Manifold for a Two-Phase Cooling System

a manifold and liquid cooling technology, applied in the direction of engine diaphragms, diaphragm valves, lighting and heating apparatus, etc., can solve the problems that conventional dry thermal management technology, air convection using fans and heat sinks, is simply not capable of efficiently thermally managing modern electronics, etc., to achieve cost-effective production and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A. Overview

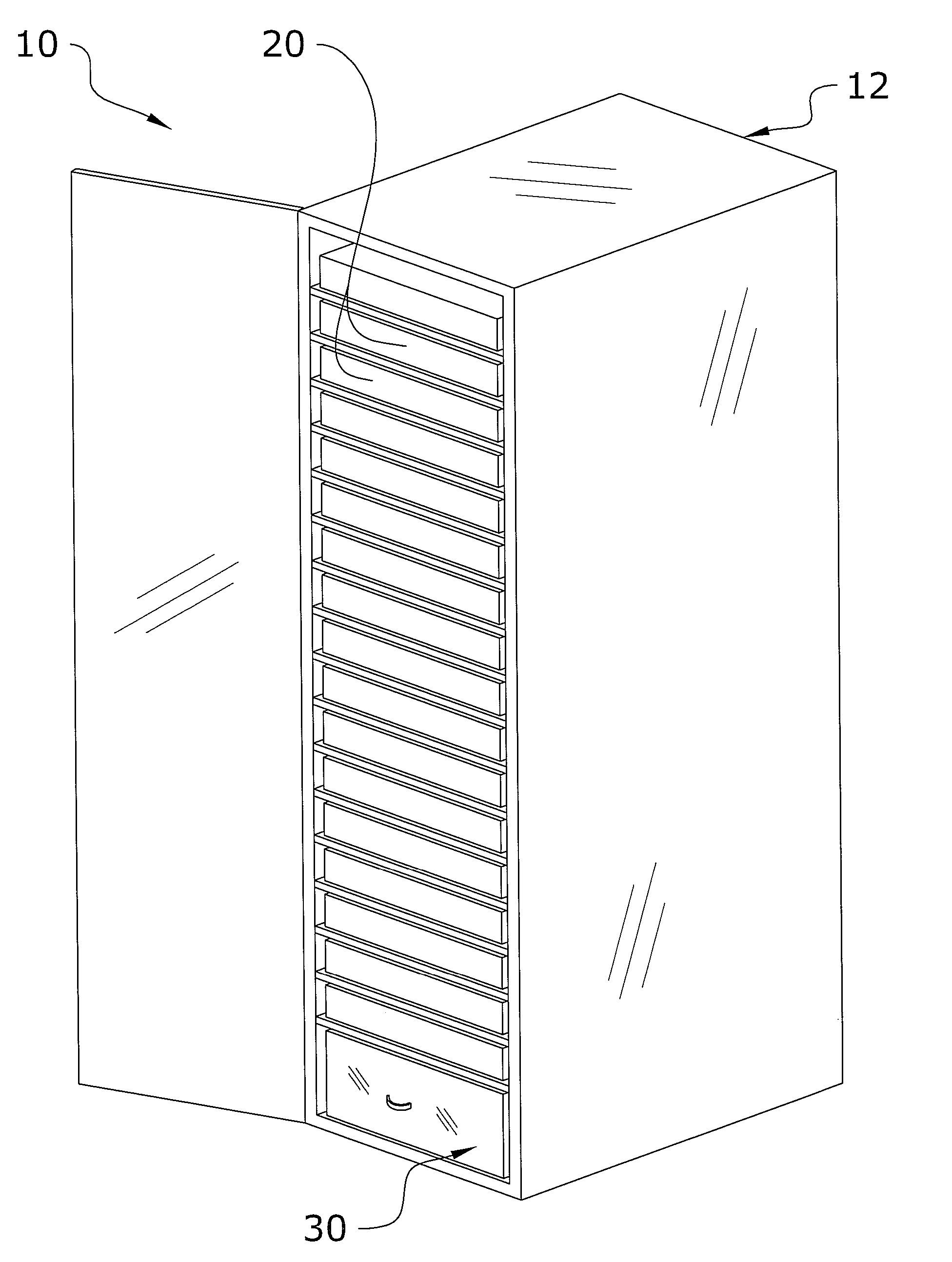

