High-efficiency dust collecting device with two gateways

a dust collection device and high-efficiency technology, applied in the field of sand grinders, can solve the problems of large power collectors, increase costs, inconvenience in assembly or operation, etc., and achieve the effects of reducing costs, facilitating installation, and prolonging the service life of sanding belt rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

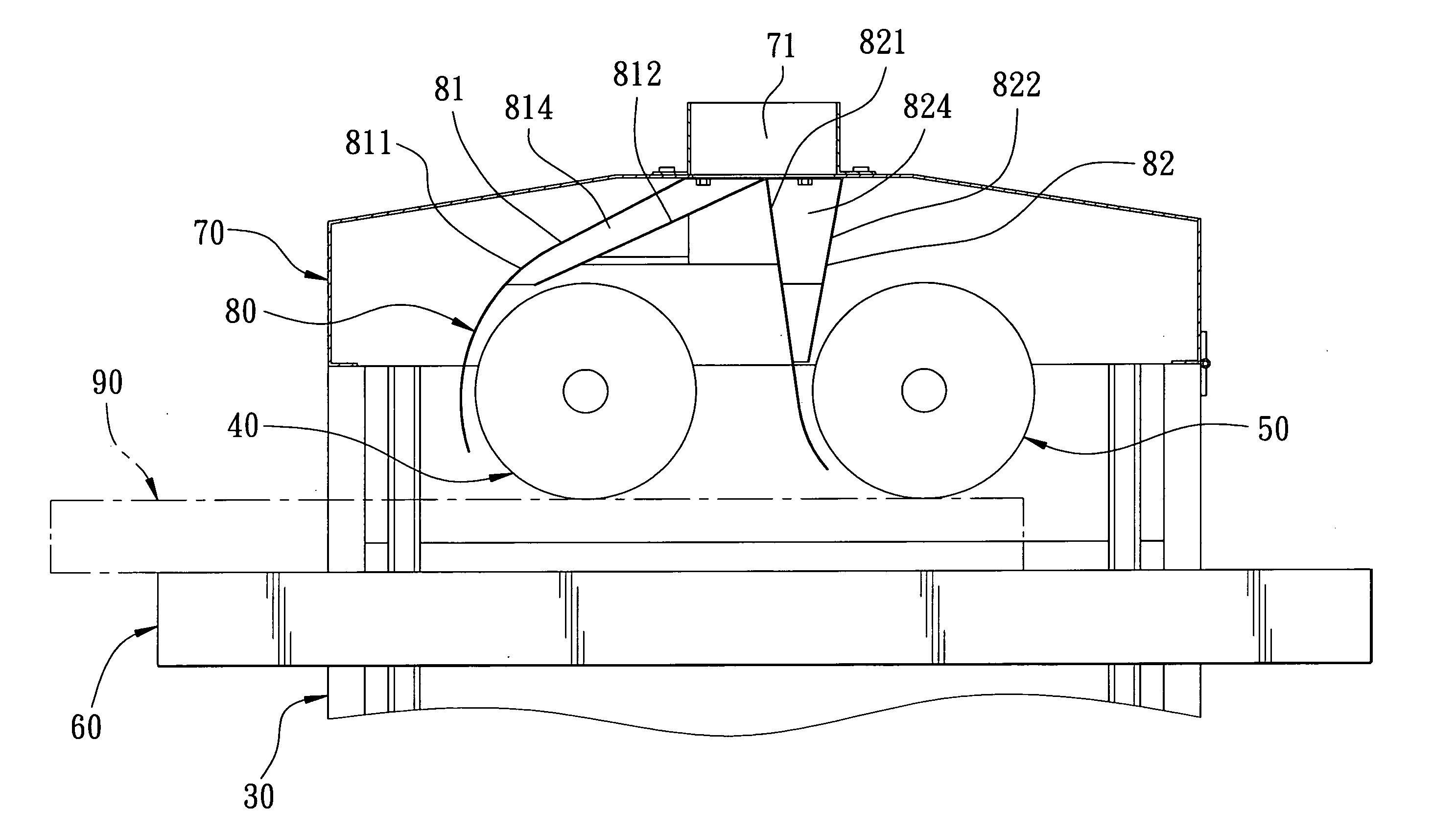

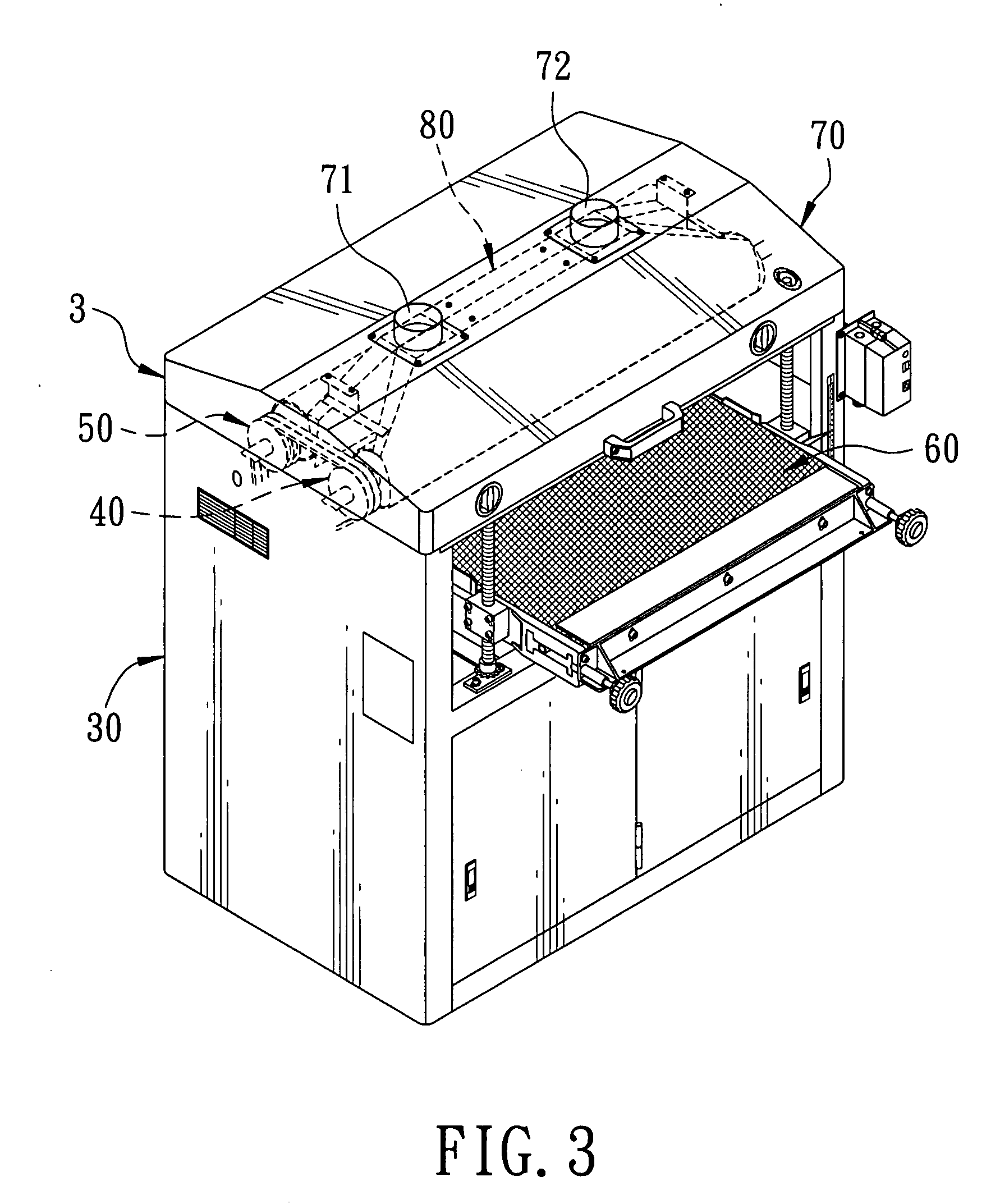

[0015]FIGS. 3˜5 show a preferred embodiment of a high-efficiency dust collecting device with two gateways for a sand grinder 3 in the present invention. The sand grinder 3 is composed of a main body 30, a front sanding belt roller 40 and a rear sanding belt roller 50 located transversely on the top of the main body 30, a conveying table 60 located under the two sanding belt rollers 40 and 50, and a cover 70. So, a workpiece is to be put on the conveying table 60 and ground below and by the front sanding belt roller 40 and the second sanding belt roller 50 in order. The cover 70 is transversely cut with two exits 71 and 72 on its top, connected with a dust collecting device 80 installed under it at one side of each of the front sanding belt roller 40 and the second sanding belt roller 50. The dust-collecting device 80 is connected with the exits 71 and 72, provided with a first gateway set 81 and a second gateway set 82.

[0016]The first gateway set 81 is formed integrally with a metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com