System and method for forming flush joints between adjacent wallboard panels

a technology of flush joints and wallboards, applied in the direction of walls, coverings/linings, constructions, etc., can solve the problems of reducing the installation efficiency of drywall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

,” one will understand how the features of the preferred embodiments provide advantages over prior art systems.

[0009]One such advantage is that the system and method can be easily and conveniently implemented to form aesthetically appealing, flat and smooth drywall joint areas without requiring complex or multiple process steps. Additionally, the system and method also provide a finished drywall with improved shear strength and a joint area that is not susceptible to deformation over time due to moisture movement of the building frame.

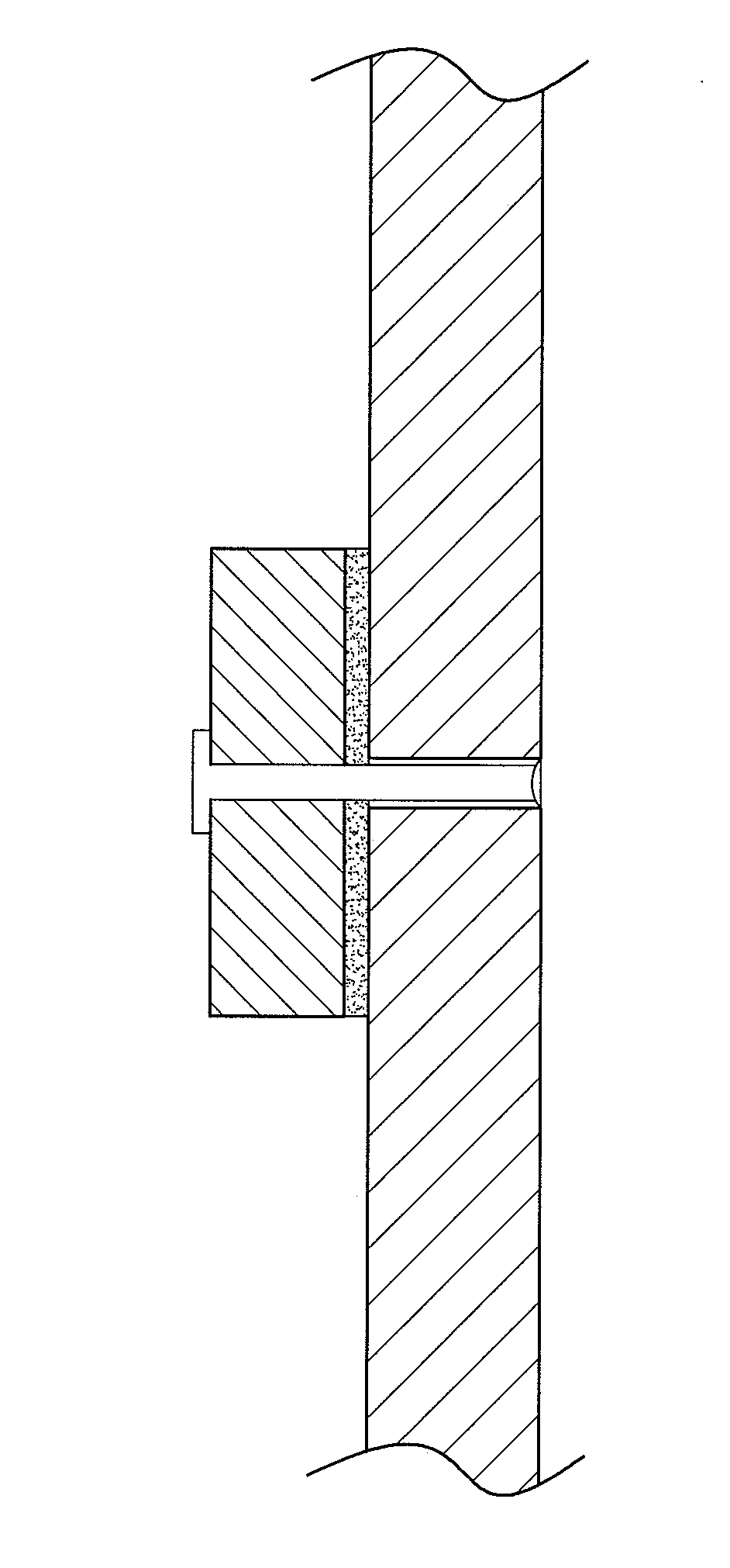

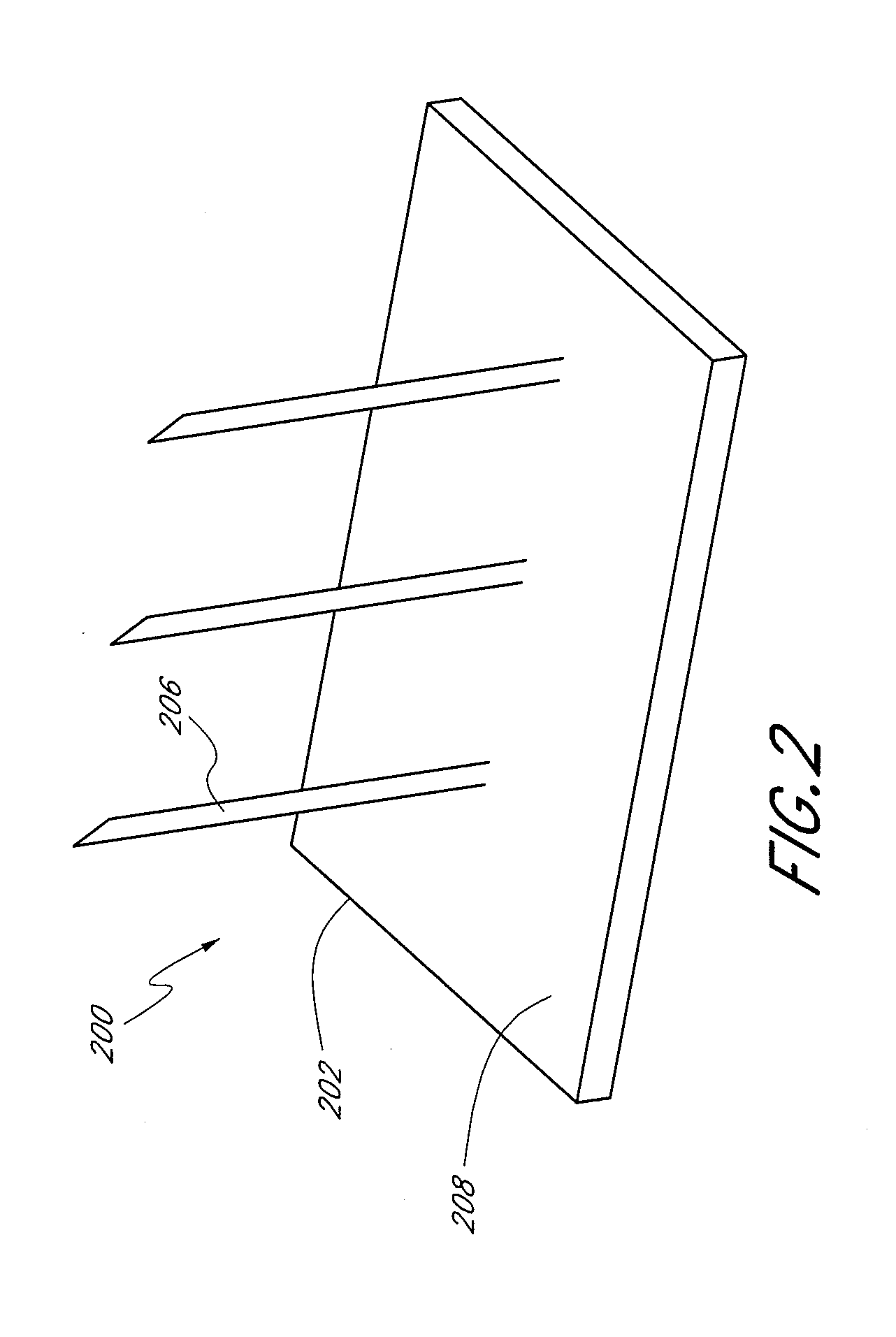

[0010]In one embodiment, the present invention provides a system for forming flush joints between wallboard panels. The system comprises a back support adapted to be attached to a back side of two wallboard panels and sized to extend across at least a portion of a joint area; a front support adapted to extend across at least a portion of the joint area on the front side of the panels; and an interconnect member, wherein the interconnect member is adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com