A core-setting apparatus used for a molding apparatus and a method for setting a core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

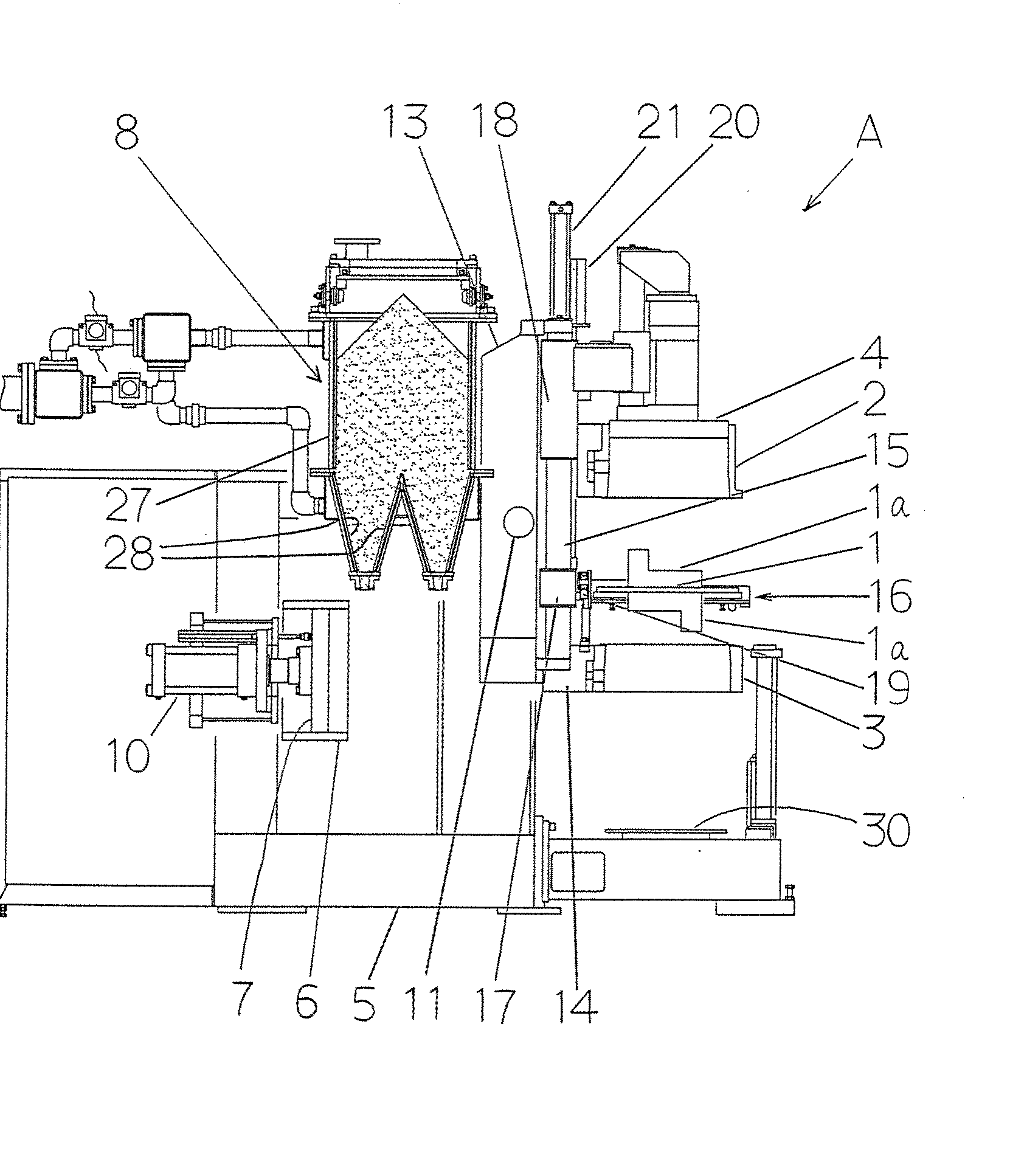

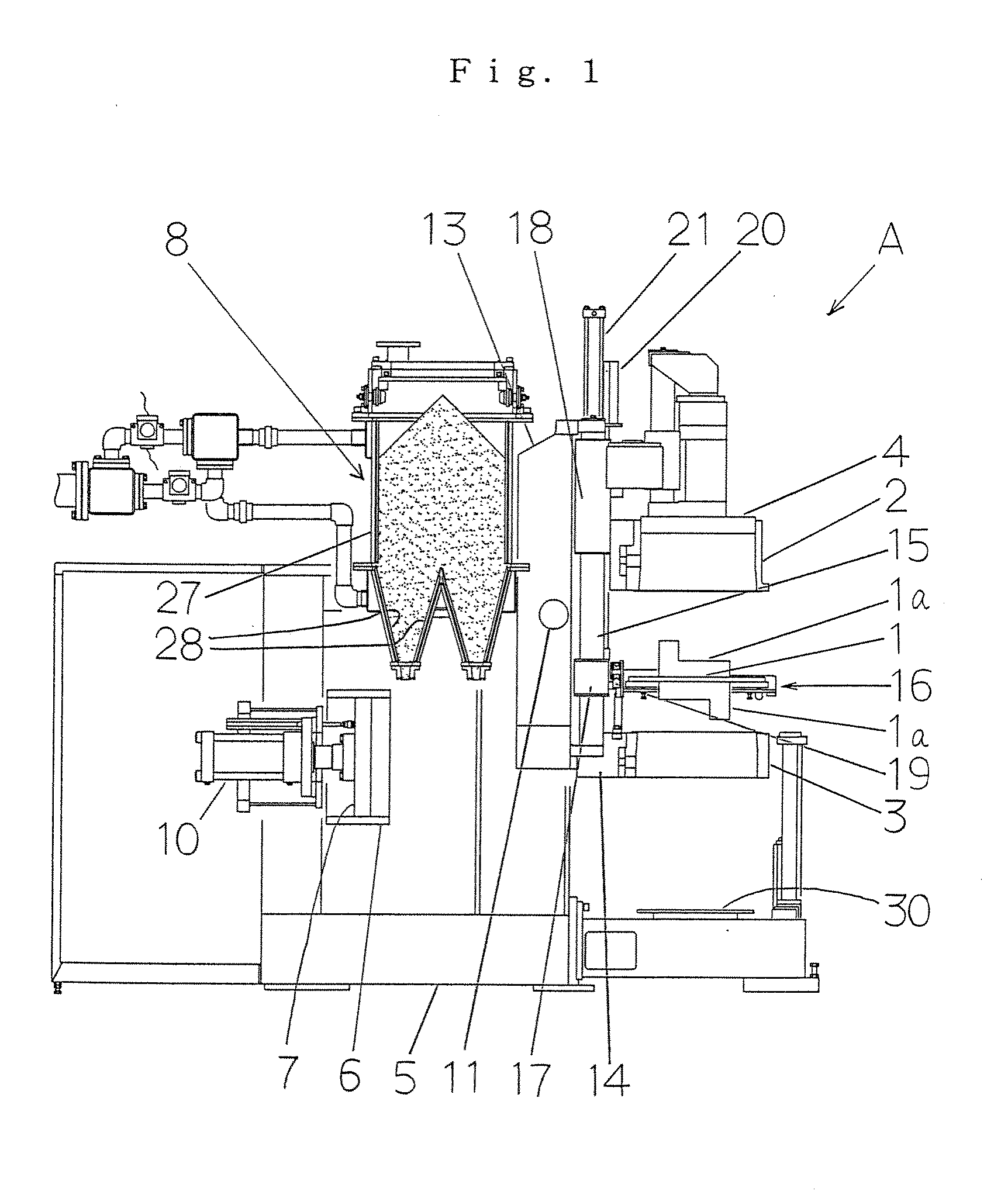

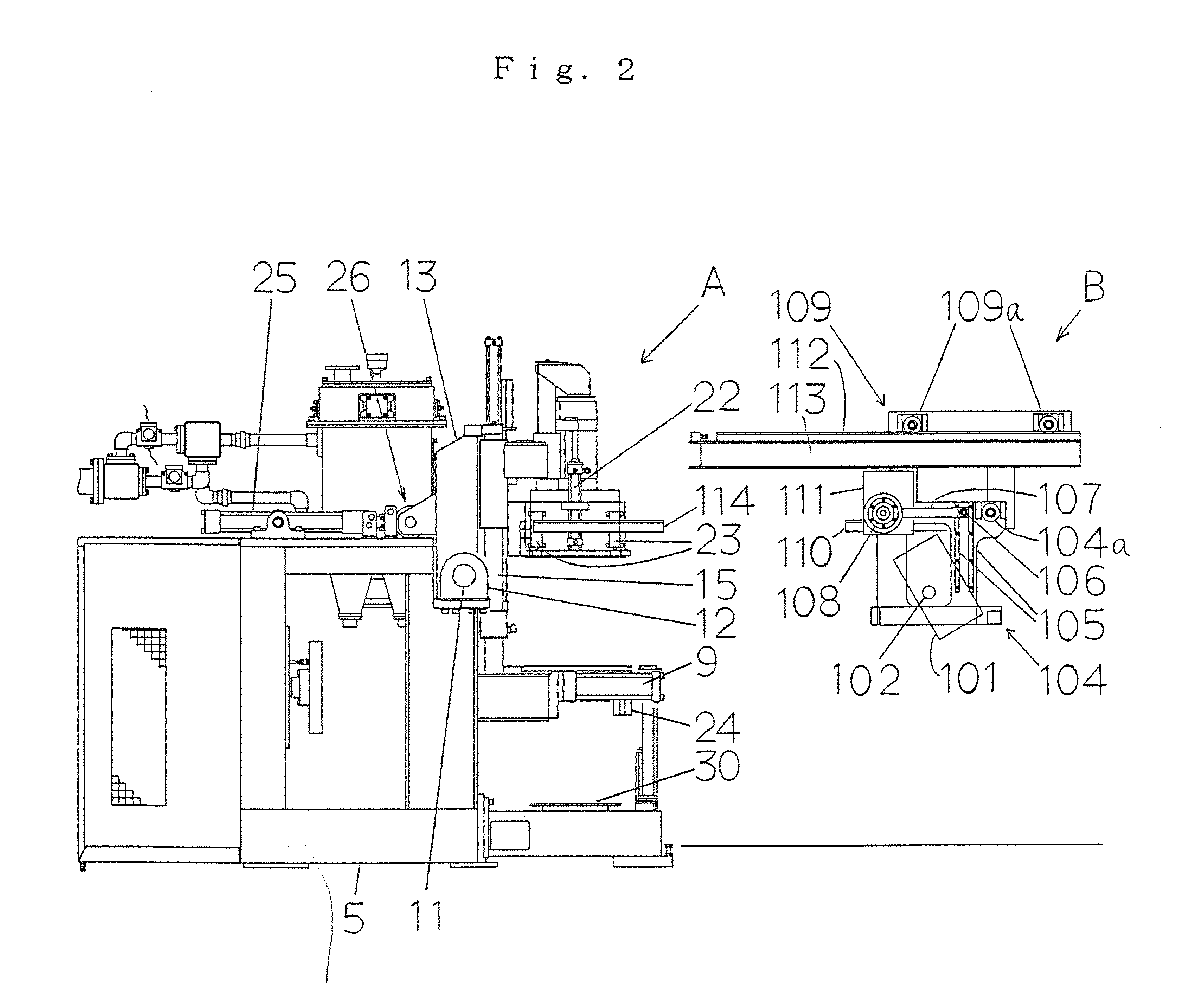

[0050] One embodiment of these inventions is now explained in detail based on figures. As in FIG. 1, a main body A of a molding apparatus comprises:

[0051] a cope flask 2 and a drag flask 3, which can hold therebetween a match plate 1, having patterns 1a, 1a, at both its sides,

[0052] an upper squeezing member 4, which is insertable into the opening positioned on the opposite side of the cope flask 2 from the match plate 1,

[0053] a filling frame 6 perpendicularly fixed to a base 5, and

[0054] a lower squeezing member 7, which is insertable in the filling frame 6, wherein the lower squeezing member 7 is disposed so that its pressurizing surface faces the horizontal direction.

[0055]FIG. 1 shows the main body A of the molding apparatus at the initial position. In this stage, the match plate 1, the cope flask 2, the drag flask 3, and the upper squeezing member 4 are disposed at the horizontal position, and the pressurizing surface of the upper squeezing member 4 faces perpendicularly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com