Axial flow fan

a technology of axial flow fan and axial flow, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of insufficient mounting space for electronic components, affecting the performance of electronic components and the operation of the motor, and inability to ensure the mounting space of electronic components is too small, so as to increase the area of the circuit board and increase the number of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

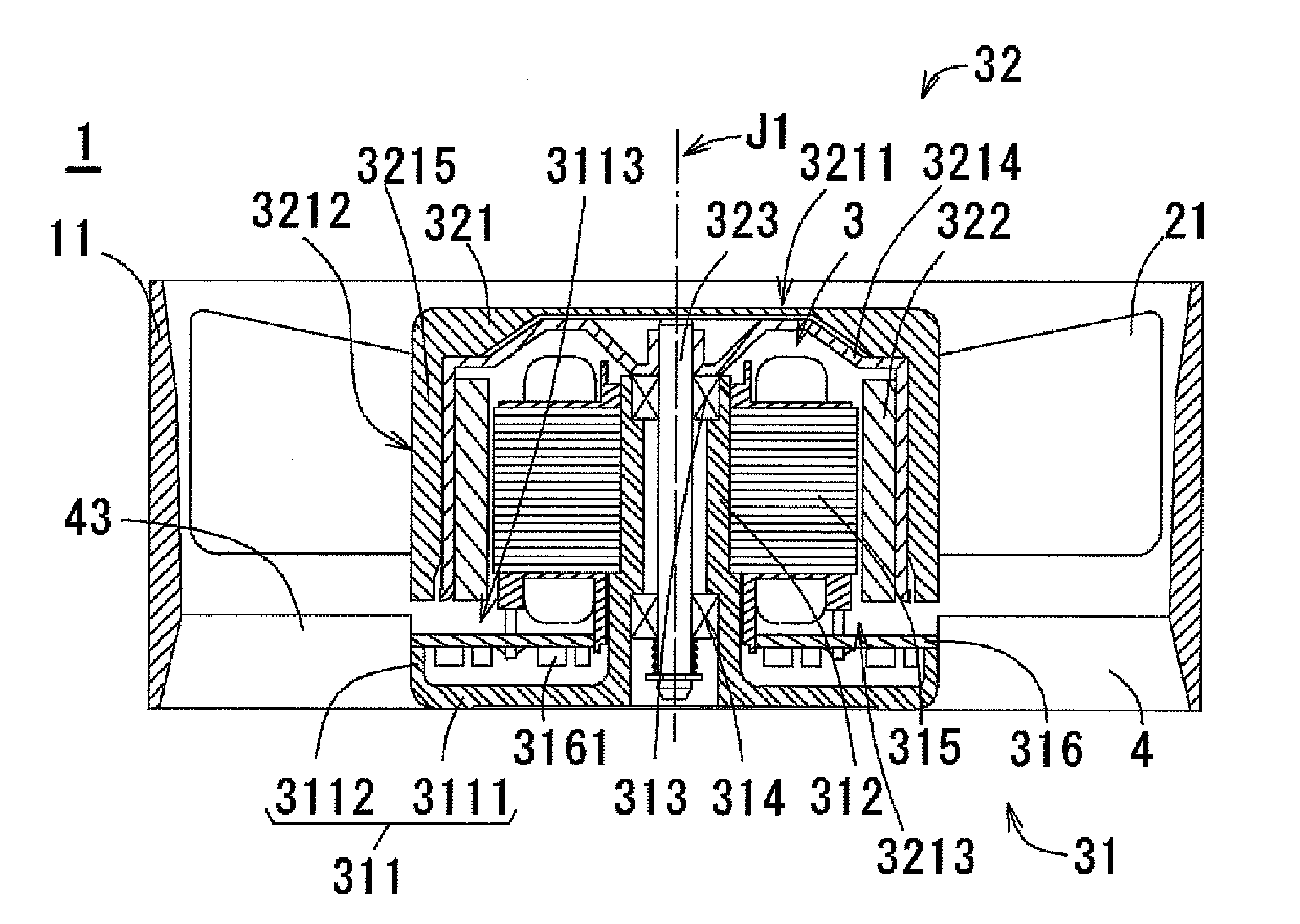

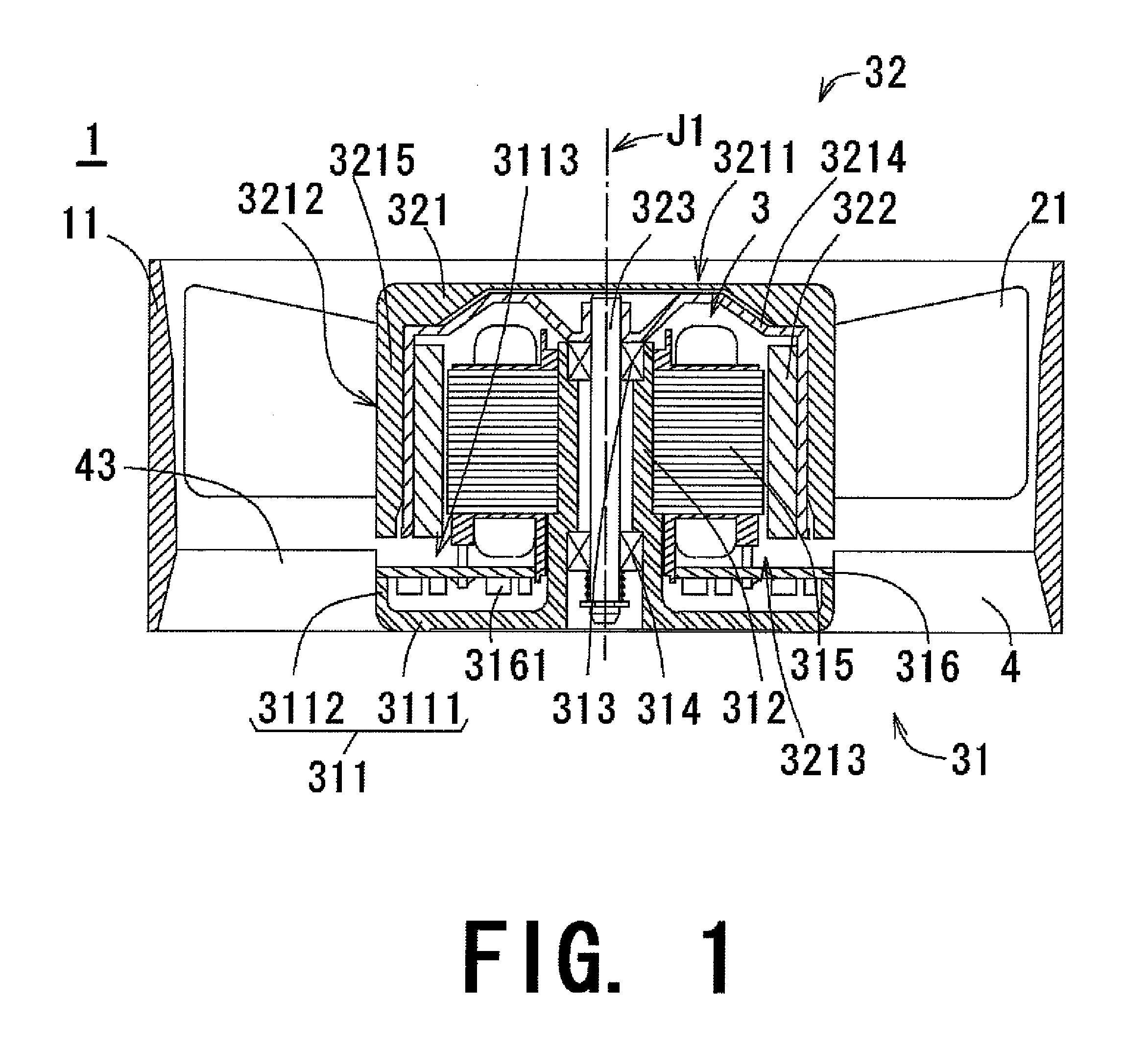

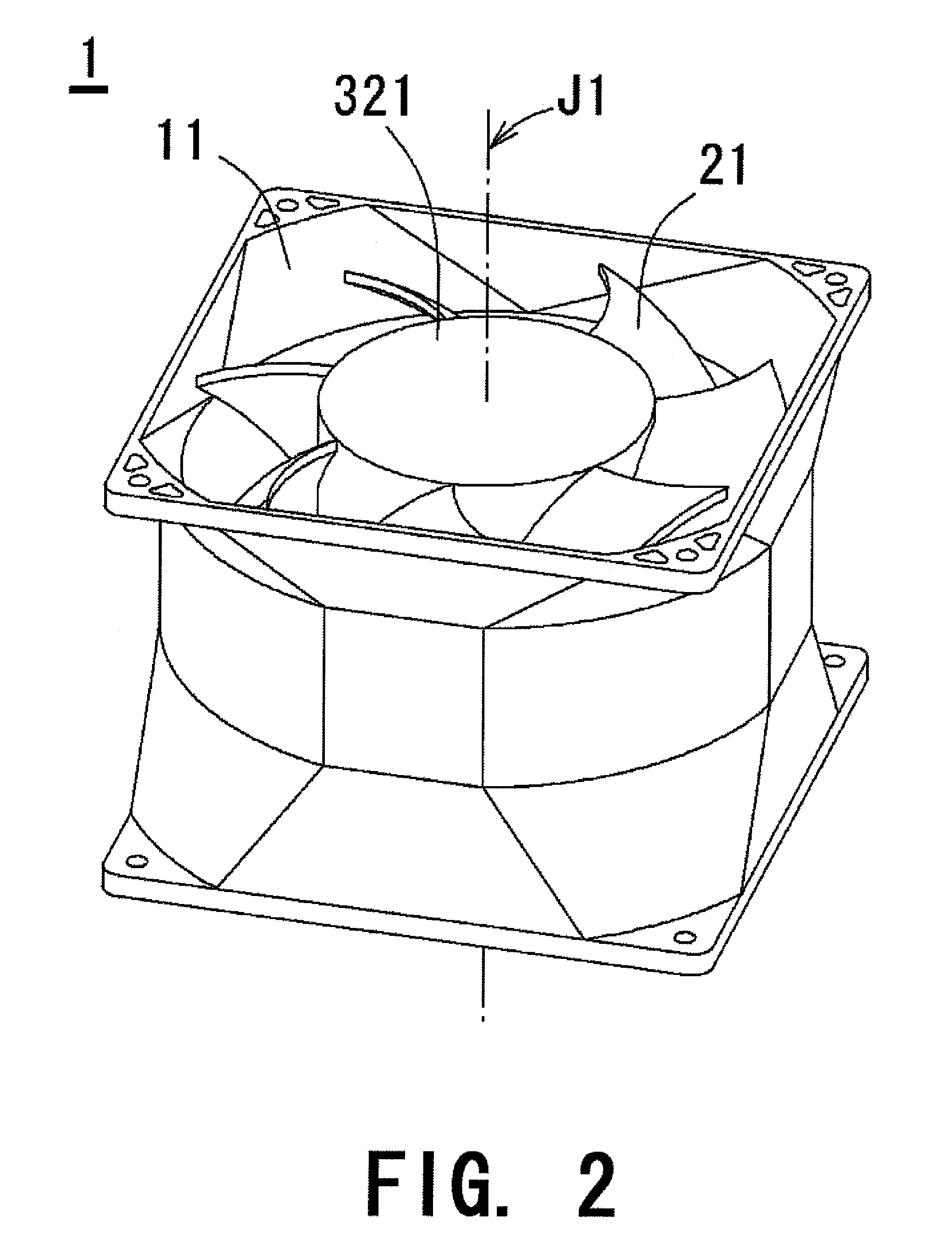

[0027]FIG. 1 is a cross-sectional view of an axial flow fan according to a first preferred embodiment of the present invention. FIG. 2 is a perspective view of the axial flow fan according to the first preferred embodiment of the present invention. FIG. 3 is a perspective view showing a positional relationship between stationary vanes and rotor vanes.

