Dishwashing Machine With Heating Control

a technology of heating control and dishwashing machine, which is applied in the direction of dishwashing/rinsing machines, cleaning equipment, and cleaning using liquids, etc., can solve the problems of unsatisfactory methods, waste of heating power, and prolonging the washing cycle, so as to reduce the use of heating energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

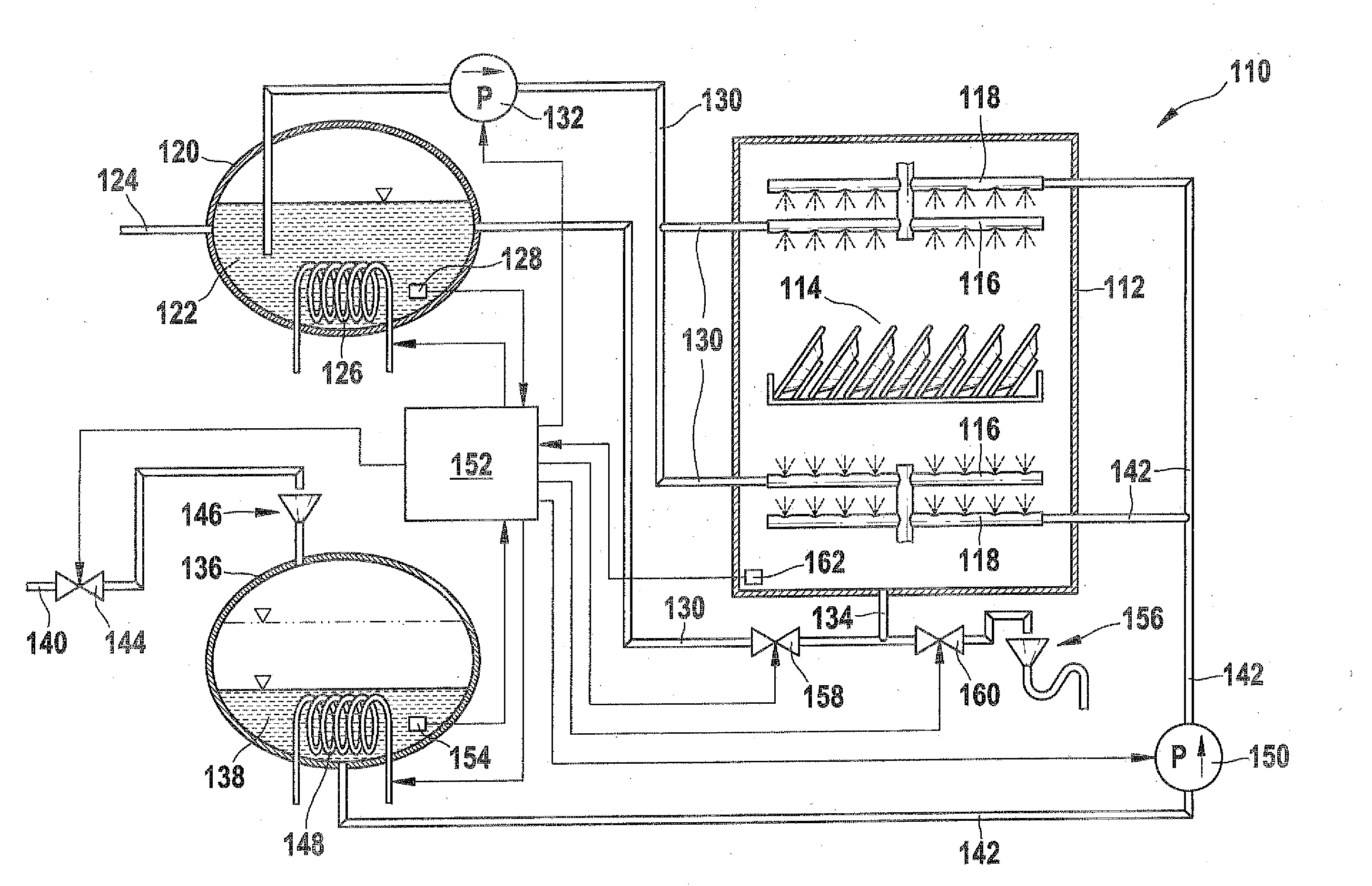

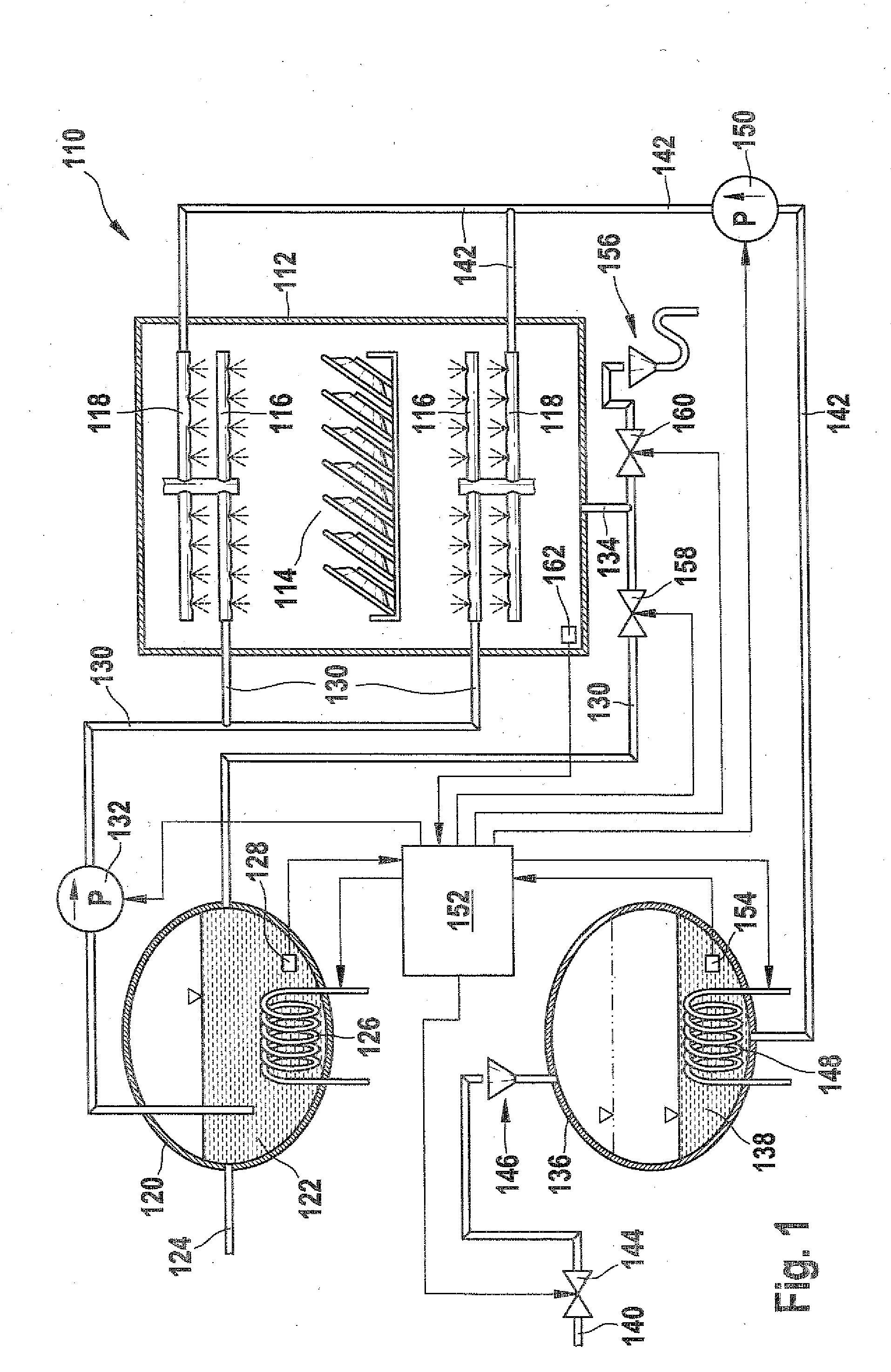

[0037]The dishwashing machine 110 has a dishwashing chamber 112 in which items to be cleaned 114 can be placed. Furthermore, there is a nozzle system in the dishwashing chamber 112, comprising washing nozzles 116 and final washing nozzles 118. This nozzle system is in this case illustrated by way of example as a system of spraying arms arranged above and below the items to be cleaned 114. However, alternatively or additionally, it is also possible to provide different types of nozzles.

