Modular sump pump pit assembly

a sump pump and module technology, applied in the direction of pumping, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of limited height clearance in many crawl spaces, significant difficulty in adding a sump pump system to an existing building, etc., and achieve the effect of convenient portability and added durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

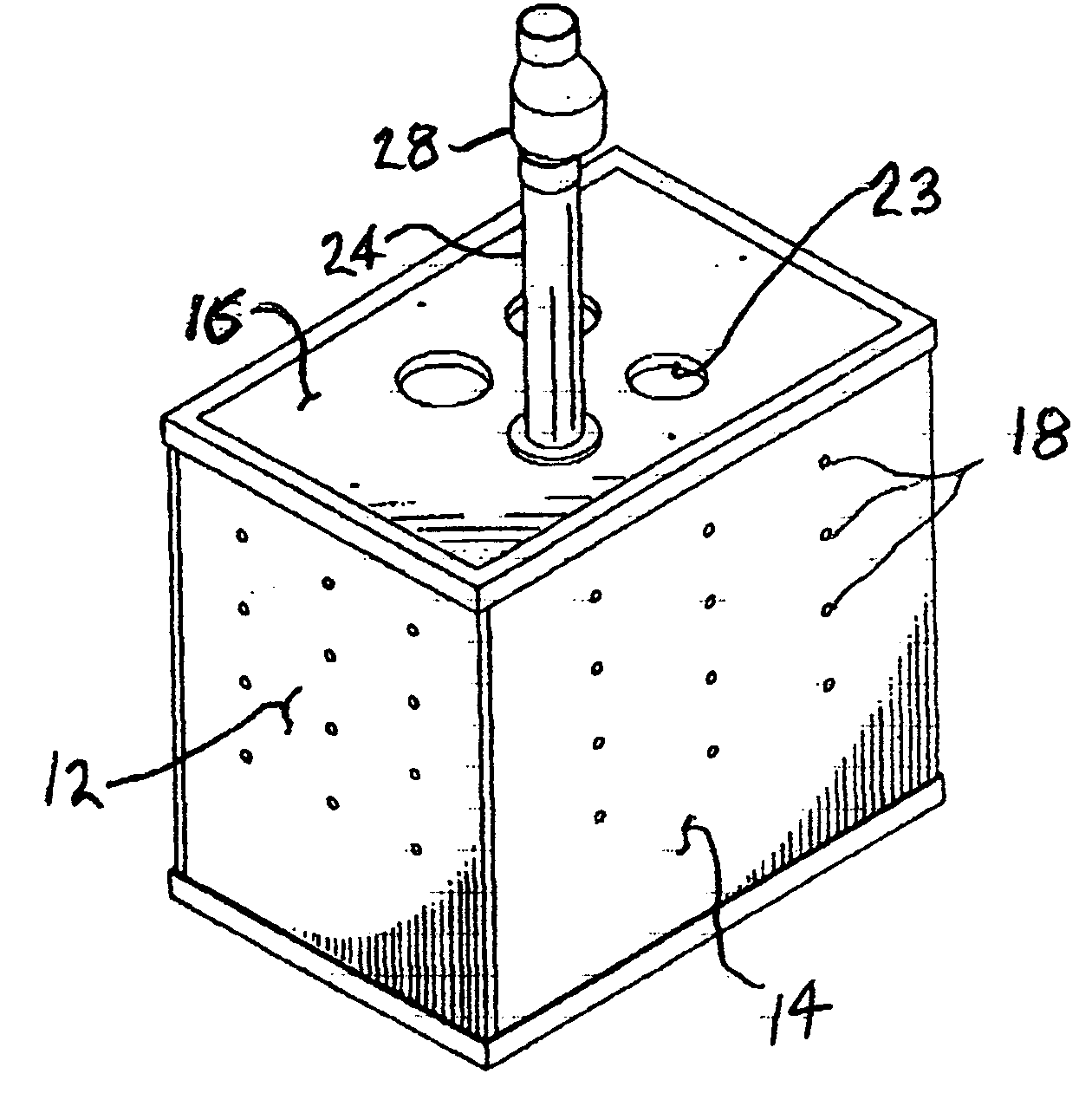

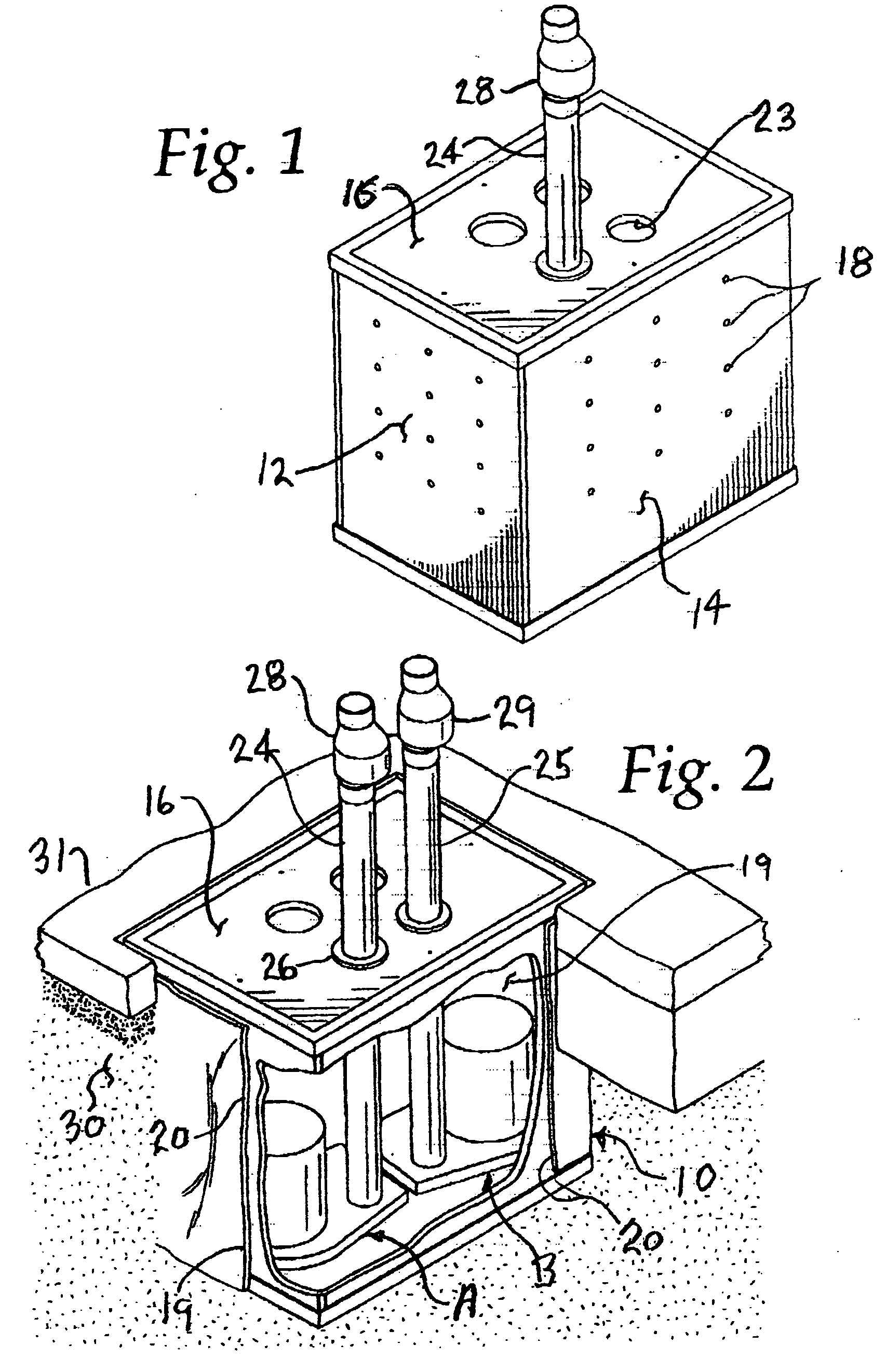

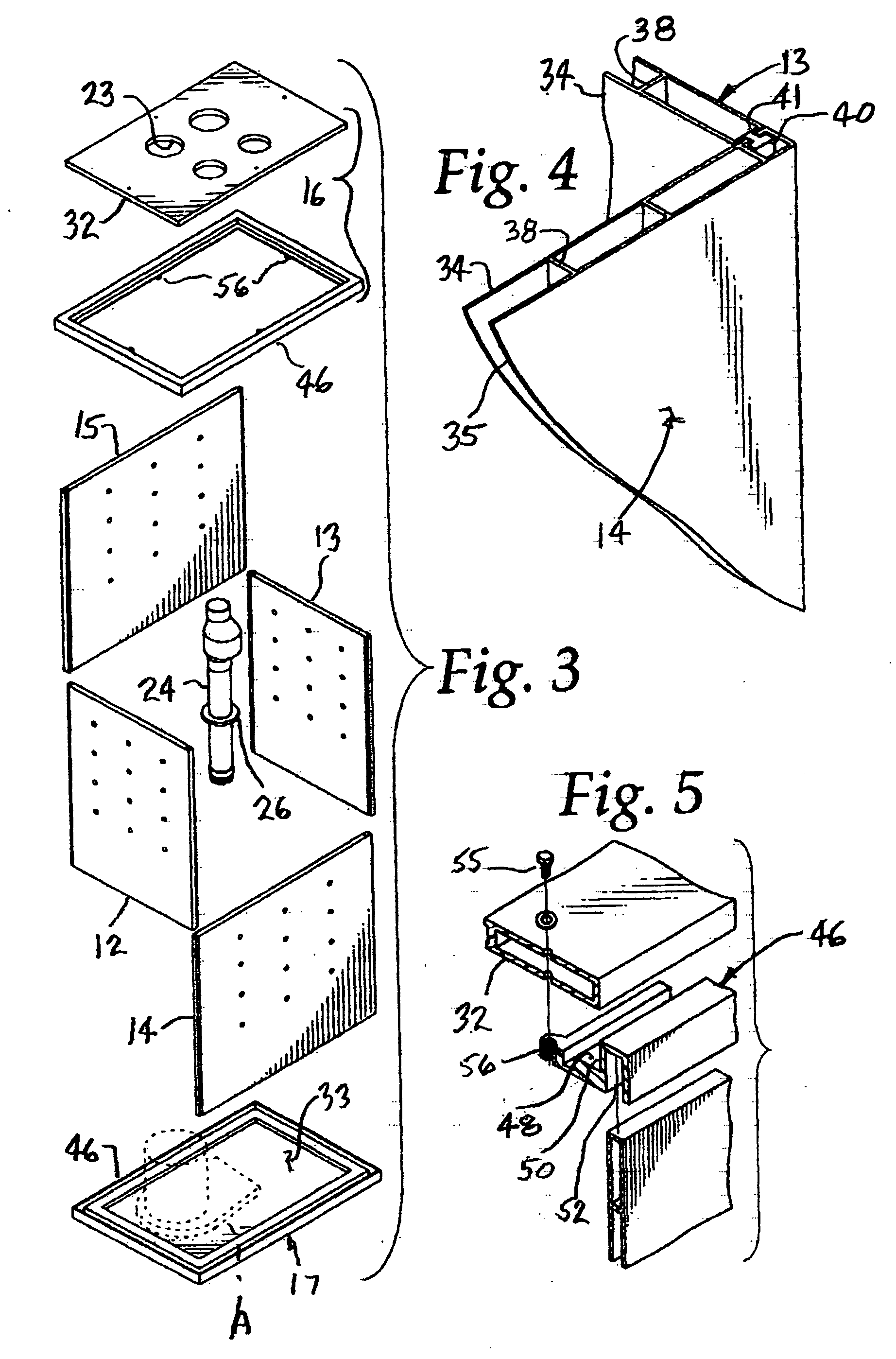

[0017]The invention provides an improved sump pump pit 10 of generally rectangular cross section, suited to hold side-by-side two sump pumps, such as but not limited to the combination of a conventional AC electric utility powered pump “A” and a DC storage battery powered backup pump “B”.

[0018]The inventive sump pump pit 10 utilizes a multiple component construction, comprised of two pairs 12, 13 and 14, 15 of similar rectangular side walls, and two generally similar rectangular top and bottom walls 16, 17, to define a pit enclosure 19. The pit side walls 12, 13, 14 and 15 can have many small openings 18 therein suited to allow water to pass inwardly to the pit enclosure 19. A porous fiber mesh wrap 20, such as of a geotextile material, can if desired overlie the side walls to filter stones or like solid debris from passing into the pit enclosure, which could damage the pump if pumped through it.

[0019]The two independent pumps “A” and “B” can be housed in the sump pit enclosure 19, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com