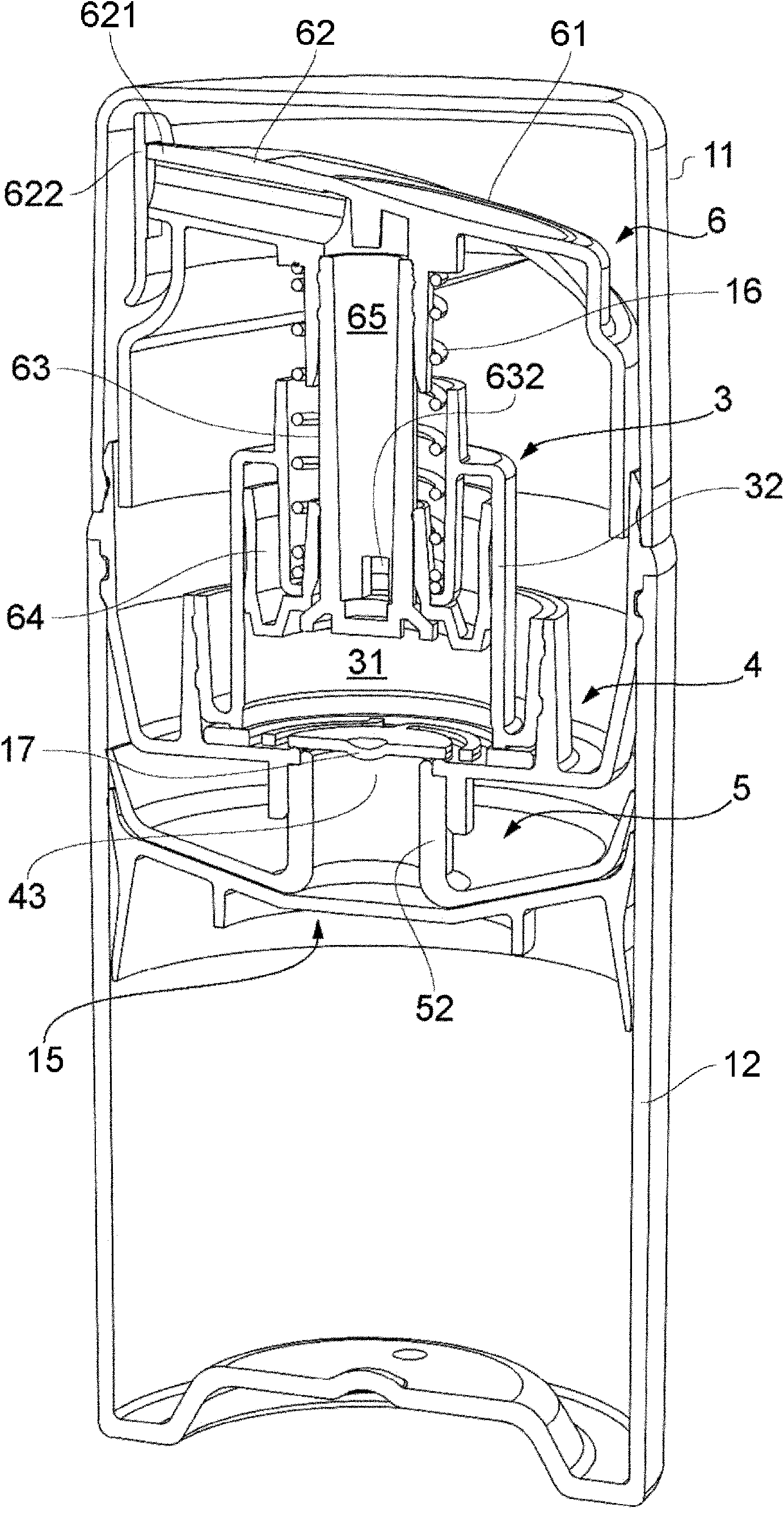

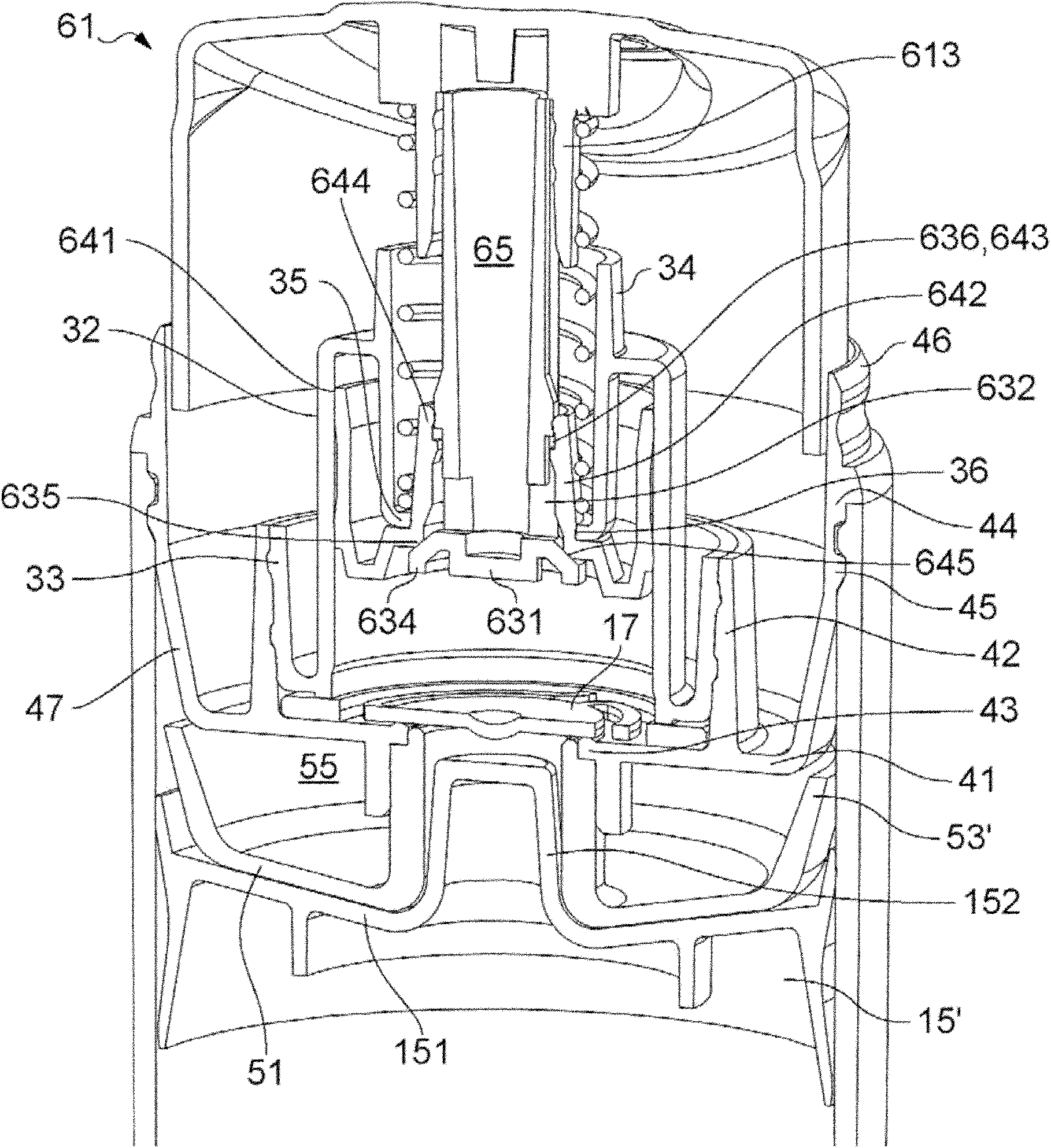

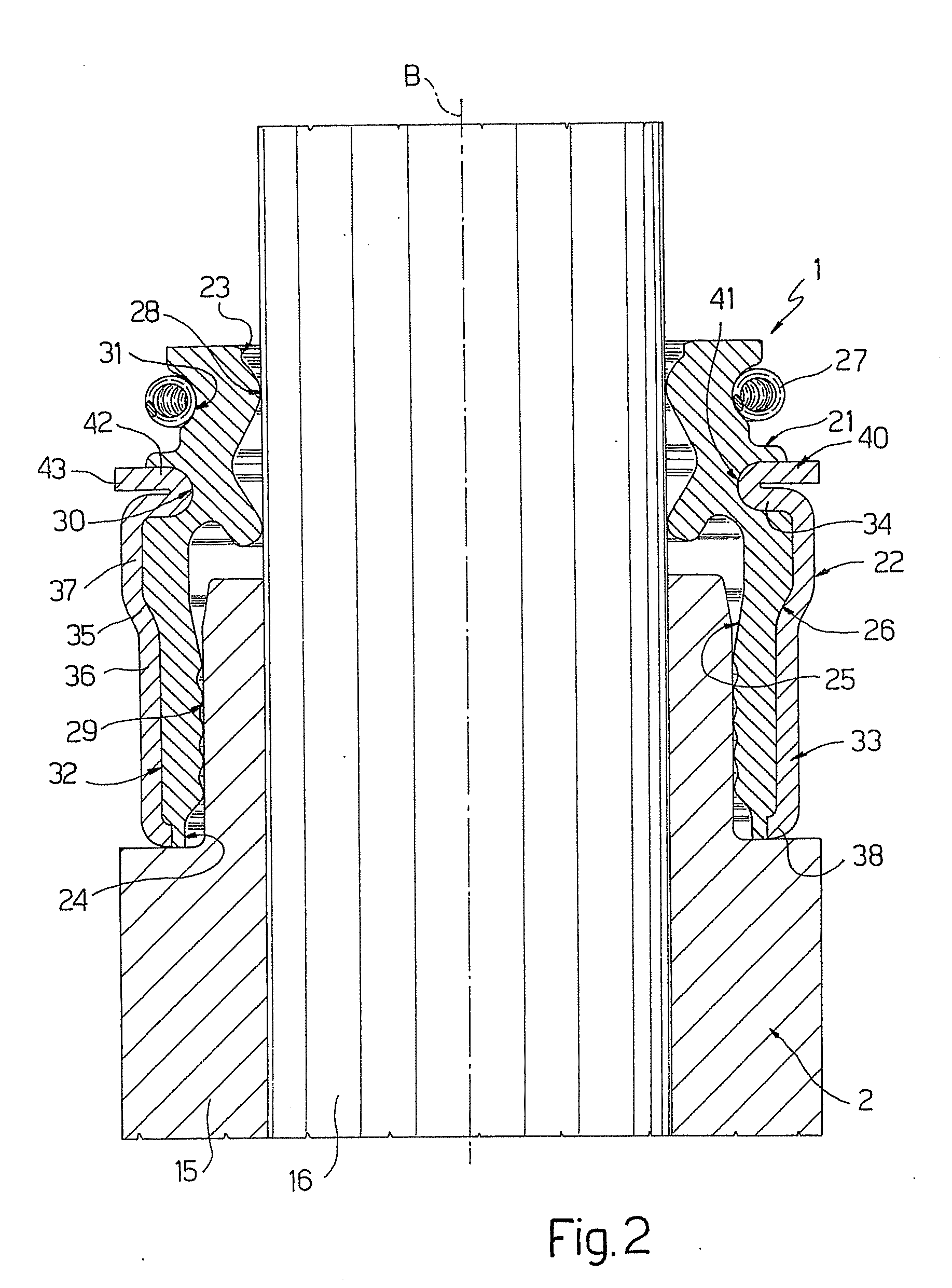

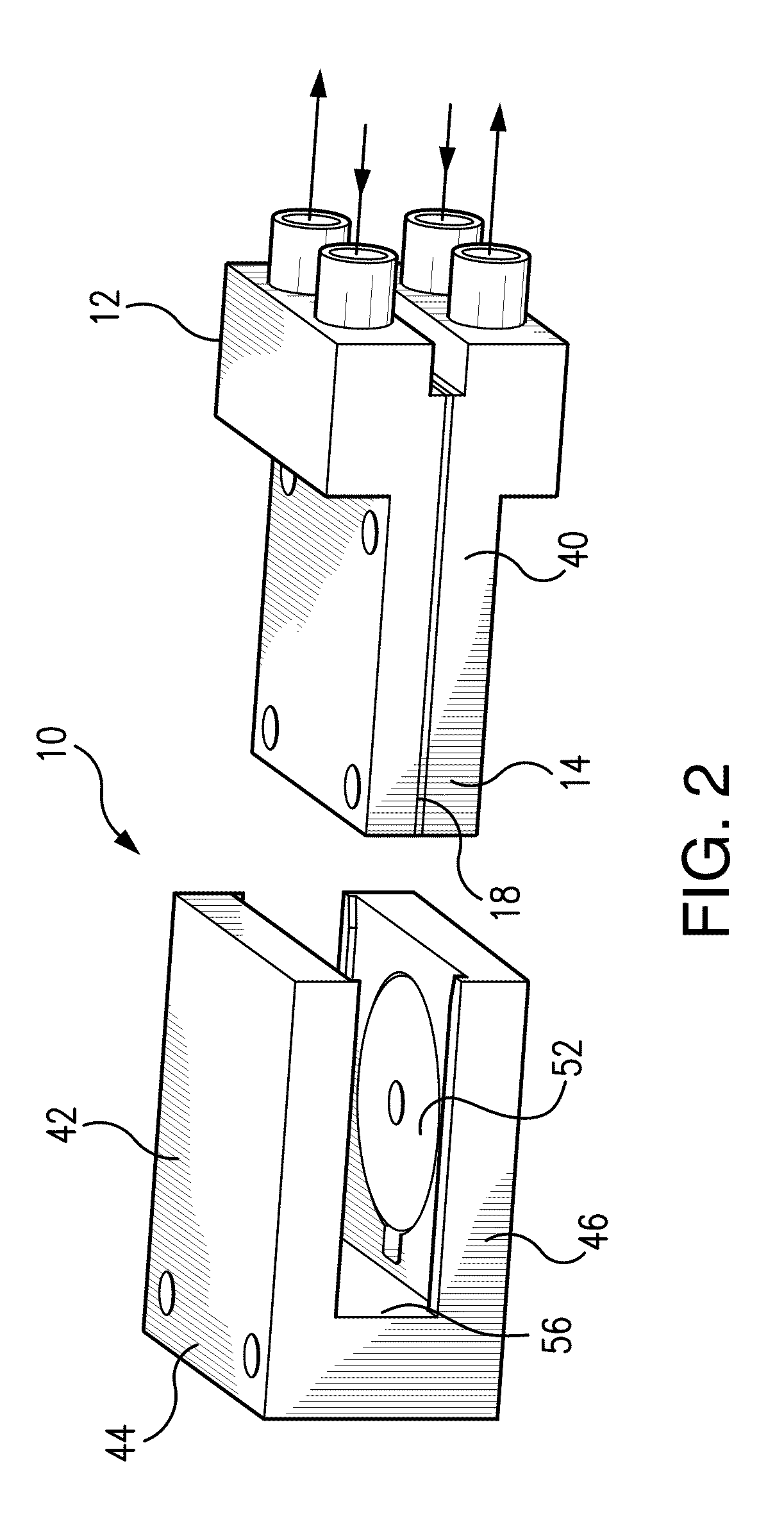

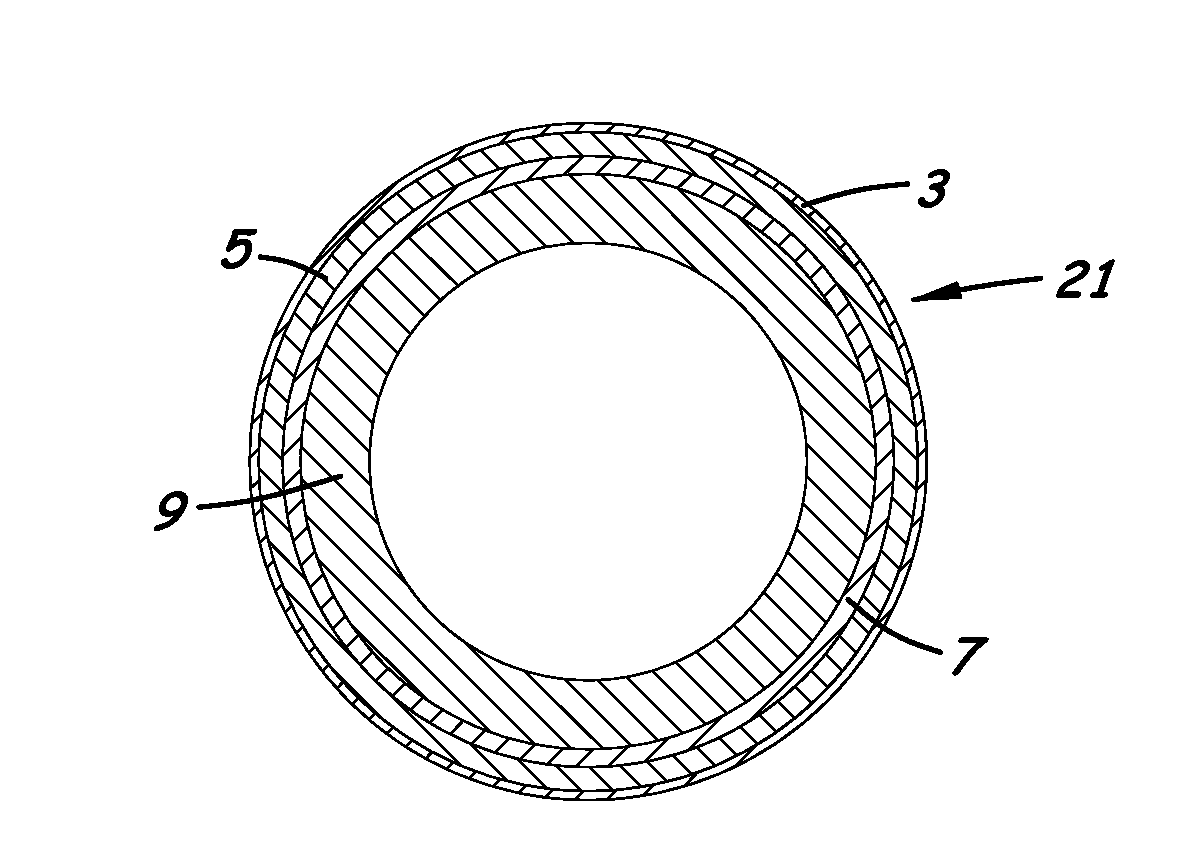

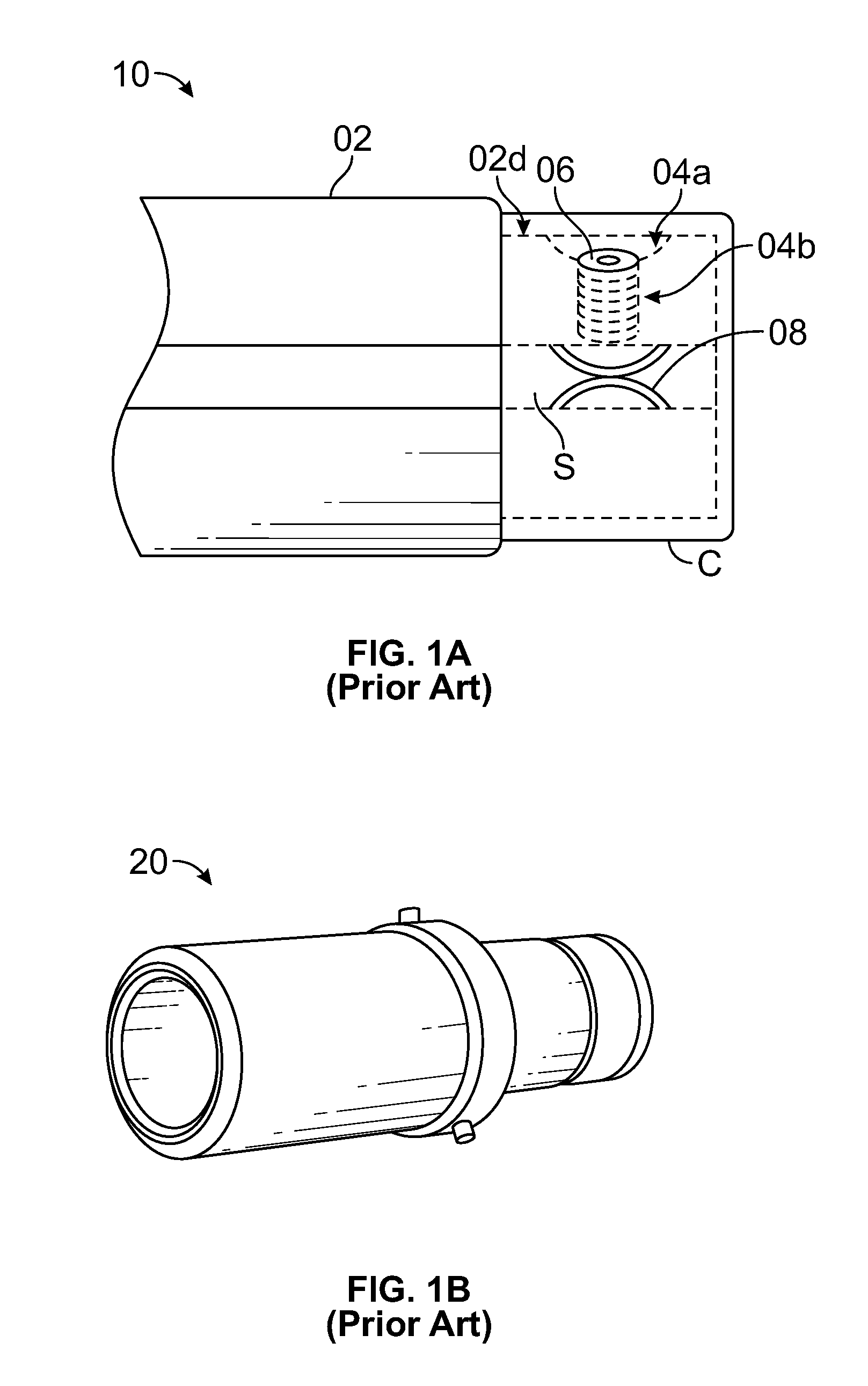

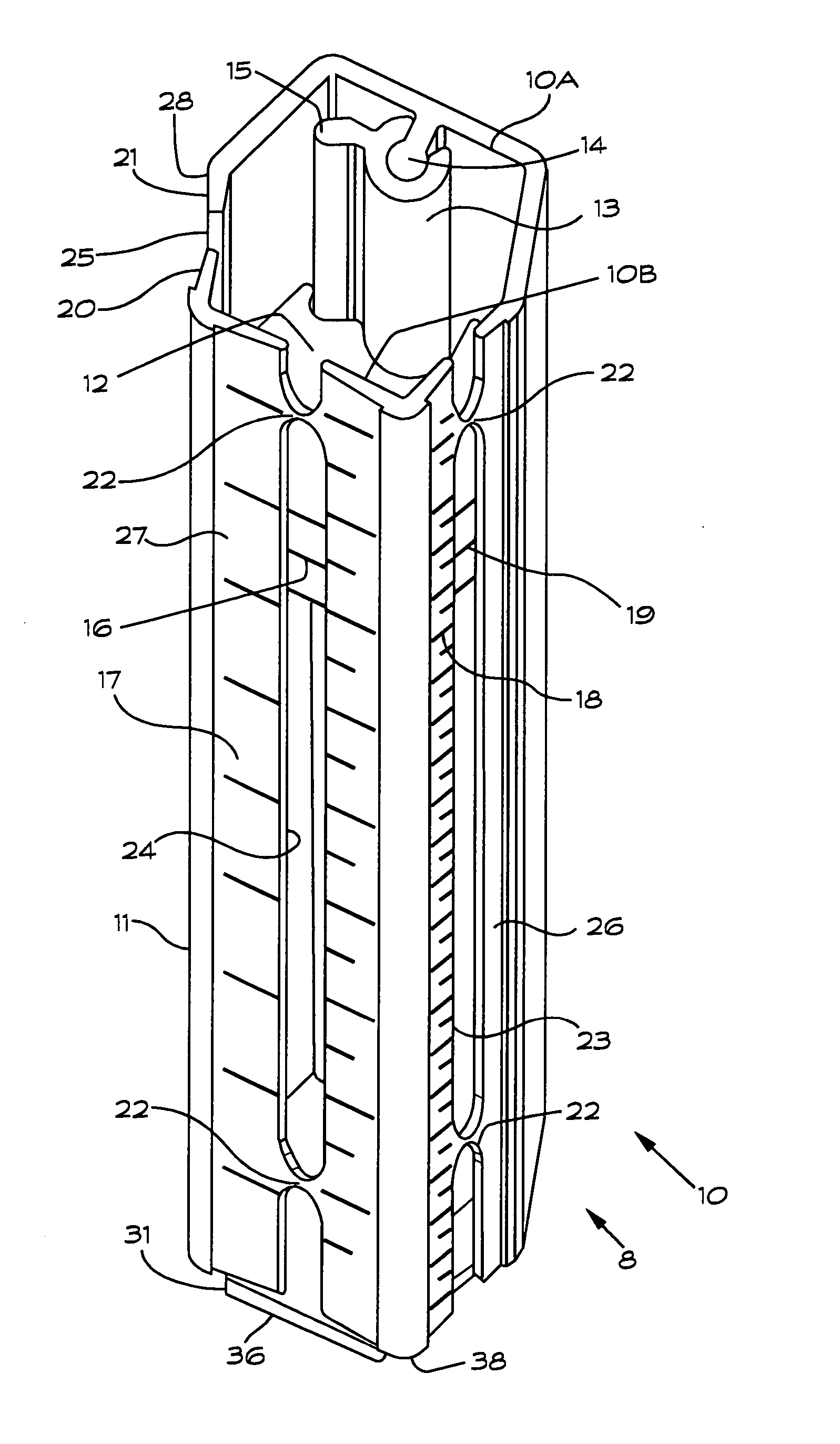

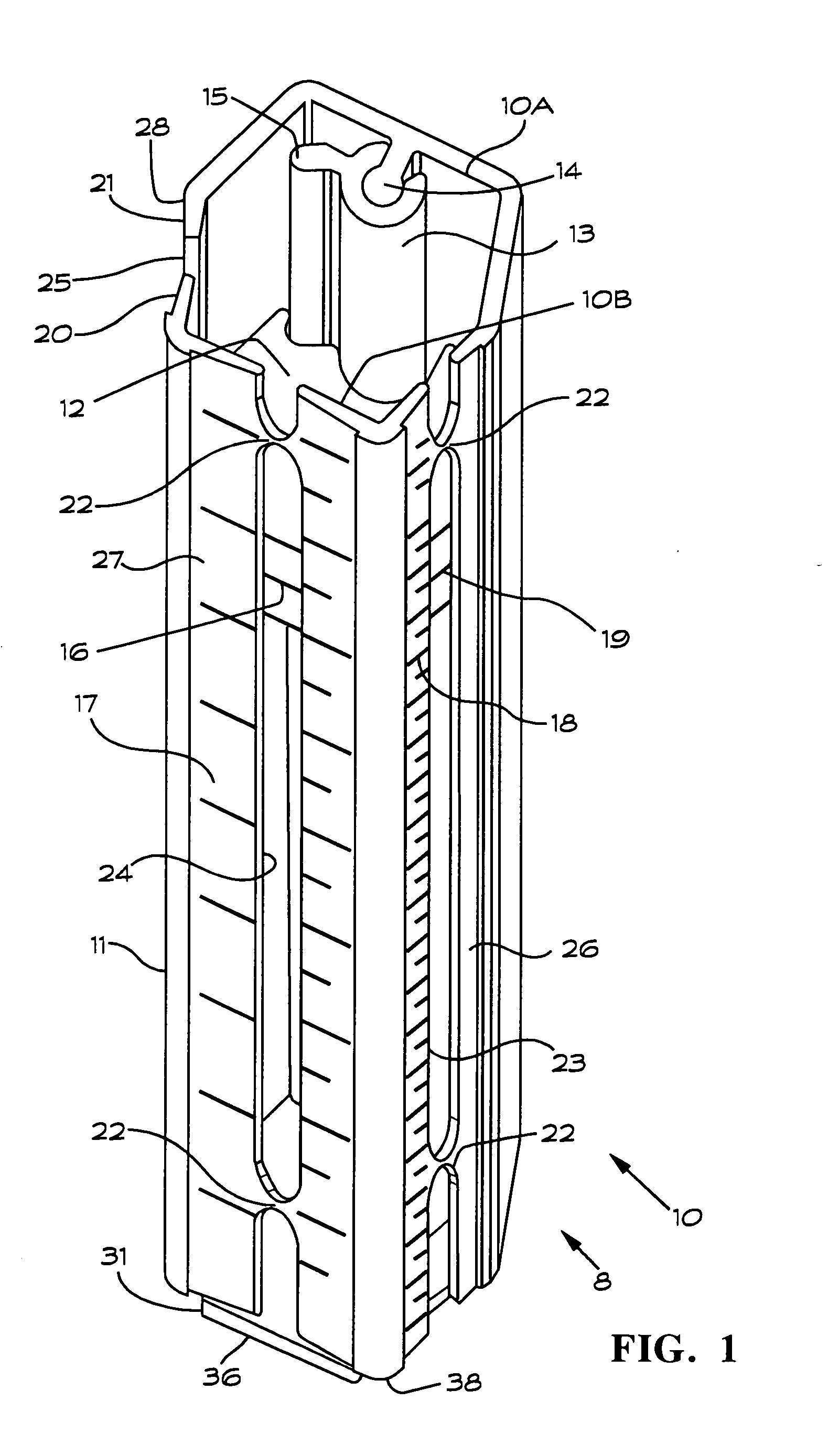

Pump dispenser and method of assembly of such a dispenser

The disclosure relates to a pump dispenser and a method of assembly of such a dispenser, in which the container interior reduces its volume progressively as product is dispensed to avoid air contact with the product. One aim is to prevent any air in the container space above the product from reaching the pump inlet, and thereby possibly reducing a dispensed dose without the user being aware. To trap any such air and keep it away from the inlet throughout use of the dispenser, an air trap member (5) having a downwardly-convex dish form is provided below the floor of the dispenser module around the inlet, to guide any such air away from the inlet and to the periphery. At the periphery a steeply-sloping peripheral portion forms a retaining lip (53), which may make flexible wiping contact with the container wall interior, allowing air past on assembly of the dispenser. A central tubular formation (52) of the trap member (5) separates the trapped air from the inlet, and can be used to plug the trap member into the inlet. A sliding follower piston (15) may have an upward central boss (152) shaped to fit into the tubular formation (52) of the trap member (5) to maximise expulsion of product.