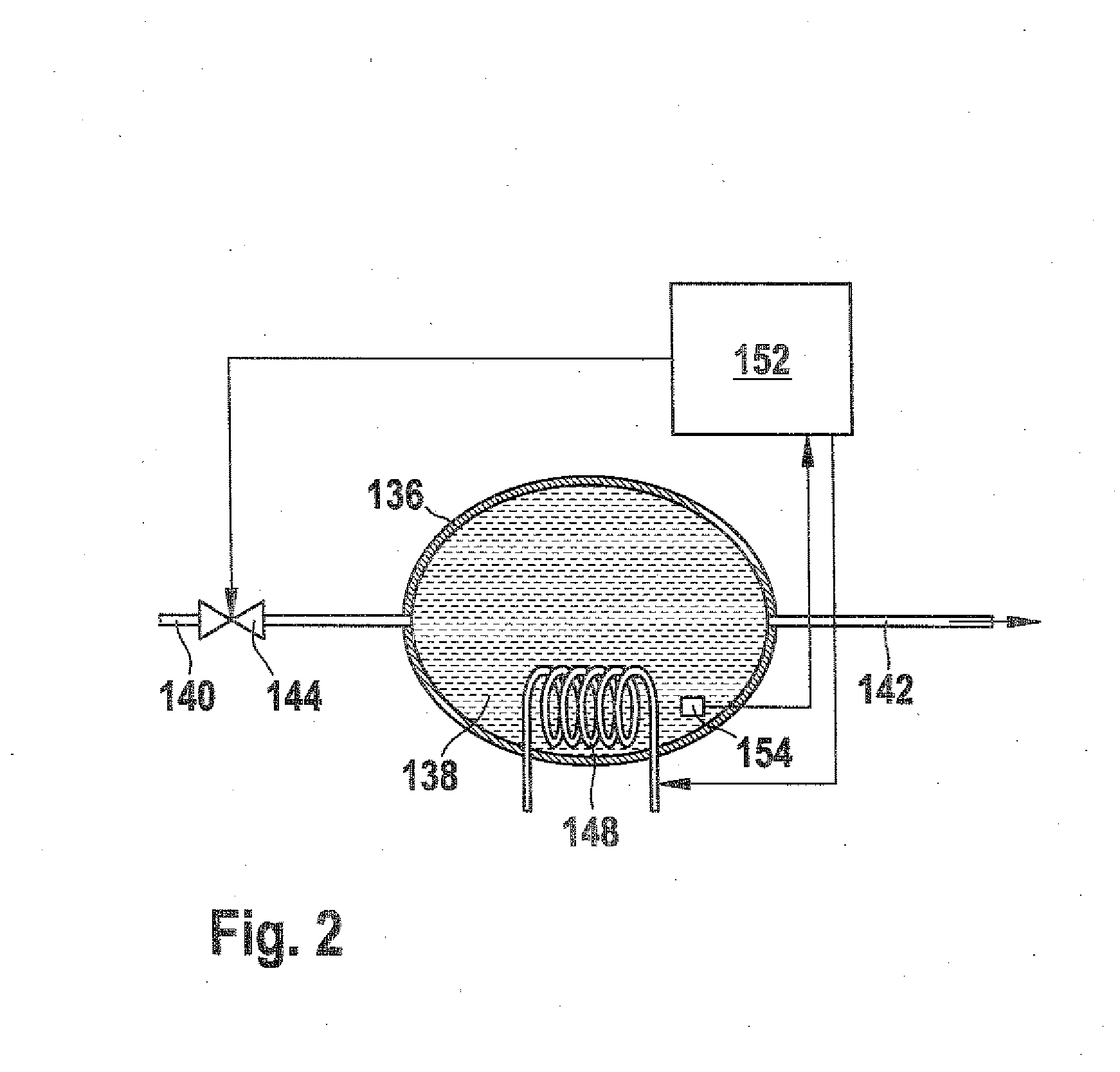

[0038]Furthermore, the dishwashing, machine 110 has a washing tank 120 which is designed to hold a washing liquid 122. The washing tank 120 may, for example, be equipped with one or more supply lines 124, for example in order to fill the washing tank 120 with fresh water and / or in order to supply a cleaning agent or dishwashing agent to the washing tank 120. In the illustrated exemplary embodiment, the washing tank 120 is in the form of a separate washing tank, although embodiments are also feasible in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com