Stent and Method for Manufacturing the Same

a technology of stents and wires, applied in the field of stents, can solve the problems of affecting the quality of products, and the elastic force of other wires, so as to reduce the damage of materials forming prevent the inadvertent dislocation of first and second members from a target place, and increase the elastic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will now be described more fully with reference to the accompanying drawings, in which an exemplary embodiment of the invention is shown.

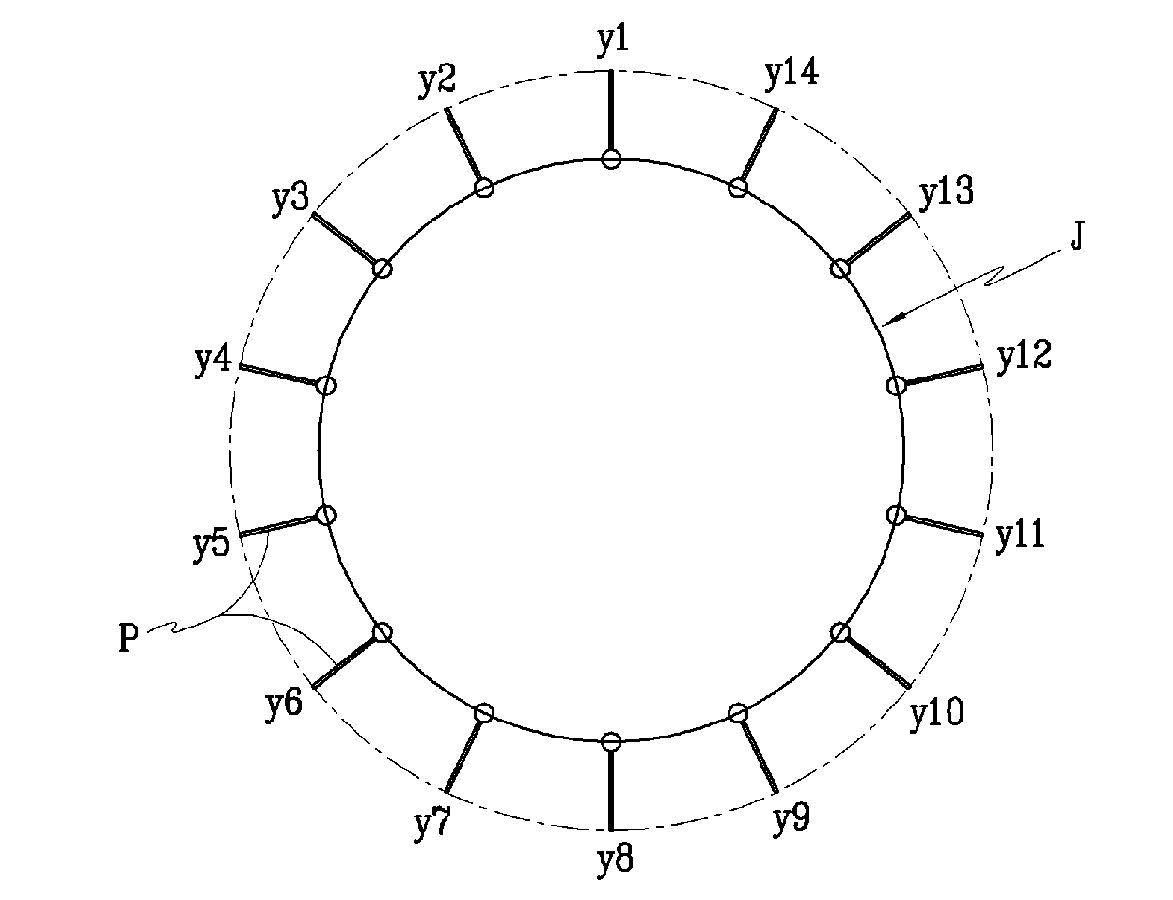

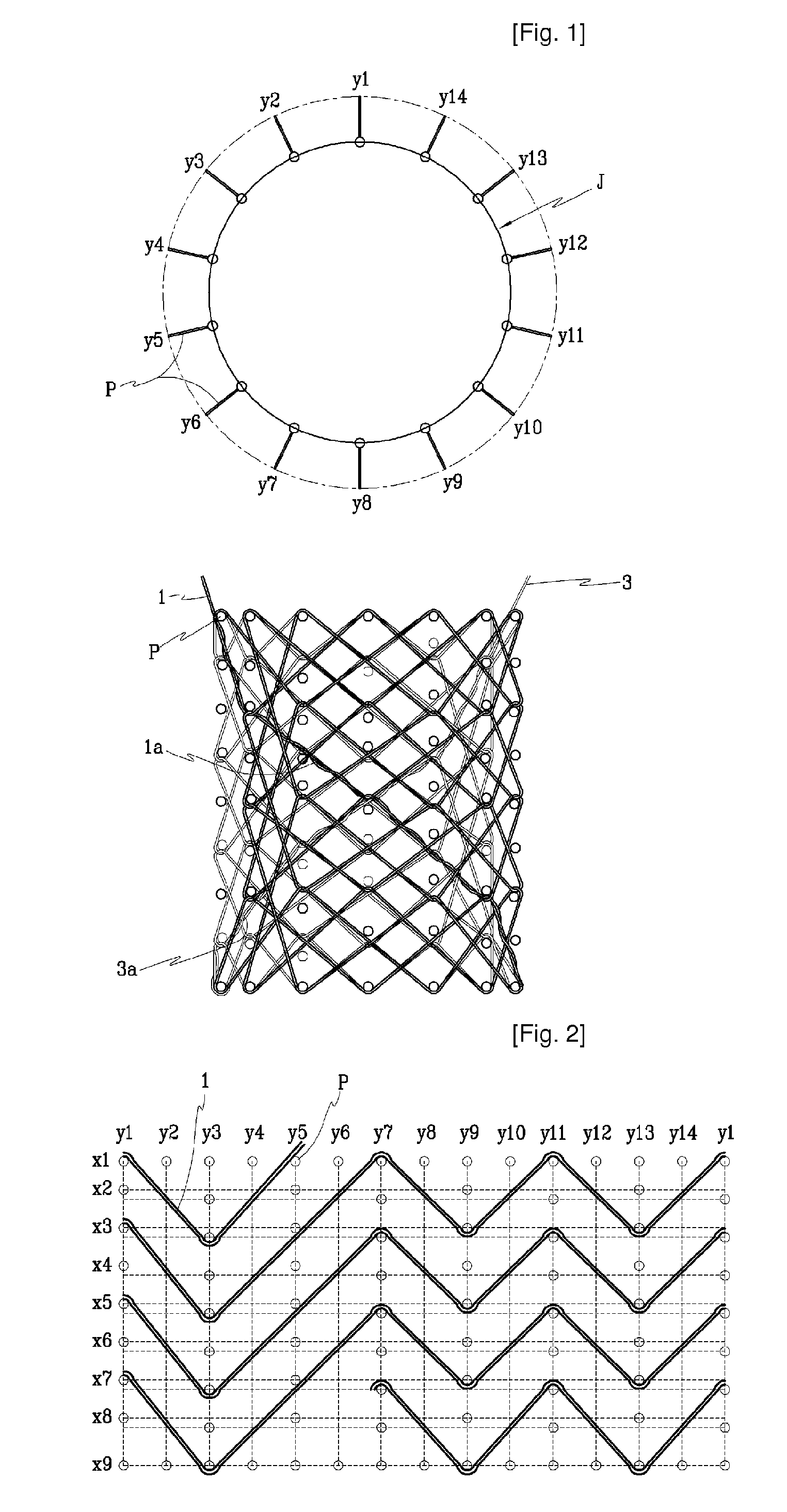

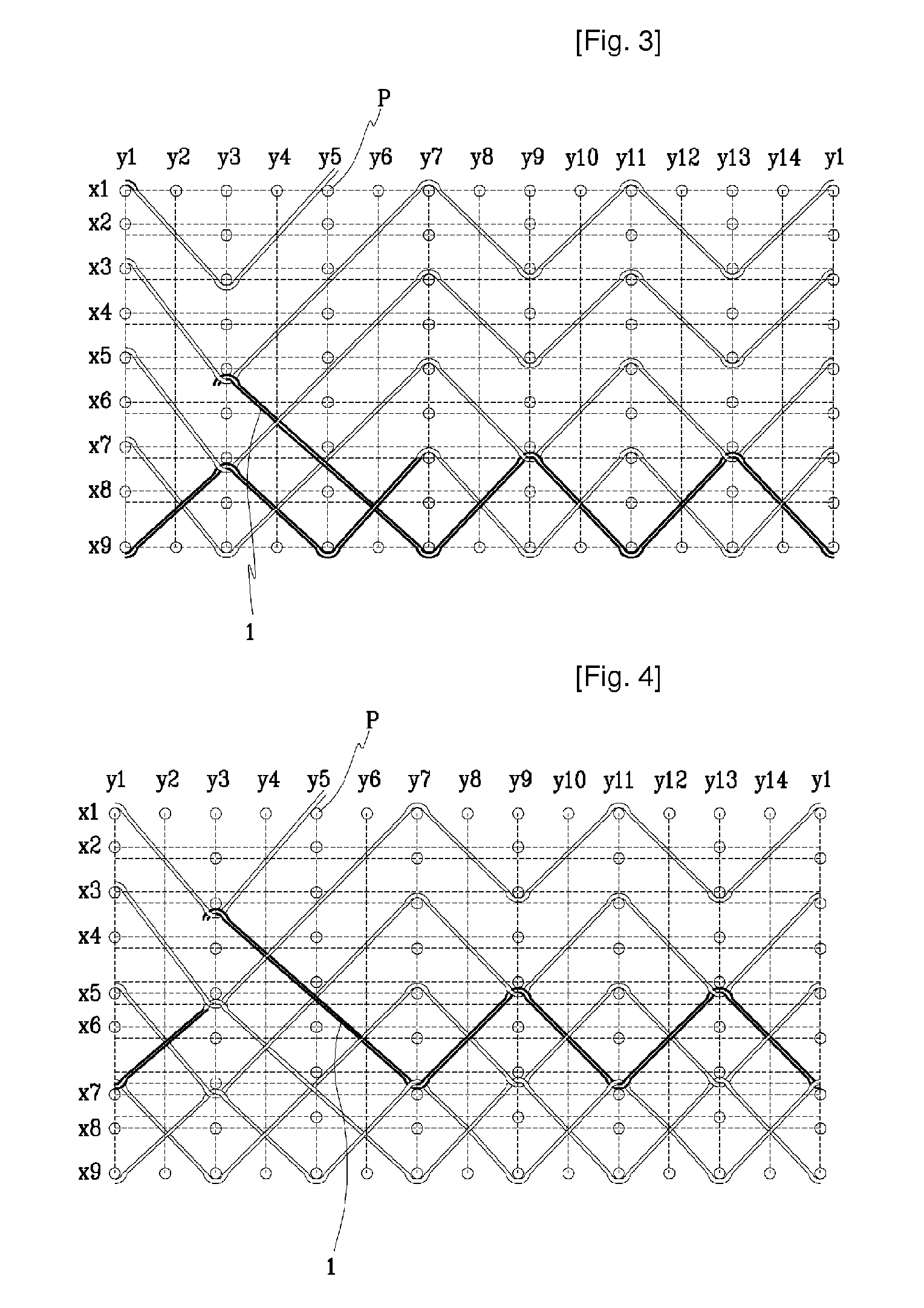

[0022]FIG. 1 is a perspective view of a stent manufactured by a method of the present invention. FIGS. 2 through 14 are views illustrating consecutive processes of manufacturing the stent.

[0023]According to an embodiment of the present invention, a stent is formed of first and second members 1 and 3. FIGS. 2 through 7 are views illustrating a process, in which the cylindrical stent is formed of the first member on a manufacturing frame. FIGS. 8 through 14 are views illustrating a process, in which a fine mesh structure is formed of the second member. The fine mesh structure is formed on the cylindrical stent formed of the first member. The first and second members 1 and 3 may be formed of a wire member, which may be coated in order to be inserted into a lumen or a lesion of a human body for a medical use. Hereinafter, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com