Owner:RIEKE

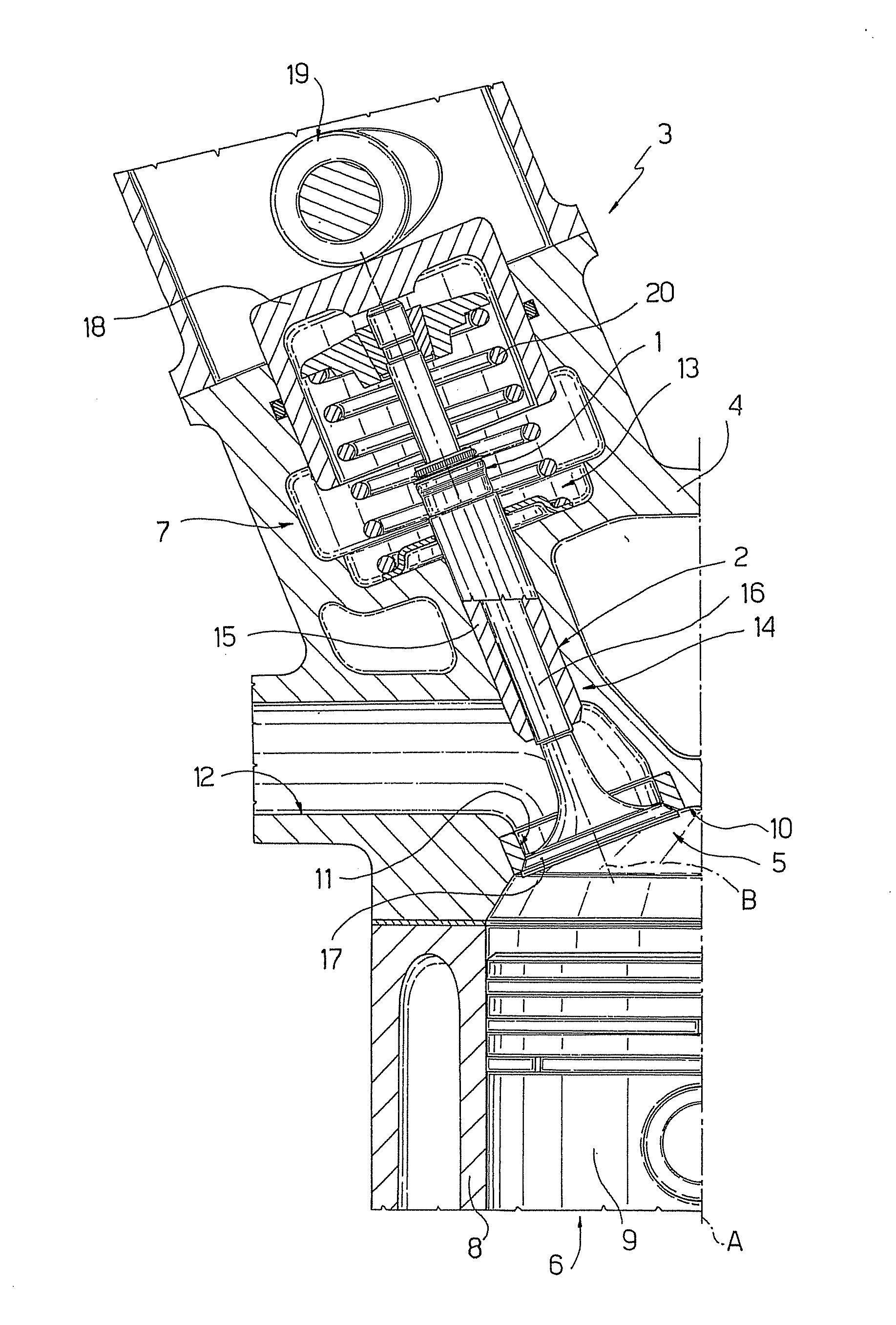

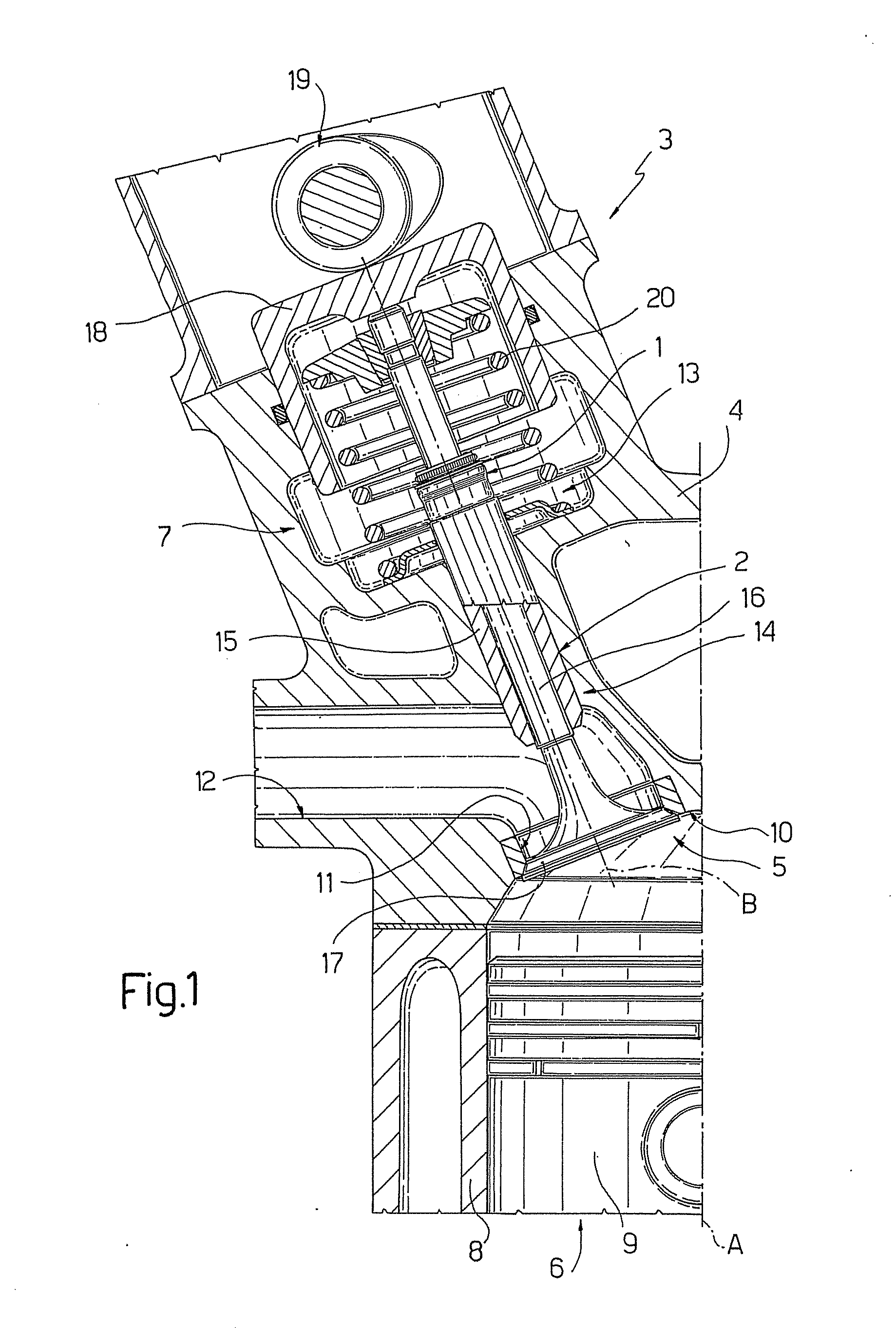

Gasket for a Valve in an Internal Combustion Engine

ActiveUS20080157480A1Simple and cost-effectiveOvercomes drawbackEngine sealsOperating means/releasing devices for valvesInternal combustion engineTubular formation

A gasket for a valve in an internal combustion engine is provided with a support element having a tubular configuration according to an axis and coaxially mounted on the valve. An elastically deformable element is interposed between the support element and the valve. The support element includes a first portion elongated according to the above mentioned axis, and a second portion extending from the first portion in a direction transversal to the axis, at least partially housed in an annular seat of the elastically deformable element and having its radially outermost end connected to the first portion itself. The support element comprises a third portion extending from the radially innermost end of the second portion and folded on the second portion itself so as to generate, in the folding area, a rounded edge cooperating with the annular seat of the elastically deformable element.

Owner:CORCOS IND DI FREUDENBERG & COSSO

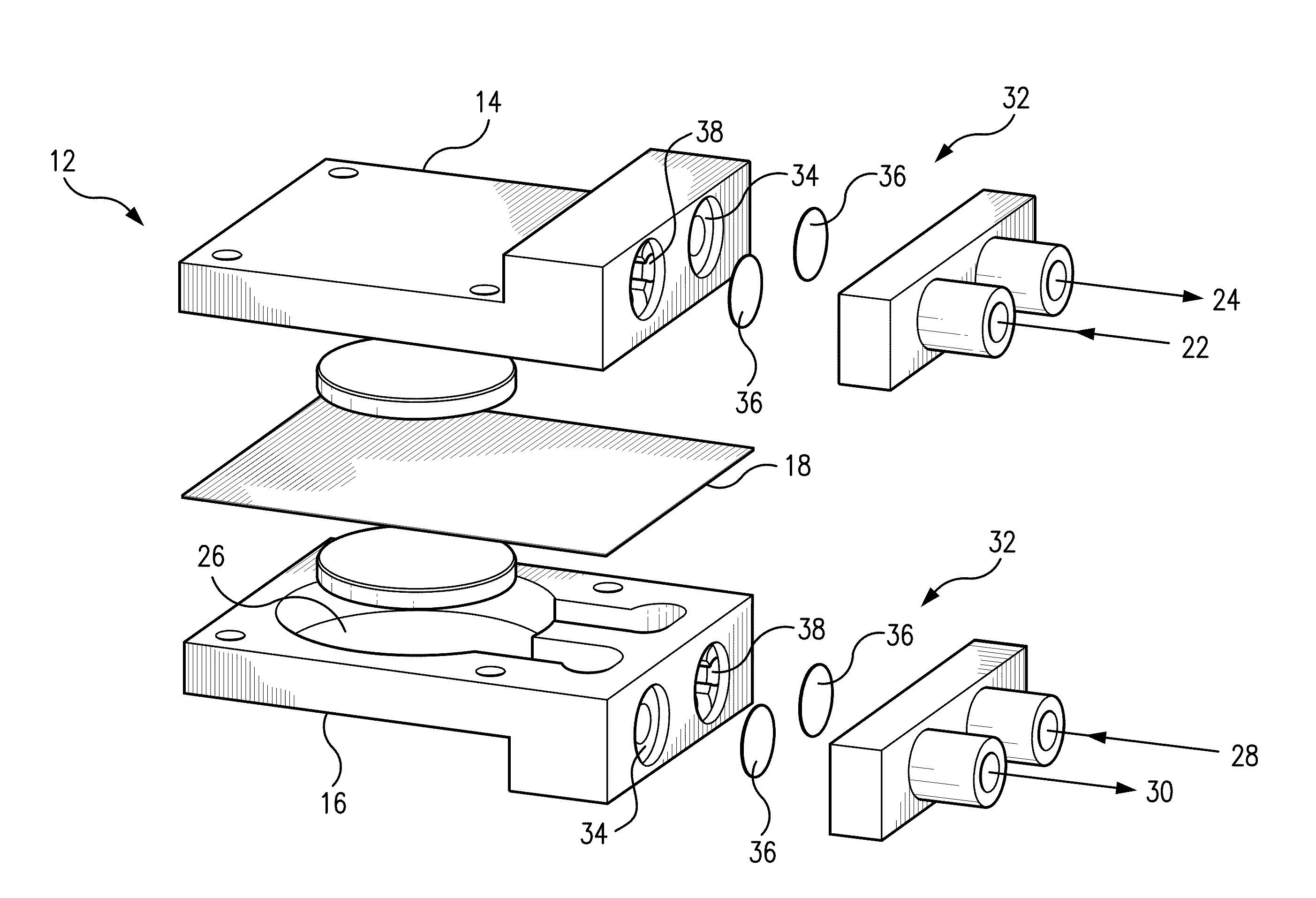

Mold for Making a Membrane for Use with a Flow Control System for a Micropump

InactiveUS20110309229A1Easy to manufactureEasy to separateMouldsFlexible member pumpsControl systemConvex side

A mold for making a membrane having a reinforcement annulus configured to be received within a flow control system for use with a micropump is disclosed. The mold has a female body portion, a male body portion and a body support member. The female body portion has a cylindrical elongate lower portion extending along an axis and having a diameter D, and a centered, concave upper face having substantially the same diameter D and having a radius of curvature R. The upper face is oriented substantially perpendicularly to the axis of the elongate lower portion and extends therefrom. The male body portion has a cylindrical elongate upper portion having a lower terminus and extending along an axis. The upper portion thereof has a diameter substantially equal to D. The male body portion further has a central cylindrical portion having a height H and extending from the lower terminus along the axis of the upper portion. The central portion has a diameter of D-G, wherein G is the annular thickness of a spacing gap extending radially outward from the central portion. The male body portion further has a centered, convex lower face having a diameter substantially equal to D-G, a radius of curvature substantially equal to R and being oriented substantially perpendicularly to the axis of the elongate upper portion. The body portion support member has a generally elongated, tubular configuration and further has an inner diameter just slightly greater than D. The body portion support member is thereby configured to receive at least a portion of the female body portion and at least a portion of the male body portion, so that the female and male body portions can be maintained along the same axis. In this fashion, the convex face and concave face are positioned cooperatively to effect manufacture of the membrane having a reinforcement annulus configured to be received within a flow control system for use with a micropump.

Owner:PICOLIFE TECH

Adhesive cord cover

InactiveUS20050031821A1Stay cohesiveEfficient use ofFlexible coversDecorative coversEngineeringTubular formation

An adhesive cord cover for enveloping a cord, such as an electrical cord or chandelier chain. The adhesive cord cover is formed from a lengthwise strip of fabric. A pressure sensitive adhesive is attached to the fabric strip, preferably along a first lengthwise edge. The pressure sensitive adhesive is positioned and configured to allow a fastening side of the pressure sensitive adhesive to be selectively adhered to the lengthwise strip of fabric to thereby form a tubular configuration for enveloping a cord. The pressure sensitive adhesive is preferably an adhesive transfer tape. The transfer tape preferably has a removable liner on the fastening side. The removable liner assists in preserving the adhesive properties of the pressure sensitive adhesive prior to use. The pressure sensitive adhesive transfer tape is preferably a continuous strip that extends substantially along the entire length of the piece of fabric.

