Measuring device

a technology of measuring tape and tape, which is applied in the direction of measuring devices, instruments, and using mechanical means, etc., can solve the problems of high possibility of error in the transcribing of the measurement viewed by the user onto paper, frequent interruption by busy professionals, and easy for such a user to view the measurement printed on the tape. to achieve the effect of reducing the possibility of transcription errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

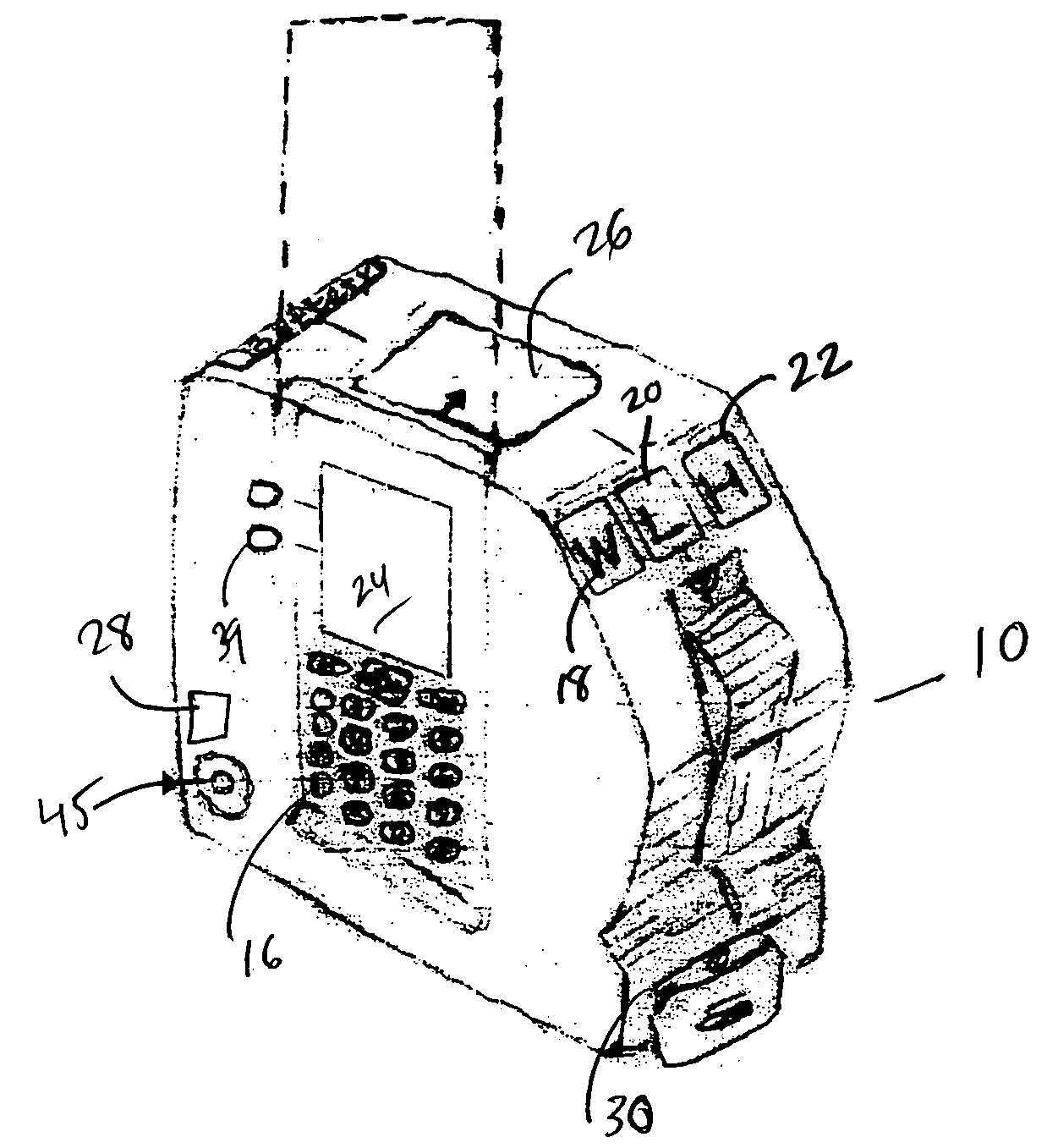

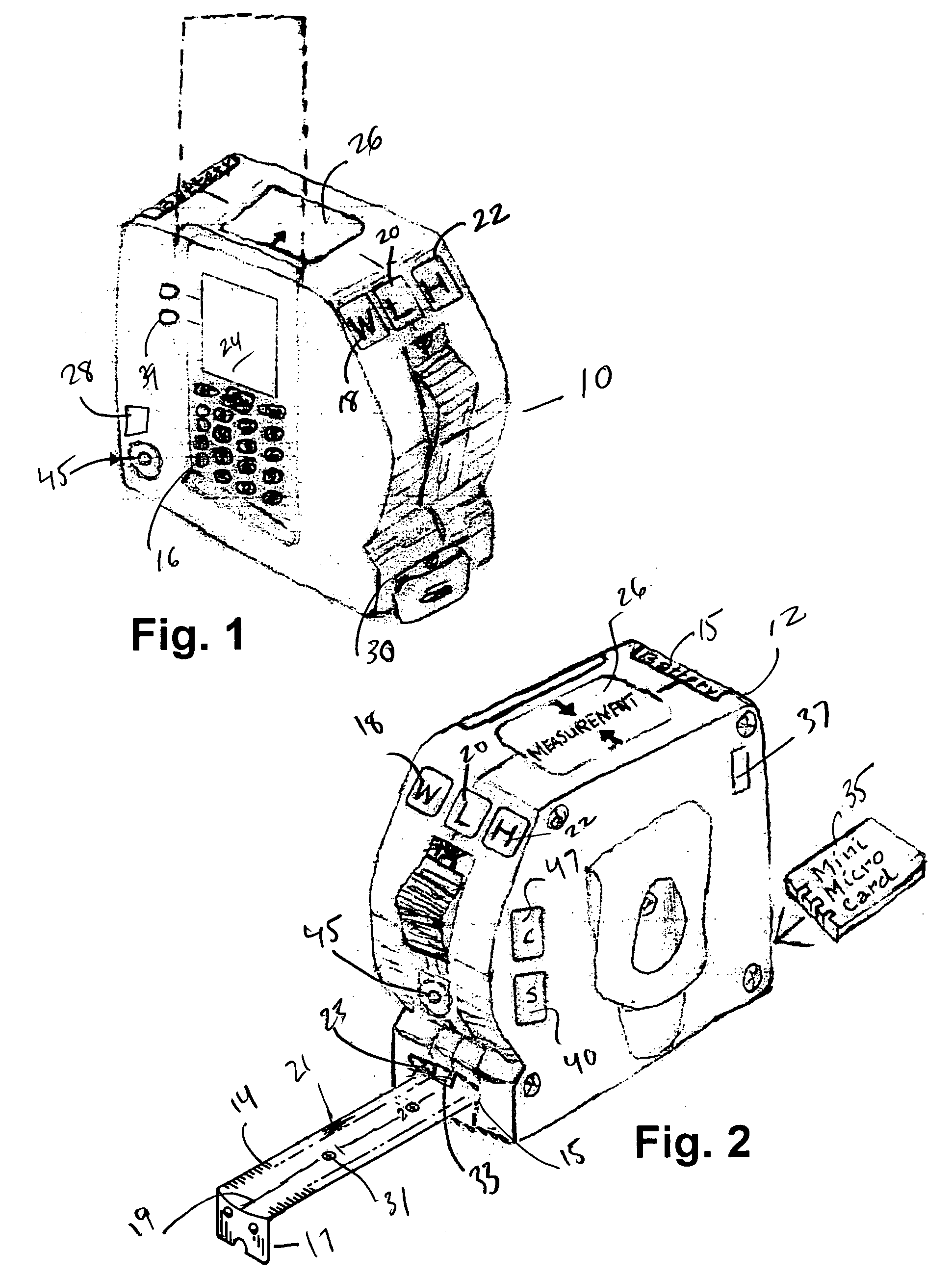

[0038]Referring now to the drawings 1-2, wherein similar parts of the invention are identified by like reference numerals, there is seen in FIG. 1 a perspective view of the disclosed device 10 showing the housing 12 which houses the extendable tape 14. Also engaged to the housing is an alphanumeric input pad 16 a plurality of function keys for width 18, length 20, and height 22 input designation, a video display 24, and an electronic measurement display 26 which can be either an LCD or LED or similar electronic means for display will provide a user-readable display of the electronic rendition of the measurement taken with the tape 14. Of course the device will function with a single electronic video display 24 producing the graphic displays of both the video display 24 and the measurement display 26. However, both displays make the device easier to use if the measurement display is on a top surface and easy to view while measuring. This user-readable display 26 can be used to both v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com