Paper multi-feed detection apparatus and paper multi-feed detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0039]Hereinafter, one embodiment of the present invention will be described with reference to the figures.

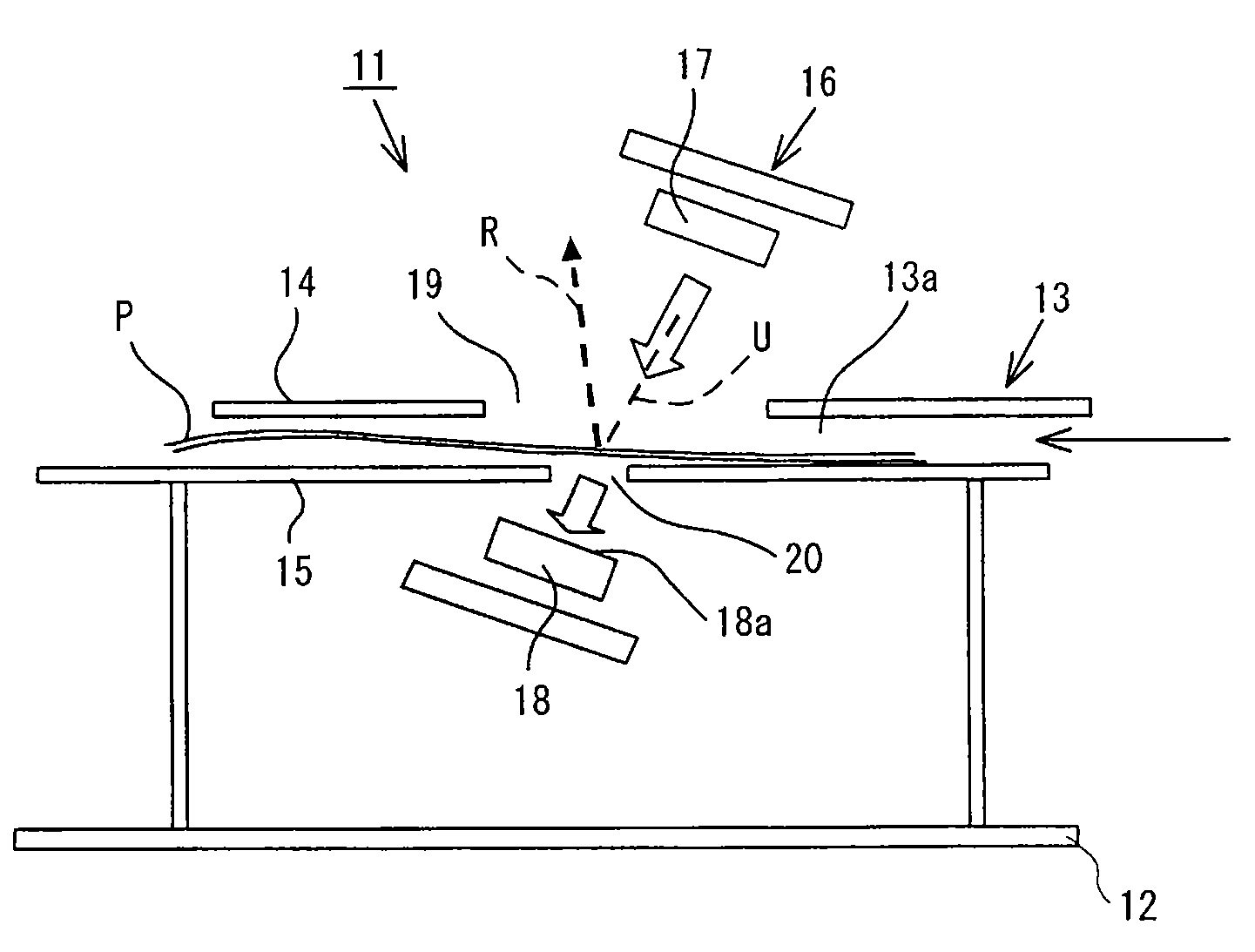

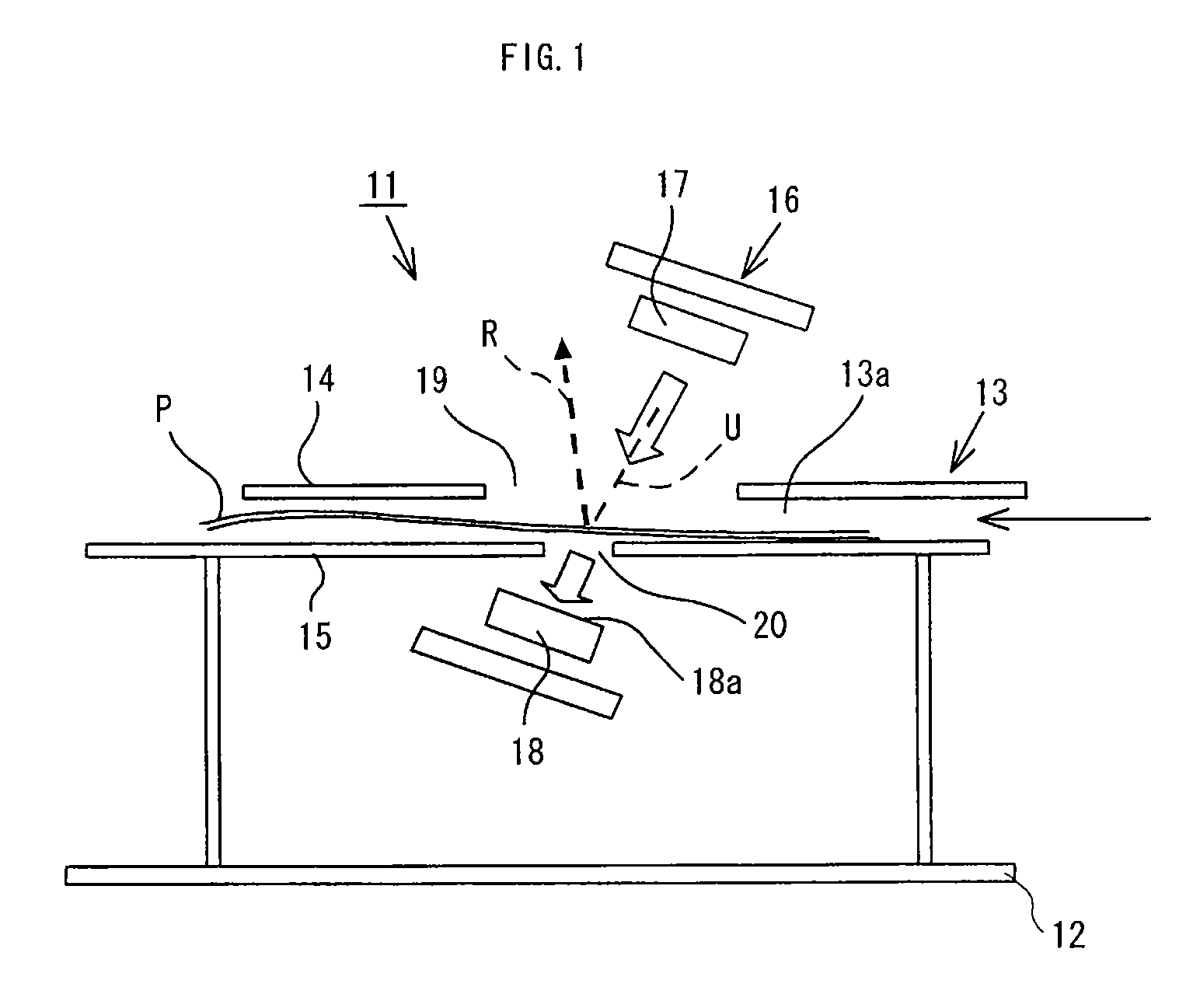

[0040]The figures show a paper sheet multi-feed detection apparatus which maybe built in a copier. As shown in FIG. 1, a paper sheet multi-feed detection apparatus 11 includes a main body 12 and a feeding path 13, provided above the main body 12, for feeding a paper sheet P in a horizontal direction two-dimensionally. A top surface of the feeding path 13 is covered with an upper feeding guide plate 14, and a bottom surface of the feeding path 13 is covered with a lower feeding guide plate 15. The upper feeding guide plate 14 and the lower feeding guide plate 15 face each other while having a two-dimensional feeding space 13a therebetween.