Owner:CLARK KIM MARIE

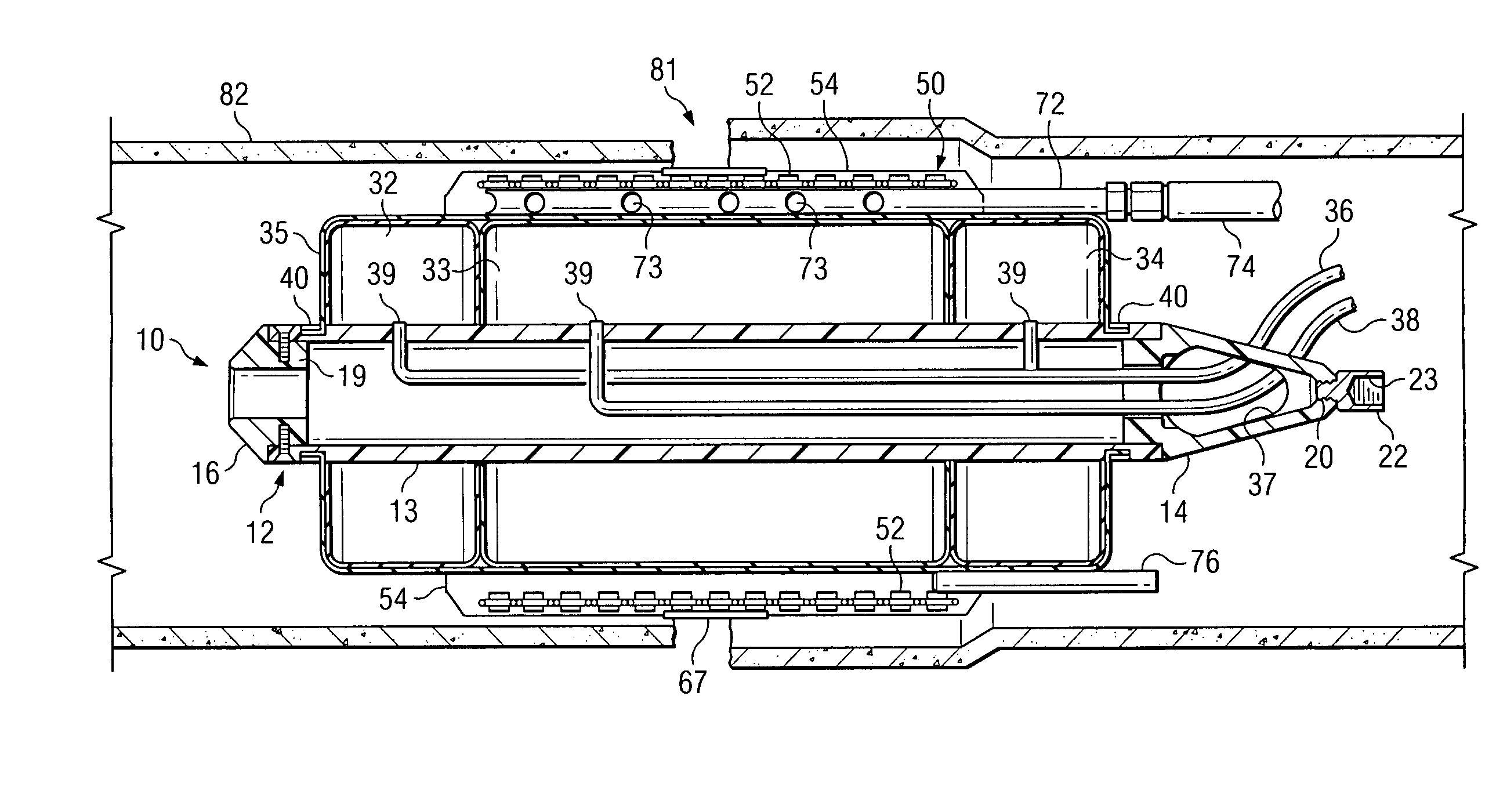

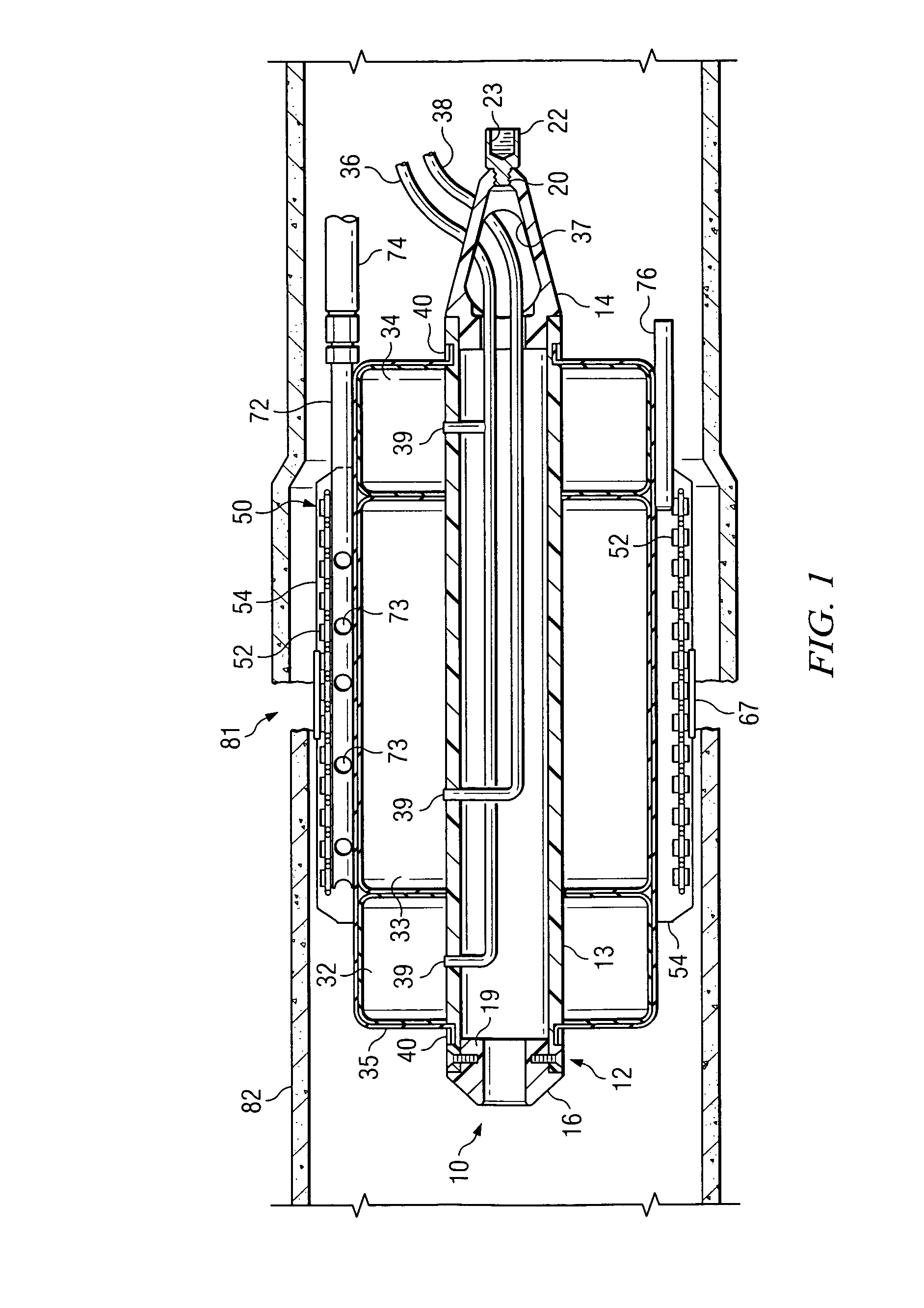

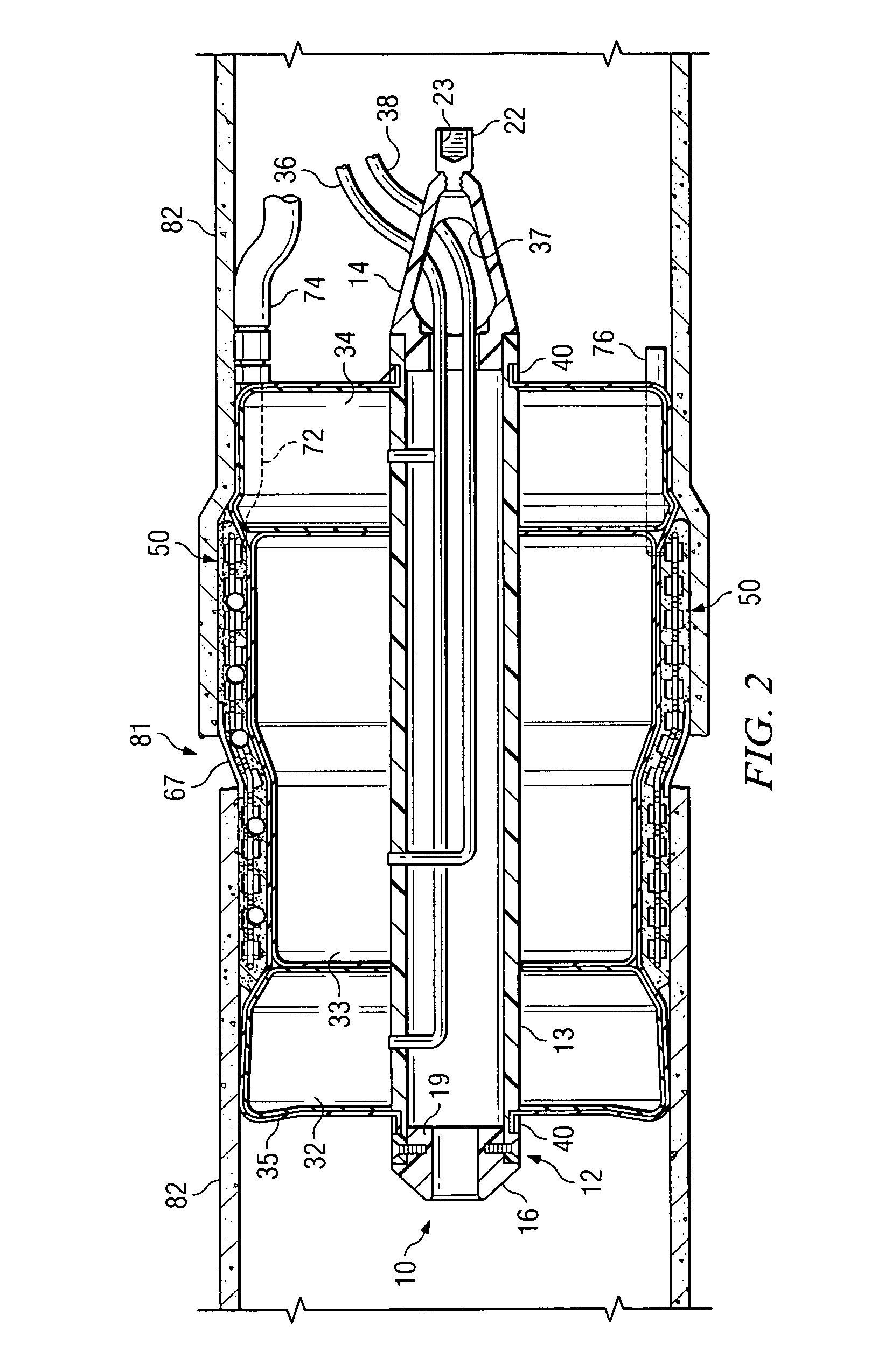

Method and apparatus for repairing underground pipes

An apparatus for repairing an underground pipe includes a mandrel having a first expander capable of extending and retracting in a radial direction, a system for causing radial expansion and retraction of the expander when in position at a pipe location in need of repair, a resilient stiffening frame disposable in a tubular configuration outside of the expander, such that the expander can be used to expand the frame into contact with the inside of the pipe, and a suitable arrangement for confining a flowable cement between the expander and the inside of the pipe to form a repair band upon setting of the cement. In a preferred form of the invention, the expander comprises a central inflatable bladder, and the system controlling radial extension and retraction of the expander includes a line supplying pressurized air to the bladder.

Owner:EARTH TOOL L L C

Mechanically self actuated liquid level sensor

A liquid level sensor for measuring liquid levels in underground and above ground containers includes a frame formed to have an elongate hollow tubular configuration that encloses a cavity. A cam pivot has an end extending into the cavity from a first inner wall portion of the frame. A cam is arranged to be pivotal about the end of the cam pivot. A float is placed in the cavity. A spring is arranged to bias the cam arm into contact with the float to force a side portion of the float into a locked position in frictional engagement with the second inner wall portion of the frame. A cam actuator pivotally mounted in a lower end portion of the frame exerts a force on the cam arm to release the float from the locked position when the lower end of the frame contacts the container bottom.

Owner:FLING JOHN J +1

Thick Fusing Belt for a Color Electrophotographic Printer

ActiveUS20100167065A1Overcome disadvantagesImprove fusion qualityLayered productsDecorative surface effectsAdhesiveEngineering

An endless fusing thick belt for an electrographic imaging device having a flexible tubular configuration of predetermined diameter, said endless fusing thick belt comprising; an outside surface toner release layer comprised of a coating and a sleeve; a silicone rubber layer positioned inside said outside surface toner release layer; a rigid material layer positioned inside said silicone rubber layer; and a silicone base layer positioned inside and affixed to the internal surface of said polyimide layer using an adhesive.

