Method and apparatus for servicing a pressurized system

a technology for pressurizing systems and equipment, applied in lighting and heating equipment, container discharge methods, cleaning methods using liquids, etc., can solve problems such as moisture and other contaminants entering the system, system performance can deteriorate, and the system can be easily damaged, so as to prevent or reduce refrigerant loss and injury, facilitate access, and increase the stability and grip of the member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

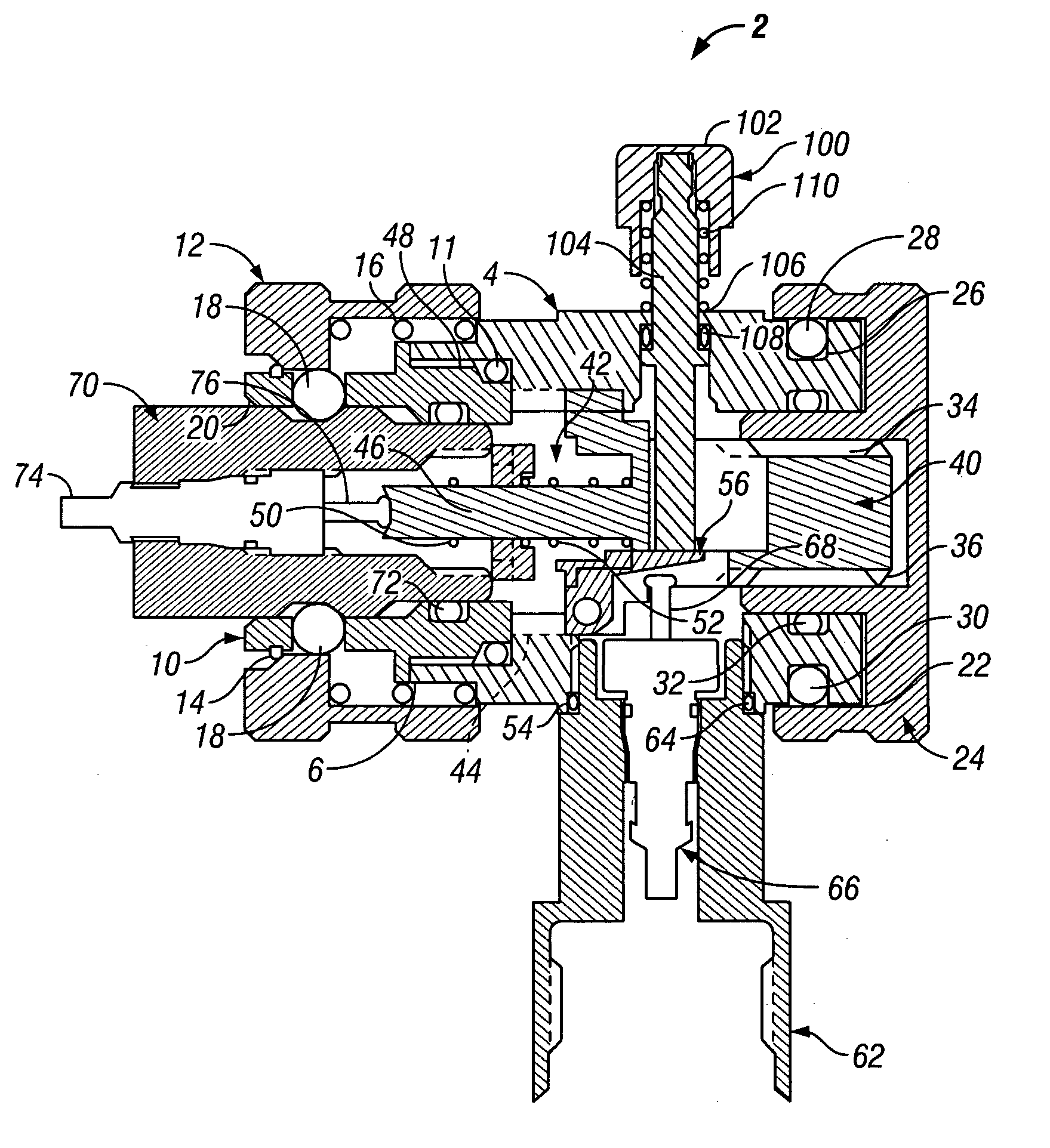

