Asymmetric compressor air extraction method

a compressor and air extraction technology, applied in the direction of combination engines, machines/engines, liquid fuel engines, etc., can solve the problems of significant off-design aerodynamic conditions, rotating stalls in axial flow compressors, and limited variable stage geometry of traditional axial flow industrial gas turbine compressors. achieve the effect of preventing the formation of coherent unsteady loads, reducing or eliminating coherent aerodynamic forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

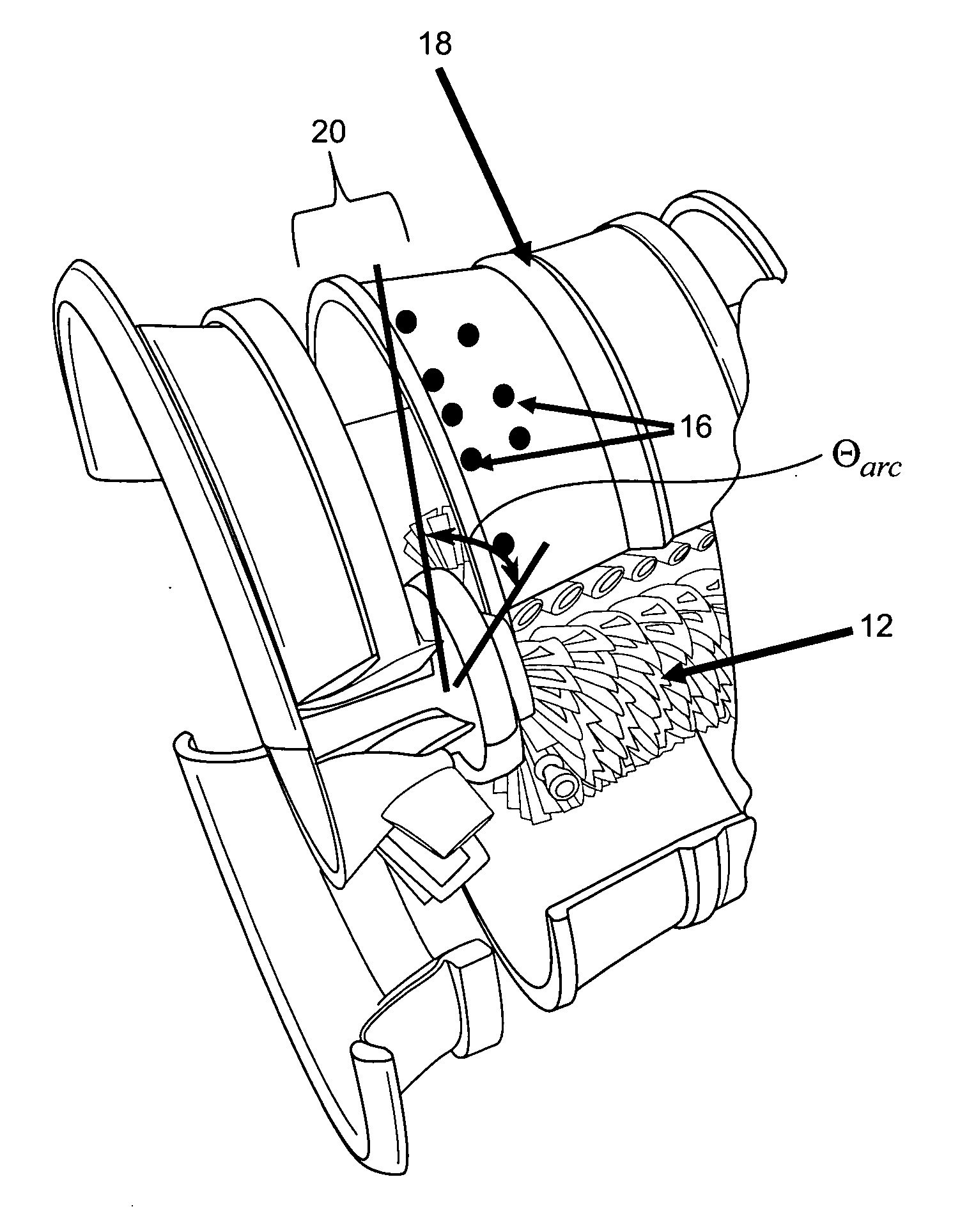

[0009]Power generation industrial axial flow gas turbines are designed to optimally operate at a fixed rotational speed and output. In addition, traditional axial flow industrial gas turbine compressors have limited variable stage geometry and air extractions. These three factors lead to significant off-design aerodynamic conditions during start-up and shutdown operations. Rotating stall can occur in axial flow compressors during these off-design operations.