Owner:LEXMARK INT INC

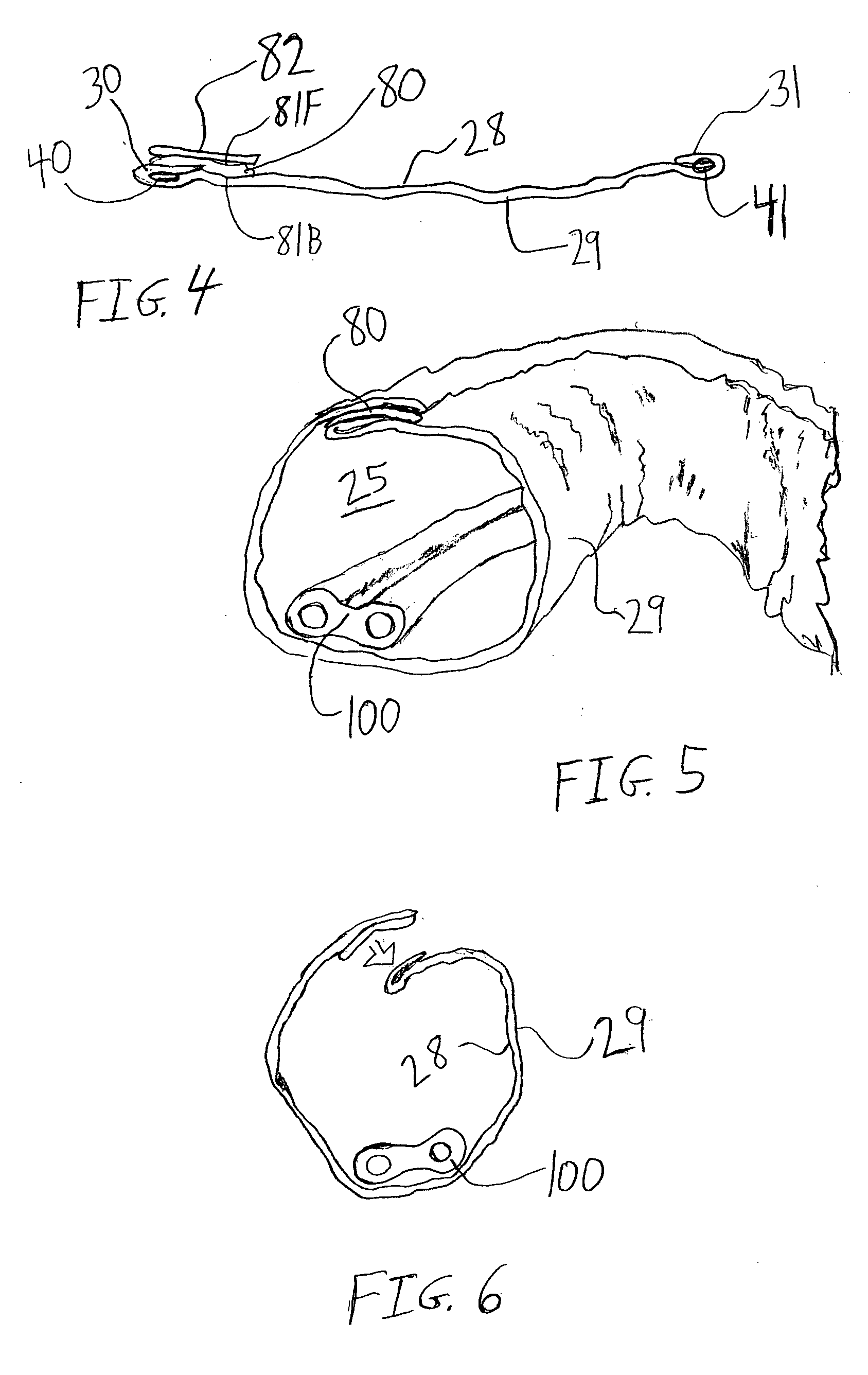

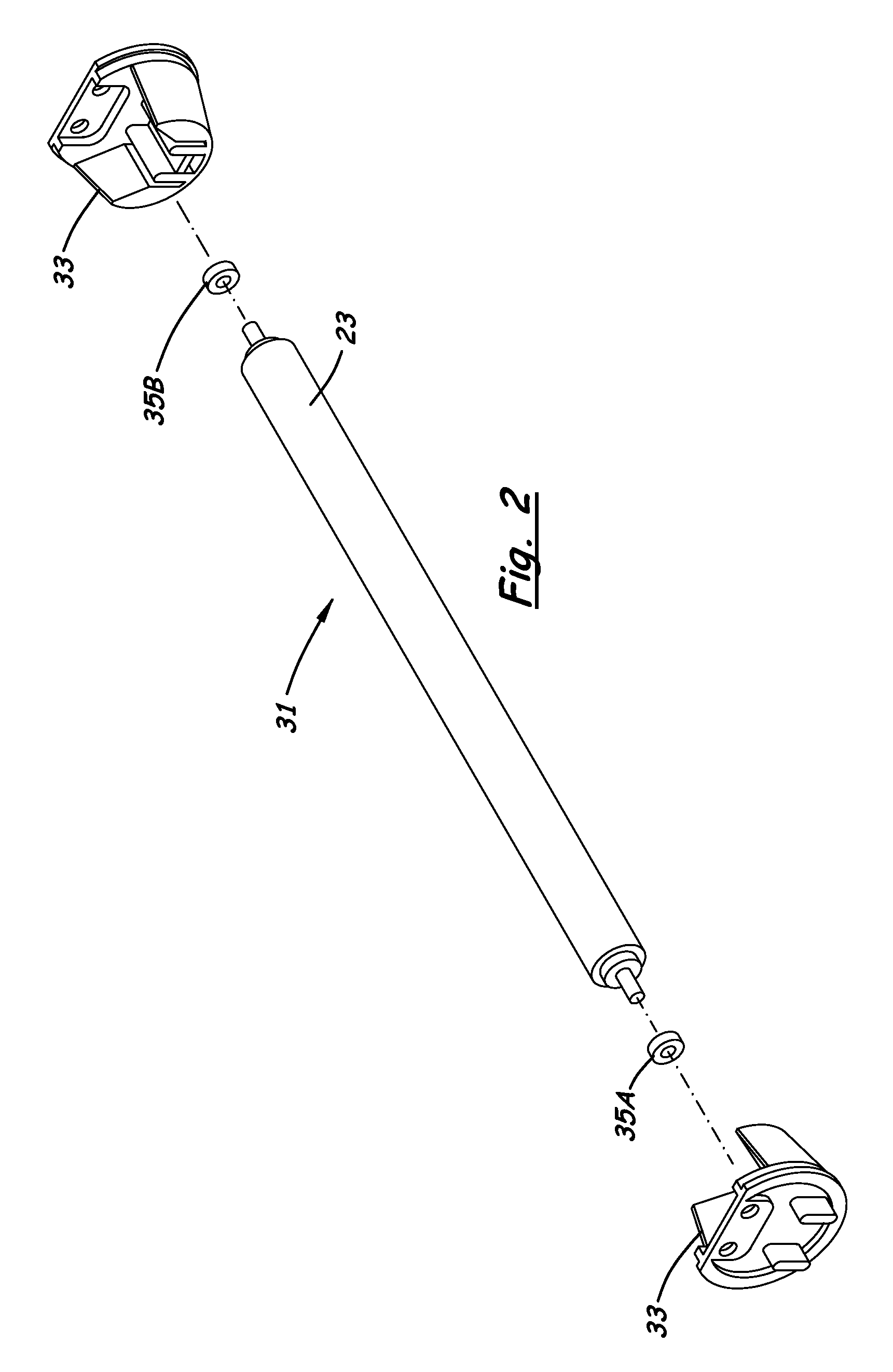

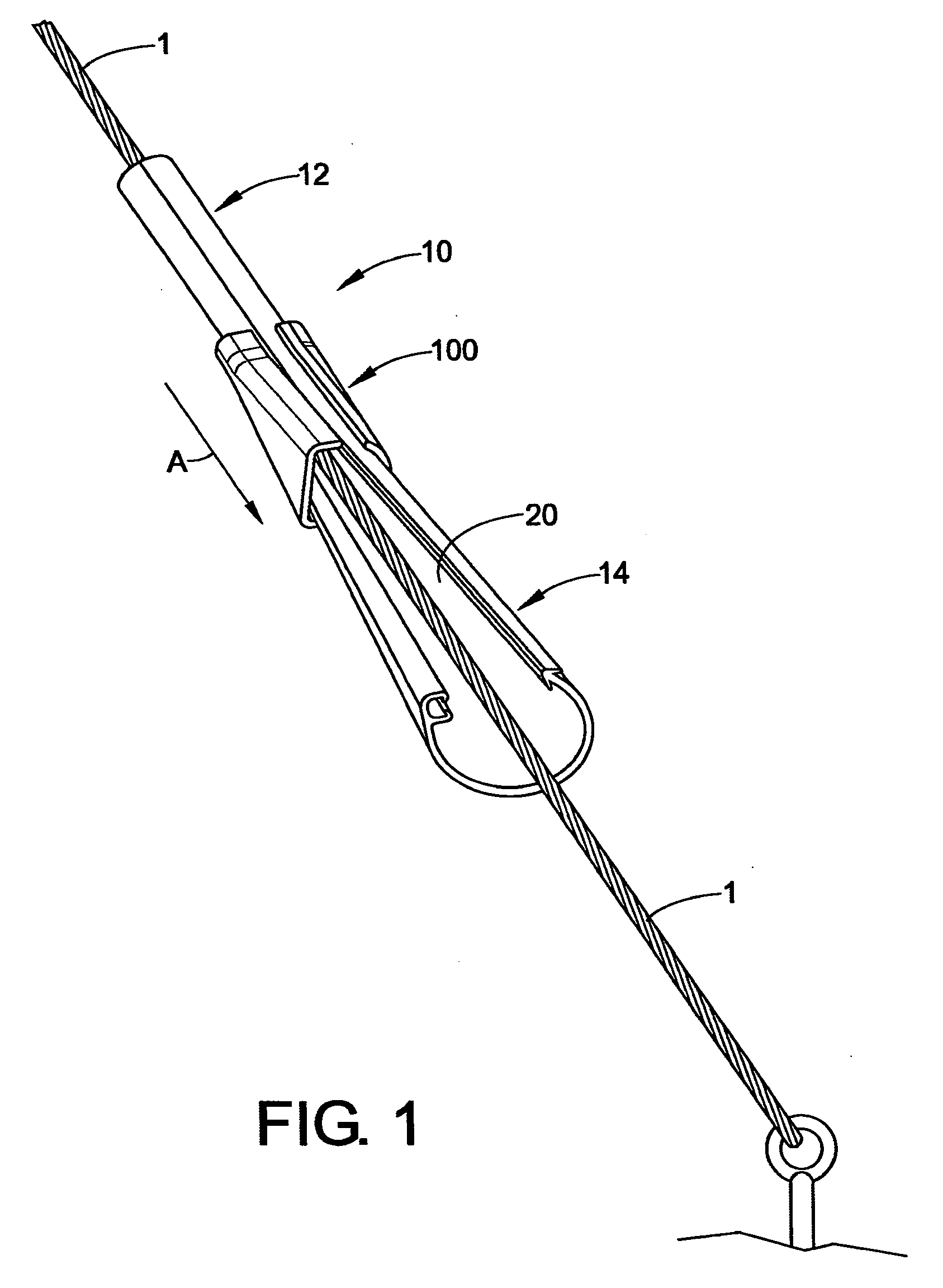

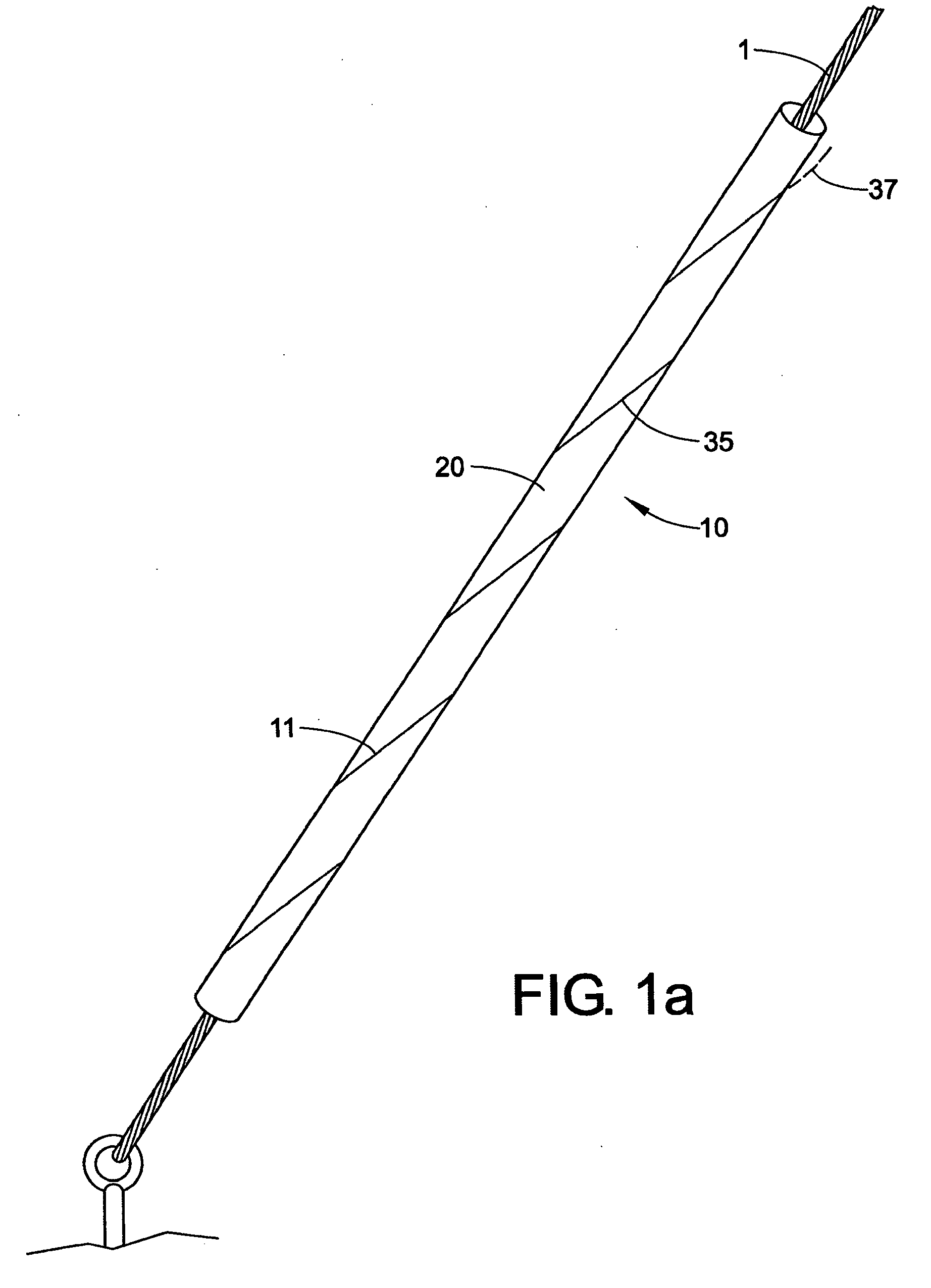

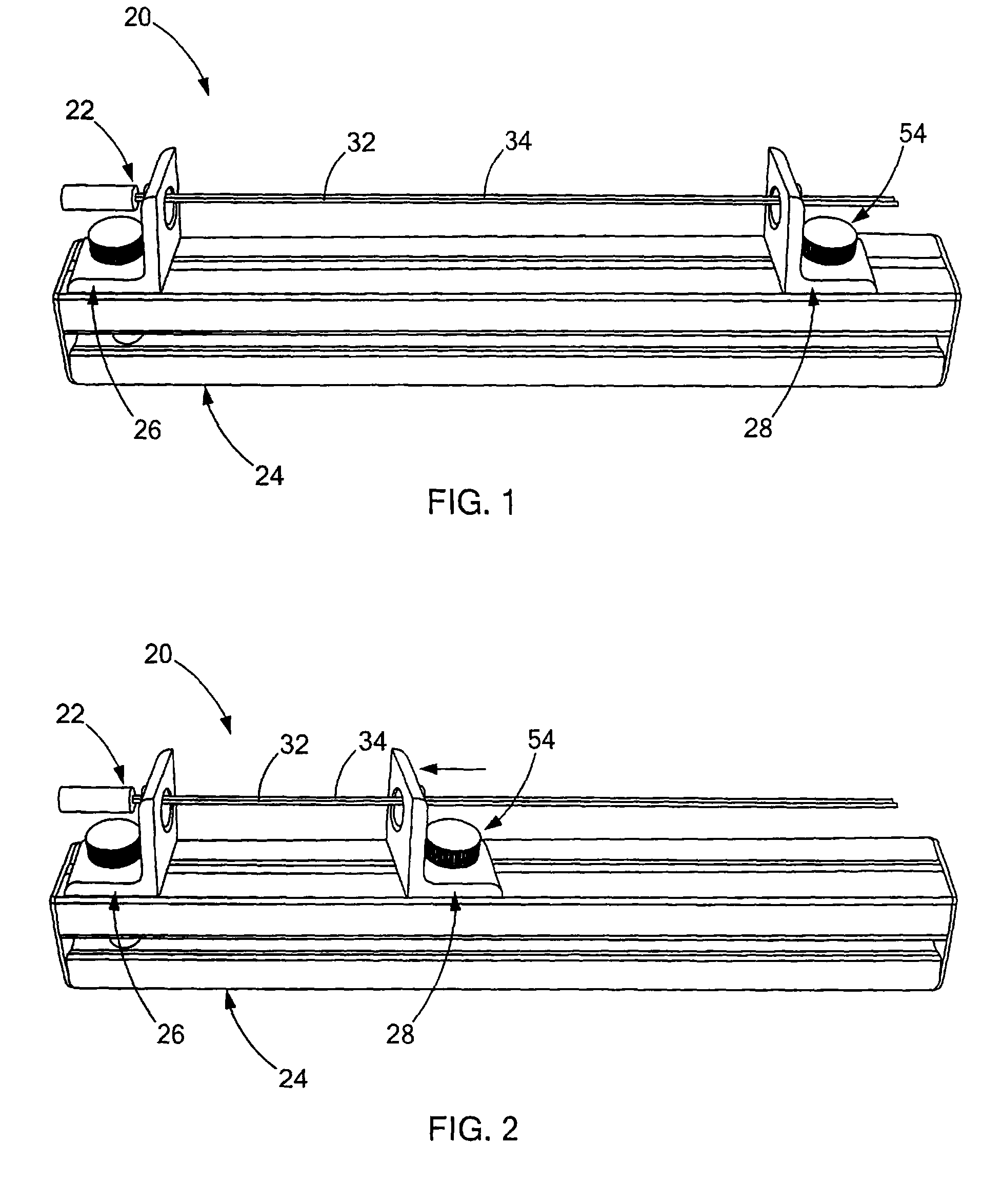

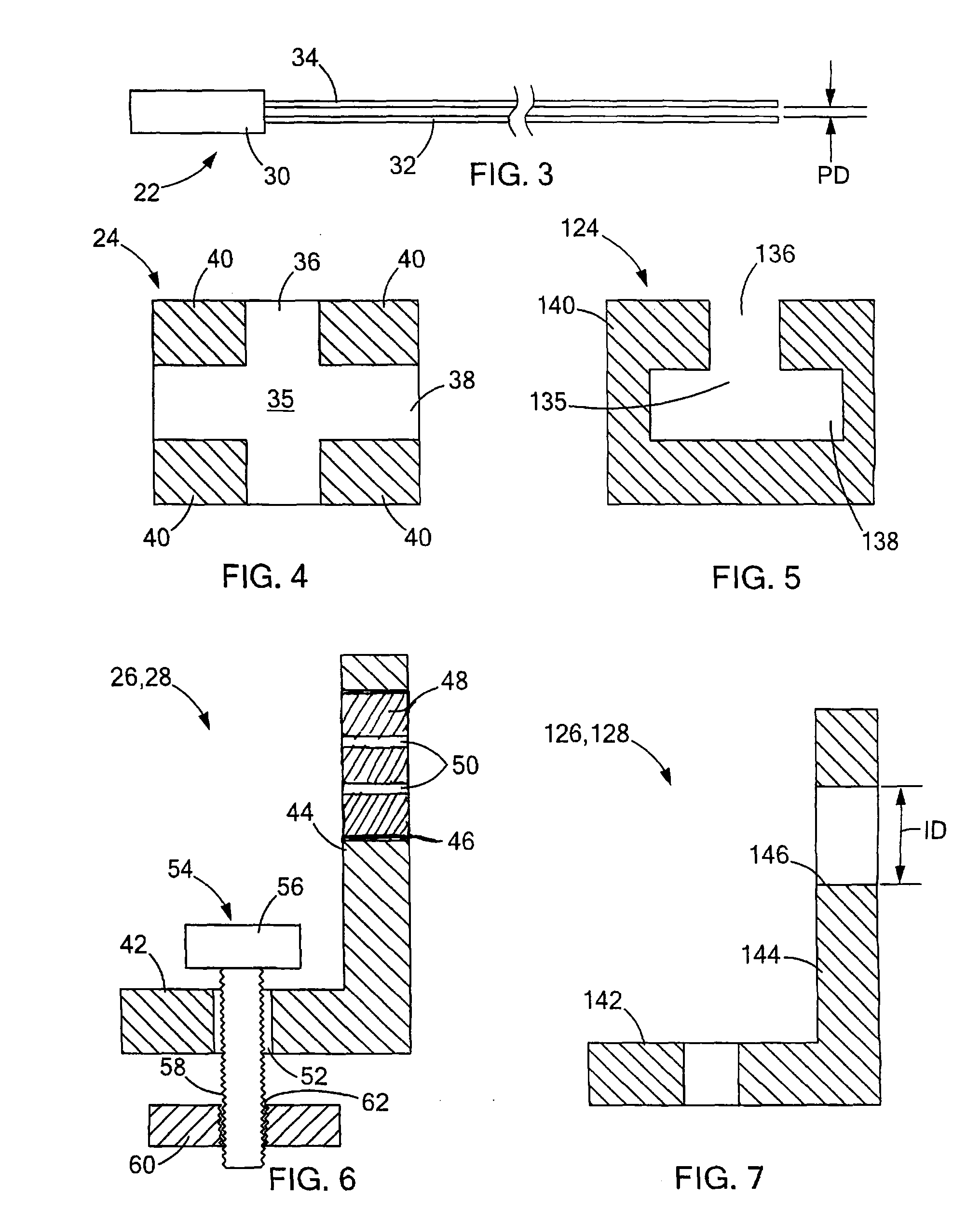

Plastic guy wire marker apparatus, bulk guy marker material, bulk guy marker dispenser system, and tool for installing a guy marker

A guy marker apparatus for use on an associated guy wire includes a substantial rectangular body member having opposite parallel first and second edges and is foldable along a longitudinal axis parallel with the first and second edges. First and second connection portions are disposed at the first and second edges, respectively, for selectively interlocking the edges in slidable abutment to hold the main body member in a folded tubular conformation and selectively in a helical conformation. A tool for applying a guy marker apparatus onto an associated guy wire includes a main body member, an alignment portion adapted to guide the guy marker in an unlocked state relative to the main body member, and a production portion adapted to guide the marker in a self-locked state out from the main body member. A forming wall disposed between the alignment and production portions moves. the marker material between the unlocked and self-locked state based on relative movement between the tool and the guy marker material. A dispensing system for a bulk roll of coiled guy marker material includes a housing having a cavity adapted to hold the coil of guy marker material having a shape memory. The housing includes an outlet opening whereby desired lengths of guy marker material may be drawn. The bulk roll includes coiled flattened layers of plastic guy wire marker material having an inherent shape memory characteristic.