[0028]As shown in FIGS. 1 to 3, the axial flow fan 1 includes a housing 11, a plurality of rotor vanes 21, and a plurality of stationary vanes 4. In this preferred embodiment, seven rotor vanes 21 and nine stationary vanes 4 are provided, for example. The rotor vanes 21 rotate inside the housing 11 and are arranged to be inclined with respect to a central axis J1 of the axial flow fan 1. The stationary vanes 4 are disposed below the rotor vanes 21 in FIG. 2 and are fixed to the housing 11. In this preferred embodiment, the stationary vanes 4 are in the form of thin plates, and the stationary vanes 4 and the rotor vanes 21 are inclined w...

second preferred embodiment

[0049]Next, a description is given on an axial flow fan according to a second preferred embodiment of the present invention. FIG. 9 is a cross-sectional view showing the axial flow fan according to the second preferred embodiment. FIG. 10 is a perspective view showing a modification of the axial flow fan according to the second preferred embodiment. In FIGS. 9 and 10, like structures and components as shown in FIGS. 1 to 7 are designated by like reference numerals in the description below.

[0050]In the axial flow fan according to the second preferred embodiment, on the axially upper end of the sidewall 3112 of the base portion 311 locking portions 3113 are provided in at least four positions in the circumferential direction for locking the circuit board 316, as shown in FIG. 9. The number of positions for disposing the locking portions 3113 is not limited to four, and any number will do so long as the locking portions are provided in more than one positions. The plurality of locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com