Pump dispenser and method of assembly of such a dispenser

A dispenser, container technology, used in packaging, spray devices, transportation and packaging, etc., to solve problems such as product extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

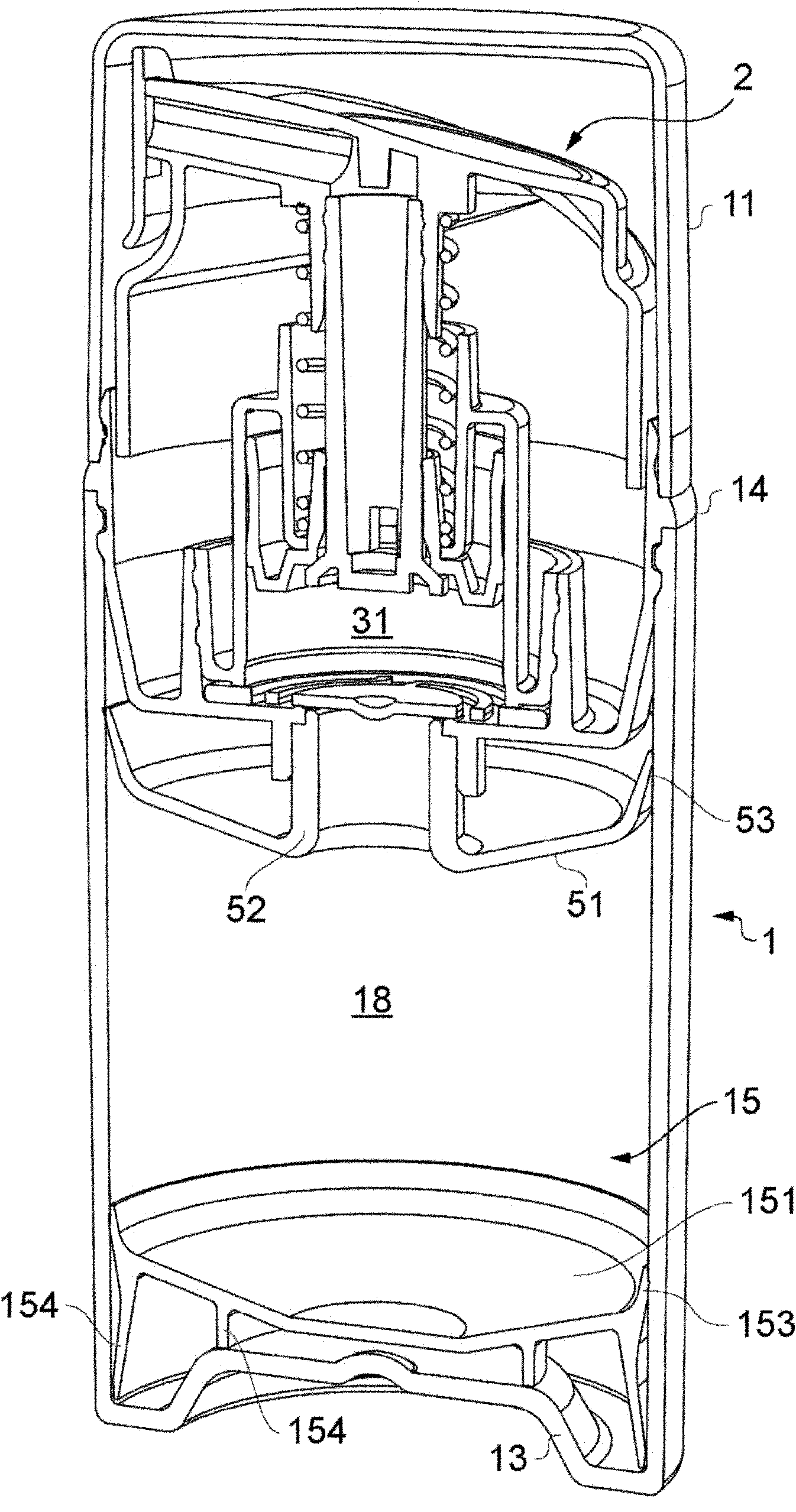

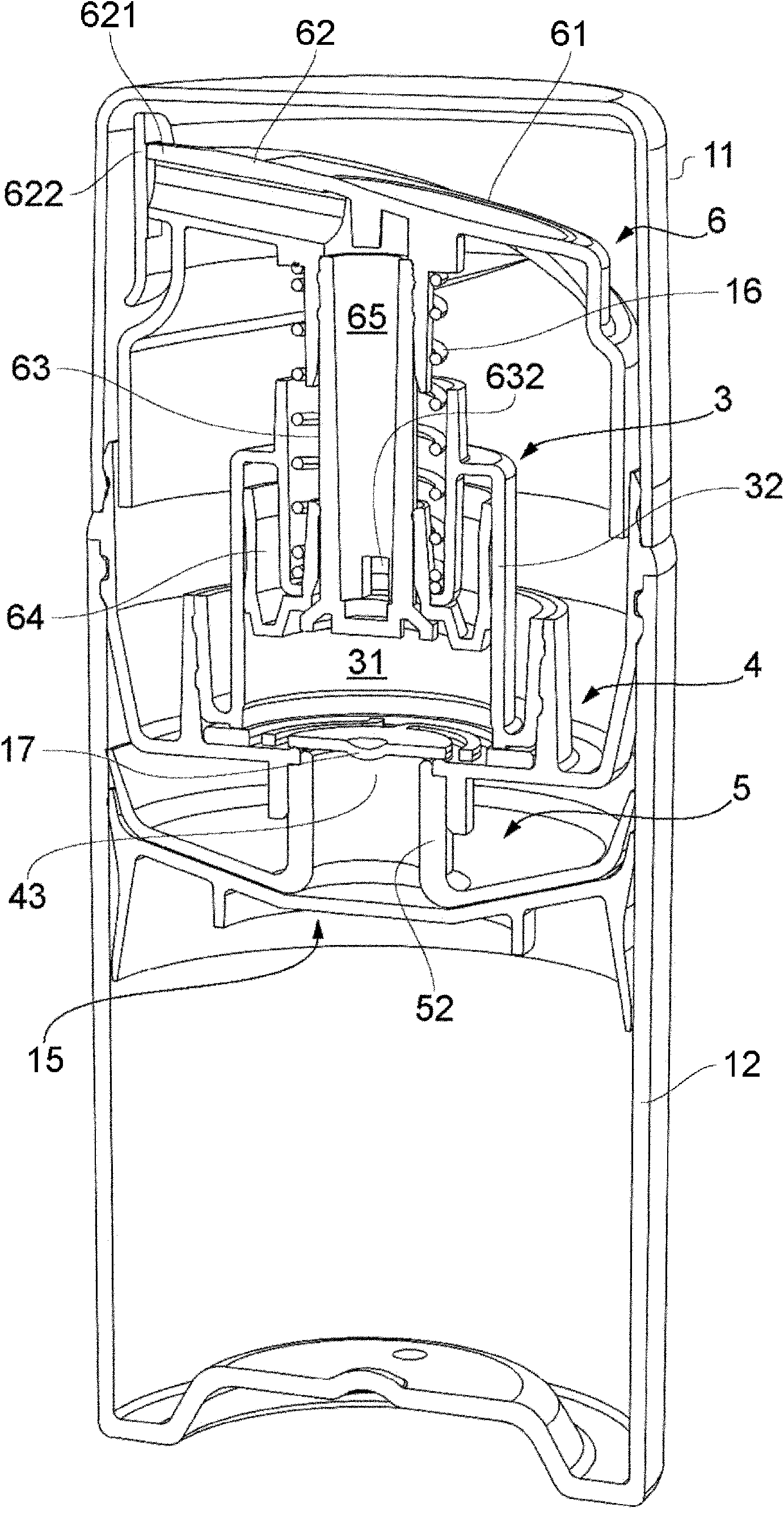

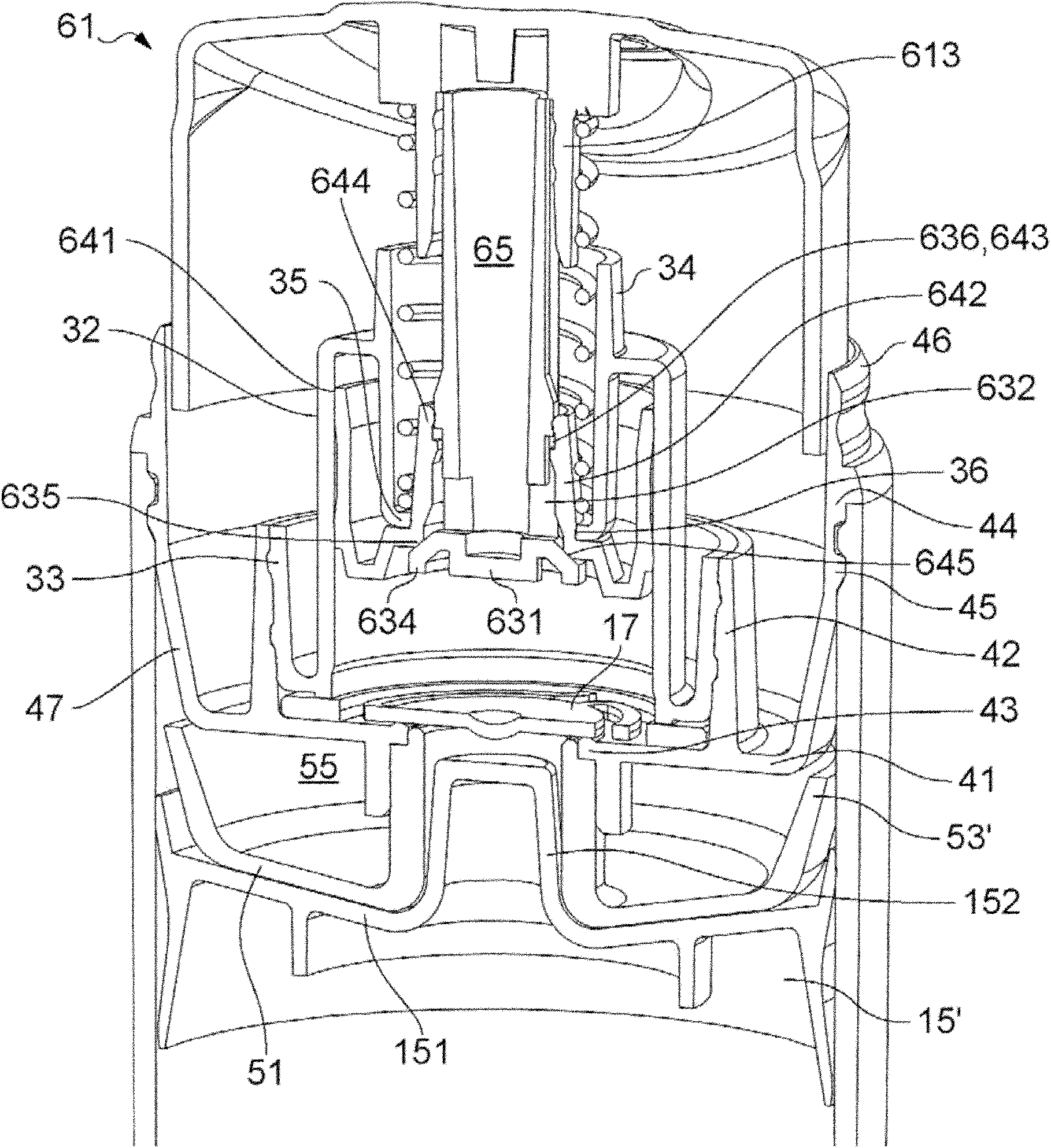

[0049] refer to Figures 1 to 3 , the hand-operated dispenser includes a cylindrical container 1 , a pump module 2 installed in a circular neck opening 14 of the container and a cap 11 covering the pump module 2 . The main components of the pump module 2 are the pump plunger 6 , the pump body 3 , the pump body base or adapter 4 and the accumulation insert 5 . See figure 2 .

[0050] A circular follower piston 15 operates in the interior space 18 of the container 1 . figure 1 shows the initial position when the container is full, figure 2 is the final position when all possible products have been allocated. The follower piston 15 has a circular sealing lip 153 , a disc-shaped central web 151 and an annular support rib 154 which initially supports the central web above the container base 13 .

[0051] In a generally conventional manner, manual depression of the plunger 6 against the pump spring 16 reduces the volume of the pump chamber 31 defined by the cylinder 32 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com