Owner:PREFORMED LINE PROD CO

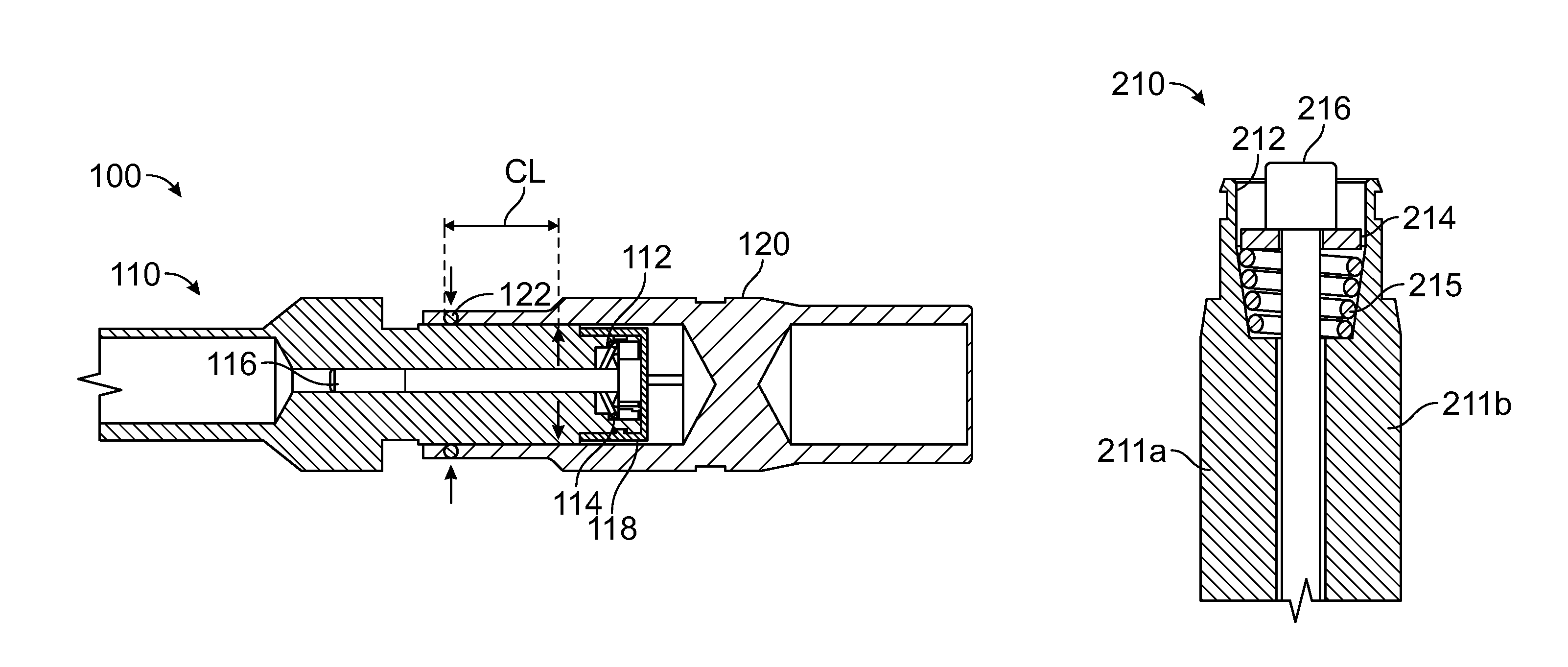

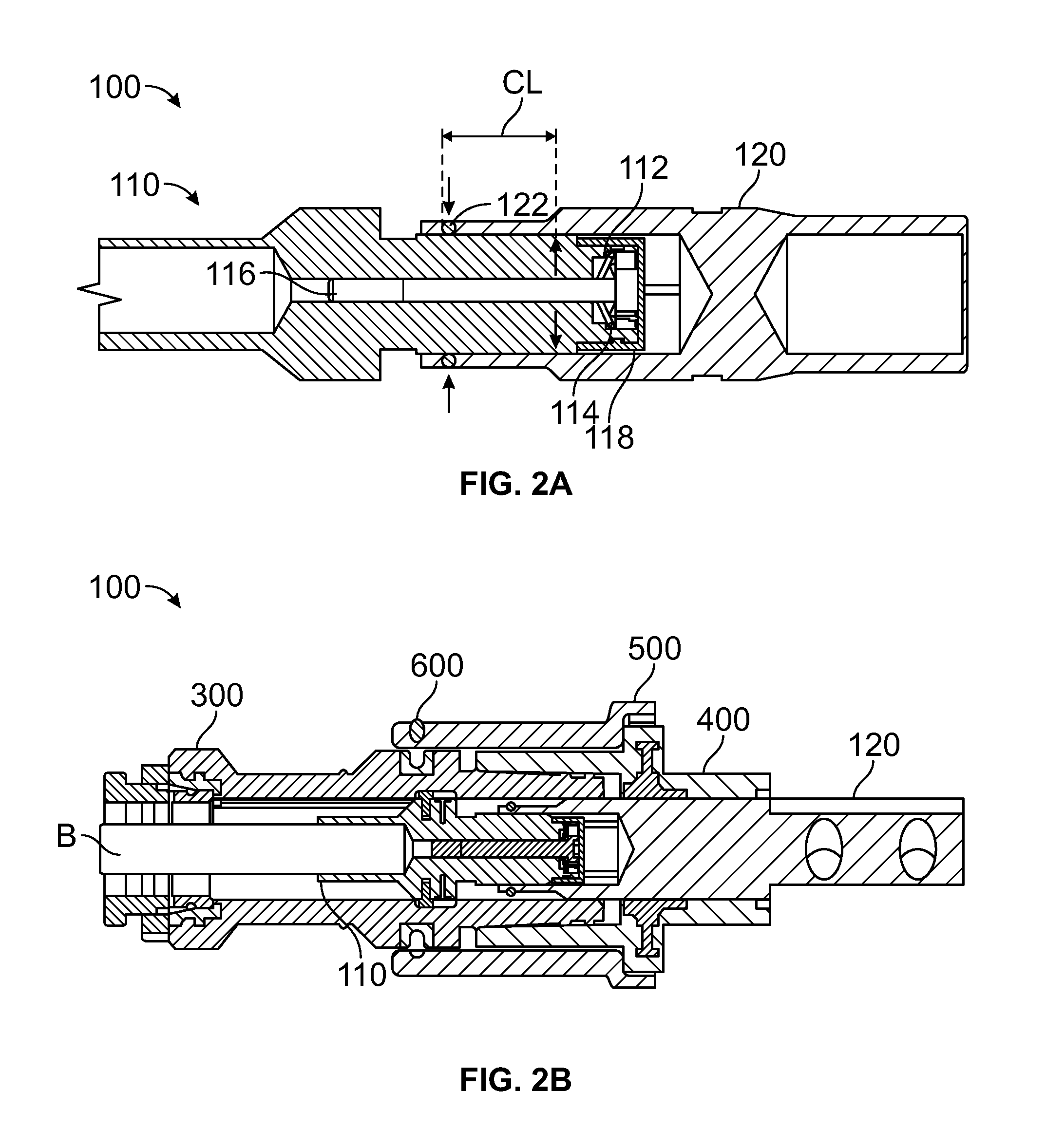

Connector assembly having self-adjusting male and female connector elements

ActiveUS9437952B2Smooth connectionEasy to adjustSecuring/insulating coupling contact membersCoupling contact membersEngineeringTubular formation

A connector assembly includes a male connector element that is manually expandable to control tightness of fit in a and a female connector element. The male connector element is having a first and a second portion configured by longitudinally bi-furcating the male connector element and includes a chamfered portion, a radially adjusting mechanism and a screw. The chamfered portion is axially configured on male connector element and receives the radially adjusting mechanism that moves the first and second portions relative to each other. The screw axially passes through male connector element and radially moves the radially adjusting mechanism to adjust the gap between the first and second portions to adjust external dimension of male connector element. The female connector element is having a tubular configuration that receives male connector element and is having a plurality of longitudinal slits configured thereon, walls of the female connector element are urged radially inwards towards the male connector element to maintain contact there-between by a spring element.

