Package

a technology for packaging and bottles, applied in the field of packaging, can solve the problems of relatively labor-intensive filling and maintaining the squeeze bottle, and achieve the effects of enhancing food safety, reducing the amount of air, and increasing the period of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

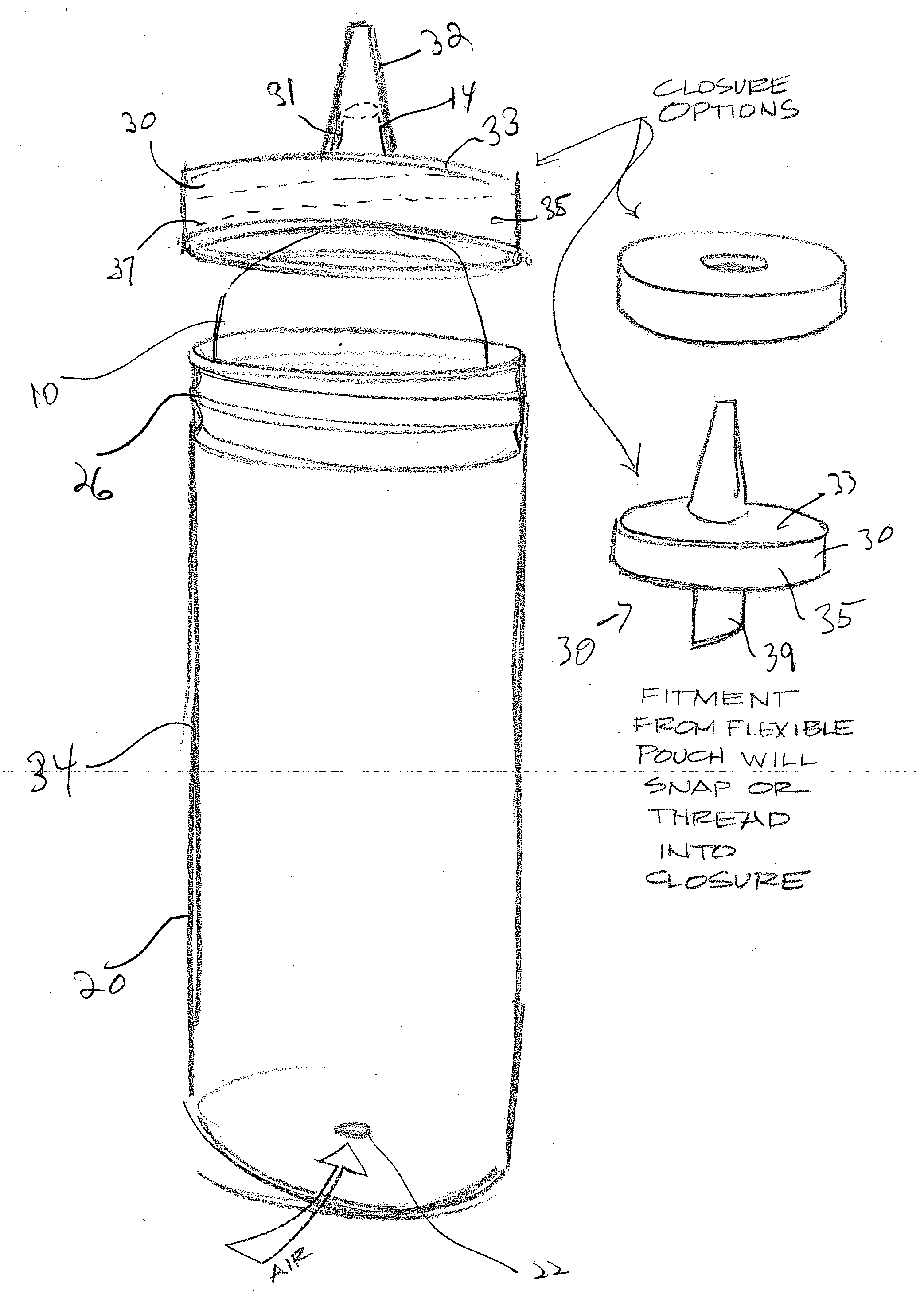

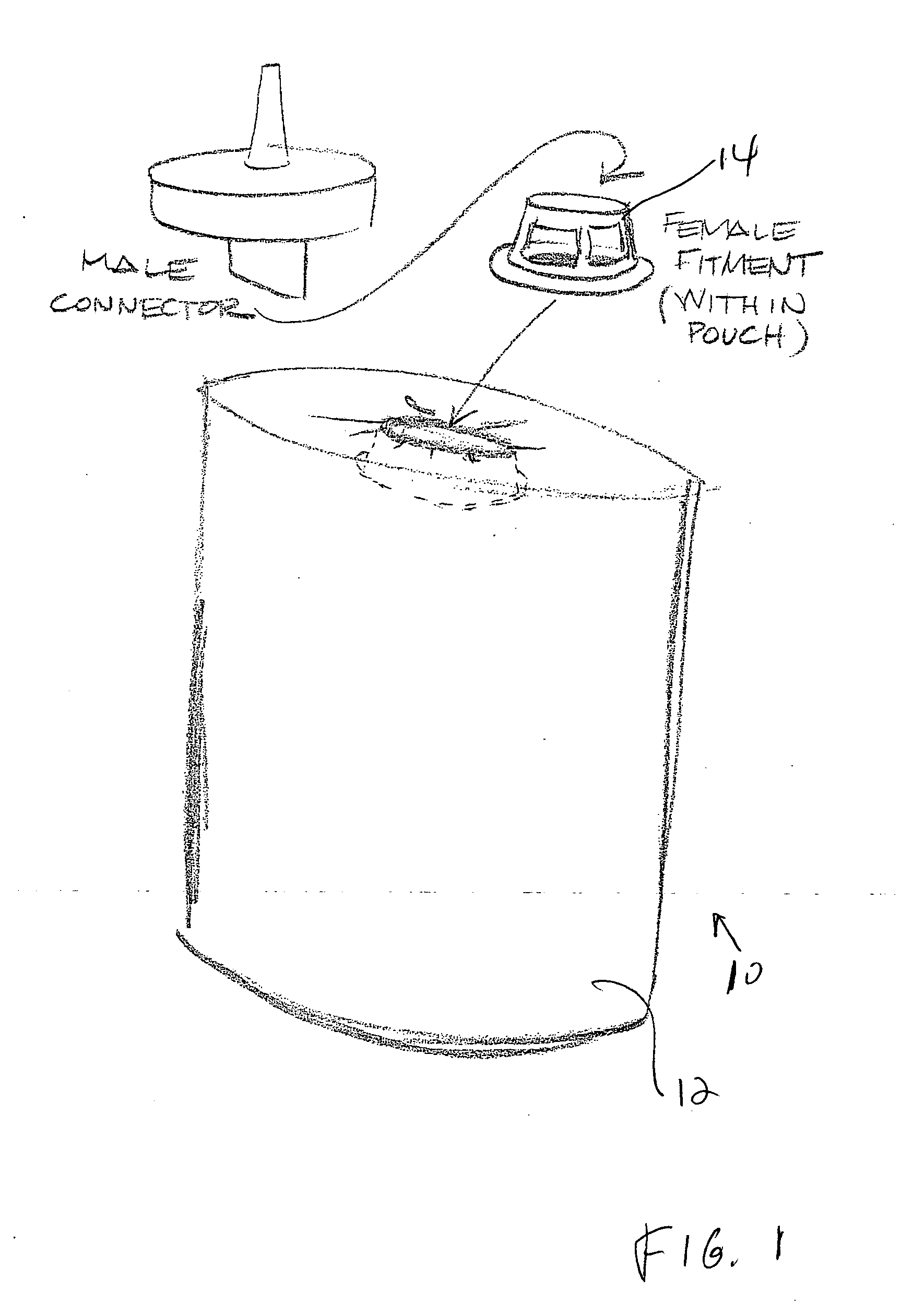

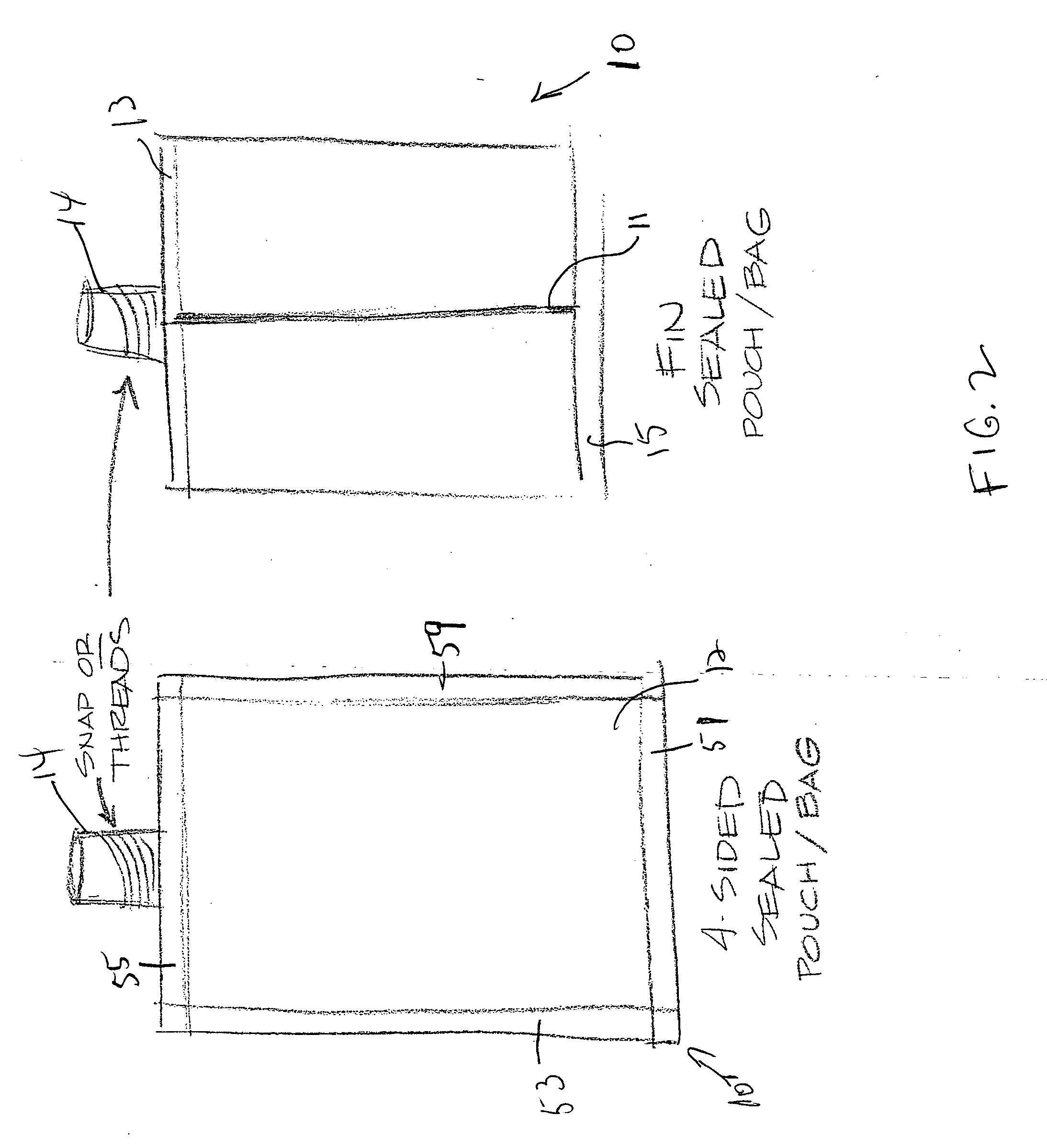

[0038]Liner 10 comprises product receiving pouch 12 and annular peripheral sealing surface 14. Liner 10 may be made of any material suitable to contain food and to be placed within an outer container. An appropriate liner 10 would be one available from PBM Plastics of Newport News, Va. which is sold as a consumer squeeze bottle liner. The PBM Plastics liner is made using their melt phase forming process. Melt phase forming utilizes billet technology. The billet or “puck” is heated to its melt temperature and then drawn and forced by air into a mold cavity. The technology allows a thin wall deep draw container with a dimensionally stable container opening. The container opening is preferably a flange, but may also include a ridge, a lip or other structure which provides a surface area for sealing a lid to the container and also provides a means to capture the container inside the squeeze bottle. The flange is, in effect, pinched between the top rim of the bottle 20 and the sealing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com