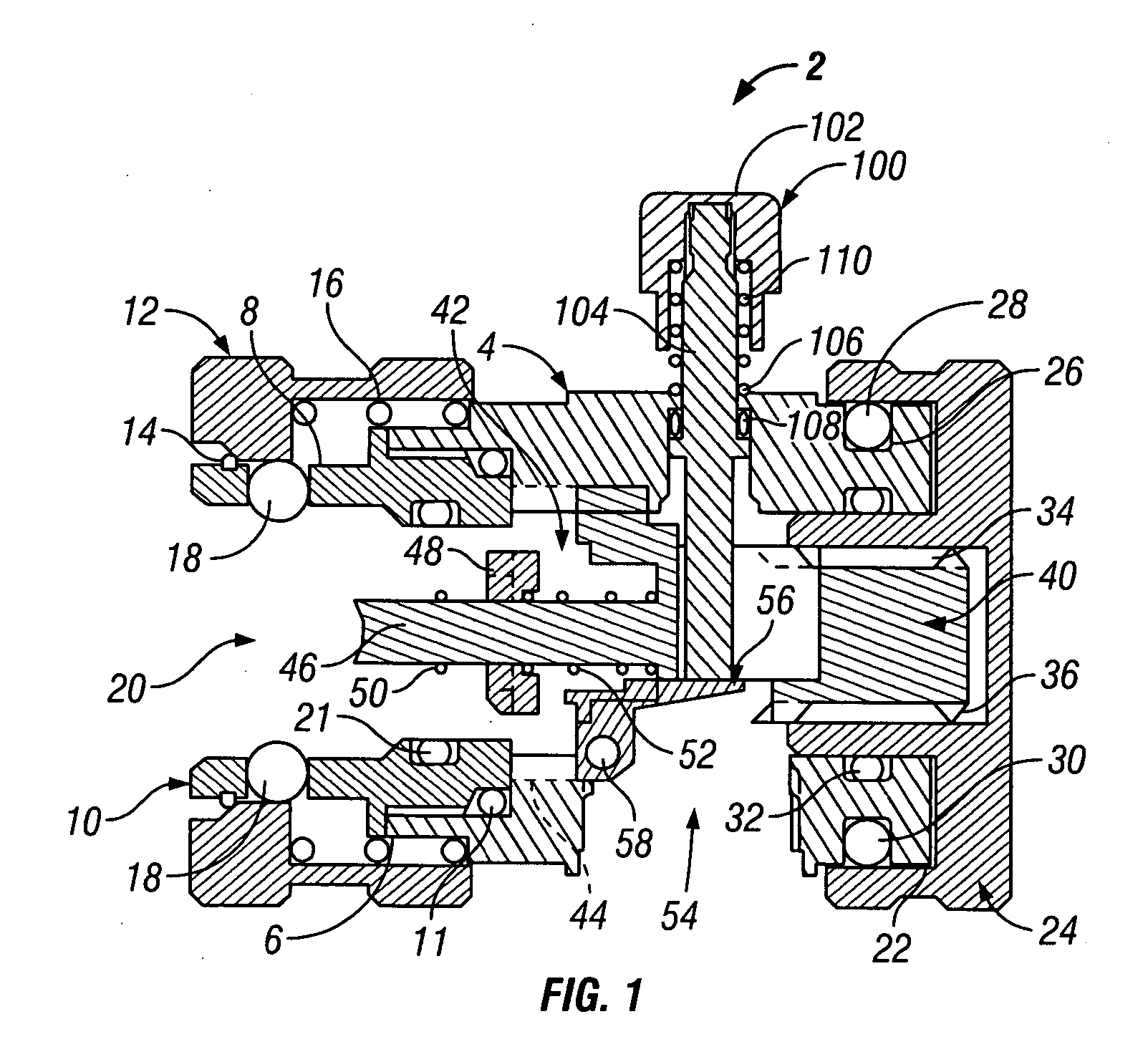

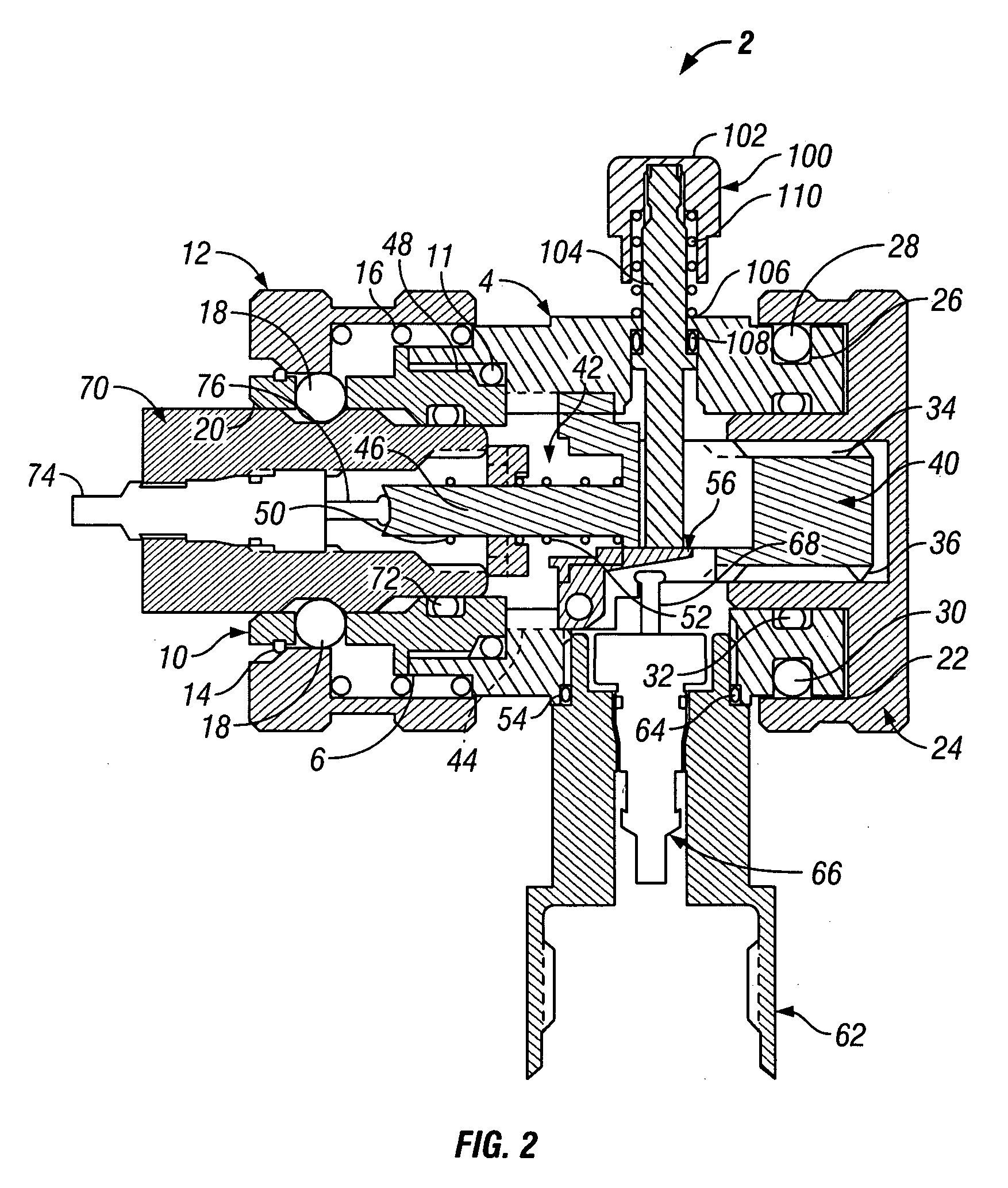

[0034] Referring to FIGS. 1-3, 5, and 6, coupling member 2 includes body 4. Body 4 has first end 6 attached to release sleeve assembly 8. Release sleeve assembly 8 includes adapter 10 which is attached by threads to first end 6. Alternatively, adapter 10 can be attached to first end 6 by pins, set screws, a snap ring, brazing, soldering, or swaging. O-ring 11 provides a fluid-tight seal between adapter 10 and body 4. Release sleeve 12 slides over adapter 10. Retaining ring 14 holds release sleeve 12 over adapter 10. Release sleeve spring 16 resides between release sleeve 12 and adapter 10 and pushes release sleeve 12 against retaining ring 14. When pushed against retaining ring 14, release sleeve 12 holds balls 18 within adapter 10. Balls 18 are distributed around the circumference of adapter 10. First end 6 includes orifice 20, which can receive a service port, which includes a valve, of a pressurized system. Balls 18 engage with the service port when the port is inserted into orif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com