Owner:APPLETON GRP

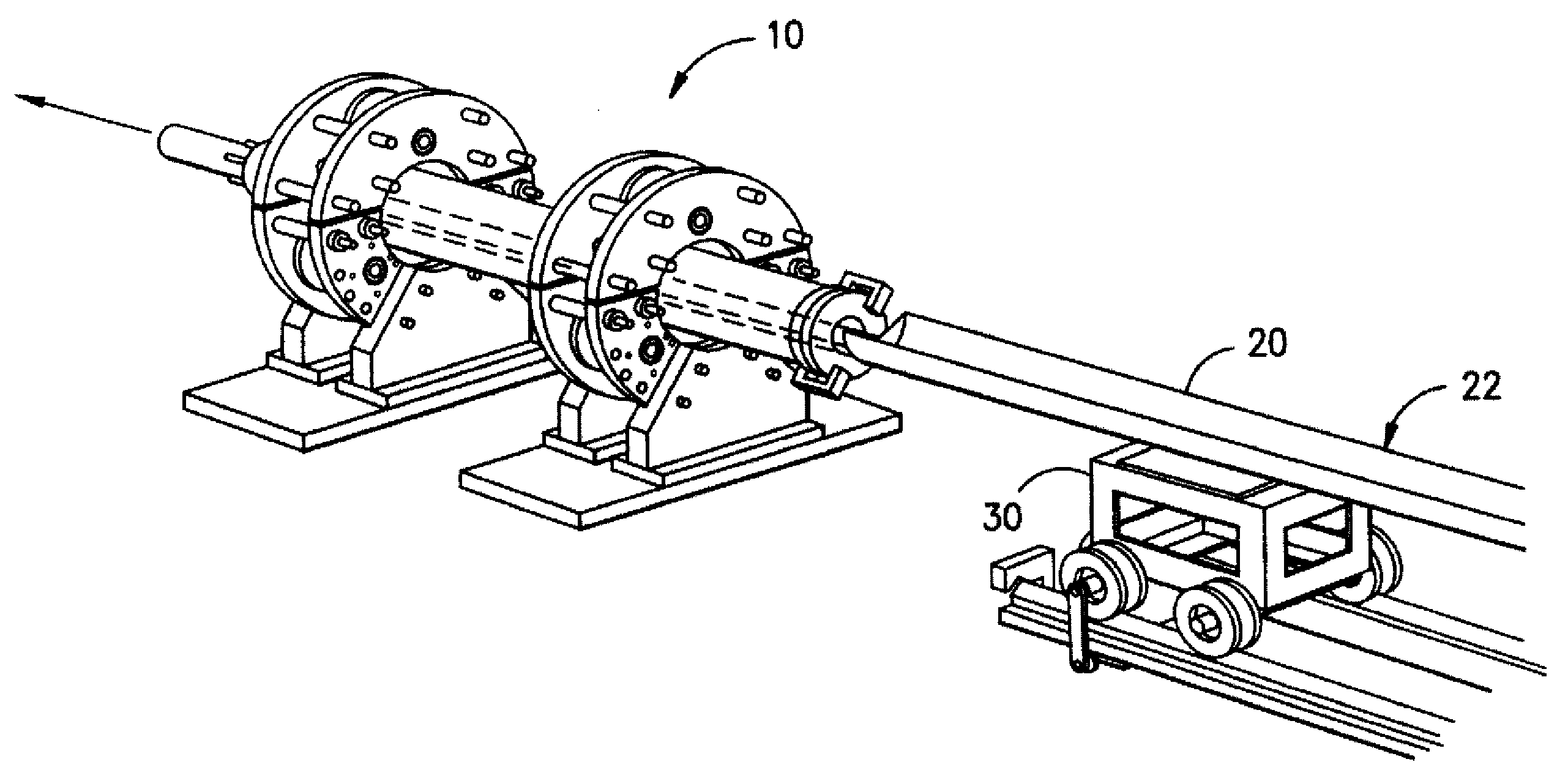

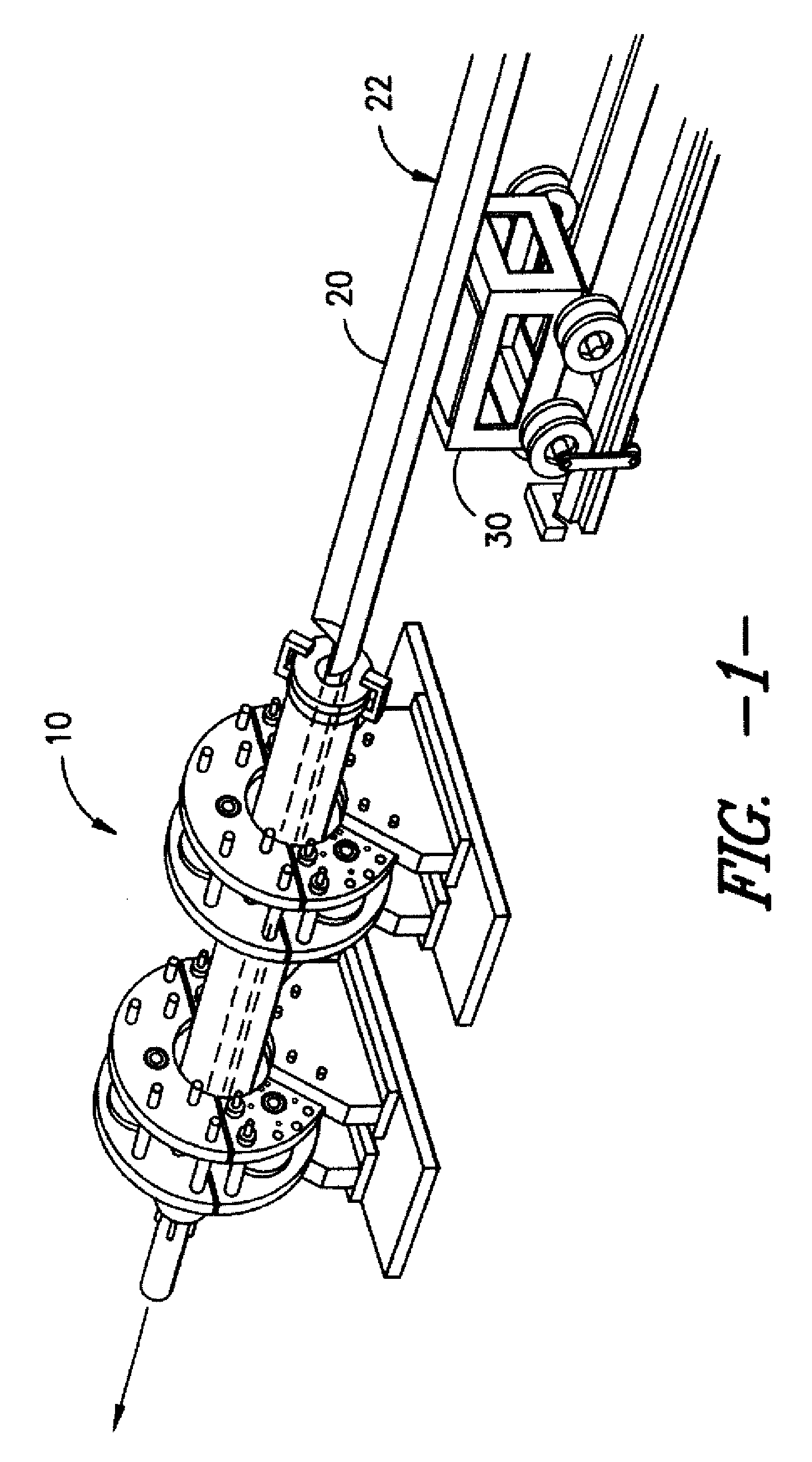

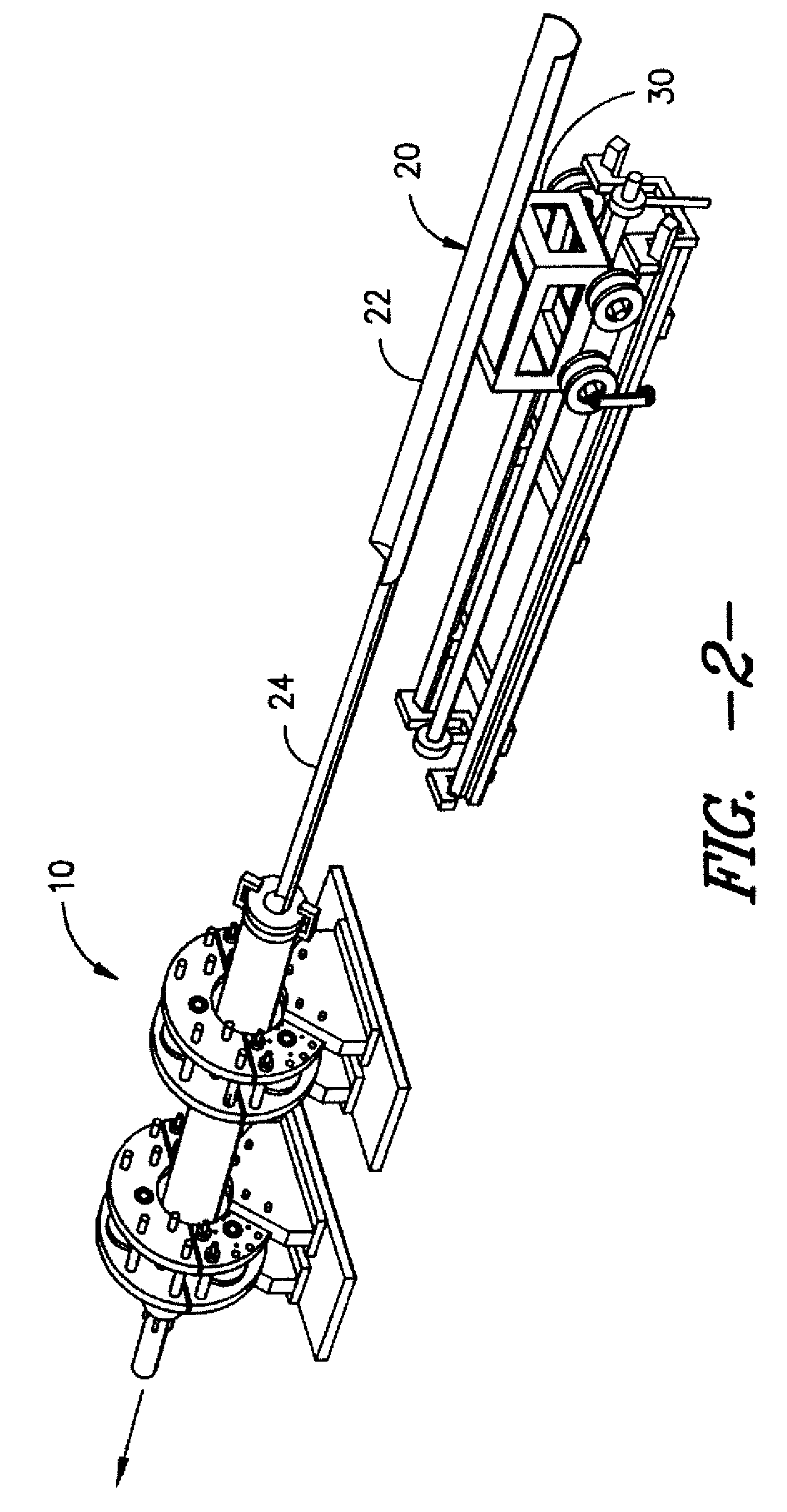

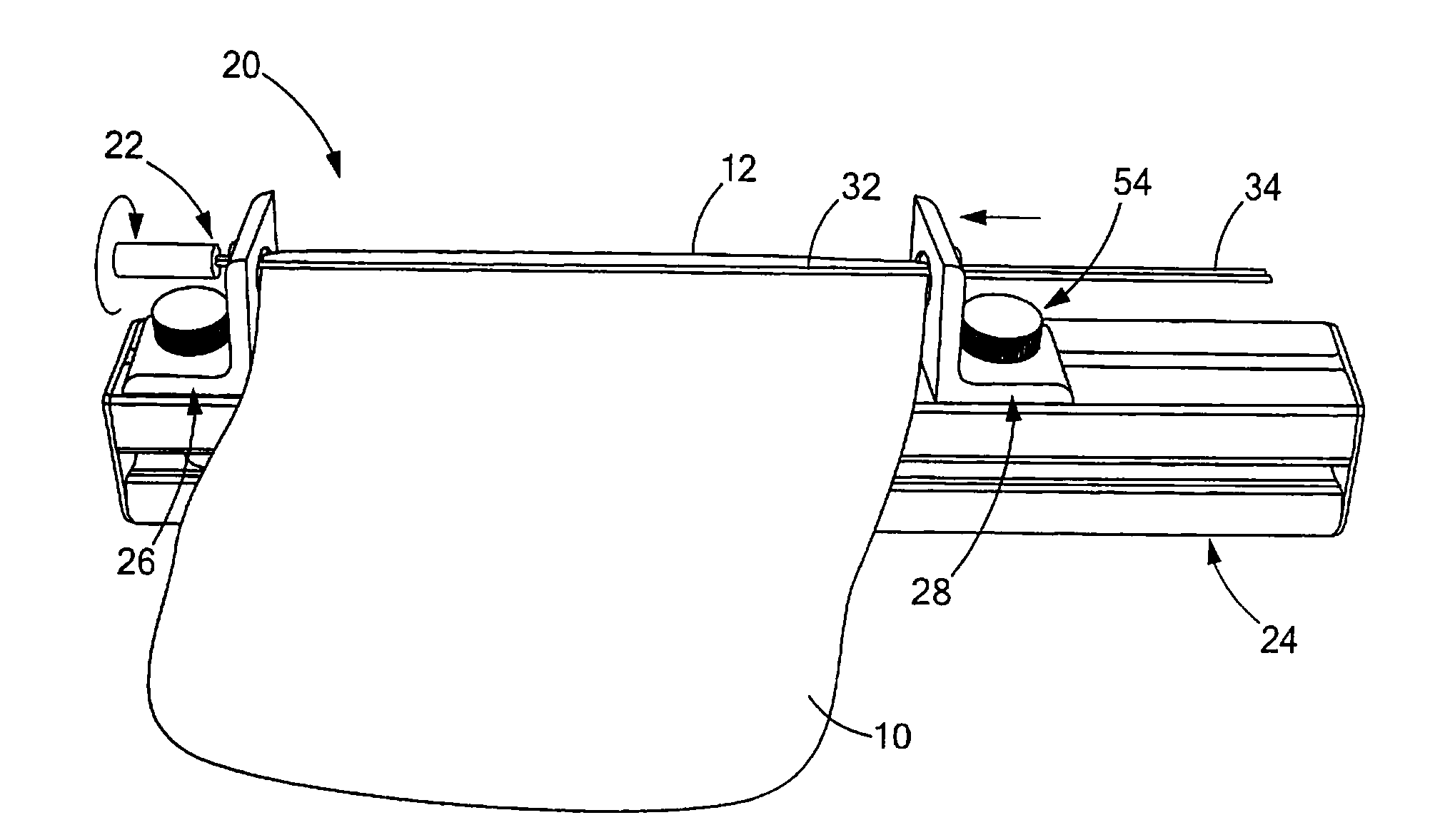

Method of making precursor hollow castings for tube manufacture

A tubular formation technique utilizing centrifugal casting incorporating a moveable launder system to deliver molten alloy along an extended length within a centrifugal caster to form a hollow tubular precursor of extended length. The technique is adaptable to all alloy systems but may be particularly suited for so called “hard alloys” that are susceptible to substantial work hardening or are difficult to extrude.