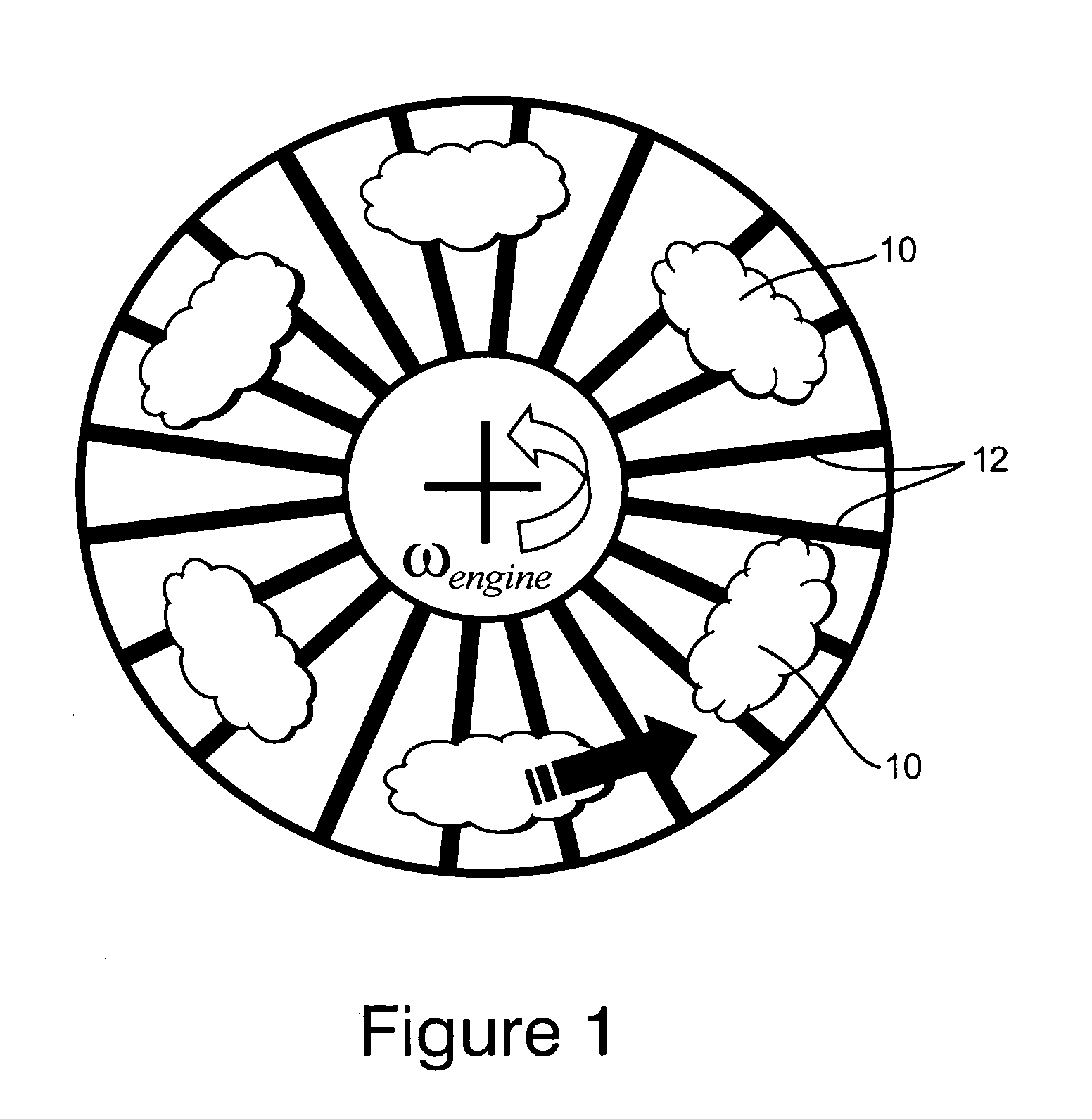

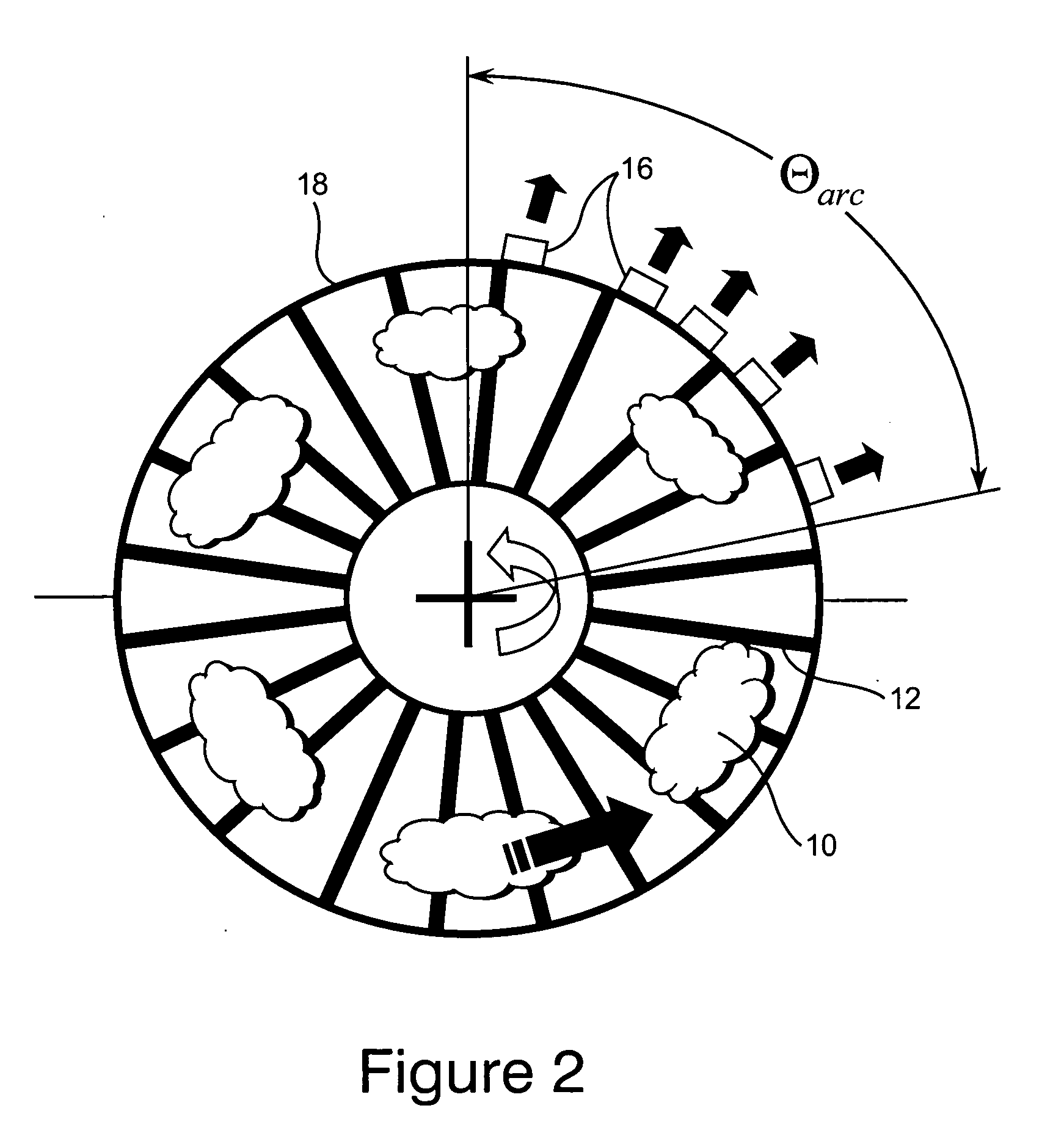

[0010]Rotating stall, schematically presented in FIG. 1, manifests itself as local stall cells 10 that rotate at about half the wheel speed (ωstall cells≈½ωengine). These stall cells provide coherent unsteady aerodynamic loads on both the rotor and stator blades 12. As the rotor changes speed, the stall cell count changes thereby setting up different excitation characteristics known as nodal diameters. The vibratory response on the rotor and stator blades from the rotating stall aerodynamic loads may lead to increased sensitivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com