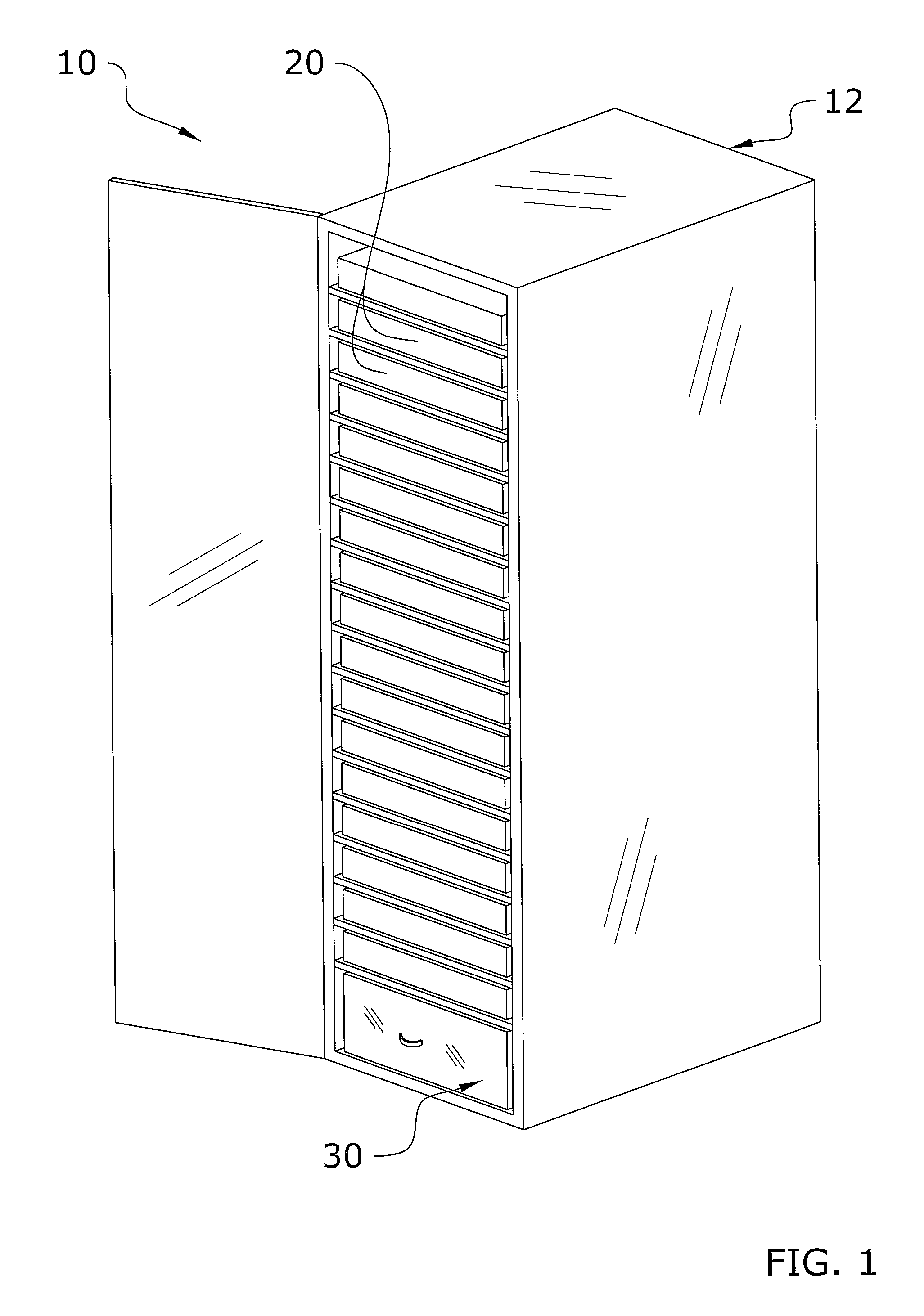

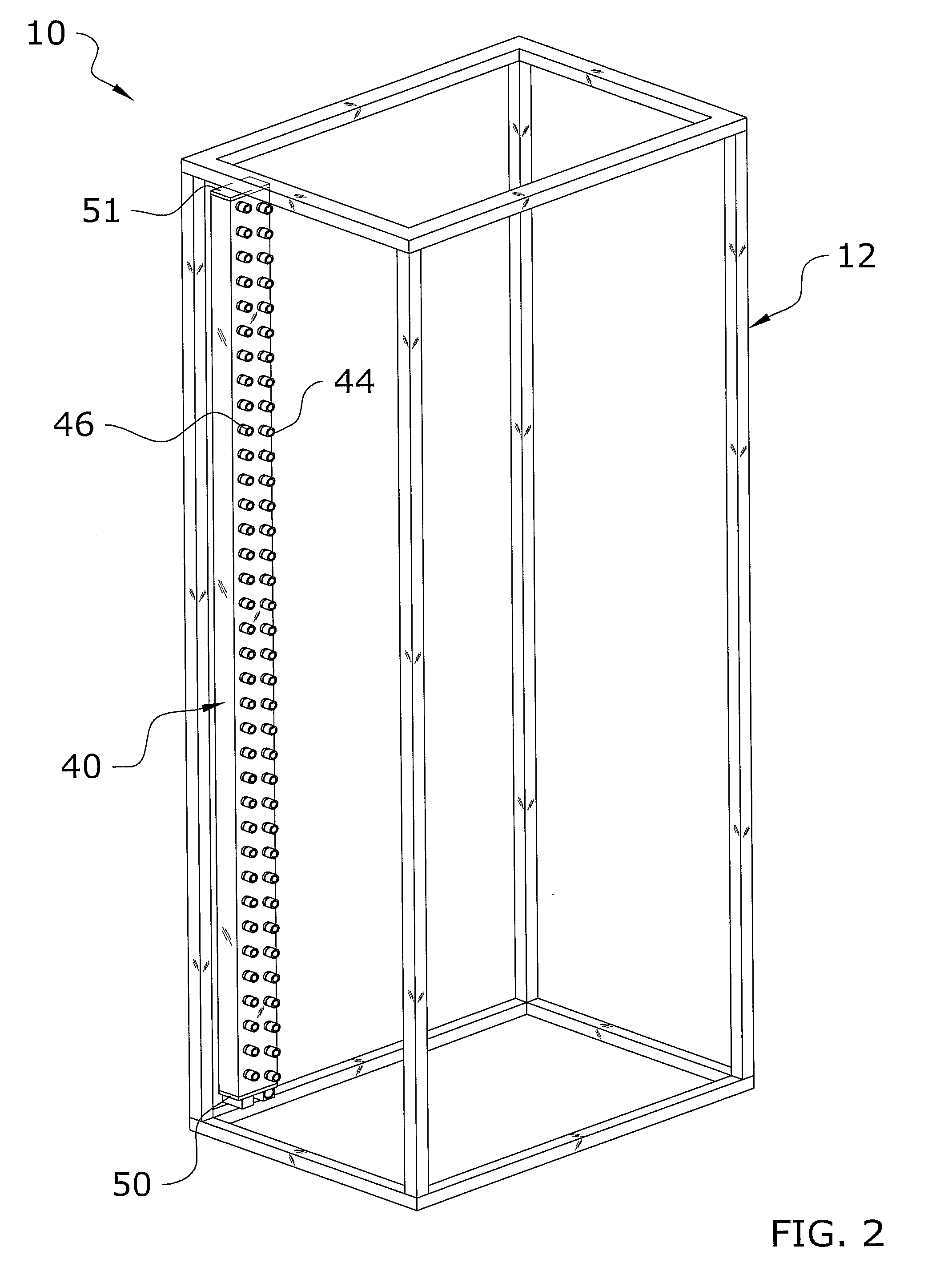

[0033] Turning now descriptively to the drawings, in which similar reference characters denote similar elements throughout the several views, FIGS. 1 through 11 illustrate a manifold for a two-phase cooling system 10, which comprises an extruded manifold having a supply chamber and a return chamber in thermal communication with one another.

B. Rack

[0034] Now referring to FIG. 1, rack system is comprised of a network rack 12 housing one or more servers 20. As is well known in the art of computer electronics and datacenters, the rack 12 provides incremental mounting positions to the servers 20. The servers 20 can be a wide range of sizes ranging from 1 U (1.75″) to greater than 12 U, or blade style. A typical seven foot tall rack 12 can provide 42 rack mounting locations.

C. Thermal Server

[0035] In the preferred embodiment of the present invention, at the bottom of rack system 10 is at least one thermal server 30. As shown in FIG. 1 of the drawings, the thermal server 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com