Owner:GM GLOBAL TECH OPERATIONS LLC

Endoscopic sheet rolling system

Owner:COOK MEDICAL TECH LLC

Mechanically self actuated liquid level sensor

InactiveUS20070157725A1Feature is removedEliminate needMachines/enginesAlarmsAbove groundEngineering

A liquid level sensor for measuring liquid levels in underground and above ground containers includes a frame formed to have an elongate hollow tubular configuration that encloses a cavity. A cam pivot has an end extending into the cavity from a first inner wall portion of the frame. A cam is arranged to be pivotal about the end of the cam pivot. A float is placed in the cavity. A spring is arranged to bias the cam arm into contact with the float to force a side portion of the float into a locked position in frictional engagement with the second inner wall portion of the frame. A cam actuator pivotally mounted in a lower end portion of the frame exerts a force on the cam arm to release the float from the locked position when the lower end of the frame contacts the container bottom.

Owner:FLING JOHN J +1

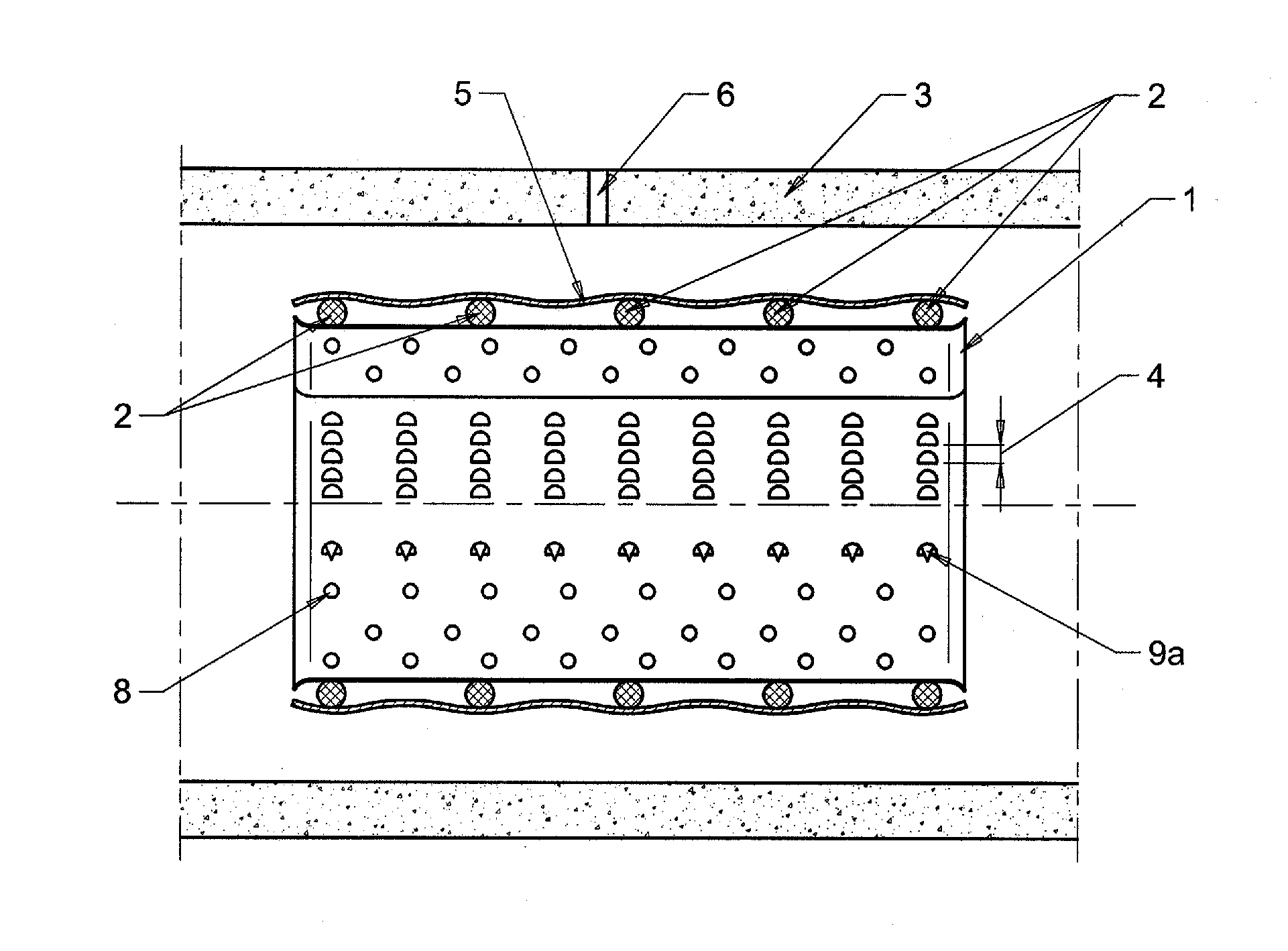

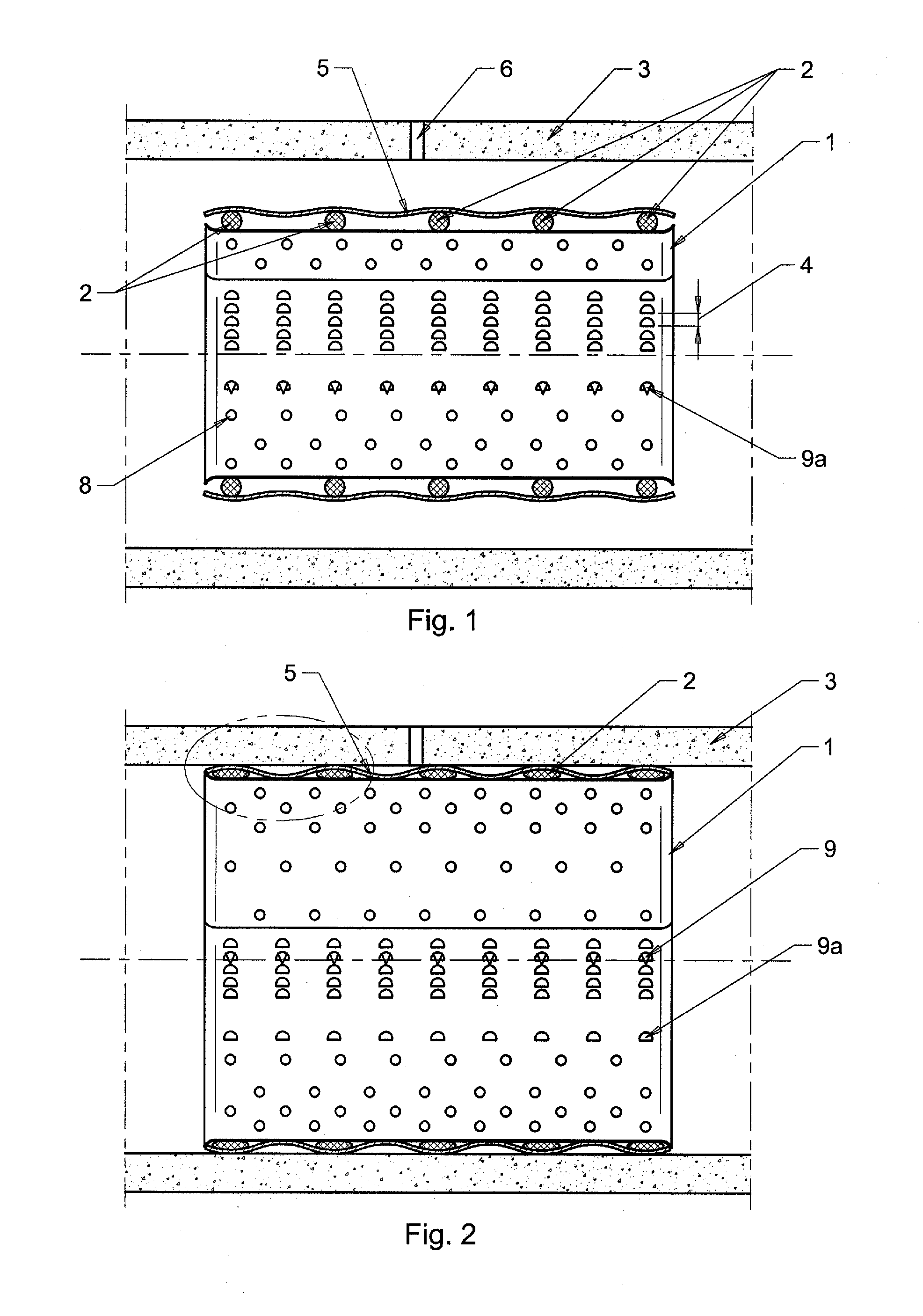

Gradient coil system and MR imaging system embodying same

ActiveUS7528604B2Manufactured as easily and economicallyImprove cooling effectTransformers/inductances coolingMagnetic measurementsPlate heat exchangerResonance

A gradient coil system for a magnetic resonance tomography apparatus has a layer structure including a gradient coil layer and a cooling layer. The cooling layer is fashioned as a plate heat exchanger, composed of plates, for cooling the gradient coil layer. In this way, a highly efficient cooling of the gradient coil layer is achieved with a lower structural height compared to conventional tubular configurations.

Owner:SIEMENS HEALTHCARE GMBH

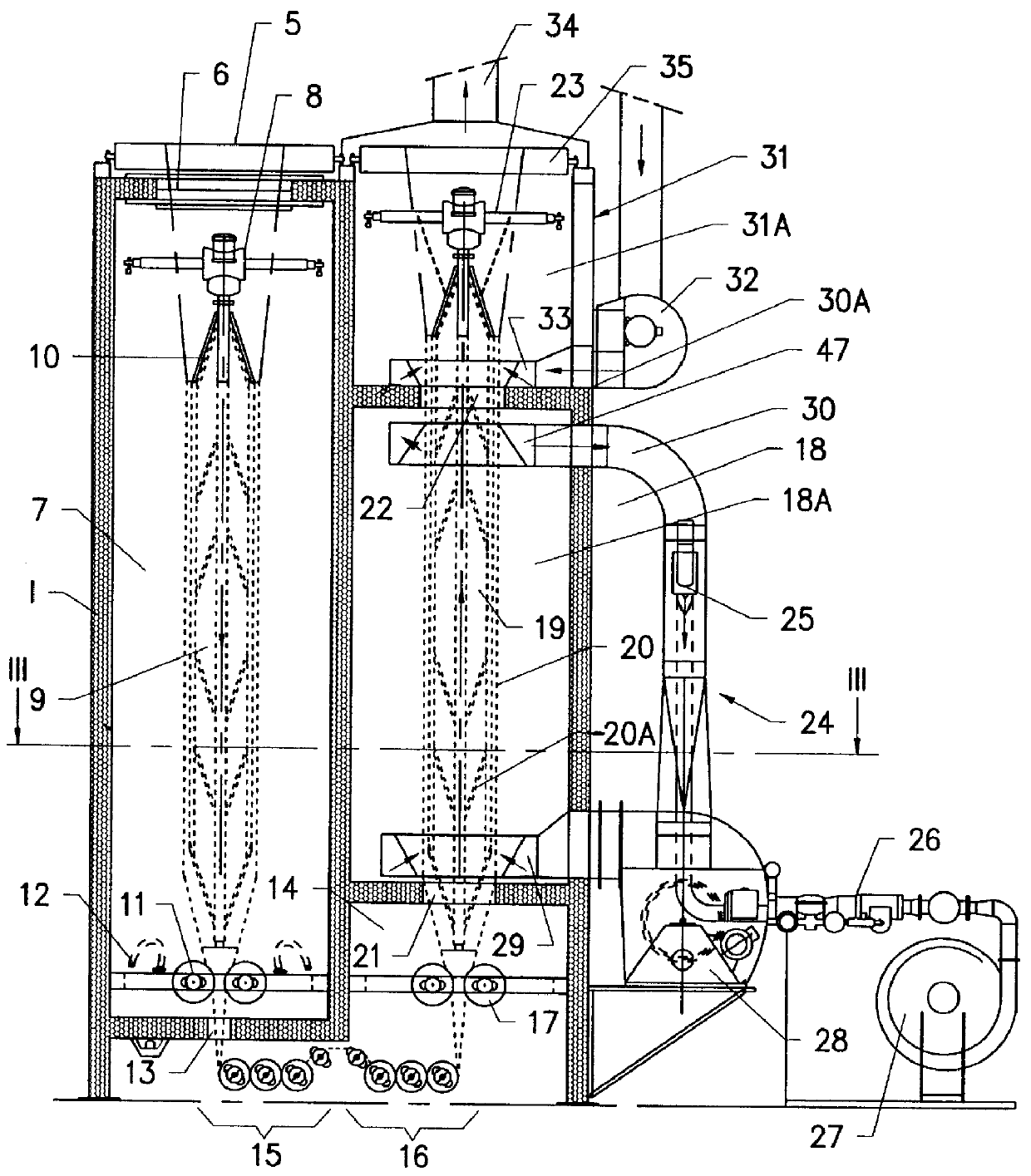

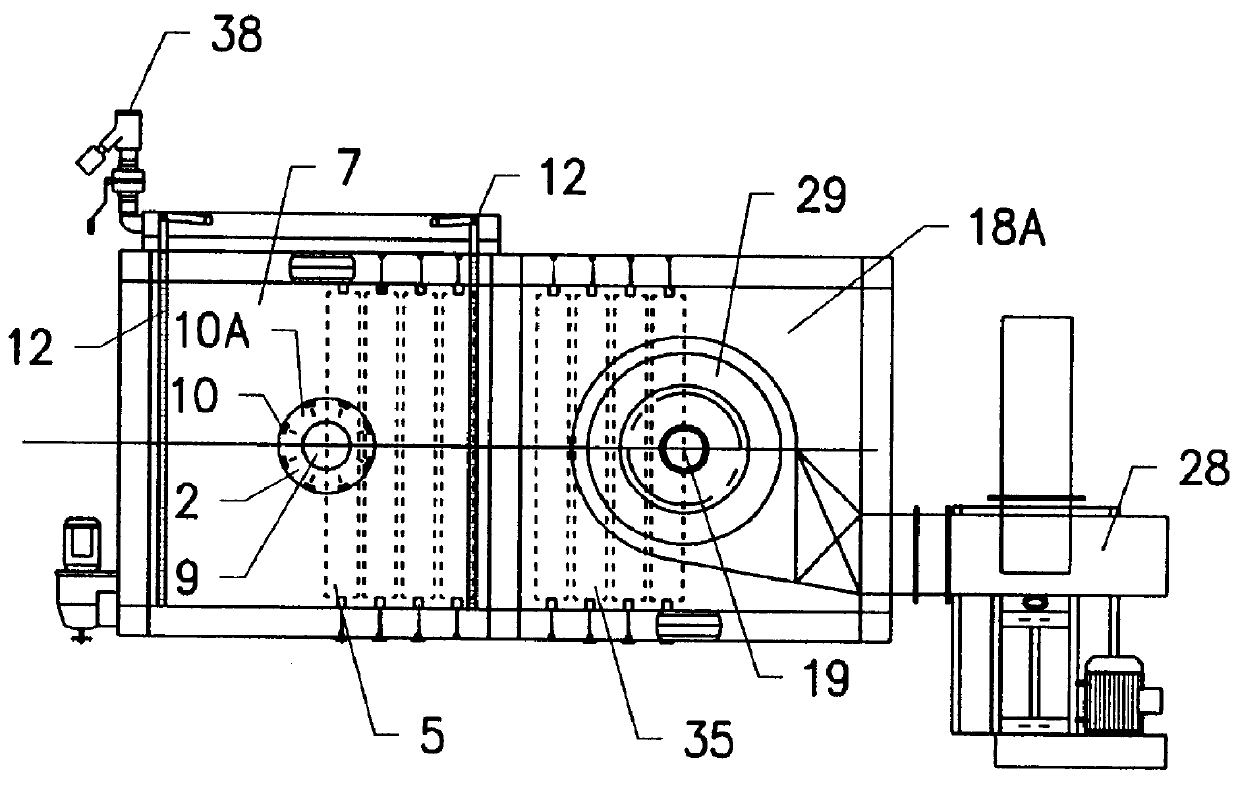

Method and apparatus for treating tubular knitted goods

InactiveUS6016591AAvoid processing stepsAvoid wastingHeating/cooling textile fabricsDrying machines with progressive movementsFiberEngineering

In a method and an apparatus for treating tubular knitted goods containing elastomeric fibers, the goods are effectively relaxed, expanded, and heat fixed or set in the desired expanded condition, while maintaining the tubular configuration of the goods and without cutting open and re-sewing the tubular configuration of the goods. The tubular knitted goods are continuously transported through a relaxing process followed by a heat fixing process and then a cooling process, while constantly maintaining the tubular structure of the goods. The goods are expanded in the radial or width direction by a tubular expander, and in the lengthwise direction by being transported between a feed roller arrangement and a draw-off roller arrangement operating at different transport velocities respectively. The temperature in the heat fixing chamber is preferably over 200 DEG C. and the transport velocity of the tubular knitted goods can be greater than 18 m / min.