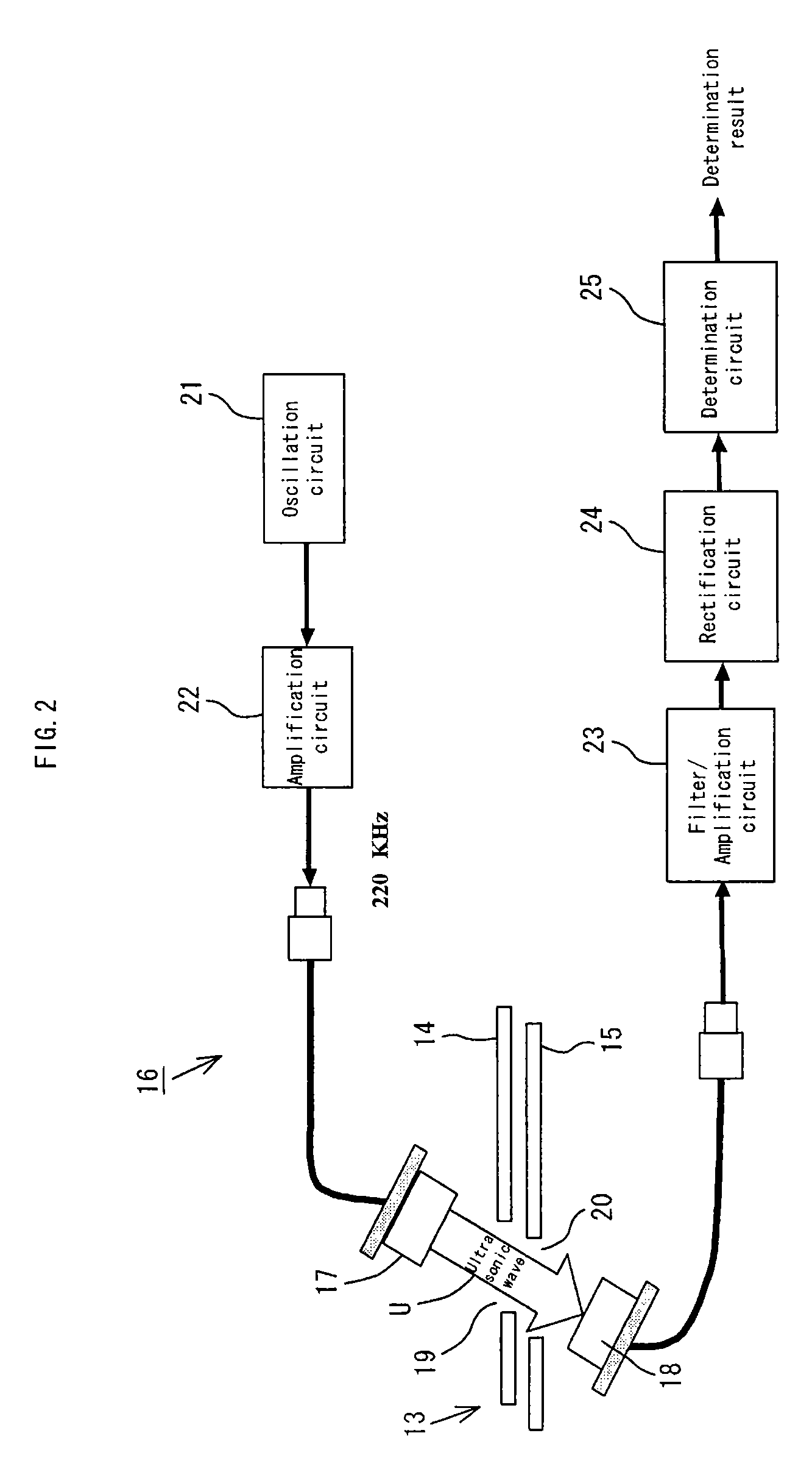

[0041]A transmitter 17 of an ultrasonic sensor 16 is provided above the feeding path 13, and a receiver 18 of the ultrasonic sensor 16 is provided below the feeding path 13. The transmitter 17 and the receiver 18 also face each other while havi...

embodiment 2

[0052]FIG. 3 shows another paper multi-feed detection apparatus 31. The paper sheet multi-feed detection apparatus 31 includes a main body 32 and a feeding path 33, provided above the main body 32, for feeding a paper sheet P in a horizontal direction two-dimensionally. A top surface of the feeding path 33 is covered with an upper feeding guide plate 34, and a bottom surface of the feeding path 33 is covered with a lower feeding guide plate 35. The upper feeding guide plate 34 and the lower feeding guide plate 35 face each other while having a two-dimensional feeding space 33a therebetween.

[0053]A transmitter 37 of an ultrasonic sensor 36 is provided above the feeding path 33, and a receiver 38 of the ultrasonic sensor 36 is provided below the feeding path 33. The transmitter 37 and the receiver 38 also face each other while having the feeding path 33 therebetween. Transmitting and receiving directions of the ultrasonic sensor 36 are set to be oblique with respect to the feeding pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com