Owner:LINDAUER DORNIER GMBH

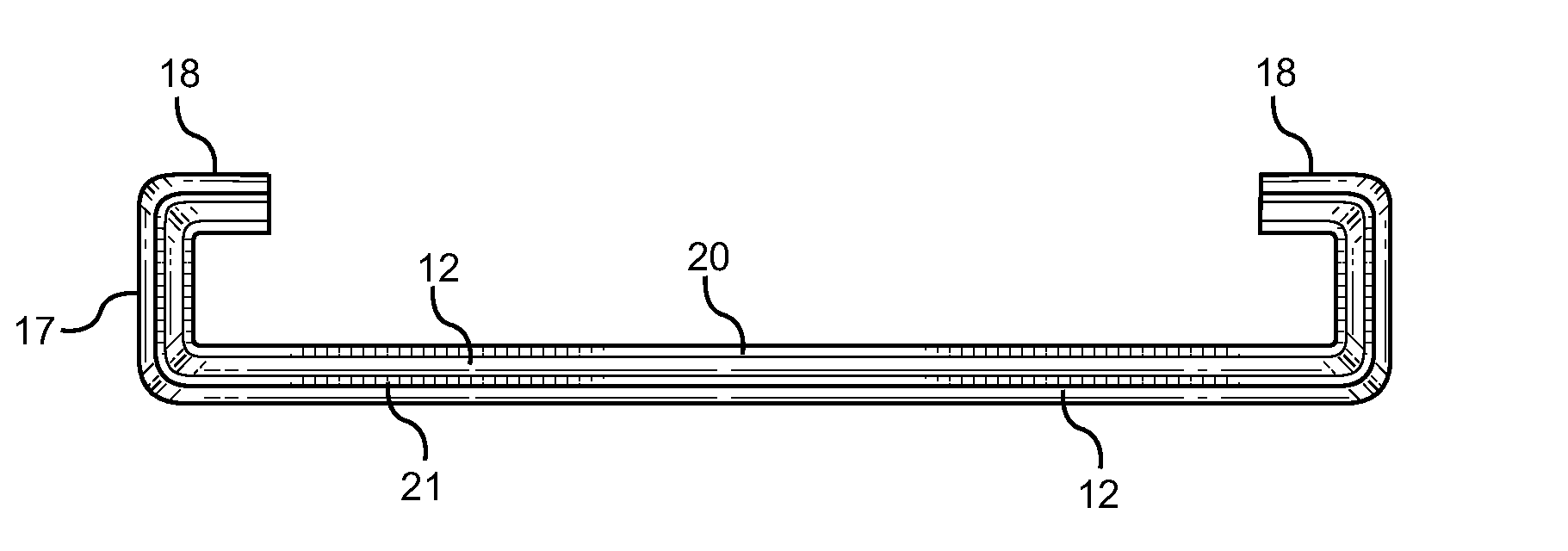

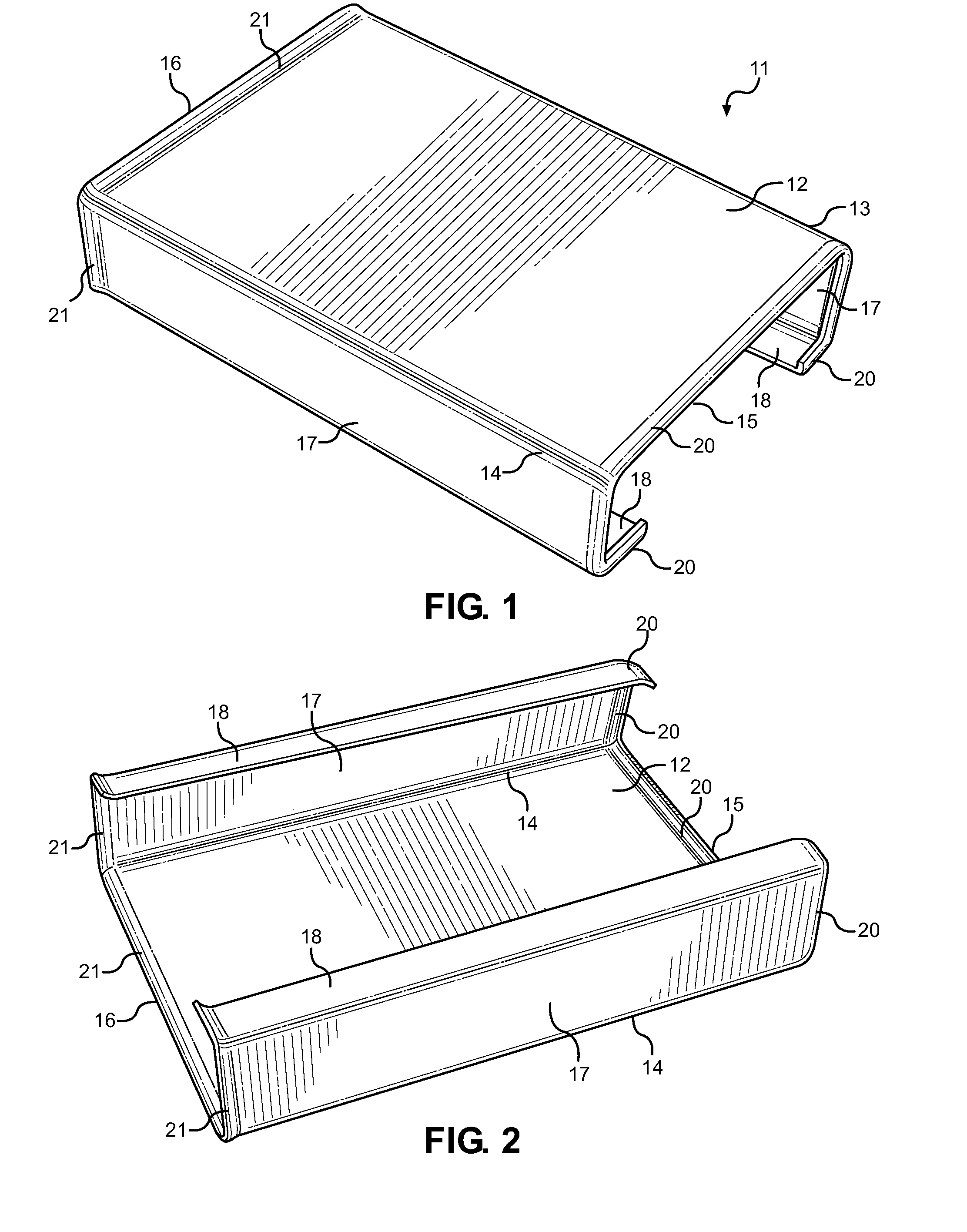

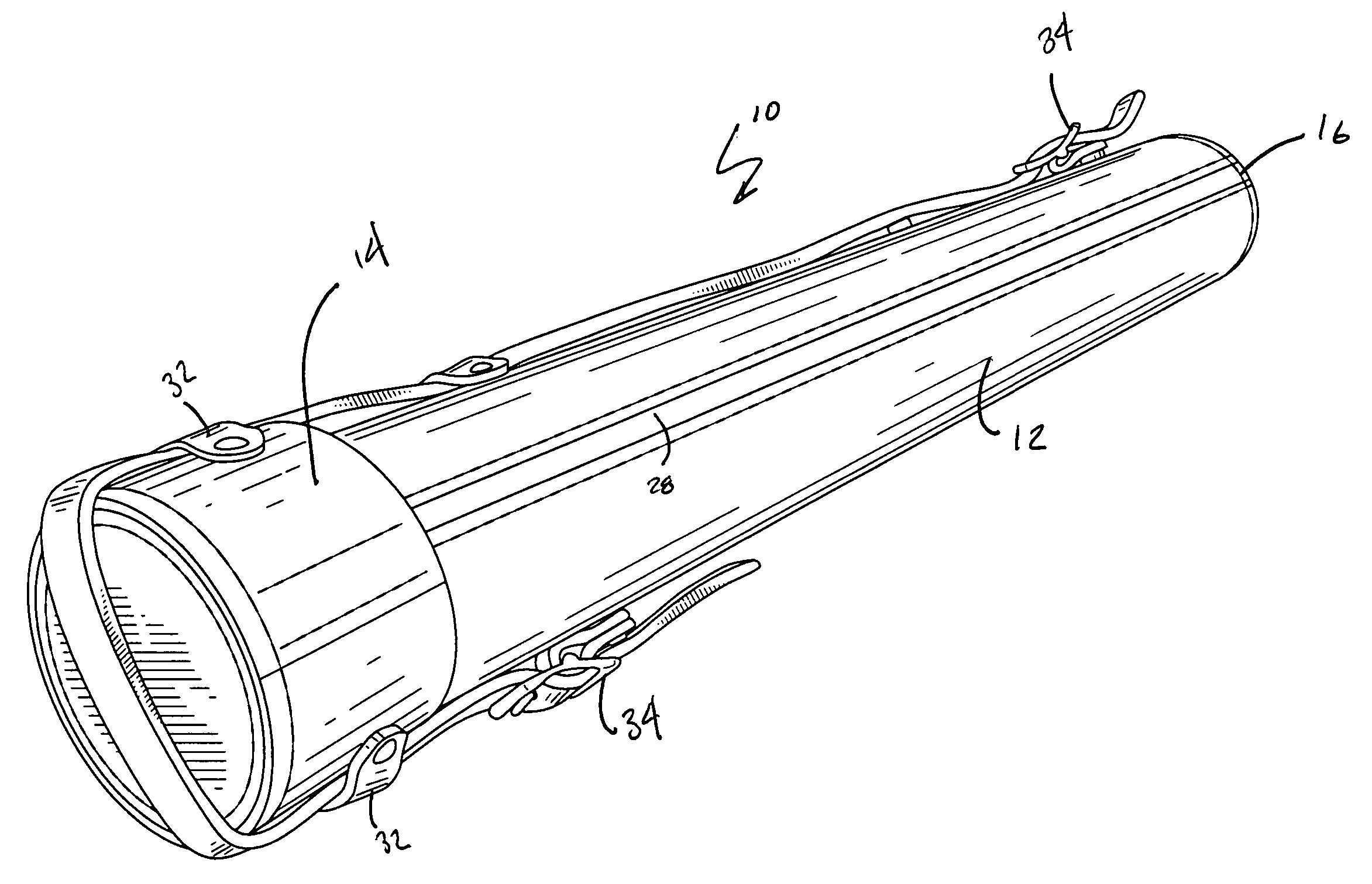

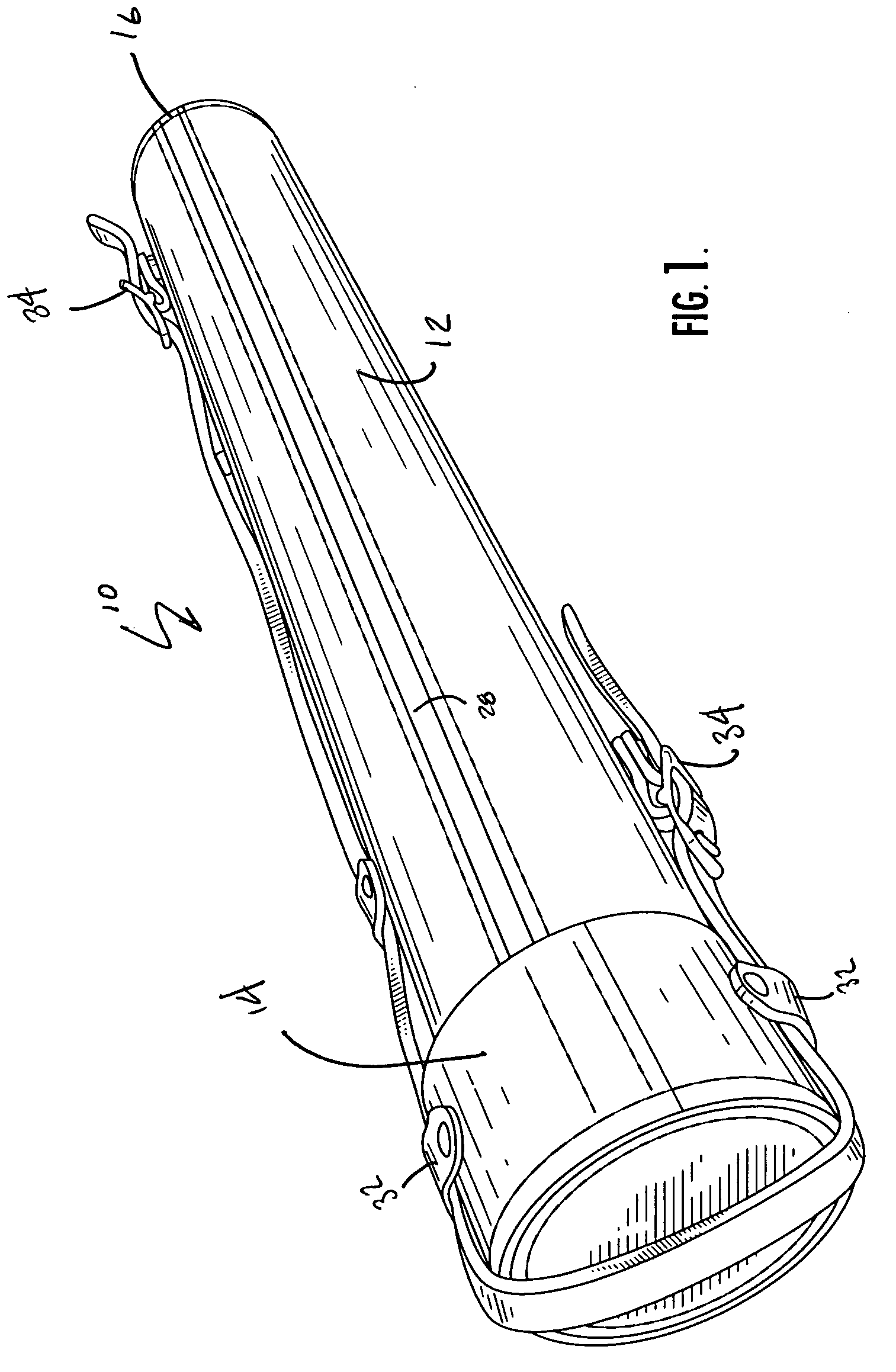

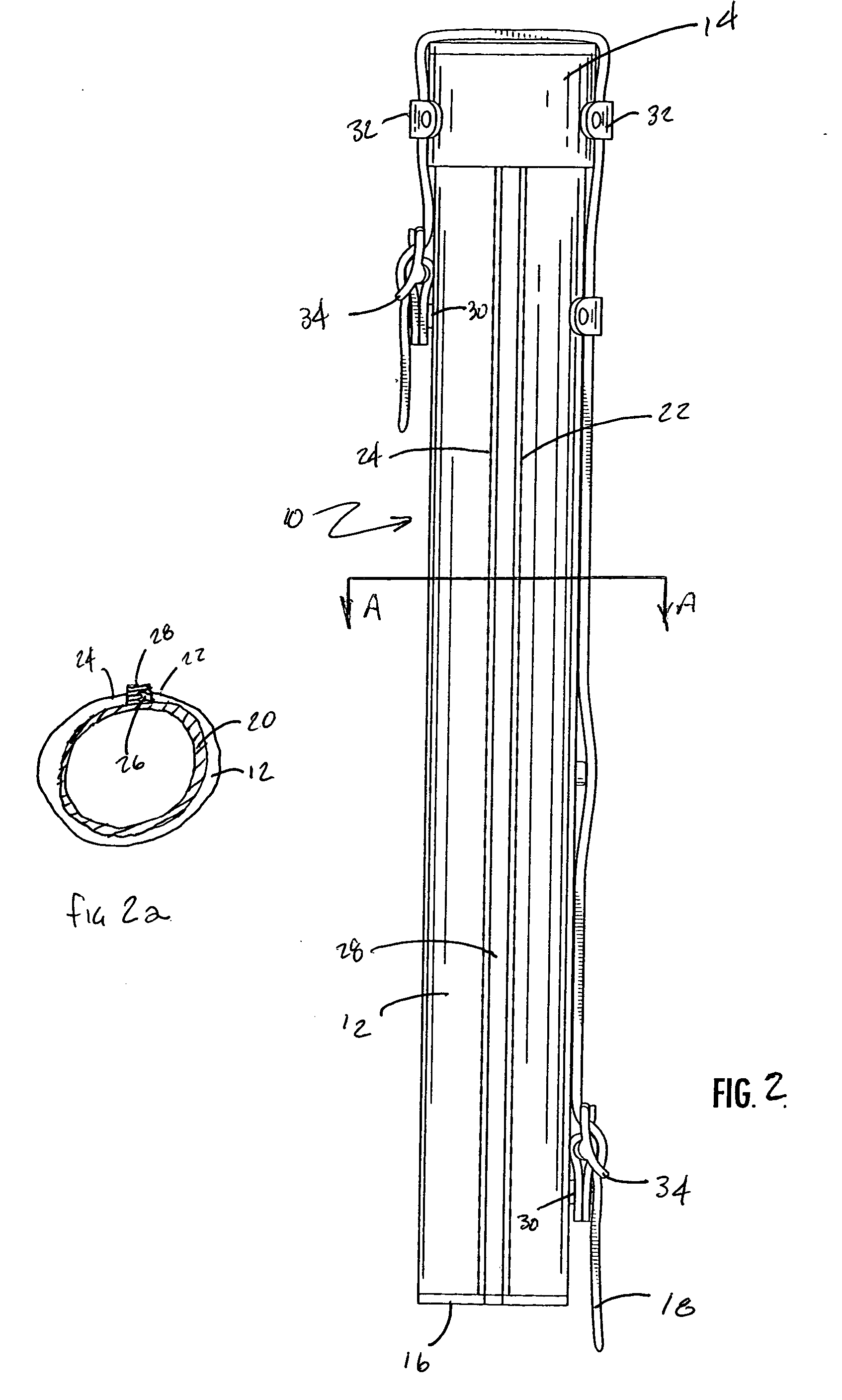

Method of manufacturing a tubular storage assembly

InactiveUS20050103790A1Easy maintenanceUniform appearanceLuggageOther accessoriesState of artEngineering

A tubular storage assembly and method of making the same is disclosed. The present invention provides a tubular storage assembly that has an outer shell of heavy weight material such as an un-cut leather hide. The outer shell material is formed into the desired shape having two opposite edges that are configured to mate in the finished assembly. A zipper or other suitable fastening system is stitched onto the opposite edges while the shell material is flat. The mating edges are drawn together and the fastening system engages to retain the shell in the tubular formation. Finally the fasteners are concealed by permanently adhering a cover strip over the fastening system. As can be seen in this manner the formation of a fully stitched tubular storage assembly is provided that overcomes the de-lamination problems often encountered in the prior art.

Owner:MASSO ROBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com